How to cut a slag block without a corner grinder. Manual method (without the use of special equipment)

DIY cinder clutch masonry. Marking, preparation and masonry technique.

Slag block. one of the most affordable and reliable building materials. Self.masonry of a cinder block is quite simple for development. It is enough to know some features and sequence of stages of laying a cinder block to build walls and buildings with your own hands. Of course, to purchase the skill of laying a cinder block, an experienced mason needs a lot of practice. However, even a beginner, albeit at low speed, can put up strong and reliable walls, performing standard instructions.

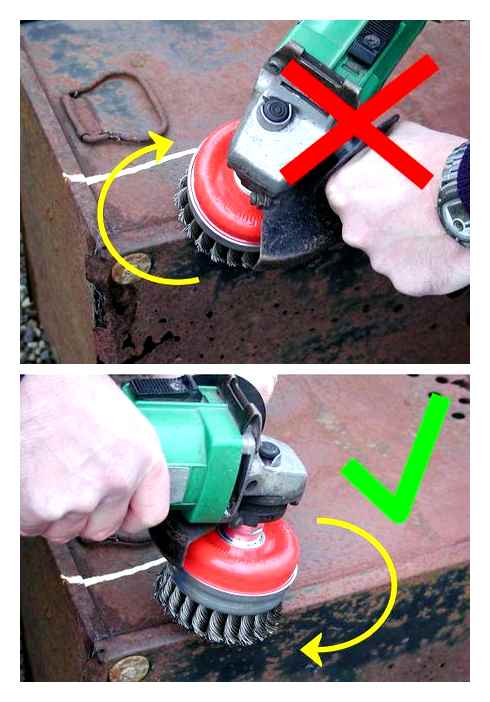

Deburring with highest feeding speed and huge edge rounding

There are several types of cinder block. The simplest separation of slag block into a hollow and full.bodied slag block. They differ in weight and degree of internal fullness, respectively. Hollow slag block is used for laying walls. A full.bodied slag block uses the construction of foundations and masonry basements. Technique and methods of masonry, both walls and foundations differ. Below, consider what types of laying of a cinder block are. about the properties of a cinder block in the article “Technical characteristics of a cinder block”.

Types of masonry of slag block

There are four methods of laying slag block:

Often, used to build foundations or basements. Walls with such masonry will be warmer, due to the thickness.

Such masonry is used to lay the supporting and external walls of the house.

In one stone from a cinder block, both walls with the outside and the wall partitions inside the house are mounted and mounted.

Only internal wall partitions are recommended to the floor of the stone. They are quite thin and cannot perform the bearing function in the structure.

The first method of wetting

The easiest option to cut concrete or brick without dust is to moisten them with water.

To do this, you can use a regular spray gun

or sprayer (made from a plastic bottle with the holes made in the lid), or a children’s water gun/automatic.

Spraying the object must be done directly during the saw so that the dust immediately gets wet, not having time to fly.

Due to the fact that the saw.holder is occupied by a corner grinder, it is quite difficult and inconvenient to saw at the same time and perform spraying, moreover, it is unsafe.

Therefore, the second person should be sprayed.

In tandem, all work can be done quickly enough and without difficulty.

This method does not require any significant efforts, but there is a lot of dirt, t.to. dust turns into a slurry, spilles on the floor, and also flies in different directions.

The second method is more effective and practical.

The second way to connect a vacuum cleaner

This method consists in connecting to an angular grinder of a construction vacuum cleaner using improvised means.

polypropylene tap for sewage with a diameter of 50mm, at 45 degrees;

adhesive tape reinforced (for greater reliability);

The described components for this method can be replaced with any suitable analogues.

Step-by-step instruction

1) Put the corner grinder on the floor, table or dr. so that it lay the disk up parallel to the plane of the base.

The corner grinder should be located quite steady.

2) take the divert with pliers or any clamp.

3) Turn on the corner grinder and literally stick the pipe along the case, under the casing angular grinder, approximately 3 cm.

4) We take reinforced tape, and tightly, in the interference, weak the diverted to the body of the corner grinder, with a slight call (a couple of centimeters) into a saw disk.

The pipe must be fixed thoroughly, so that it holds absolutely motionless.

5) we take the masking tape, and glue it the open side of the casing, connecting it with the removal.

