How To Cut A Square Hole In Glass

Cutting round glasses

We offer the possibility of cutting out rounded glasses. A roller from the glass cutter is attached to one jaw of the caliper. Another sponge rests on the glass through a rubber washer. The roller is rolled a couple of times in a circle, then 3-4 tangents are drawn with a standard glass cutter, making it easier to chip the glass along the edges of the cuts. Sharpened edges are cleaned with a file or emery under running water.

How to Cut a Square Hole in Six Seconds

How to cut a round hole with a glass cutter

Cutting glass with a glass cutter involves not only drawing horizontal lines using templates or rulers, but also creating some non-standard designs. One of these is cutting a round hole inside a single piece of glass. To do this, use the same glass cutter, fixed on a special leg, resulting in a tool similar to a compass.

The most common devices of this type are made with a rubber suction cup at one end and an adjusting bit at the other. They are firmly fixed on the glass surface and allow making ovals of various diameters.

Another way to make a hole in glass

Another method for making a hole in glass.

For work, a drill made of hard metal plasticine for the production of a small bath, a combination of equal shares of camphor and turpentine, as well as a piece of dense rubber.

Hole in glass video

One of the fragile materials is glass, which must be handled with great care. To carefully drill a hole in the glass without cracking it, you should follow the recommendations, carefully select the tools for work.

How to cut a round hole in glass video

Glass is inherently extremely fragile and must be handled with extreme caution. In order not to receive additional losses during its cutting, you need to use the tools correctly and adhere to the appropriate working technique. First of all, you should familiarize yourself with the cutting device itself.

Unconventional glass drilling methods

A thin steel drill, heated to white, is hardened in mercury or a piece of sealing wax and sharpened. Then a saturated solution of camphor is prepared, in turpentine, a drill set on a brace is moistened with it, and glass is quickly drilled, which is moistened at the point of convergence with the named solution. This method can drill 1 cm thick glass in less than one minute.

In order to drill a hole in the glass, we recommend that you take a triangular file, lower it into turpentine and carefully drill a hole.

You can also drill the glass on a lathe with a copper rod, grease it with oil and sprinkle it with emery. Pay particular attention to the hole when the drilling process comes to an end and only the last thin layer remains, as this can easily crack the glass.

Glass cutting sequence

To properly cut the glass with a glass cutter, you need to carry out a set of preparatory measures:

- Finding a convenient place for slicing. A writing desk or other flat surface will do;

- Cleaning glass from dirt, dust and other foreign materials;

- Preparation of protective equipment. gloves, goggles, and a waste box.

Caution! During cutting, the glass should not vibrate or vibrate, its surface should closely adhere to the working area.

Cutting glass with a diamond glass cutter is like a drawing lesson in school. It is enough to take a ruler or template, attach it to the glass and draw the desired line along them with a working tool. After that, a shallow, barely noticeable trace will remain on the surface of the material. The process itself should be accompanied by a slight crackling sound.

In order for the work to be done efficiently, you should adhere to some recommendations:

- At a distance of 3-5mm from the edge of the glass, it is necessary to reduce the pressure on the tool in order to maintain its edge;

- The cutting tool is extremely sharp, so you don‘t need to press too hard on it. This way you can get a deep cut with convex edges;

- Keep the line running time to a minimum. A meter-long piece of glass is cut in 2 seconds;

- Under no circumstances should a new cut be made along the same mowing line.

After laying the mowing line, you need to divide the solid sheet of glass into two parts. This is done by tapping the cutter’s handle on the made mowing line. To do this, you first need to slip a piece of glass to the edge of the table, so that the line is at its end, and gently knock along its entire length. You just have to hold the second piece of glass sheet with your hand so that it does not fall.

Caution! For those who will be engaged in glass cutting for the first time, it is recommended to “practice” on waste and other pieces in order to gain experience and feel the intricacies of working with the tool. In most cases, this is sufficient to avoid unforeseen situations and unwanted losses in the future.

Using a homemade drill

You can drill glass by making your own tool for this, the design of which includes a diamond roller from a glass cutter and a metal rod. The diamond roller, which will act as a cutting part, is tightly fixed in the slot made on the end part of the metal rod. By fixing such a tool in the drill chuck, you can drill any glass product, while the result will be of sufficient quality.

Homemade glass cutter drill

By hardening a conventional drill, you can endow it with the ability to drill through glass. To do this, the working part of the drill must be heated white with a gas burner, and then cooled by dropping it in sealing wax.

What tools are used to drill glass

So that the drilling of glass does not end with cracking and complete destruction, it is very important to know not only how, but also how to properly drill the glass. There are many tools on the market today, some of which can be used to create holes in glass.

