How to cut an angle grinder without chipping ceramic tiles

Figured design for pipes

Many people wonder whether it is possible to cut the tile with an angle grinder figuratively? Of course it is possible, and of different shapes: square, oval, circle, rhombus, ellipse. To do this, you need to read the article to the end and practice in practice.

When carrying out independent repairs, an angle grinder is often used to cut tiles, as a rule, it is used when working with durable facing material or simply because there is no tile cutter. However, it is not so easy to make a cut with such a tool without chips. In order for the surface of the tile to remain flat, you need to know some of the subtleties of such work. So let’s take a closer look at how to cut tile with an angle grinder.

Operational Safety Angle Grinder

This tool has its own hazard category for this reason, you must strictly follow the safety rules:

- To avoid direct exposure to shards or sparks, the tool must have a protective cover.

- For comfortable work and to avoid damage to the electric wire, the length of the cord must be at least 2 meters.

- It is not recommended to hold the angle grinder vertically while cutting, otherwise it may break out of your hands, cause injury and break the material.

- Cut tiles using protective equipment: respirator, goggles, gloves, headwear, overalls and sufficiently durable shoes.

- Hold the tool with both hands and cut the material by rotating the circle “away from you”.

- Do not press hard on the disc.

- Use the appropriate cutting wheel for each material. an abrasive for metal, and a diamond dry cutter for tiles.

- To avoid electric shock, do not cut material immersed in water.

- Sawing an angle grinder is recommended in a ventilated area because dust is explosive.

Rules for cutting ceramic tiles on a homemade machine

There are certain strict rules for cutting tiles on a machine from an angle grinder, which mainly ensure the safety of work.

- It is only necessary to cut the tiles “from yourself”. In this case, the pressure on the tile with your hands should be moderate.

- Cutting must be done from the front of the material.

- For fixing tiles, clamps are usually used, which should be located in the center of the cut.

- If the cut is made for the first time, then it is worth trying to do it on waste, because there is a high probability that cutting the tile the first time simply will not work.

- It is not necessary to keep the angle grinder plugged in when not working.

- Store the machine indoors and out of the reach of children.

- The cutting process must be carried out in goggles or a mask, because in addition to the dust from the tool, rather large pieces of material also fly.

Tile cutting methods

There are several options for how to properly cut tiles. That is, you need to get an even cut without chips and defects. There are three directions.

- Tile cutting with an angle grinder along a straight mowing line. This is the easiest option. A cut line is applied to the ceramic surface of the tile. The tile is clamped into clamps so that the cut area is located outside the table surface. That is, it seemed to be hanging. It is necessary to cut in this position “on oneself”. This makes it possible to clearly see the cut line. The angle grinder is switched on and the material is cut exactly along the mowing line with a disc.

- Bevel cutting. This is when the edge needs to form an angle, usually 45 °. Everything is done in the same way as in the previous case. Only one more stage is added. this is the formation of a chamfer. For this, the disc of the angle grinder is brought to the cut edge at the required angle. There is no need to cut anything here, the edge is simply ground at an angle. The angle can be brought to the ideal state by grinding it by hand with emery paper or a file.

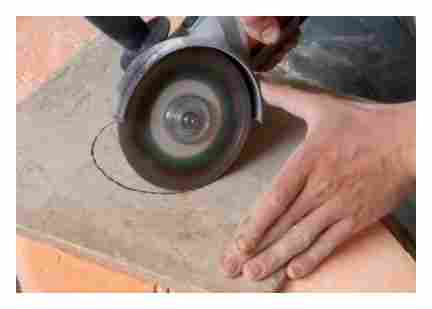

- How to make an angle grinder a hole in a ceramic tile. It is clear that small-diameter holes cannot be cut with a disc, but you can try more than 100 mm. It should be noted that this is the most difficult option, therefore it is very important to correctly carry out all the stages from preparatory to basic. So, a circle is applied to the tile, along which the cut will be made. Further, the resulting circle must be divided into four parts, drawing two mutually perpendicular mowing lines so that both of them pass through the center of the circle. Now you need an angle grinder, holding it at an angle, make a cut around the circumference. It is necessary to cut in small sections. Even if the corners remain, they can be earned. There is no need to saw through, the main thing is to make a small incision. After that, the circle is sawn through on the applied lines (mutually perpendicular). Next, you just need to separate four segments of the sawn circle one by one. And at the end, the edges of the circle are necessarily reworked to the required accuracy.

