How To Cut A Window In A Wooden House

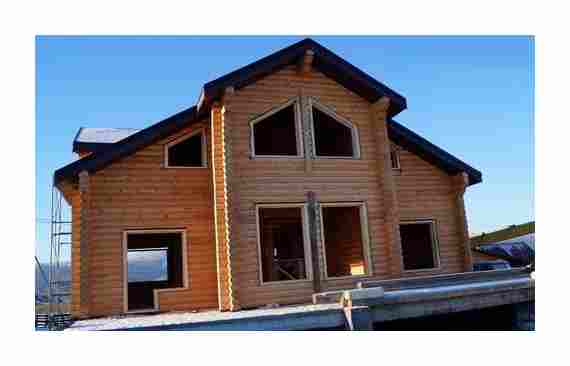

Cutting technology for window and door openings

Openings for windows and doors can be cut in two different ways:

- Openings are cut after complete shrinkage of the house. Initially, a solid wooden frame is installed, which does not have window and door openings. And only when the house gives a final shrinkage (as a rule, after 12 months), openings of windows and doors are cut along the outlined boundaries. It should be noted that due to the significant amount of waste received, this method of cutting openings is much more costly.

- Window and door openings are cut directly in the process of making a log house. At the same time, in the places of openings, it is necessary to make gaps for joinery and cut vertical grooves at the ends of the walls. Bars are subsequently inserted into these grooves, the task of which is to perform a guiding function during the subsequent shrinkage of the house. The remaining gap in the upper part of the grooves is insulated. Strict adherence to construction technology guarantees smooth, beautiful and compact openings for windows and doors at the exit.

Whatever cutting technique you choose, you should outline the location of windows and doors in advance so that it does not turn out that dowels and dowels are already installed in place of windows or doors. Installation of dowels and dowels must be done on those walls where it is planned to cut down more than two windows. Otherwise, such a wall can sag under the weight of the roof.

How we carve out window and door openings

- We proceed to the felling of a log house, leaving openings somewhat smaller than necessary for the project.

- Then, in the middle of the opening, we skip one solid crown (as when constructing a blank wall). We do this every 3-4 crowns.

- We cut out these logs only after the house has completely shrunk. It should be noted that window and door openings with this cutting method are usually made several centimeters narrower than necessary, which simplifies the process of final alignment of the openings.

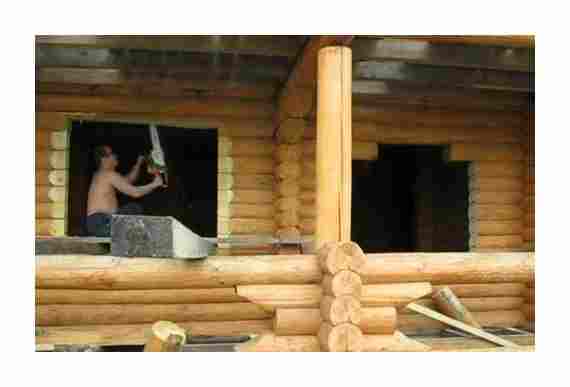

- We cut openings using a chainsaw, while cutting the upper and lower logs only by half, which simplifies the further execution of the mowing.

- Okosyachka is the process of casing openings, which prevents their deformation. Thanks to the jig, the rims of the timber can move freely during vertical shrinkage, preventing the squeezing of the logs.

Cutting window and door openings

We build wooden houses and baths from round timber, timber, gun carriage, cut out window and door openings. We have been working all over Belarus for over 10 years.

Only specialists with extensive experience are involved in the construction of log houses.

When cutting out window and door openings, it is important to comply with all technical conditions. After all, even a slight deviation from technology can lead to irreversible consequences. For example, if window and door openings were cut incorrectly, in the process of natural shrinkage of the house they can simply be squeezed out.

The cost of cutting openings

What is included in the cost of cutting openings using the example of a 66 m bathhouse project (Russian wheelhouse, Russian corner, 3 doors, 2 windows):

- rough cutting of window and door openings are included in the cost of building a bath;

- cutting out curtains (in window and door openings) for a cashier, inserting cranial strips into window and door openings. 630 BYN.