- The drill, the working part of which is made of hard alloy and has the shape of a feather or a spear, allows you to make a hole in glass with a diameter of 3–12 mm. Using such a drill requires certain skills. However, even their presence and maximum accuracy when performing work will not help to drill glass with this tool without small chips.

- A better drilling of holes is possible with a diamond drill for glass, the working part of which also has the shape of a spear. Such a tool, on the cutting part of which is applied with a diamond coating, provides a softer drilling.

- Glass drills, made in the form of a tube, are used in cases when it is required to make a large hole in the glass. It is more convenient to use a tubular drill complete with a drilling machine.

- When using brass drills, on the cutting part of which diamond spraying is applied, it is necessary to take care of their high-quality cooling, for which water or turpentine is supplied to the processing zone.

- Tubular glass crowns made with diamond dust on the cutting part also need high-quality cooling. If you do not know how to cut a large hole in glass, such a tubular drill can help you solve the problem.

The main types of drills for glass

How to drill a hole in glass at home: we disassemble all the options

If you need to create an even and neat hole in the glass surface, it is not necessary to contact experienced and qualified specialists, whose services are quite expensive. This procedure can be performed with your own hands in a home workshop, but, of course, for this you need to know how to drill glass, which tools, consumables and equipment to use.

To drill through glass, use one of the methods discussed in this article.

We understand the features of the material

Before wondering how to drill glass at home, you should at least in general terms get acquainted with the characteristics and features of this material.

The glass production process is quite complex. It is carried out in industrial enterprises equipped with special equipment. The main stage of this process is the preparation of a melt, which includes several components. Such a melt for glass is subjected to sharp supercooling, while the crystallization process is not completed completely.

To prepare a melt, a mixture of components that make up the future glass is subjected to significant heating. up to 2500 °. Depending on the chemical basis of the melt, glasses are distinguished:

- oxide category;

- sulfide;

- fluoride type.

For the manufacture of bottles, oxide glass is used (it is also silicate)

Glasses, which can be opaque, are subdivided into different types depending on the main characteristics of the material. So, glasses are distinguished:

- quartz, which is obtained by melting quartzite, also known as “rock crystal” (this material can be of natural origin and is found mainly in those places where quartz deposits have been affected by lightning);

- optical type, used for the manufacture of the main elements of optical devices (lenses, prisms, etc.);

- characterized by high resistance to aggressive chemicals and high temperatures;

- for industrial use (the most extensive category of glasses used in everyday life).

The question of how to drill a hole in glass most often arises when using the latter type of product. Industrial products, in turn, are also divided into several categories:

- potassium-sodium type (such glasses, characterized by a clean and light internal structure, have a relatively low melting point, therefore they are often used to make glass products of complex shapes);

- potassium-calcium type (glasses of this type have a surface without a pronounced luster, are highly hard and difficult to melt);

- lead type (such glasses have a pronounced luster, which makes them very similar to crystal, high fragility with a sufficiently high plasticity of the internal structure, significant specific gravity and a higher price when compared with the cost of other types of products);

- borosilicate (they are highly resistant to temperature extremes and mechanical stress and a fairly high cost).

In most cases drilling of window or display glass is required

There is also a classification of glasses by purpose. So, various types of glass are used for:

- glazing of windows and other translucent structures;

- manufacturing of containers;

- reducing the level of radiation;

- fiberglass production;

- protection of smartphone screens;

- making utensils;

- production of thermometers capable of measuring temperatures in the range from –200 ° to 650 °;

- the manufacture of laboratory glassware (such glasses are characterized by high thermal stability);

- production of medical devices (ampoules, tubes, medicine containers);

- fireplace screens and ovens (in such cases, heat-resistant glass is used);

- the manufacture of light bulbs (in this case, the so-called electric cone glasses are used);

- production of incandescent lamps, X-ray tubes, ignitrons (this requires vacuum glass);

- creation of elements of optical devices. cameras, microscopes, telescopes, etc.;

- the manufacture of thin-walled chemical containers and other products that require high resistance to chemical and thermal effects (for this, quartzoid glasses are used, also known as vikor).

Drilling thick glass is best done on a machine

Product preparation

When wondering how to cut a hole in glass so that the hole formed in it is as accurate as possible, and the glass itself does not crack, it is important to know how to properly prepare it for processing. To drill glass with your own hands, you must perform the following preparatory steps:

- The surface of the glass to be drilled is degreased with alcohol or turpentine. After that, it must be wiped with a dry cloth.