Attention! The tile should be cut along the front side of the tile. Thus, the appearance of chips can be avoided. They will form on the reverse side, which after facing no one will see.

Homemade tile cutter from angle grinder

It should be noted that cutting tiles with an angle grinder is, first of all, an inconvenient process. Holding the tool in your hands and guiding it accurately along the applied mowing line requires certain skills and experience in carrying out operations of this type. Therefore, you can install an angle grinder on the bed, fix it well on it, that is, build a kind of machine like an electric tile cutter. over, it will be cheaper than the last.

The installation method of the angle grinder can be vertical or horizontal. In principle, there is not much difference in how to install the tool, because the main requirement for a home-made machine is a strong attachment of an angle grinder so that it does not vibrate during the process of cutting ceramics.

A horizontally installed tool must be secured in space so that the cutting wheel is positioned exactly vertically. In this case, it must be in the slot of the table. And this slot will serve as a cut-off mowing line, such a kind of landmark. You can do without the slot, and install the angle grinder on the bed so that the disc is slightly farther than the edge of the table. This design is considered not the best, because the cut parts of the ceramic tiles will have to be held on outstretched hands all the time. And this, with a large volume of cutting operations, is physically difficult. Optimally, if the entire tile will lie on the table, then it is easier to move it along the plane, pushing it lightly with your hands.

The vertical installation of the angle grinder is determined by two conditions.

- The tool reducer, or rather its outer part, should be located at the level of the table surface, it can be slightly lower, but not more than 1-2 mm.

- 90 °. this angle should be between the table surface and the cutting diamond disc.

All conditions are defined, you can proceed to the manufacture of the machine. This will require a steel sheet with a thickness of 4-5 mm, metal band clamps, with which you can fasten the angle grinder, respectively, the angle grinder itself, plus a few bolts with nuts and washers.

- First, you need to cut out a platform from a steel sheet, the dimensions of which could accommodate the largest ceramic tile. It is imperative that a disc and an angle grinder make a slot on the sheet, which was mentioned above. Its length must be greater than the diameter of the cutting element.

- Now the tool itself is attached to the table with clamps, on which a steel platform with a slot is preliminarily laid. It is also bolted to the base of the table.

- Craftsmen advise to put the clamps in rubber or plastic tubes. Thus, do not damage the surface of the housing of the angle grinder.

Attention! If the tile cutter is made using the technology of a vertically installed tool, then you need to understand that during installation the protective cover will have to be removed, because it will interfere and will not fit into the assembled structure. And this increases the danger of working with such a machine. Therefore, the advice is to cut ceramic tiles on such a machine, being away from the direction of the cutting disc. That is, left or right.

How To Cut Tile On A Dry Cut Angle Grinder-Diamond Blade-SIMPLE & EASY!

There is one more element that will not be superfluous in the design of a homemade electric tile cutter. This is an emphasis on which the tile will abut, thereby creating the size of the required cut-off part. This element must be movable in order to adjust the cut size. Therefore, under it you will have to make a slide with slots for almost the entire length.

On the slide, the stop is fixed tightly, you can use electric welding. The slide itself will move across the cut mowing line on bolts, which, when relaxed, allow the slide to move, and when secured, hold them firmly in one place. Both the stop and the slide can be made from a metal corner or steel strip.

Why an angle grinder is the perfect tool for assembling a DIY tile cutter.

- Firstly, it is the only power tool that can generate a disc rotation speed of up to 5000 rpm.

- Secondly, it is a simple assembly that turns a handheld device into a stationary machine.

- Thirdly, when cutting at high speed, microcracks will not form, which, when laying tiles on walls or floors, can cause large chipping of the material.

Features of working with the tool

In the process of performing facing work, you will inevitably face the need to correct the size of the tile. In order to make an incision, tile cutters are usually used in various variations, as well as improvised tools. If a glass cutter is sufficient for the wall tile, it is much more difficult to break the thick floor material. Can an angle grinder cut such ceramic tiles??

The angle grinder is one of the most popular tools that, in addition to its direct task of sanding surfaces, can also perform other functions. With its help, metal, ceramic tiles, stone and other durable materials are cut.