Errors when cutting window and door openings

Among the main mistakes that are often made when cutting out window and door openings are the following:

- They begin to cut openings directly during the felling of the house. In the process of shrinkage, logs may be squeezed out.

- Openings of the required dimensions are immediately cut. As a result, after the final alignment, the window and door openings are larger than required.

- They forget to cut openings, which leads to their deformation.

- Dowels are not installed on walls with two window openings. The wall can sink under the weight of the roof.

- Use polyurethane foam instead of mineral wool

Door and window openings in a wooden house

In general, door and window openings in the walls are arranged immediately after the installation of the frame of a wooden house on the foundation. This is done initially by the construction team according to the project. But there are situations when it is necessary to make a door or window opening in a wooden house that has already been fully built. Most often this is due to the need to arrange an additional doorway in order for warm air from the heating system of a wooden house to quickly penetrate into all rooms of the house. Well, or just wanted to cut out an additional window opening.

It is quite natural that the more solid the wall, the easier it is to arrange an opening in it. precisely, it is not even so much easier as faster and at the lowest cost. It all depends on the material from which the wooden house is built.

Door and window openings in a wooden house made of logs or beams

Indeed, in order to arrange door or window openings in the walls of a wooden house made of logs or timber, not so much is needed. This is a plumb line, a long ruler (The longer, the better. A meter flat rail will do), a marker or pencil with a thick lead, a hammer, nails and an ordinary gasoline or saw.

Just in case, it is also worth preparing 100×100 mm bars. in the height of the room, that is, 2-2.5 meters long. a little more about them further.

There are times when, when sawing a door or window opening, the wall of a wooden house begins to bend in one direction or another. In the event of such a problem, through holes for bolts are drilled in these bars and the wall of the house at equal distances from each other. Then the prepared bars are attached to the wall of the house on both sides (it is enough only from the inside) from the deflection, and the protruding part of the masonry of the wall of the house between the bars is pulled together with bolts.

Arrangement of openings in wooden houses

Then the work on sawing the opening in the wall of the wooden house is resumed, and after the installation of the window, these bars are removed, since the window itself already strengthens the window or doorway.

For your information. If your wooden house is made of logs, then the openings must be arranged, leaving not the whole, but 1/5 or 2/3 of the logs at the top and bottom of the opening. This is done so that the window and door openings are milled correctly in the future.

Jigging (casing) device in the opening

For more information about the device of the casing (casing) of window and door openings, the use of a cranial bar and the installation of windows and doors in a wooden house, read this article.

Important. Before sawing the opening, make sure that there are solid logs or beams above the future opening, which will evenly distribute the future load on the walls on opposite sides of the opening.

For your information. If the frame of a wooden house is assembled from glued beams, then when sawing, the boards glued together may peel off. To avoid this problem, boards are nailed to the walls of the house on both sides of the opening being arranged.

Doorway in a wooden house from a bar

Door and window openings in a wooden frame house

In order to make an opening in the wall of a frame house for a door or window, in the place of the proposed opening, you will first have to get rid of the cladding, both external and internal, and remove the entire internal pie from insulation, etc. That is, in fact, it is necessary to leave only the frame made of beams.

Then, a frame for the future window or door is arranged between the bearing vertical racks, and the remaining sections of the wall are sewn up again.

Window opening device in a wooden house

As you can see, if you have the necessary tools, skill and desire, it is not at all difficult to arrange an additional door or window opening in a wooden house. The main thing here is the right place in the wall, a steady hand, slowness and the help of one or two people.

Instructions for installing a reinforced-plastic window in a log house

Okosyachka is assembled as follows:

- the lower casing jumper fits into the opening

- the combs are lined with rolled tow (mezhventsovy insulation)

- window carriages are stuffed on the crest

- the upper jumper is inserted into the upper gaps and lowered into the grooves.

The whole structure is fastened with self-tapping screws. In this case, it is necessary to ensure that the self-tapping screws do not “hook” the ridge, otherwise there will be no benefit from the casing. The slots between the logs and the casing are also clogged with tow. By the way, tow will not only insulate the opening, but will save you from the squeak when the house shrinks.