This design allows you to easily connect a construction vacuum cleaner and saw a corner grinder without dust.

For such work, only a construction vacuum cleaner can be used.

When sawing, the disk should be brought into the processed material from the engine, closer to the pipe.

So all the dust will go through the discharge to the vacuum cleaner.

Drinking objects we carry out the engine forward.

Safety precautions

Such a dust growing system does not carry any serious structural changes in the device of the corner grinder.

We only attached the pipe to the tool body.

And with masking tape, the second part of the casing was closed, this element can create a false impression of security.

Maslar tape is designed only for dust protection.

Therefore, it is necessary to observe all safety measures when working with corner grind.

During the repair or construction, it is sometimes required to carry out concrete work: cut the opening under the window, niche, stroke the walls for wiring. Masters know how many small particles are formed. Cleaning after such events is a very laborious lesson. We offer to figure out whether the cutting of concrete is possible without dust and how to organize this process.

Price category

Before laying walls from cinder blocks, you must find out the price of work. Builders usually take 20 for laying one slag block. Based on this, you can find out how much the construction of the necessary building will cost, knowing its size. Of course, it is better to put the laying of slag blocks yourself, while you can strongly save. In this case, the costs will only be on the material itself.

Price for 1 piece of slag block:

| Type of slag block | Price for one |

| Full.bodied | 36-42 |

| Hollow | 22-30 |

| Half.block | 22-24 |

| Decorative block | 60-65 |

To determine how much material goes for construction, you need to know the dimensions of the future building, as well as the dimensions of the slag block itself, which are 390x190x188 mm. It can be seen that the size is quite large, so the construction speed increases significantly, compared to ordinary bricks.

Useful tips from professionals

The evenness of the laying on the cord and the construction level must be checked as often as possible to avoid the curvature of the walls and rows in the future.

If the walls are not planned to be finished in the future, then the seams between the rows should have an attractive appearance. To do this, you can use a small rounded stick, which needs to press the seams a little after each laid row, until the solution has yet hardened.

When marking blocks, you must use colored crayons. They are best seen on slag blocks, compared, for example, with a regular pencil.

To increase plasticity to the solution, you can add a little detergent.

It is necessary to knead exactly as many solutions as it will be spent at a time. Otherwise, the unused solution can harden and will not be suitable for construction.

It is advisable to plaster the outer walls, because the slag block is afraid of moisture. In this case, the plaster will protect the material. But since the plaster is poorly applied to the slag block and can fall off over time, it is necessary to use an armus. The internal walls can be sheathed with drywall.

Electric jigsaw

Masters know such a jigsaw as a saber’s saw. This saw is used in the construction of medium and large facilities.

On the jigsaw you can change the blades (put wheels with different sizes of teeth, change the blurted or spoiled discs; the shape of the cloves on the disks can also be different. large and small teeth).

As a rule, for the convenience of builders, many models of saws are produced with interchangeable batteries so as not to be attached to the power source.

When working with this type of tool, it must be remembered that cutting wet material is not permissible, this may entail injury. Saw “rinses” crumbs and can injure the builder.

Before starting work, it is better to try on the tool. Lose a saw with a saw without on food.

It is necessary to cut the middle part of the saw, the length of the working cutting surface should be approximately 25 centimeters.

In order not to be injured, you should hold the saw tightly in your hands.

Features of cutting corner grinding

After choosing equipment and a circle for it, before cutting concrete with a corner grinder, you need to get acquainted with the recommendations of work:

In this case, in case of a reverse blow, it can be held, which will minimize the displacement of the cut line; The work should be carried out only on a flat surface so that a person’s balance remains; The power cord should be placed from the disk from the opposite side to exclude damage by negligence. A cut cord can cause the attack wave of the unit and short circuit in the mains; The tool must be held tightly in your hands until it stops it completely; When changing the place of sawing, the corner grinder needs to be turned off so as not to accidentally hurt the surrounding objects; When turning off the electricity, be sure to turn off the equipment from the network

This will prevent its inclusion when feeding electricity without operator control.

Tip: In the process of work, the discs are heavily heated, therefore, turning off the corner grinder, it cannot be touched to cool completely.

Cutting concrete along the line

After a corner grinder for concrete was prepared, you can start work.