As far as tiles are concerned, working with an angle grinder has its own characteristics. In order to complete the task, you will need a special nozzle and a tile fixer. The tool will do the rest for you.

For additional protection, you should put a cap on the angle grinder, of course, it will reduce the usability of the tool, but will protect you from fragments and the disc itself.

Direct cut on the tile with a grinder

On the front of the tile, a marker indicates the cutting line, then the angle grinder turns on, and when it picks up speed, you can start cutting. You need to start from the nearest edge and carefully at the risk to the other side of the tile. When the glaze is evenly cut, make a second pass. Slice until tiles separate from each other.

Important! Ceramic tiles are fragile, so you should not press hard, and the first cut is made to remove the glaze. If you start to cut straight from the edge, then at the end the tile may burst. Therefore, it is recommended to cut evenly from edge to edge in several passes.

Important points when working with tiles

Before you start working, you need to figure out how to cut correctly so as not to spoil the finishing material in the future. The disc on the grinder must be tightened with a wrench, the tiles must be laid on a flat surface, preferably a board or plywood, in order to exclude vibration from which fragile ceramics can burst. If possible, then it is better to tighten with a clamp, if not, then it is good to press the tile with your foot.

Curly cutting

In a tile, you often have to make round holes, for example, for a pipe.

Sequence of work:

- markup: draw a circle, mark the center;

- cutting begins on the inside of the marking and at an angle, the tool is carried out along the entire circumference;

- at the next stage, the circle is visually divided into sectors that need to be cut and removed one by one;

- the cut is processed with a file until a flat circle is obtained.

Cutting curb slabs

Paving slabs differ from other materials in their structure. Concrete is taken as a basis, and granite crushed stone is used as a filler. For cutting such workpieces, an angle grinder is recommended to purchase combined or segmented diamond wheels.

The work area should only be set up outdoors as there will be a lot of dust during the cutting process. If it settles on an already laid tile, you need to immediately remove dirt, since dust eats into the material and changes its color.

It is recommended to carry out work in protective clothing, respirator and goggles. For products of small thickness, the standard through-cutting technology is used, and the thick tiles are first notched, then the excess part is chipped off.

Ceramic cutting technique

The work begins with drawing lines to cut off excess parts. To do this, many use a simple pencil or colored markers to better see the line of the cut. Experts recommend marking the workpieces with a glass cutter or other cutting tools. during the cutting process, a lot of dust is generated, when removed, the mowing line drawn with a pencil will be erased, and they will have to be reapplied.

Straight cut

To make a straight clean cut without chips, you need to follow these rules:

- the tile is fixed on the table so that the cut part goes beyond its limits;

- markings are applied to the workpiece;

- the cutting tool is positioned at right angles above the cutting line;

- The angle grinder must be moved slowly and smoothly towards you so that the trim line is visible.

Obtuse angle

If you need a tight joint, cut the tile at an angle. To do this, you need to have experience in performing such work. To facilitate the task, you can make a straight cut, and the corner can be made using sandpaper or a grindstone.

The subtleties of working with porcelain stoneware

Tiles are used to decorate not only the walls, but also the floor. To do this, use a harder porcelain stoneware tile. it is cheaper than marble or granite, but not inferior to them in strength.

Many are wondering how to cut tiles without a tile cutter. In this case, you can also use an angle grinder with cutting wheels.

Basic requirements for a tool for processing porcelain stoneware at home:

- Use only blades specially designed for cutting porcelain stoneware and other hard materials, with a diamond coating of the maximum height.

- the angle grinder must be equipped with a speed controller.

- To avoid chipping, it is recommended to buy solid metal discs with a minimum thickness.

Recommendations for preparing the workplace and performing cutting:

- A flat, stable surface is selected to securely fix the tiles. It is recommended to put a thin layer of foam under it.

- The workpiece is secured with clamps.

- Using a marker or glass cutter, the mowing line is guided to cut. It is recommended to pre-stick adhesive tape on the surface of the workpiece in order to minimize the likelihood of chips.

- You need to saw at a short distance from the markings so that there is a margin for subsequent leveling and grinding of the cut.

Tile cutting discs

The cleanliness of the tile edge after cutting depends on the correct angle grinder attachment. You can use different discs, while the quality of the work performed will also be different.