Further installation of metal-plastic windows in a wooden house is practically no different from the usual installation of window structures in an apartment. In other words, the usual installation of the window is carried out in compliance with steam, noise and thermal insulation, a detailed description of which you can find in the article “Features of installing windows with your own hands”.

The gap that remains between the walls of the log house and the window is filled with boards of small thickness, which are wrapped in tow in advance. As the house shrinks, the boards need to be changed to other, more suitable ones. In order for the boards to be easily changed, the platband, behind which the boards are located, must be attached only to the window. Therefore, when the need arises for replacement, it is enough just to remove the platband, change the boards, and put the platband in place.

The main options for casing (okosyachki)

The simplest version of the casing is a 50×50 cm bar inserted into a vertical groove of the same dimensions, cut out at the ends of the window opening logs. This option is used only when installing wooden windows. And since we are considering the installation of a metal-plastic window in a log house, it makes no sense to consider this option in detail.

With another version of the jig, a spike is made at the ends of the logs (the so-called comb), on which a carriage with grooves is put on.

Window carriage. this is a vertical bar measuring 150 by 100 centimeters, with grooves 50 by 50 cut at the ends, into which boards of 150 by 50 are inserted with spikes at the ends (horizontal jumpers).

Due to the ridge, the logs, when the house shrinks, slide inside the groove, without pressing down the window structure and not deviating vertically. Sometimes the spike is made on a carriage, and the groove is in the logs, while the basic principle of operation of this casing option remains unchanged.

Note! When assembled, the window should be 7-8 centimeters in height less than the window opening (such a gap is left based on the shrinkage of the house).

Instructions for installing a window in a wooden.

The main feature of the installation of window structures in a wooden house is that during the entire service life of a log house, in contrast to a reinforced concrete, brick or stone house, it behaves very unstably. In other words, wooden structures tend to “dry out”. And if this instability is not taken into account during installation work, then big problems can arise.

There is an opinion that the blockhouse shrinks only in the first year after construction, and then the house does not change its parameters. However, this is not quite true. Indeed, a wooden house shrinks especially noticeably in the first year, but then, for at least 5 years, this process does not stop (and in some regions, depending on climatic conditions, the shrinkage of a log house continues throughout the entire period of operation). As the wood (beams or logs) dries up, the wall height of the house can be reduced by 1.5 cm for every meter of masonry. That is, if the height of the wall is 4 meters, then the blockhouse can “shrink” by as much as 6 centimeters. Now imagine what will become of the window if you leave only the standard 2-2.5 centimeters gap for the polyurethane foam? That’s right, the frame is at least deformed, and the sash will jam.

Nevertheless, the installation of reinforced-plastic windows in a log house is quite a feasible task. But only on condition that a cage (or, as this system is also called, a window) will be installed in the opening, which will give the window independence from the enclosing structures (walls) of the house, and will take on all the loads. In this case, the jaw:

- does not allow the logs to move from the vertical in the window opening;

- does not interfere with vertical shrinkage of the walls;

- strengthens the enclosing structures in the area of the window opening.

In order for you to have an idea of how the window is installed in a log house, we have prepared detailed instructions describing all the stages of installation work. But first, let’s figure out what a siege is, and what variants of this system are used today.

Expert advice

An experienced specialist should know not only the technology of installing metal-plastic windows, but also the technology of building a log house. Only in this case, he will be able not only to correctly determine whether it is possible to install a window structure in each specific case, but also, if necessary, install a classic casing in the opening.

If in your log house the role of the casing is played by the box left over from the old wooden window (in other words, when you removed the platbands in order to measure the opening as accurately as possible, you found that there were no windows), then when installing a metal-plastic window, there are two possible scenarios:

alteration of a window opening for a window;

significant reduction in the translucent part of the window, since the thickness of the window frame will be added to each side of the window structure.

And most importantly, never give your consent to the installation of a metal-plastic window in a log house without first installing a window in the opening. Even if your house has stood for more than a dozen years, and you think that the blockhouse has completely “dried out”. Remember the tree. it is a “living” material that “breathes” throughout its entire service life, with all the ensuing consequences.