- A fishing line for a cutting trimmer is planned. At the same time, it is advisable to fix the wood bars along the line, which will allow the fishing line for the trimmer of the cut to make more even;

- The corner grinder will be turned on, and an incision is performed with a depth of approximately 5. 10 mm;

- Bars are removed;

- A cut is made to the required depth. If the cut is dried, the procedure should periodically stop to make it possible to cool down the tool.

How to cut concrete with corner grinder correctly, the video shows with all the details. The process is best done with the cooling of the tool.

- An ordinary spray gun spray water directly to the furrow to reduce the amount of dust;

- Water is sprayed directly to the disk, in the absence of a current source. This will reduce the heating of the diamond discs, and will extend their service life;

- If it is impossible to spray the liquid to the disk, cooling can be performed by air. Periodically, the circle should be removed from the cut and give it the opportunity to work in the air.

In case of questions about cutting concrete, if you want to find out how the concrete of concrete with a corner grinder is performed and other details on the use of similar equipment, introduces the video in this article.

Production of a casing for a vacuum cleaner

Small particles of the material that are formed during cutting the “corner grinding”, the equipment of the corner grinder helps, in which the vacuum cleaner helps. But if it is not, you can make a device yourself. The photo shows a protective casing on the disk of a corner grinder, made by yourself.

For the manufacture of a convenient nozzle, you will need:

- Simple plastic canister;

- Construction cut;

- The capacity of suitable sizes, in which the diameter of the neck is suitable for the vacuum cleaner hose.

- Chanisters are cut on two sides of the landing holes, they are needed to easily change the direction of rotation of the disk;

- A slot under a circle of a suitable size is performed;

- A hole is cut for fixing the “corner grinder” disk;

- The hose joins the neck of the canister through a transition ring with a clamp;

- The corner grinder is laid in the casing, and all elements are connected;

- Extra holes are closed with lids.

Features of cutting corner grinding

After choosing equipment and a circle for it, before cutting concrete with a corner grinder, you need to get acquainted with the recommendations of work:

In this case, in case of a reverse blow, it can be held, which will minimize the displacement of the cut line; The work should be carried out only on a flat surface so that a person’s balance remains; The power cord should be placed from the disk from the opposite side to exclude damage by negligence. A cut cord can cause the attack wave of the unit and short circuit in the mains; The tool must be held tightly in your hands until it stops it completely; When changing the place of sawing, the corner grinder needs to be turned off so as not to accidentally hurt the surrounding objects; When turning off the electricity, be sure to turn off the equipment from the network

This will prevent its inclusion when feeding electricity without operator control.

Tip: In the process of work, the discs are heavily heated, therefore, turning off the corner grinder, it cannot be touched to cool completely.

Cutting concrete along the line

After a corner grinder for concrete was prepared, you can start work.

- A fishing line for a cutting trimmer is planned. At the same time, it is advisable to fix the wood bars along the line, which will allow the fishing line for the trimmer of the cut to make more even;

- The corner grinder will be turned on, and an incision is performed with a depth of approximately 5. 10 mm;

- Bars are removed;

- A cut is made to the required depth. If the cut is dried, the procedure should periodically stop to make it possible to cool down the tool.

How to cut concrete with corner grinder correctly, the video shows with all the details. The process is best done with the cooling of the tool.

- An ordinary spray gun spray water directly to the furrow to reduce the amount of dust;

- Water is sprayed directly to the disk, in the absence of a current source. This will reduce the heating of the diamond discs, and will extend their service life;

- If it is impossible to spray the liquid to the disk, cooling can be performed by air. Periodically, the circle should be removed from the cut and give it the opportunity to work in the air.

In case of questions about cutting concrete, if you want to find out how the concrete of concrete with a corner grinder is performed and other details on the use of similar equipment, introduces the video in this article.

Production of a casing for a vacuum cleaner

Small particles of the material that are formed during cutting the “corner grinding”, the equipment of the corner grinder helps, in which the vacuum cleaner helps. But if it is not, you can make a device yourself. The photo shows a protective casing on the disk of a corner grinder, made by yourself.

For the manufacture of a convenient nozzle, you will need:

- Simple plastic canister;

- Construction cut;

- The capacity of suitable sizes, in which the diameter of the neck is suitable for the vacuum cleaner hose.