The following types of discs can be used to cut tile material:

- Stone. This is the cheapest angle grinder attachment, the roughness and thickness of which make it impossible to get an even and clean cut. After using stone discs, the tile has many chips and an inaccurate cut, it takes a lot of time to refine the material, and the process itself is quite laborious.

- Steel. Such nozzles are solid, segmented, combined. Without cooling with metal samples, you can work continuously for no more than 1.5 minutes. Then the angle grinder must be allowed to cool slightly without turning off. Experts recommend using steel discs with additional diamond coating for high-quality cutting of slabs. They are thin, during the work a lot of dust does not form, and the cut is smooth and clean.

- Solid steel. They are used for ceramic tile materials. the cut is clean, and the side of such a disc can additionally grind the edge. The instrument should be allowed to cool periodically. If a solid red streak appears (sparking), it is recommended to apply the disc several times over any abrasive surface, such as a concrete base.

- Metal segmented. Nozzles of this type are designed for processing natural stone, porcelain stoneware, paving slabs. The working surface of the discs is divided into segments that allow cooling the nozzle during operation.

- Combined (turbocharged). These are versatile discs that can be used for any material. The nozzle has an intermittent cutting edge and wavy working surface, which increases the thickness of the mowing line of the cut and generates more dust.

How to cut tiles without damage

You can use different tools to neatly trim tiles when laying it, but masters who are independently engaged in repairs are more often interested in the question of how to cut tiles with an angle grinder without chips.

Segmented dry cutters

This type of attachments for an angle grinder is a steel disc with evenly spaced slots directed from the cutting edge to the center and dividing the disc into equal segments. The segmented nozzle can be used to cut porcelain stoneware and natural stone tiles. The slots between the disc segments increase the life of the bit by improving the air cooling of the tool during cutting of hard facing material, but increase the formation of chips.

Stone discs

Stone discs are several times cheaper than dry cutters, but they wear out during operation and must be replaced with new ones. In addition, they are thicker than dry cutters, so the thickness of the mowing line for cutting with a stone nozzle is wider and, accordingly, more dust is generated during operation.

In the process of cutting with a stone nozzle, you need to control the condition of its cutting edge. if a chip or burr forms on the edge, the disc must be replaced immediately, since such damage is fraught with destruction of the nozzle and causing injury.

Shaped tile cutting angle grinder

If it is required to cut an oval shape from a ceramic tile, then short cuts are made with an angle grinder tangentially to the outer contour of the figure in order to cut off small fragments of ceramic to be removed. At the end of cutting, the surface of the cuts is refined with an abrasive tool until the lines are smooth and there are no chips.

When it is necessary to cut a figured hole in the tile, the angle grinder cuts the material exactly along the contour, gradually moving away from it inward and increasing the depth of the cut. After cutting through the tile, the edges of the hole are finished with coarse sandpaper.

Angle Grinder Cutting Large Holes

The center of the circle is marked on the ceramics with an alcohol marker and a through hole with a diameter of 3-4 mm is drilled with a carbide drill exactly along the mark. Then, on both sides of the tile, a contour of a circle of a given diameter is applied. an angle grinder with a disc makes cuts 1-2 mm deep along the contour of the future hole on both sides of the tile, and then make through cuts inside the contour and remove small fragments of ceramics from it with nippers. The inner surface of the cut along the perimeter of the hole can be processed with coarse sandpaper or a file until there are no chips.

Tile cutting with an angle grinder is performed using a diamond grinding wheel

How to Cut Porcelain Tile-using an angle grinder

Ceramic Cutting Discs Angle Grinder

To cut ceramic tiles, an angle grinder uses stone or diamond-coated steel discs (dry cutters). Dry cutters, in turn, are divided into solid and segmented. The more intense the diamond spraying on the dry cutter, the more efficient and durable the disc will be.

Discs come in stone or steel

Cutting rectangular holes in tiles with a grinder

Mark the cut contour with a marker and a ruler on the front side of the tile and drill holes with a diameter of 5-7 mm exactly in its corners, without going beyond the contour boundaries, with a carbide drill. Then the angle grinder makes through cuts between the holes along the perimeter of the rectangular contour, the cut out fragment of ceramic is removed and the corners and the cutting surface are finished with coarse sandpaper or a file.

Cutting Tool Grinding Machine

Solid dry cutters

This type of dry cutter can not only cut ceramic tiles, but also process the cutting edge with a working side surface. The absence of detonation of the tool during operation due to the solid shape of the disc increases the cutting speed, allows you to cut a fragment evenly and reduces the number of chips.