How to cut a window in a wooden house. preparatory and main stage of work

Everyone knows that wood is easy to process. But not everyone fully understands how to cut a window in a wooden house so as not to violate its geometry. In fact, everything is quite simple, but you will need to learn the nuances and some secrets. It is necessary to choose the right place for the openings, to determine the dimensions in order to provide the required illumination, but, at the same time, not to weaken the heat and sound protection of the interior. Quite often, log cabins are erected in one piece, without any holes in the wall, and they are cut out after the log structure has shrunk. In other cases, the owners may think about redeveloping rooms already during the operation of the house or after purchasing it. And here again the question of cutting openings is raised.

Preparatory stage

First you need to decide exactly where you need to place the windows. From the side of the room, the window sill should be above the level of the finished floor approximately at a height of 80-90cm. But this is a standard size, and individually it can be installed both higher and lower. There are several things to consider here:

- aesthetic;

- rational;

- functional.

For example, if the furniture pushed to the openings is visible from the street side, then it does not look beautiful. Therefore, the window sills are made slightly higher than the level of the floor cabinets, and the piers are slightly wider. In dressing rooms and dressing rooms, windows are located in the upper part of the wall, and in spacious halls they can be placed 40-50 cm above the floor. But in this case, you will need to take care of the safety of others, especially children, who gladly climb the windowsills.

The opening itself in the wooden wall is cut to size slightly larger than the window block. In this case, they rely on the following requirements:

Learn how to frame a window ~ Building tutorials made easy

- the width of the opening should be 7 cm larger than the window on each side. a total of 14 cm. The casing box will take 5 cm each, the remaining 2 cm will be filled with polyurethane foam;

- the lower level of the opening is reduced by 5cm. the window sill will take 4cm and the foam. 1cm;

- the upper level of the opening rises by about 10 cm. further shrinkage of the frame is taken into account, which occurs gradually over several years after the installation of the box, as well as the thickness of the casing crossbar and the layer of polyurethane foam.

The marking of the opening can be affected by the diameter of the crown logs. Stability and reliability of the structure will be ensured by inserting the casing into the lower and upper logs by at least half, or even two-thirds of the size of its cross-section. The window, in this case, will be maximally protected from various deformations. Often, the dimensions of the openings are adjusted to the typical dimensions of the window blocks, taking into account the casing.

How and what to cut the opening

There are two main ways to cut a window in a wooden house. Both of them are widely used, but are selected based on specific conditions.

The classic version provides for the design of an opening in a finished blank wall after shrinkage of a log house or at the stage of house redevelopment. In the first case, the approximate location of the window is planned in advance in order not to mount pins in this area. They will still be removed, so the efforts made will be completely in vain. After the log house has shrunk, the markings are “refreshed” by correcting the verticality of the lines with a plumb line, and the horizontal. with a building or laser level. It will not be superfluous to check the clarity of the corners. No shrinkage is required during redevelopment.

The speed of installation of the casing box and window block depends on the thoroughness of drawing marking lines on the wall.

Cut openings for windows using a petrol or saw, if the electrical network is within reach. Often, after cutting a hole in a wooden wall, the crowns begin to move slightly. This situation should not be ignored. It is necessary to expose strong vertical bars or metal strips on both sides of the fence, securely tightening them with bolts. It is recommended to dismantle the support bars only after installing the casing.

The second option for the design of window openings provides for cutting holes in the process of laying the crowns. In this case, the estimated area of the opening is increased by about ten percent, taking into account the shrinkage of the frame. The nuance here lies in the location in the middle of the future window of one or two logs. They are left in the opening as spacers with a step of 3-4 crowns. At the same time, by means of wooden dowels, whole and cut logs are fastened together at a distance of about 40-50 cm from the edge of the slope. This trick helps to avoid the curvature of the walls during the shrinkage of the structure. After a year and a half, auxiliary sections of the logs are cut out.

The latter method makes it possible to save the basic material. The effect is especially noticeable if there are many windows in the house. But there is a significant disadvantage here. The fact is that no one can predict how the shrinkage of the log house will go. Therefore, after a year, and even after two, the opening may turn out to be much larger than the required one. It is difficult to eliminate such errors, since it is not always possible to properly seal huge gaps. In this regard, many developers prefer to dwell on the first option for cutting out windows.