- Chanisters are cut on two sides of the landing holes, they are needed to easily change the direction of rotation of the disk;

- A slot under a circle of a suitable size is performed;

- A hole is cut for fixing the “corner grinder” disk;

- The hose joins the neck of the canister through a transition ring with a clamp;

- The corner grinder is laid in the casing, and all elements are connected;

- Extra holes are closed with lids.

Thermal methods

Another budgetary method, for the use of which a professional tool is not required, is associated with alternating exposure to artificial stone of high and low temperatures. He does not withstand their sharp shift and begins to crack.

For heat treatment, a soldering lamp for heating and cold water for cooling is required. Due to the use of water, the method is not recommended if under the object in which dismantling is carried out, there are residential premises or electric equipment. But it is perfect for solving such a problem as breaking a concrete foundation.

First, concrete is heated for a long time with a soldering lamp, and when it is hot, watered with ice water. The monolith is covered with deep cracks, through which it is easily broken when impact with a sledgehammer.

Cracking monolith to destroy Zabivniesvai.ru

In winter, instead of wedges, you can use ordinary water flooded in the holes. Freezing in severe frosts, it will expand and destroy the connections in the thickness of the material.

How to cut cellular concrete

When calculating the foam blocks for the house, you can try to choose them in size so as to lay products without cutting. But this method is very laborious, and most likely it is unlikely to succeed.

Another option may be to vary the thickness of the vertical seams. But this is also not so easy to do. The large width of the gaps between the blocks is able to seriously worsen the thermotechnical characteristics of the masonry.

In addition, it is impossible to do without the use of non-standard elements when performing door and window openings or some complex architectural forms of the building.

Feet.concrete products are easily processed with your own hands when arranging openings can not do without cut elements to create complex architectural forms requires a cut of details

This material is very easily processed: it can be cut at any angle, give a variety of shape. Therefore, it will be easier to figure out how and how to cut foam blocks.

For such work, you can use manual or mechanical tools:

- Knife habits on wood;

- Manual saw for sawing cellular materials;

- corner grinder (angular grinder) with diamond disks;

- Cable equipment;

- A saber.type electric saw;

- Tape saw for blocks.

Grinder Safety: How to Properly Use an Angle Grinder

Ordinary manual wood saw than cut foam block? The easiest way is a special hand saw! Cutting concrete blocks angular grinder dry cutting blocks with strings Sable saw “Bosch” fishing line for a trimmer for cutting blocks with tape saws

Tip: Do not use chain electric saws. They give a large width of the cut, an uneven cut and wear out quickly.

Laser equipment is also used to cut concrete.

Hand tool

The easiest and cheaper will be the use of manual tools. But it is suitable only for small volumes of work.

Manually easily easily cut the elements to fit the door and window openings, the device of the walls of the walls. Foam blocks with a hand tool is distinguished by maneuverability of operations, ease of execution.

For greater accuracy of working with hand tools, you will also need:

The following tools are suitable for this:

- Krywalk will help if the cuts are required by several blocks. With large volumes of work, the tool will often need to sharpen, which is quite laborious. In addition, it is hard to work with such a device.

- A special manual saw for cutting porous materials differs from the usual hacksaw with a larger metal thickness. due to this, it bent less. The saw also has a special spraying or attack of solid alloy on large teeth. Tools are made with one or two handles. The canvas is performed different lengths.

Kryuovka on wood is not suitable for working with porous materials than you can cut foam blocks. with a special hacksaw for cellular materials, a hacksaw on foam concrete

A more effective option will be the use of a mechanized tool.

Electric tool

The power tool has much greater performance than manual. If the volume of work performed is quite large, then the use of mechanized cutting will be more effective.

- Electric saber saw is good for not very large in terms of work. The principle of its action is similar to the usual electronics. It works from the mains.

- The strip saw is a tape, on one side of which steel teeth are fixed. She produces the cut much faster and more precisely than manual devices.

- Corner grinder with diamond disks is an angular grinding machine (corner grinder), when cutting foam blocks creates a large amount of dust and noise. This leads to the need for constant cleaning of the tool so that it does not overheat. In addition, when working with it, personal protective equipment will be required.

Note: but the use of corner grinders is possible when cutting niches, an increase in window and doorways in finished walls. For these purposes, use disks with a diameter of 30 cm. Dust collection is better to carry out an industrial vacuum cleaner.

