How To Cut Cable Duct At An Angle

Choosing a cable channel for wiring by cable cross-section and other parameters Tips on how to choose a cable channel for wiring by type of execution and cable cross-section. Filling table for cable ducts. The main mistake when choosing.

Types of cable ducts

First you need to decide on the type of cable channel. We talked about the types of cable channels in detail in a separate article, now we will briefly repeat it again. They are distinguished according to 4 criteria:

- According to the method of installation and location in space.

- According to the material from which it is made.

- By design.

- In appearance.

To choose a cable channel for wiring, you need to take into account all the differences, let’s look at what they are.

They are distinguished by the method of installation:

- Wall mounted. In section, they have a rectangular or square shape, depending on the dimensions and the number of wires to be laid. A separate option is distinguished here. Mini cable channels, they are needed for laying single or just thin wires and cables, such as a television and Internet cable.

- Outdoor. They have a semicircular shape. This shape is needed because it sits on the floor to prevent tripping over it.

- Corner-ceiling. In section, they resemble a right-angled triangle, depending on the model and manufacturer, there may be a different shape. This is your choice if you are doing ceiling wiring. They are installed at the junction of the ceiling and wall.

- Skirting boards with cable duct. They come in completely different shapes and designs. Installed instead of the usual plinth, at the junction of the wall and floor. Perfect for hidden laying of TV and Internet cables, as well as electricity. To choose a plinth for laying cable products, you need to decide on the number and size of the grooves for the wires, otherwise they may simply not fit in and you will have to get out of the situation differently, and this can worsen the appearance of the room.

According to the material from which it is made, it is divided into many types:

- Pvc.

- Metal (galvanized steel or aluminum). Suitable for outdoor use, in rooms with increased fire hazard and harsh environmental conditions.

- Halogen-free (do not contain bromine, fluorine, iodine, chlorine, astatine), are recommended for use in closed, unventilated rooms.

By design, the following cable ducts are distinguished:

- Smooth. Solid smooth body.

- Perforated. Lighter and cheaper than conventional ones.

- Flexible. They can be crimped or composed of links, like a chain. They are chosen for the installation and routing of the cable cutter line in geometrically difficult areas, such as along a semicircular ledge on a wall or column.

- Transparent. Rather not a constructive, but a design solution. Suitable for lighting the ceiling with LED strip. They can be wall, ceiling and in the form of a plinth.

In appearance, cable ducts differ in color, can be made with wood texture, etc. In fact, among all this variety for home and office, plain white PVC cable channels for outdoor wiring are most often chosen.

There are many manufacturers on the market, their products differ in both quality and appearance and design, but the essence remains the same. Manufacturers Legrand and IEK are popular.

Selecting a cable channel for wiring along the cable cross section and other parameters

How to choose the size of the cable channel

Some “experts” advise you to choose the size on the principle of “just fit.” That is, the size of the channel should be such that when it is filled with a group of cables, the main requirement is fulfilled. That its cover is closed. This is fundamentally wrong.

Cables are heated by electric current. Regardless of the current and cable cross-section, heat is always generated, this is described by the Joule-Lenz law, about which, by the way, there is a whole article on the site. This means that the cables must cool down, and before that they must give off heat to the environment. If the cables completely fill the space of the cable channel, they will give off heat to each other, thereby heating up even more.

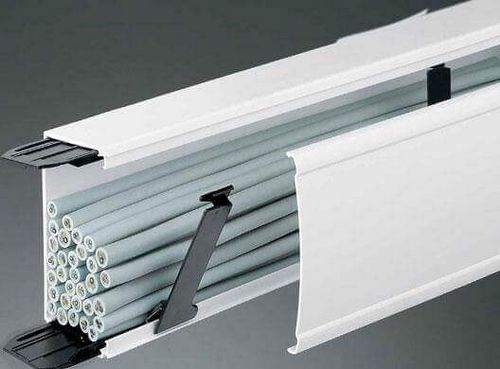

The PUE says that when laying cables in a pipe, it is not recommended to fill it by more than 40%. We believe that the same rule is reasonable to apply when choosing a cable channel for wiring. But you can make the fill factor a little higher. Up to 50-60% percent, otherwise you simply will not be able to make a turn when installing the cable, or the box on it will not close.

That is, the cable channel must be selected for the cross-section of the wire and their number. Therefore, if you are going to lay two cables in one box (for example, 3×2.5 for a socket and 3×1.5 for lighting), based on the size of the cables, the dimensions of the channel cable should be from 25×16. According to this logic, count for a larger number of cables of different cross-sections.

Cable channel filling table, which will help you choose the appropriate size for the cable cross-section (click on the picture to enlarge):

Finally, we recommend looking at useful things on the topic:

Summing up, I would like to note. In order to choose the right cable channel for wiring, first of all, you need to decide on its type according to the method of installation and location in space, then. With the required size, and only then with the appearance and color. Do not forget about the required dimensions of the cable duct, otherwise the wires will warm up, and in case of repairing the wiring, it will be difficult for you to find the right cable if there are too many of them in a small channel volume.

External

For the outer corner. The plinth is applied to the right side of the miter box (or. To the one closest to you, if the template is placed across the desktop), aligned along the plane and the wall, and then cut off or sawed off using the template.