Direct Cutting Ceramic Angle Grinder

On the front side of the ceramic tile, a cutting line is applied with an alcohol marker. the angle grinder is turned on and given a couple of seconds to set the set speed.

The disc on the grinder must be fixed correctly. using a special wrench and in accordance with the direction of rotation indicated on it.

The optimum rotation speed of a disc with a diameter of 100-125 mm when cutting ceramic tiles is 6-8 thousand revolutions per minute. The tile is placed on a flat wooden surface, secured with a clamp through a rubber sheet gasket, or you can simply press it against the board with the sole of your foot (wearing special shoes!).

Cutting ceramic tiles can be straight and curly

Exactly along the intended mowing line, an incision is made with a depth of 1-5 mm, depending on the material and thickness of the tile. From the edge of the material, they begin to cut slowly, then the angle grinder is moved faster. this way the cut is smoother. After making a cut, the tile can be broken by placing a pair of nails under it opposite the beginning and end of the cut.

How to cut tiles with an angle grinder: no chips or dust

Tiling is almost impossible without cut rows. As a rule, they are located along the edges. Very often, the need for cutting tiles appears at doorways, in the places where pipes are located, and so on. where neat laying is required. And for these purposes a special tool should be used. The correct choice of the device will allow you to get high-quality pieces, and therefore, to make the styling at a high level.

Instructions on how to cut

angle grinder is the popular name for an angle grinder. Not everyone knows that people began to call this tool that way since the 70s. It was at this time that the first samples began to arrive in the Union. And they were called “Eltos-angle grinder”.

In general, an angle grinder is a multifunctional tool. It is capable of processing materials thanks to the diamond wheel. The unit allows you to perform not only a straight line, but also a figured cut.

Recommendation: It is not necessary to cut the tiles to the full thickness. If you make a line-cut, then the product will break very pliable.

Of course, when compared with the results of a tile cutter, an angle grinder has more fragmented edges. At the same time, preparatory manipulations are not needed to carry out the process.

The disadvantage is that you cannot do without dust and chips. The only thing is that they can be compensated for by the protective casing of the tool itself, personal protective equipment, as well as the use of a special disk. For example, a good cut quality, practically no chips can be provided by a disc designed for metal processing. This is largely possible due to the reinforced relatively smooth surface.

Tiles are easy to cut with wet cutting attachments. This will allow you to get the absence of chips, as well as a flat and smooth cutting surface. In this case, the nozzle must be new, and the cut itself must be made from the back of the tile.

Tools

There are many ways to cut tiles. For this, special tools are used. For instance:

- tile cutters;

- nippers;

- glass cutters;

- drills with appropriate attachments;

- Angle Grinder.

Each option has its own characteristics, advantages and disadvantages.

For example, the tile cutter is a very popular tool used for this purpose. It can be performed in three variations:

- electric;

- manual;

- tile cutter tongs.

The first option is more suitable for the conditions of mass work. This means that the volumes must be large. Such a device is capable of even the most durable materials from which tiles can be made.

In the process of cutting the material, water is supplied, which makes it possible to obtain smoother edges, not to heat the material and not to spread dust. The only drawback of such a device is its high price. over, one-time work is not for him. Better to rent an electric tile cutter.

As a result, the hand model is a fairly popular model. But in this case, everything will have to be done by hand. An alternative is the tongs cutter. The tool is designed for thin metals. In this case, there is another drawback. subsequent processing of the ends is required. grinding. And this is not always good.

A glass cutter, a drill, as well as wire cutters, can also cut tiles. In the first case, there is a limitation in the thickness of the products. As a result, the tiles may not cut through. The drill together with the nippers allows you to get a good cut.

Next, consider the application of the angle grinder in more detail.

Training

If an angle grinder is used for cutting, it is recommended to check the tool for damage and function before the procedure. You need to insert a disc to work on cement or metal. There is certainly a difference between them, but not significant.

It is necessary to inspect the tool itself, otherwise some flaws can ensure poor-quality work.

Do not forget about personal protective equipment. This means that you should also wear a hat on your head, protective gloves on your hands, and clothes on your body to protect your eyes. glasses. The latter is perhaps the most important. After all, dust, small fragments can get into the eyes with a very fast rotation of the disc. This can be a dangerous injury. Therefore, you should think about your own safety first.