- Cable or string equipment for cutting light concrete also requires the possibility of connecting to the mains. For its operation, running water is needed. String for cutting foam blocks are metal cables with the inclusion of diamond elements. Perlin.

Sliding the blocks with a saber electric saw Ribbon saw for machines for cutting concrete angular grinder diamond cutting with a rope

The price of such equipment is quite high. Therefore, its application should be economically justified.

Laser equipment

recently, such a tool could only be used in industrial conditions. New technologies have made it possible to create enough mobile equipment.

Delivery and connection of equipment takes a little time.

There are a lot of advantages of this method of processing foam concrete:

- The cut is very accurate and even.

- The surface of foam blocks does not require additional grinding.

- Heating is plunged by a small area of the element.

- The design of the wall is not subjected to deformations.

- You can perform large volumes of work.

- It is easy to make cuts of complex shape.

- The ability to set the cut modes.

Laser cutting are quite significant

When working with a laser tool, there is no noise. But such equipment has a high cost. For this reason, it is not widespread.

How to cut cellular blocks

If you have to work with a manual tool, then the question. how to cut foam blocks, is solved quite simply:

- Foam block is laid on a flat horizontal surface.

- Design the spaces of the saw.

- The block is installed on the supports. you can use other blocks.

- Holding the element with the hand, with smooth movements they saw off the necessary part.

- The rope is thrown onto the block.

- The cable is fixed in a special machine.

- The equipment drives the string into effect. the element is sawing.

Pyla for foam blocks mechanized cutting of the string blocks for cutting foam block is driven by a special aggregate

Technologically this is a rather complicated way of sawing.

Saw on foam concrete step 16 mm

Slag block and any other stone, both natural and artificial, tolerate compression and poorly broken or bend. Hence the first rule of reliable masonry arises. the overlying stone should rest on the underlying masonry with the entire surface. In order to achieve this, it is necessary to apply the solution to the entire surface of the underlying block when laying slag blocks, and not just at the edges.

The side faces of the stones should be located only at right angles to the horizon. If you do not observe this rule, then the stones begin to perform the function of wedges, which under the load push the masonry, destroying it.

Each next row of blocks should shift relatively lower by a quarter or half of the block, that is, it is impossible to allow the vertical seams of the neighboring rows coincide. If the seams do not coincide (proper masonry), then the vertical load spreads throughout the wall, and if the seams coincide (incorrect masonry), then the load spreads along the column, sharply increasing the probability of destruction of part of the wall.

And some tips: when working in hot or windy weather, it is advisable to moisturize the blocks, this increases the clutch between the solution and the cinder block; If a break is expected during the masonry, then the solution should not be spread out on the upper row; Every 3 to 4 rows, it is necessary to check the horizontal and vertical of the rows.

На изображении: элементы шлакоблока: 1 — верхняя постель, 2 — большая боковая грань — ложка, 3 — маленькая боковая грань — тычок.

Чтобы было легче понять какую кладку из шлакоблоков можно использовать при строительстве стены, надо запомнить что у блока есть 6 граней: 2 противоположные на которые блок укладывается — верхняя и нижняя постели; большие боковые грани — ложки; маленькие боковые грани — тычки. Кладка ведётся горизонтальными рядами и шлакоблоки укладываются на постели.

Высота каждого горизонтального ряда формируются из высоту камня и толщины горизонтального шва раствора, который обычно равен 10 — 12 мм.

На изображении: 1 — кладка в полшлакоблока, 2 — кладка в шлакоблок, 3 — полтора шлакоблока.

Ширина кладки, которая в конечном итоге является толщиной стены, должна быть кратной 1/2 шлакоблока.

Факторы влияющие на надёжность стены из шлакоблока или любого другого камня

Прочность кладки определяется качеством шлакоблока и свойствами раствора. Максимальная прочность кладки из блоков равняется 40 — 50% предела прочности самих блоков. Такая ситуация объясняется вот как: раствор во время кладки ложится на блоки неравномерным слоем, возникают микроскопические перегибы и пустоты, это приводит к тому, что формируется разное давление на шлакоблок на разных участках стены, в блоке возникает напряжение на изгиб, а как раз такую нагрузку шлакоблок выдерживает плохо.

На изображении: этапы разрушения каменной кладки, 1 — появление трещин, 2 — формирование отдельных столбиков, 3 — полное разрушение стены.