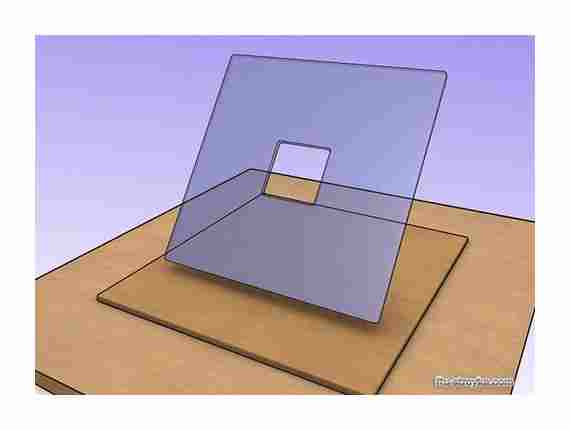

- A glass sheet or mirror must be laid on a surface that will prevent the product from sliding during processing.

- The surface on which the glass sheet or mirror will be laid must be larger than the workpiece itself. The edges of the sheet should not be allowed to protrude beyond its limits.

- On the place that needs to be drilled, it is advisable to stick masking tape or a piece of plaster to prevent the tool from slipping.

- The center of the future hole is indicated using a conventional marker.

- If you are familiar with drilling glass at home only from video, then in order to gain practical skills, it is better to pre-train on unnecessary glass fragments. Such training will allow you to subsequently drill quality glass.

- Drilling holes in glass should be done as carefully as possible, without unnecessary haste. At the same time, minimum pressure should be applied to the tool used.

- The drill for glass and ceramics, which will be used for processing, should be positioned strictly perpendicular to the surface of the product.

- Do not drill holes in the glass in one pass, you must periodically stop the process to allow the tool to cool completely.

- When the glass sheet or mirror is almost completely drilled, stop the process, turn the workpiece over and continue on the back of the workpiece. This approach will allow you to drill a hole in a mirror or glass sheet as efficiently as possible, to minimize the risk of chips and cracks.

- To make the edges of the hole you drilled even more neat, you can additionally process them with fine sandpaper.

Practical advice

How to properly drill the glass to get a high-quality result? To solve such a problem, it is enough to adhere to the following recommendations:

- To minimize the risk of cracking and splitting at the drilling site, the glass can be treated with honey and turpentine.

- The pressure applied to the drill from above should be minimal.

- The drilling process itself must be performed for 5-10 seconds, after which it is imperative to cool the tool in a vessel with water.

- The drill must not be rocked from side to side.

- The distance of the center of the hole from the edge of the workpiece must be at least 1.5 cm.

Naturally, before you drill the glass, you must degrease it and lay it on a flat surface, which is best used as a wooden base.

Drilling glass with a conventional drill

Many home craftsmen are interested in the question of how to drill glass or a mirror, using not a tubular or other special drill, but an ordinary tool. In order to perform this procedure, you will need the following tools and consumables:

Machining 101: How to drill a square hole at home without special tools.

- drill, with which metal, ceramic and tile material are usually drilled;

- low-speed drill, instead of which you can use a screwdriver;

- a piece of ordinary plasticine;

- turpentine;

- alcohol solution.

A plasticine glass edge is needed to keep the coolant in the drilling area

The drilling itself is performed in the following sequence:

- The glass sheet or mirror must be laid on an absolutely flat surface, while the edges of the workpiece should not protrude beyond its limits.

- The area of glass that needs to be drilled must be degreased using cotton wool soaked in an alcohol solution.

- After fixing the drill in the chuck on the tile and glass, the minimum number of revolutions is set on the drill. Before starting work, it is necessary to check the degree of drill runout: if it is too large, then the tool should be replaced with another.

- On the surface of the glass to be drilled (in the place of direct processing), it is necessary to fix a piece of plasticine, in the middle of which a small depression is made in the form of a funnel. Turpentine is poured into such a depression, through which holes are drilled in the glass.

- In order not to throw away the cracked object after drilling, such a process should be carried out as carefully as possible, without making great efforts. The minimum rotation speed of the drill chuck must be 250 rpm, and the maximum cannot exceed 1000 rpm.

How to make a hole in glass using sand

Few know how to make a hole in glass using ordinary sand. You will need:

- the sand itself;

- petrol;

- a small amount of tin that can be replaced with lead;

- gas-burner;

- a vessel made of metal, for which it is permissible to use an ordinary mug.

The surface of the glass to be drilled is degreased, as in all previous cases. A pile of wet sand is poured onto the area where the center of the future hole should be located, in which, using a sharp object, a depression is made with a diameter corresponding to the cross section of the hole being created.