Chips and dust are inevitable?

You can put it this way. Indeed, everyone can perform certain manipulations to reduce such negative phenomena.

In addition, you can watch video and photo materials about this. After all, a lot depends not only on the tool itself, attachments to it, but also on the cutting technique. This aspect also affects the presence of chips and dust.

Be that as it may, but it is important to devote enough time to this moment. And then the result will please you with the high quality of work.

Is it possible to cut tiles with an angle grinder?

Another tool for processing tiles is a tile cutter. But not every owner has this device in the arsenal, but with an angle grinder everything is somewhat simpler. In addition, the tile cutter cannot handle complex curly cuts with exact observance of the given geometry and parameters.

Another advantage of the angle grinder is the ability to use a variety of discs. They can be selected in accordance with the type of tile, its thickness and coating characteristics.

What disc to cut ceramic tiles angle grinder?

There are at least 6 types of discs suitable for use with an angle grinder. The quality of work and the achievement of various results at the request of the master will depend on the choice of the nozzle.

Curly cutting

It is more difficult than the first option, it requires a certain skill. The tile is processed with short cuts along the tangent of the mowing line to the outer contour of the drawn figure (oval, circle). This will allow you to cut off small extra fragments, and then achieve the desired configuration.

They also plan small allowances for trimming, and at the end they refine the contour by grinding, achieving smooth lines and removing chips.

Making rectangular holes in tiles

After delineating the boundaries of the rectangle, steel plates are applied to its outer surface. The longitudinal plate will act as a ruler, and the transverse one will limit the movement of the cutting tool.

Scotch tape or clamps are used to fix the plates. Next, small grooves are cut, bypassing the created contour by the device, and then gradually deepen inward.

It is possible to facilitate the work with a drill. She drills several holes with a diameter of about 5 mm inside the contour, and then an angle grinder creates through cuts between the perforations.

Safety engineering

An angle grinder for cutting tiles is one of the most traumatic power tools. Therefore, compliance with safety measures will help to maintain not only health, but sometimes the life of the master.

What rules should be followed:

- work only in a special suit, glasses, gloves, respirator, safety shoes;

- do not remove the protective cover from the device body;

- remove the power cord from under your feet, do not allow it to fall under your feet or into the cutting area;

- cutting tiles with an angle grinder without chips is performed only in the direction away from you, firmly holding the unit with both hands;

- immerse the nozzle into the tile no more than ⅓ of the radius of the circle;

- avoid maximum and minimum indicators of rotation speed;

- do not allow any liquids to get under the body of the angle grinder;

- work only in a well-ventilated area due to the high explosiveness of dust.

How to cut tiles with an angle grinder. basic rules of work, types of cutting

It is extremely rare in the process of facing the master deals exclusively with whole tiled elements. For finishing complex planes, outlining communications, joints and corners, it is required to trim the tiles to the specified parameters, including curly cutting.

Only an angle grinder can perform the most difficult tasks. How to cut tiles with an angle grinder, which disc is better, how to avoid chips and dust? Let’s figure it out together.

How to cut tiles with an angle grinder without chips or dust?

The processing is preceded by a thorough measurement. the markings are applied with a marker on the outside of the ceramic tile. Since it is impossible to make a perfectly straight cut in most cases, small allowances are made for trimming with a sharpener or file.

Features of working with the tool

In the process of performing facing work, you will inevitably face the need to correct the size of the tile. In order to make an incision, tile cutters are usually used in various variations, as well as improvised tools. If a glass cutter is sufficient for the wall tile, it is much more difficult to break the thick floor material. Can an angle grinder cut such ceramic tiles??

The angle grinder is one of the most popular tools that, in addition to its direct task of sanding surfaces, can also perform other functions. With its help, metal, ceramic tiles, stone and other durable materials are cut.

Even thick, durable porcelain stoneware can be cut with the angle grinder thanks to the special attachment

As far as tiles are concerned, working with an angle grinder has its own characteristics. In order to complete the task, you will need a special nozzle and a tile fixer. The tool will do the rest for you.

For additional protection, you should put a cap on the angle grinder, of course, it will reduce the usability of the tool, but will protect you from fragments and the disc itself.