Using a miter box at home

The easiest way to adjust the strips of the skirting board is to cut it with a miter box. It the device is a U-shaped structure (something like a box without one of the walls). In the sidewalls of the miter box, cuts are made in advance, which are later used as a template for cutting both the plinth and other materials.

Cutting skirting boards at an angle using a miter box, see this

The miter box has the following advantages:

- It allows you to precisely trim the edges of the skirting board according to a ready-made template.

- It’s easy to do it yourself, using four planks, a square and a saw. At the same time, you can cut template grooves for every taste, depending on the required type of work.

- It makes it easy to form both inner and outer corners.

The only drawback of this method applies only to those cases when the miter box is made by hand: it is necessary to be extremely careful, in advance to outline the mowing line for patterned cuts using a protractor, without deviating a degree.

Cutting a corner on a ceiling plinth using a miter box has its own characteristics. You may also be interested in reading an article on the topic, plastering walls with your own hands, types of plaster.

DIY installation

Once the corner is properly cut, it must be attached to the wall. This can be done in the following ways:

- Thin carnations. This way works for wooden skirting boards, mounted on wooden walls. You can’t drive a nail into a concrete or brick partition.

Wall mount options

There are several ways to mount the trunking to a ceiling or wall:

- Glue the structure with superglue or a special solution. Not the most reliable option, since under the influence of moisture or other harmful factors, the integrity of the adhesive base may be violated, and the cable channel may come off. And also there is no way to dismantle without harm for repair.

- Screw to the surface with galvanized self-tapping screws. Suitable for wood or plasterboard surfaces.

- For concrete or brick walls, dowel-nails are used.

- Combine the method of gluing and screwing in screws.

If you decide to fix the cable channels without the possibility of subsequent dismantling, then you can use glue. In this case, the operation algorithm will be as follows:

- Glue is applied in a zigzag between the edges of the box with a step of 1.5 cm;

- The processed base is pressed against the wall, but not fixed, but taken to the side;

- When the rest of the glue base on the wall dries up and turns into a thickened mass, install the cable channel in the same place;

- Hold, pressing the box with force against the wall, waiting for the glue to dry.

The cable is laid only after the glue has completely solidified and the structure is securely fixed to the wall.

Installation nuances

The creation of convenient and high-quality wiring in an apartment or a private house ensures reliable and safe connection of all electrical appliances. Before deciding how to fix the cable channel to the wall, and on which screws it is better to plant the boxes, it is worth planning.

General recommendations include:

- Position the switches on the side of the door handle at a height of 90–160 cm from the floor;

- From the ceiling you need a minimum indent of 15 cm, and from the window. 10 cm;

- Horizontal mowing lines should be placed at a distance of at least 30 cm from the floor.

Novice masters of installing cable channels for electrical wiring of any kind should stock up on material 10-15% more than according to the calculations in the drawings.

Method number 3. “Self-tapping screws with a press washer”

If there is a need to fasten the cable channel in metal, less than 2 mm thick or in an aluminum profile, then for fastening we advise you to use self-tapping screws for metal, also called “bugs”. By the way, the correct name for bedbugs is self-tapping screws with a press washer. They do not need to pre-drill a hole. There is nothing difficult in installing an electrical box on a metal surface, the main thing is to choose good self-tapping screws and charge the screwdriver.

There is also a special gun with which you can independently attach the cable channel to concrete. A detailed description of the installation is provided:

Method number 1. Self-tapping screws

If you decide to install electrical wiring in a wooden house or apartment with plasterboard partitions, then the installation of the cable channel must be done with special wood screws. The fastening step depends on what kind of load will occur on the plastic box, or rather, how many wires need to be pulled inside, and what their cross section is. As a rule, in order to securely fix the cable channel on a wooden wall or drywall, it is enough to screw the self-tapping screws every 40-50 cm. If the walls are uneven, it is better to reduce the fastening step, this will hide all defects and gaps.

Do not choose too long self-tapping screws to install the cable channel with your own hands. To securely fix the box in the wall, it will be enough to screw in fasteners about 40 mm long. For screwing it is best to use a screwdriver with a Phillips bit. We talked about how to choose a screwdriver for home repair in the corresponding article!

Method number 4. Liquid nails

Well, the last way to attach a cable channel in an apartment or house is with a special glue “liquid nails”. The need to glue the cable duct to the wall arises if another installation option is not possible. Most often, liquid nails are used when installing an electrical box on a tile in a bathroom or a smooth metal surface. However, it is unlikely that it will be possible to fix the box well with only glue. The glue mixture is more often used as an additional fixation option. It can be combined with self-tapping screws or even quick assembly.

There is a very important nuance of attaching the cable channel to the glue. First you must apply the adhesive mixture to the surface of the box, and then lean it against the wall according to the markings. Once you have leaned the back wall against the wall, remove it and wait a few minutes for the glue to thicken slightly on both surfaces to be glued. After the liquid nails have at least a little “seized”, press the cable duct against the wall as much as possible, the main thing is not to break it. In this simple way, you can attach the cable channel to the glue with your own hands.