Making a hole with molten solder

Molten tin (or lead) is poured into a depression formed in a hill of wet sand, after which it is necessary to wait a few minutes. Then the sand is removed from the surface of the product, and a piece of metal-glass alloy is easily removed from the processed material, the dimensions of which fully correspond to the geometric parameters of the hole being formed. A gas burner and a metal mug are used to bring tin or lead into a molten state.

The cut made according to the above method is of high quality and does not require additional refinement.

How to make a hole in glass: methods and instructions

Making holes in glass may seem like a simple operation, but in practice it is a rather complicated and demanding procedure. The structure of the glass is malleable for mechanical processing, but at the same time it is very fragile. Therefore, the peculiarity of the operation is not so much in the choice of the force of influence as in the approach to its organization. The main task of the master is not to lead to the formation of cracks, chips and fractures of the main surface. How to make a hole in glass without violating this condition? You can accomplish this task using special technologies and tricks that are available to almost any master. The following will discuss the most popular and effective methods.

High-tech processing methods

This category of methods for creating holes is more likely to be industrial, although private craftsmen also acquire the appropriate equipment for their needs. We are talking about lathes and units that provide sandblasting abrasive cutting. The best quality result is provided by waterjet. how can you make a hole in glass using such equipment? First, the installation is fixed in machine clamps. there are practically no restrictions on dimensions, including thickness. Next, consumables are refueled. They are composed of sand and water. The hole is created as a result of circular cutting with a water-sand jet along a pre-marked mowing line. Automation itself will position the cutting direction, providing an almost perfectly straight cut.

The nuances of making holes by drilling

Glass cannot be drilled with the usual drilling method. If we are talking about a workpiece of the same small dimensions, then you can use a standard set of drills and drills, but before that, the work equipment should be prepared in a special way. First of all, a drill of a suitable standard size is heated to a white shade. Next, it must be immersed in sealing wax and held until the latter melts. After that, the tip is moistened in turpentine and you can start the work process. There is another option that allows you to make a round hole in the glass by drilling. its step-by-step instructions are presented below:

- Camphor and coarse sandpaper particles are crushed.

- The prepared elements are poured into a small container and diluted with turpentine.

- A small piece of copper wire is prepared for the drill, which must be clamped in the chuck.

- The previously prepared paste is placed on a cleaned glass surface.

- A plywood guide is prepared for positioning the copper tooling.

- You can start drilling.

Smelting a hole

In this case, you will need to initially prepare the equipment for the preparation of liquid tin or lead. The glass surface is also prepared accordingly. It should be treated with gasoline, acetone or alcohol. Further, moistened sand is poured onto the marked hole formation zone. There should be enough of it to create a funnel, the bottom of which will fit the edges of the hole. After that, metal is poured into the created funnel. It will cool down in 1-2 minutes, after which it will be possible to remove the sand snap along with the cast mold. This is the best option if the question is about how to make a hole in glass without a drill and with smooth edges. But the problem may arise in another aspect. No matter how accurate the sand funnel is, it will be impossible to control the diameter that will form when glass is melted with metal.

Glass preparation for processing

Before any operation to create holes or simply cut, appropriate preparation should be done. The working surface of the glass should be clean and, if possible, have no defective areas. during drilling, they can chip off the sides, which will ruin the workpiece. It is recommended to mark the cutter line of the future hole so that the physical surface imperfections are within the circumference, but not outside. As an additional measure, the glass can be treated with chemicals, which, in particular, will rid it of oil traces. If there is a question about how to make a small hole in the glass, then you will have to prepare the fixing equipment. The method of fixing the workpiece will depend on the technology for creating the hole, but in most cases such elements are mounted on a vise of a suitable configuration. damping soft material is placed directly into the contact areas.

Soldering iron cutting

From the point of view of the quality of the result, this option can be called the opposite of the previous one. In this case, the master will be able to relatively accurately maintain the boundaries of the marked hole diameter, but the edges may be uneven. The process begins by creating risks with a file. The task of this operation is to accurately mark in depth for the future melt with a soldering iron. Now you can proceed to the next step. how to make a hole in the glass without drilling with a soldering iron? After warming up the tip of the machine, you can start cutting. over, one should not rush in this process. It is advisable to perform melting in small pieces, if necessary, cooling the glass. otherwise there is a risk of deformation and areas not intended for processing.

Making large holes

Drilling methods are not always theoretically permissible for making holes in glass, and not only for reasons of a high risk of the formation of the same chips. In the case of holes with a diameter of more than 10 cm, no household equipment can cope with this task. But in this case, there is an exit, in which the drill is also used. It is necessary to make a small through point in the prepared surface in the very center of the planned hole. To do this, you can use any small-format glass with a diameter of less than 1 cm. You should not be afraid of third-party chips, because they will fall on an area that will be removed anyway. Now another question: how to make a hole in the glass, having a small through opening in the center? A piece of wire is pushed into the created small hole and fixed. The other end is fastened with a glass cutter. Further, after checking the reliability of fixing the elements and the smoothness of the tool in a circle, you can start cutting in a circle.