How to cut tiles

Now let’s go directly to the process itself and consider how to work with the tool in order to make an incision without chips and with a minimum amount of dust. In relation to this nuance, three areas can be distinguished:

- Straight cut. This kind of work is the easiest. In order to cut ceramic tiles of an angle grinder along a straight mowing line, first of all, it is necessary to fix it on a flat surface so that the edge remains in weight along the mowing line of the cut. You need to hold the tool so that you can see the cutting direction, that is, the circle will move towards itself. In this case, it is important to observe the safety rules.

- At an angle of 45 degrees. Cutting tiles at an angle is somewhat more difficult. In order to make a bevel cut with an angle grinder, you first need to cut the tile at a right angle. The diamond wheel is then guided in such a way that it can be used to remove excess material at an angle. You can bring the edges to perfection with sandpaper.

- Hole in the tile. This type of work is only suitable for making large diameter holes. In order to cut out its angle grinder, you must first draw the contours of the circle on the front side with a marker. Then, with straight lines, located crosswise at right angles to each other, designate the center point. Then proceed to sawing. The angle grinder must be guided at an angle so that the wheel makes a small indentation around the circumference of the hole on the inside of the mowing line of the basting. Move gradually, cutting the tiles evenly. When you are deep enough, file the straight lines of the mowing line. It is necessary to carefully remove 4 sectors of the circle one by one.

Tile cutting options with an angle grinder

A prerequisite for preventing chipping: you need to work exclusively on the front side of the tile. This way you will damage the top layer less, and the defects on the back side will be hidden by the grout during installation. After making the cut, the edges of the tile are processed with sandpaper stuffed onto a block, so make sure in advance that you can grind off a certain amount of facing material.

Used attachments

Tile cutting with an angle grinder is performed using a diamond grinding wheel. This attachment can be made in several variations. Basically, for this type of work, a fine diamond wheel is used, designed for dry cutting. Of course, there will be a lot of dust, but this way you can make a neat cut.

If you plan to work for a long time, a wet cutting wheel can be used to prevent overheating of the tool. In this case, you will need to additionally equip the water supply. This can be done manually using a spray bottle, or you can simply dip the disc into water.

To protect against possible breakage of the nozzle, before starting work, you need to carefully inspect the tool and securely fasten all its parts. In addition to the protective cap for the angle grinder, use goggles, a mask and gloves to protect against dust and sharp discs.

Diamond wheel for angle grinder can be used in both dry and wet cutting

Features of tile cutting angle grinder: how to cut without chips

When carrying out independent repairs, an angle grinder is often used to cut tiles, as a rule, it is used when working with durable facing material or simply because there is no tile cutter. However, it is not so easy to make a cut with such a tool without chips. In order for the surface of the tile to remain flat, you need to know some of the subtleties of such work. So let’s take a closer look at how to cut tile with an angle grinder.

Cutting tiles with an angle grinder has certain features that must be taken into account so as not to spoil the material

How to turn an angle grinder into a tile cutter

It is not always convenient to keep the angle grinder suspended and do all the work entirely by hand. In order to improve the quality of the cut, you will need an assistant. However, it would be much more rational to turn an ordinary grinder into an analogue of an electric tile cutter.

We have figured out how to properly cut ceramic tiles with an angle grinder. The same principles apply to the tile cutter, but you have both hands free. Let’s consider what needs to be done to improve this tool.

First, choose a suitable location for the machine. The base of the future tile cutter can be made of sheet metal, in which a groove will be cut to deepen the disc. All work will be carried out along this mowing line, besides, it will be much easier to navigate by such a mark.

The most important step is fixing the angle grinder. In order to secure the tool in the desired position, it is necessary to use special clamps. Their analogue can be made independently, but at the same time there is a risk that the fastening bolts will break off during the work.

For frequent use and convenience, the angle grinder can be secured with a tile cutter

This version of a homemade electric tile cutter can be improved by adding a reservoir of water and a wet cutting attachment to it. This will help to avoid dust and cool the instrument.

After fixing the angle grinder, a test cut can be carried out. The principle of operation is as follows: the tiles are laid according to the marks, the angle grinder is turned on and the disc is slowly lowered. The tile will be sawn on the front side, while you need to feed it from yourself.

If done correctly, you will get a ceramic tile cut in two with neat edges, no chips, cracks or notches. The final look of the tile can be given with fine sandpaper.