Если стена испытывает излишнюю нагрузку, то она в первую очередь покрывается вертикальными трещинами, которые чаще всего располагаются по вертикальным швам. Со временем трещины расширяются и монолитная стена превращается в набор столбиков, которые могут выдвигаться из плоскости стены и в итоге кладка разрушается.

От качества раствора в многом зависит надёжность кладки, особенно важен такой показатель как пластичность раствора. Пластичный раствор равномерно ложиться на камень, в результате уменьшается напряжение на изгиб и увеличивается надёжность стены.

Замешивая раствор строго соблюдайте пропорции с учётом качества песка и цемента, не готовьте впрок.

От толщины шва также зависит крепость кладки, чем толще слой раствора, тем тяжелей его равномерно расположить на шлакоблоке и вероятность появления напряжения на излом увеличивается. По этой причине каждый вид кладки выполняется с определённой толщиной шва (для шлакоблока это примерно 1 см.), и увеличивать эту толщину без риска снизить прочность конструкции не получиться.

Особенности резки кирпича

Кирпич – прочный стеновой материал, способный выдерживать многотонные статические нагрузки. Но его так же характеризует хрупкость и ломкость. Поэтому для резки керамических изделий не подходит пеоратор или отбойный молоток. Чем тоньше и острее будет режущая поверхность, тем чётче получится рез, и тем меньше шансов на появление сколов.

Залог качественного реза – надёжная фиксация кирпича. Для этого можно использовать, как специальные приспособления, так и подручные средства. Перед работами нужно хорошо увлажнить изделие. Это поможет избежать обилия пыли в процессе резки.

Широкое разнообразие инструментов для резки стеновых изделий можно разделить на две группы: ручные и электрические. Пользоваться ими можно как на стройке, так и в домашних условиях.

Инструментальная резка

Дело пойдет гораздо быстрее, точнее и качественнее, если использовать инструмент для резки кирпича. Его выбор не слишком обширен: обычно для этого применяют углошлифовальную машину ( угловую шлифмашинку), бензорез или специальный станок для резки кирпича.

Без строительного угольника и карандаша для нанесения разметки не обойтись и в этих случаях. Кроме того, вам потребуются индивидуальные средства защиты, так как процесс резки сопровождается образованием большого количества пыли и мелких осколков. Это перчатки, очки и респираторная маска.

угловая шлифмашинка

Чем распилить кирпич, если вам нужно небольшое количество нестандартных камней?

Для этой цели лучше всего подойдет угловая шлифовальная машина, которую в народе называют угловой шлифмашинкой. В отличие от оборудования, речь о котором пойдет ниже, такой инструмент есть практически у каждого домашнего мастера.

Совет. Рекомендуется использовать угловую шлифмашинку мощностью около 2 кВт. Менее мощный инструмент может не справиться с задачей, а слишком мощным тяжело работать.

Устанавливаемый на машину диск для резки кирпича может быть двух типов:

-

Абразивный – недорогой, но и не слишком практичный. Он быстро «стирается» и может деформироваться или треснуть в процессе распила, что повлияет на качество среза и безопасность мастера.

В любом случае оптимальный диаметр диска – 23 см. Круг меньшего размера не прорежет кирпич на всю толщину, поэтому его в процессе придется переворачивать. А слишком большими кругами не так удобно работать.

Алмазные диски, в свою очередь, различаются по виду кромки и бывают:

- Со сплошной кромкой. Самые дешевые из аналогов, дают на срезе ровную поверхность. Но нагреваются во время работы и быстрее изнашиваются.

- С зубчатой турбированной кромкой. Зубчики на ней расположены по спирали, поэтому пыль и прочие отходы хорошо отводятся от рабочей зоны. Такие диски можно использовать для сухой и влажной резки, они обладают самым длительным сроком эксплуатации и лучшими рабочими характеристиками.

- С сегментной кромкой. У таких дисков по кромке сделаны пропилы, разделяющие рабочую плоскость на отдельные участки. Зона разреза при работе таким диском постоянно вентилируется, поэтому медленнее нагревается. Но при влажной резке возникает риск залипания отходов в прорезях, поэтому его используют преимущественно для сухой резки.

Чем пилить кирпич, и какой использовать диск – решать вам. Теперь вы знаете об особенностях любой режущей насадки.