I would like to mention one more very important point. After the window openings are cut, the ends of the logs must be treated with antiseptic compounds intended for impregnating the ends. They have special properties that help protect wood from uneven shrinkage and, at the same time, do not create an impervious film.

At the next stage of work, they begin to install the casing and the direct installation of the window with a window sill. Finally, the cracks are filled with foam, slopes and ebb tides are installed.

ASSEMBLING THE WINDOW FRAME

The window frame is made of timber, the size of which depends on the structural features of the window: the number and thickness of glass, the gap for the glazing bead. All wooden elements are assembled together with self-tapping screws, spikes, grooves, wood glue. Then glass is inserted into the finished structure, sealant is applied to the frame perimeter and glazing beads are nailed.

BOX WITH A CUT IN A CUT (“MONOLITHIC SPIKE”)

The window structure is made of edged, unplanned and unpolished wood with initial moisture content. As well as in the first two variants, this box needs finishing of slopes.

The work begins with the manufacture of a groove (5×5.5 cm) in the center of the vertical ends. Then a solid box with additional elements in the form of a “T” sign is assembled from a bar (15x10x20 cm). The lower end of the jumpers is fixed with iron pins. The spacers are boards (5x15x20 cm) fixed with screws to the frame racks.

WHAT YOU WILL NEED TO WORK?

When installing the box in a log or timber structure, you will need:

Beam or logs;

Self-tapping screws and nails;

Sealing material;

Chisels or similar tool;

Marker and tape measure.

VARIANT WITH BASKET BAR

A vertical groove must be made along the entire length of the end part of the window opening. Then you need to take a block (50×50 mm) (it should be slightly shorter than the opening height) and insert it into the knocked-out hole so that the upper end does not reach the opening surface during shrinkage. The bar will act as a vertical guide and prevent horizontal displacement.

In the future, the window frame must be fixed to the bar with self-tapping screws, the length of which must be insufficient for the protrusion on the back side. Insert the roll seal between the structure and the ends.

This installation method involves the installation of the structure in an already assembled state. The lack of grooves makes the box slightly thinner compared to the end cleat system.

Screws are used to fix the window frame, and the holes are closed with a mounting clip.

Do not fill the gaps between the structure and the ends with construction foam.

Installation of a window frame with a filling element is suitable for all wooden buildings, minus houses made of large logs with a width of more than 0.35 m.The system is made from unpolished or uncut edged boards with natural moisture.

BOX ASSEMBLY METHODS

A window in a wooden house consists of several functional elements: boxes, frames, etc. The window frame is designed to separate the building wall from the opening and frame so that shrinkage does not violate their structure. Its absence threatens the geometry of the opening and the destruction of the entire window system.

Structures are divided into several types:

With a thorn on the side panel;

With filling block;

With a cutout in the construction of the house (“thorn-monolith”).

MANUFACTURE OF WINDOWS IN WOODEN BUILDING: BASIC NUANCES

The installation of the window system depends on the type of wood material (logs or beams) and the shrinkage of the building. If well-dried wood is used in the work, then the shrinkage of the structure will be minimal.

Houses made of dried wood are ready for the installation of windows almost immediately after the completion of the construction of the main timber or log structure. Such buildings are characterized by minimal shrinkage (approximately 1.15%), which will not affect the geometry of the structural materials.

The movement of a house made of uncut profiled logs has a higher rate and is equal to 2.6%. Freshly cut material dries 9-11%.

Maximum shrinkage lasts about a year after the completion of construction. In the future, this figure drops to 5%. Thus, the average size of movement and shrinkage of houses made of logs with “natural” moisture or cylindrical bar is 3.5%.

When determining the gap between the upper log and the window frame, you need to know that for each meter of the cutout, 1% shrinkage is equivalent to 1 cm.

How to make a window in a wooden house

As you know, wooden houses are made from natural materials that ensure the reliability, durability and environmental safety of the building. To protect the structure from the penetration of cold air, and therefore to increase the temperature inside the room, the arrangement of the “correct” window system will help.

BOXES WITH STUDDED SIDE LEAF

To install the system, a vertical ridge formed on the cuts of the opening and recesses similar in height on the sides of the box are used. The structure is assembled directly in the window niche:

The lower element of the window sill is installed;

The spikes are closed with a sealant;

The rest of the system is installed.