Another way to make a hole in glass

For work, you will need a hard alloy drill, plasticine for making a small bath, a mixture of equal shares of camphor and turpentine, as well as a piece of dense rubber.

How to make a hole in glass

How to make a hole of any diameter in glass

Glass is thoroughly degreased with acetone, gasoline or alcohol. Then a handful of slightly moistened fine river sand is poured into the place where the hole will be. After that, a tapered hole is made in the sand crust with a sharpened stick to the glass. Its diameter in the lower part of the cone must be equal to the diameter of the hole to be produced in the glass. Then, molten solder (tretnik or tin) with a melting point of 200-300 ° C is poured into the sand mold made. After the solder has solidified, remove its cone. together with the glass column adhered to it: the hole is ready.

If the glass is poorly degreased, it can burst in an arbitrary direction and ruin the work.

Drilling a hole in glass

A hole in the glass can be drilled with a carbide drill. The secret to the success of this operation. in the liquid with which the glass is wetted. It is prepared from aluminum alum dissolved in acetic acid, or from a one-to-one mixture of camphor or turpentine. A plasticine roller is made around the drilling site. Liquid is poured into the resulting bath. During processing, the glass must lie on a soft cloth.

Drilling a large hole in glass

The drill is made from a piece of aluminum, duralumin or copper tube 40-60 mm long. From one end, a wooden cork is driven into it to a depth of 20-25 mm, and at the other end, the teeth are cut out with a triangular file. A short screw 4-5 mm thick is screwed into the cork so that its smooth part protrudes by 10-15 mm. The head is sawed off. They are glued to the glass on both sides along a cardboard washer with a hole equal to the diameter to be drilled. The glass is placed on a piece of rubber. A pinch of abrasive powder is poured into the drilling site. Then insert the end of the screw protruding from the cork into a hand drill, lubricate the teeth with turpentine and start drilling. When the tube goes deep into the glass by at least 1/3 of its thickness, the glass is turned over and the drilling is finished on the other side.

Drilling glass

- Small holes in the glass are drilled with a conventional drill, which is pre-hardened. The tip of the drill is white-hot and then quickly pressed into the sealing wax and held until the sealing wax stops melting. When drilling, the tip of the drill is abundantly moistened with turpentine. Small glass items can be drilled in water.

- A hole in the glass can be drilled with copper wire. To do this, prepare a paste consisting of coarse emery, camphor and turpentine. One part of camphor in powder is dissolved in 2 parts of turpentine and mixed with 4 parts of coarse emery. The resulting paste is applied to the place where you want to drill a hole. A piece of copper wire is clamped into a drill chuck. It is convenient to drill glass through plywood (conductor), which has pilot holes. The glass must be on a firm and level surface.

- To drill holes with a diameter of more than 4 mm in thick glass, use a copper tube. On the glass around the proposed hole, a ring-shaped fence with an inner diameter of 40-50 mm and a height of 8-10 mm is made of plasticine or putty. Corundum powder is poured inside the ring (it is easy to prepare it by crushing a piece of an unusable emery wheel). The powder is poured with a small amount of water to make a liquid slurry. Holes are drilled with a copper tube clamped in a drill chuck. The diameter of the tube should be slightly less than the diameter of the selected hole. It is very important that the end of the tube is strictly perpendicular to its axis. this is easy to achieve by cutting the tube on a lathe.

- A hole in the glass can be made with molten solder. A small hill of slightly moistened river sand is poured onto the glass surface, previously thoroughly degreased with acetone, gasoline or alcohol. A conical depression is made in it with a sharply sharpened stick and an area equal to the future hole is cleared of sand. Molten solder with a temperature of 250-300 ° C is adhered to the resulting sand mold. After the solder cools down, the sand is removed, and the solder cone is removed along with the glass circle adhered to it.

Making holes in glass

There is an old, but for some reason forgotten nowadays method of making holes in glass. The place on the glass, where the hole should be, is thoroughly washed from dirt and grease with gasoline, acetone or alcohol. Then wet fine sand is poured onto the washed place and a funnel is poured into the sand to the glass with a sharp-pointed stick of the required diameter. Molten solder (lead or tin can be used) is poured into the mold prepared in this way in the sand. After 1-2 minutes, the sand can be dumped and the solder cone removed. An even through hole is formed in the glass.