Нужно лишь помнить, что пилить нужно не точно по разметочной линии, а немного отступив от неё, чтобы разметка осталась «в теле» нужной вам части. Иначе за счет люфта инструмента и толщины режущей части диска она получится меньше необходимого размера.

Держа угловую шлифмашинку на весу, сделать качественный срез сложно. Лучше закрепить и её, и кирпич в зажимной станине. С её помощью можно делать аккуратный распил не только вдоль или поперек кирпича, но и под любым углом.

Специальная станина для угловая шлифмашина облегчит работу

Очень важно при выполнении подобных работ не забывать о технике безопасности.

Инструкция требует выполнения следующих пунктов:

Инструмент необходимо держать двумя руками, чтобы при обратном ударе он не вырвался из рук и не нанес травмы вам или окружающим. Это требование также обеспечит и более высокую точность реза.

При работе очень важны устойчивое положение и правильный захват инструмента

- Электрический питающий кабель должен находиться на максимально возможном удалении от рабочей зоны во избежание его разрезания или наматывания на диск со всеми вытекающими негативными последствиями.

- Выпускать угловую шлифмашинку из рук и класть на землю или другую поверхность можно только после полной остановки вращения диска.

- Режущий круг обязательно должен быть закрыт защитным кожухом. Использовать угловую шлифмашинку без кожуха нельзя

Станок для резки кирпича

Специальные машины для резки кирпича стоят дорого, покупать их для разовой работы не имеет смысла. Это сложное оборудование предназначено для тех, чья деятельность связана с кладочными работами.

Состоит оно из следующих узлов и элементов:

- Металлическая станина;

- Силовой агрегат с электродвигателем и алмазным кругом;

- Система фиксации кирпича или камня;

- Большинство моделей также оснащаются системой подачи воды в зону распила.

Такое оборудование позволяет быстро и с высокой точностью выполнит распил любой сложности. При этом мастеру всегда виден процесс резки, он может его контролировать.

А система орошения минимизирует количество выбрасываемой в воздух кирпичной пыли, делая работу максимально комфортной и безопасной.

Как распилить кирпич с помощью этого станка?

- На него нужно нанести разметку и установить в рабочей зоне, зафиксировав в нужном положении;

- Режущая часть инструмента опускают к рабочей зоне и ориентируют на разметку;

- Затем включают двигатель и настраивают скорость вращения, после чего осуществляют резку. На фото – процесс распила кирпича на станке

Иногда возникает необходимость в резке не отдельных кирпичей, а в прорезании в кирпичной кладке различных ниш, дверных и оконных проемов. В таких случаях самым эффективным инструментом станет бензорез, с помощью которого осуществляется алмазная резка кирпичных стен.

Выбор диска для резки

Для нарезания кирпича и бетона используются алмазные и абразивные диски. Алмазные круги отличаются более высокой надёжностью и длительностью эксплуатации. Преимущество абразивных в низкой стоимости, однако менять их придётся чаще. Кроме того, абразивные диски могут деформироваться и ломаться в процессе работ, что делает их более травматичными в сравнении с алмазными аналогами. Среди алмазных дисков оптимальным вариантом для работы с кирпичом станет сегментный круг либо насадка с зубчатой кромкой. Диски со сплошным алмазным напылением подойдут для резки бетона.

Резка бензорезом

Цепь бетонореза имеет специальное алмазное покрытие. Использование бетонореза для резки штучного кирпича нецелесообразно.

Резать штучный кирпич бензорезом не очень удобно. Инструмент этот громоздкий и тяжелый. Бензорез с кругом напоминает большую угловую шлифмашинку, только с мощным бензиновым двигателем. Бензорез с цепью похож на бензопилу, но все элементы мощнее и предназначены для восприятия значительных нагрузок. Цепь изготовлена по специальной технологии, она, как и круги, имеет алмазное покрытие.

Бензорезы хорошо справляются с устройством проемов и снесением кирпичных стен. Устройство проема с помощью бензореза с кругом аналогично выполнению работ с угловой шлифмашинкой.

При использовании бензореза с цепью задача упрощается, так как глубины реза достаточно для сквозной резки стены любой толщины.

Практически любой бензорез снабжается принудительной подачей воды, что поможет сберечь ваши легкие и глаза от пыли.