On the outside of the window, the edges of the structure can be protruding or aligned. In the second option, after the installation measures, it will be necessary to install slopes that will close the “border” slots.

Such a system does not require the use of construction foam or unnecessary fasteners. Only the elements of the window sill require rigid fixation.

After making the box, a window block with an ebb is installed on it. Platbands are mounted on both sides of the system using self-tapping screws or nails.

Rules for installing windows and doors in a wooden house

10 Aug 2017.

How to Install Window Casing and Interior Trim

Wooden structures made of pine beams are environmentally friendly, warm, comfortable, beautiful buildings, which, due to their execution from natural “living” material, have their own characteristic construction features. For several years after the completion of installation, they shrink, from which window and door openings suffer most. If windows and doors are installed in a wooden house without taking into account shrinkage processes, they can be severely damaged.

In order for windows and doors to function without breaking from the pressure of the shrinkage of a log house, it is necessary to follow the rules for their installation in a wooden house using casing of door and window openings.

The purpose of the casing (okosyachki) of openings: strengthening the walls and maintaining the operability of windows and doors during the shrinkage of the log house.

Installation of windows in a shrink box

Note that the casing of window openings in a wooden house for plastic or wooden windows is not fundamentally different. The general rule when installing windows in a log house assumes that all joint cavities should be sealed with a soft insulation, for example, it can be mineral wool. In this case, polyurethane foam is not recommended, because the hardened foam during the shrinkage process can simply be simply torn off from the surfaces.

- The procedure for installing a window into a shrink box: removing the sashes from the window; installation of a window frame in the opening with attachment to the casing with special anchor plates; sealing the joints of the junction of the imposts to the box with sealant; installation of an ebb tide; checking the opening and closing of windows; fastening the platbands to the window frame.

Manufacturing of casing for window and doorways of a house from a bar

We make casing using shrink boxes. Before installing windows and doors, shrink boxes are first installed in the openings, which leave a gap for vertical shifts of the structure (the frame shrinks only vertically, there are no horizontal shifts of the structure due to shrinkage) in order to protect the glass from cracking or the door leaf from breakage.

For the manufacture of shrinkable boxes, dry wood with a moisture content of 12-16% is necessarily used, which in itself will not shrink and will not harm the products that will later be installed in boxes. We make such shrinkable boxes, which are 11 cm smaller in width than the openings and 4-5% (percentage of log shrinkage) lower in height. That is, if, for example, the width of the window opening is 90 cm, then the width of the box inside it will be 79 cm.There is a gap on the sides of the insulation of 2 cm, and the thickness of the shrink box frame itself is 3.5 cm.It is fastened with black self-tapping screws on wood. We install boxes in openings without sawing anything, so that the box can be effortlessly set to the level that is needed when installing a window or door. You can learn more about the features of shrinkage mechanisms for rounded logs and profiled beams in one of our previous articles.

Various methods of compensating for shrinkage in door and window openings are widespread, for example, there are such types of casing:

A mortgage block. A simple and cheap design, the box of which is made of 40 mm edged board. In the opening on the inside, a groove is cut out for a square bar, to which a finishing board is attached. This method of manufacturing the casing provides for additional finishing of the slopes after installing the window frame.

Siege “in the thorn”. For the manufacture of a jig in a thorn method is used a solid rectangular bar in the shape of the letter “T”. The vertical “leg” is inserted into the groove and acts as a window slope.

Siege “in the pack”. A spike is cut out in the sidewalls of the opening, onto which a deck in the shape of the letter “P” is later planted. Most expensive design.

It will be useful to know that the shrink box aligns the wall and prevents it from further deformations, which does not guarantee, for example, a cage in the form of a foundation bar.

Installation of doors in a shrink frame

Casing doorways is just as important as casing windows. It is recommended to do it even in decorative openings, which are also subject to shrinkage processes. There are slight differences in the manufacture of casing for entrance and interior doors. The front door cage is distinguished by the obligatory presence of a threshold, the size of which is usually 4-5 cm.Inside rooms with flat floors, the shrinking box has a U-shaped structure, without a lower part.

As you can see, the installation of the casing, as well as the installation of windows and doors, must necessarily be carried out by experienced craftsmen who will provide all the necessary design parameters so that the shrinkage of the log house is symmetrical and does not harm the doors and windows installed in the house. And about which windows and doors to choose, you can read in previous articles on our website.

Shedding is a necessary element when installing windows in a wooden house

Shedding (okosyachka) is a necessary element of a properly prepared window opening in a wooden house. This is the protection of the new window from deformations (distortions, torsion, deflections). The casing is, in fact, an additional frame made of a casing (bar) made of dry and durable material, and fixed in a window or doorway (for installing doors, it is also necessary to make a casing). The thickness of the casing (okosyachki) is 25-50 mm, depending on the thickness of the timber and the height of the structure, the width. along the thickness of the walls.

Who is responsible for the windows in a wooden house

Traditionally, there is a division of work: builders and specialized organizations in this area are engaged in the manufacture of casing with its installation. The work related to the correct measurement of windows and their manufacture is performed by window companies. This is a very important point in the distribution of responsibility. If the casing is made and installed incorrectly, and the window is subsequently damaged because of this, the manufacturer of the casing is responsible for the destruction of the window. If my friend Uncle Vasya did it, then you will have to install a new window at your own expense.

Installation of windows in a wooden house. features of the building material

A wooden house is a “living” organism that literally breathes and therefore the microclimate inside it will always be comfortable. not a “stone bag”. The disadvantage of a wooden house can be considered a strong shrinkage during the first 3 years and after the first year of heating.

Not all buyers are aware that the process of installing windows in a wooden house has its own specifics. For the correct installation of windows in a wooden house, additional construction work is required to prepare the window opening. If the window is installed in a “bare” window opening, the resulting loads from the shrinkage of the building can deform the window structure, changing its geometry. Ultimately, this can lead to irreversible damage to the window, requiring a complete replacement.

When installing windows in a wooden house

It is necessary to order windows in a wooden house after the manufacture and installation of the casing, when the window opening is completely ready for taking measurements.

Measurement must be carried out according to the internal size of the box. Mounting clearances comply with the normative values of the current standards.

Installation of windows in a wooden house. installation features

The installation of windows in a wooden house requires mandatory work on the preparation of the window opening. Failure to comply with these rules can lead to disastrous consequences after the house shrinks during its further operation. The portal WINDOWS MEDIA understands the intricacies of technology.

Plastic windows are the optimal solution for glazing a wooden house

For country houses whose owners consider heating costs, warm plastic windows are a smart choice. The new development of energy-efficient windows REHAU GRATSIO will be the optimal solution for owners of wooden houses.

Another advantage of REHAU GRACIO windows is the 12% increased light opening compared to standard systems. Owners of such windows will get more daylight in the room, which is very beneficial for eye health.

The appearance of the REHAU GRACIO windows fully justifies its name. The bevels of the profile surface create a graceful, sophisticated window shape. The hallmark of REHAU windows. the glossy surface will provide easy window care. Dust and dirt will not be absorbed into the surface of the profile and can be easily removed during window cleaning.

The durability of the REHAU GRATSIO profile, confirmed by tests, is at least 60 conventional years of operation

The combination of impeccable properties with an affordable price allows REHAU GRATSIO windows to become the optimal solution for glazing modern wooden houses throughout Russia.

The article contains contextual and visual advertising

Basic tips for doing the work yourself

The recommendations of the masters who know all the subtleties of measuring and installing window structures will help to get the right result:

If you have accurate information, you can choose the model of the window, the type of opening mechanism, the color of the frame, the type of glass unit, the finishing of the slopes.

The result of the performed measurements should be:

- Correct opening parameters.

- Correct calculations of the dimensions of the window structure.

- Fast and high-quality installation of the frame, window sill, ebb, mosquito net.

Preparing the scheme

A drawing of an entrance metal door is a large-scale diagram of a door leaf, according to which the assembly and installation of the product will be carried out, with the dimensions of the door frame applied to it, the locations of the stiffeners, hinges.

We arm ourselves with a tape measure and take measurements from the doorway.

The standard door size is considered to be 90 x 200 cm, if the actual dimensions of the opening are much larger than the data, it makes sense to install a separate unit on top or on the side of the door leaf.

The side block can be made deaf or hinged, and the upper one can be closed with sheet metal, glazed or grilled.

All this is also applied to our drawing.

The dimensions of the door frame should be 2 cm less than the doorway. this will be the mounting gap in which the unit is adjusted to avoid distortions. Below is a sectional diagram of a metal door.

Most often, the door is mounted on 2-4 hinges, their number depends on the weight that your structure has.

Hinges are external and hidden, the second option is more difficult to manufacture and requires certain skills.

Since we are trying to make a “door for beginners”, we will focus on the first option.

To evenly distribute the load, the hinges must be made at an equal distance between themselves, and the upper and lower hinges should be located at a distance of 15 cm from the edge of the door.

You can make the stiffeners in any direction. horizontally, vertically or with a mesh, as well as diagonally. everything is at your discretion.

The ribs must be made so that they do not pass in places where the installation of the lock, peephole, door handle will be performed.

You determine the number of ribs yourself, it must ensure that the door is not bendable under its own weight, otherwise after a while the door will need repair.

So, the drawing is ready.

Installation of plastic windows in a wooden house

Materials for the manufacture of platbands in a wooden house

Modern platbands are made from materials such as:

- solid wood;

- PVC;

- MDF.

Aluminum platbands are less common. The classic option is solid wood. They are best suited for a log house. Plastic platbands are advantageous in that they are not afraid of moisture, microorganisms and other factors that adversely affect the wood. MDF is a sheet material that is made from wood waste, that is, from shavings. Due to the binding components, it has a sufficiently high strength, resistance to atmospheric influences and durability.

We prepare materials and tools

We offer you an approximate list of tools:

- welding machine;

- drill;

- a set of screwdrivers or screwdriver;

- Angle Grinder;

- clamps;

- files or grinder;

- trestle or door assembly table;

- measuring instruments (corner; tape measure, etc.);

- building level.

For a standard size metal door you will need:

- steel sheet 2-3 mm thick. 100 x 200 cm;

- metal corner 3; 2 x 3; 2 cm. 6 r.m. (for the door frame);

- profile pipe 5 x 2; 5 cm. about 9 r.m. (for door frame and stiffeners);

- metal plates 40 x 4 cm with a thickness of 2-3 mm. at least 4 pieces (for attaching the door frame to the walls);

- door hinges;

- Castle;

- fittings;

- anchor bolts;

- anti-corrosion coating;

- metal paint;

- polyurethane foam.

Choose the fittings and lock to your taste. Manufacturers offer a large selection of locks, the most reliable of which are three-sided.

A lock with crossbars on three sides is, of course, more difficult to install, but it is also not easy to break it.

If you are making a metal door for a utility room (shed), then it is allowed to make a lightweight, economical option. in this case, a thick reinforcing bar is used for stiffeners instead of a profile pipe.

Insulation of window openings

When gaps appear between the window block and the slopes or window sill, foam rubber or seals are used for small voids, but there is an option that is more convenient. polyurethane foam.

The foam expands to fill gaps of any size and shape. It hardens during the day and provides thermal insulation due to the air bubbles contained in it. The composition is destroyed by sunlight. Painting or varnishing of filled voids is a must.

Window openings must be insulated from the outside and from the inside. Polyurethane foam is the most convenient option.

Preparatory work

As in other cases, the manufacture of a metal door begins with paperwork, in other words, we have to create a drawing.

In order for the drawing to be accurate and consistent with reality, you have to decide on the dimensions.

The structural diagram of the entrance door proposed for acquaintance will acquaint you with the names and location of the main nodes and elements.

- Wooden windows in the house

- Plastic windows for a wooden house

- Do-it-yourself okosyachka (siege) in a wooden house

- Installation of a window sill

- Installation of a plastic window

- Installation of plastic windows in a wooden house video

As our compatriots are “let go” by the Soviet past, a craving for what was “as before” in life comes to many heads. And this is not nostalgia, because a person has never seen this “before”, but his grandfathers saw at best. This is a special sentimental state of mind associated with love for everything that a city dweller sees only in pictures.