How To Cut Ceiling Plinth With Wort

How to cut a corner of a ceiling plinth. simple and correct ways

The aesthetic perception of the entire room directly depends on the beauty of the ceiling decoration. This is especially true of the quality of gluing the baguette: if it is not difficult to do this on straight sections of the walls, then when decorating the corner sections, you will need to know how to cut the ceiling plinths.

Other pruning methods

As a rule, in ordinary rooms, the evenness of walls and ceilings is rarely observed. In case of slight deviations, they can be trimmed during the fitting process. If the deviation of the angle from the standard 90 degrees is large, you need to know how to cut the ceiling plinth without a miter box.

There is only one way out in such a situation. to carry out a procedure on how to cut corners on the baseboards on the ceiling in place:

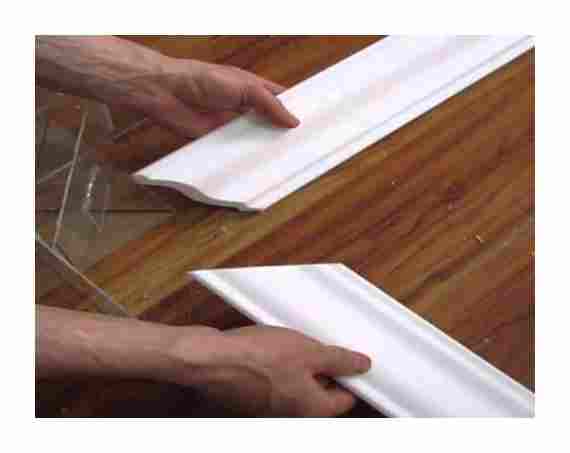

- To carry out the procedure, how to properly cut the plinth to the ceiling, you need to arm yourself with a finely sharpened pencil (with its help you can apply clear marks that are not visible from afar), a fragment of a baguette, a ruler and a good office knife (if a plastic or wooden plinth is mounted, then a saw).

- Attaching a frieze to the corner, make a pencil mark along the outer edge. Do the same with the back of the corner. As a result, the line should form a cross on the ceiling. The intersection point of the marks will be the convergence point for the edges of the ceiling frieze. To transfer the scheme of how to properly cut the ceiling plinth at the corners, a frieze is applied and rests with the end part in the corner.

- Next, using a ruler, you need to connect the edges of the frieze and the markings. A simple operation, how to cut a plinth for a ceiling on a solid surface, will not give a positive result: there will still not be a complete connection along the cut of the corner of two separate moldings. In this case, you have to carry out additional trimming in place. This option is suitable for not very wide friezes (up to 5 cm).

- To trim the corner more accurately, you need to put the plinth on the end. When cutting, the knife should move obliquely at an angle of 45 degrees (so that the edge is sharp). After that, fitting in place, if necessary, will be on a very small scale.

- A similar procedure, how to properly cut the plinth on the ceiling, is carried out in relation to the second plank. It must be attached to the place of future installation, resting its end on the adjoining side of the corner. Next, mark a point with a cross, apply a marking and cut off at the bottom. If adjustment is required, then it is carried out even before spreading with glue.

Similar actions are carried out on the outer corner. It is most convenient to first cut one corner, and adjust the second along it.

Varieties of ceiling plinths

The classification of the baguette is carried out according to the material of manufacture:

- Plaster. The most ancient representatives of ceiling plinths. For their casting, special matrices were used. Various solutions were used as an adhesive assembly. The name “fillets” is also used for plaster moldings. In modern construction, they are used very rarely due to the high cost and inconvenience of installation. In addition, more reliable and inexpensive imitations of plaster fillets have appeared.

- Polystyrene (polyurethane). The most common type of skirting board. Products of this type are characterized by low cost, excellent aesthetic characteristics, ease of installation and a rich assortment in terms of external design. The width of polystyrene moldings varies from 5 to 250 mm. They can be used in any type of room, complementing various interior styles.

- Wooden. Expensive and rather bulky baguettes, with the help of which wooden houses with the corresponding interior are mainly made out. To install wooden planks, in addition to glue, screws and nails are often used.

- Plastic. An excellent option for bathrooms and other rooms with high humidity. Installation is carried out on special moisture-resistant glue or secret self-tapping screws.

When installing the above products, you need to know how to cut the ceiling plinth. This does not apply to plastic products that come with special angled adapters.

Ways to get a beautiful angle

The most difficult area when decorating the ceiling surface with a frieze is the corner areas. If you just cut the skirting board at the right angle, ugly gaps will remain. To achieve a snug fit between two adjacent products, you must also trim their edges. There are several ways to do this.

Using decorative corners

This refers to special corner adapters, which are usually completed with polyurethane and polystyrene friezes. Decorative corners are glued to the very corner, and the baguettes are adjacent to them on both sides. Adjustment in this case is either not required at all, or is carried out with a simple clerical knife.

What tool is needed

When installing the ceiling plinth, it must be cut to size or in the corners.

The following tools will usually help you to cut the corner of the skirting board:

- Hacksaw for wood. It is used to work with wooden products.

- Hacksaw for metal. This tool is convenient for cutting plastic, foam and polymer friezes. As a result, it is possible to obtain a fairly clean joint without burrs. When working with saws, it is convenient to use a miter box.

- Stationery knife. It can be used to cut styrofoam baguettes without using special tools. The main thing is that the knife is well sharpened and has a thin and even blade. If you act carefully, the cut is smooth, without any dents.

When using the saw, it is important not to use excessive force, otherwise the skirting board will be crumpled. It is best to practice on some unnecessary piece first. This will allow you to get beautiful fragments in the future.

How to cut a corner with a miter box

In rooms with even corners and walls, cutting the ceiling plinth using a miter box is usually not very difficult. The tool has the form of a U-shaped groove with made guides for the saw at an angle of 90 and 45 degrees. Having placed the element requiring cutting inside the device, insert the saw into the guides. During the cutting process, the baguette must be firmly held in place to avoid defects. Cutting off the plinth is quite difficult, since it is necessary to achieve its simultaneous adherence to two planes. If the width of the baguette is small, then it is more convenient to press it to the near side. “How to cut ceiling plinths. cutting tools and rules”.

How to cut off the corner of a ceiling plinth if you are making an outer corner:

- Before cutting the corners of the ceiling plinth with a miter box, it is washed down at an angle of 45 degrees.

- The miter box is exposed in a comfortable position. This will make it possible to determine the exact location of the skirting board: first of all, this concerns the edge of the product that will be adjacent to the ceiling. To avoid confusion, it is best to place the right-side plank on the right and the left-side plank on the left.

- The surface is pressed against the lower surface of the miter box. In this case, the second part rises, turning out to be the closest. It must be applied to the wall of the miter box in such a way that during operation it will not wobble. With this arrangement, the front side of the product turns out to be turned in the opposite direction.

- Cutting must be done at an angle of 45 degrees from yourself. If done correctly, the two halves are folded together to create a beautiful outer corner.

After the correct sawing of the ceiling plinth in the corners is completed, both pieces must first be applied to the ceiling “dry” in order to check the coincidence of the corner geometry. If necessary, trimming is carried out with a knife. It is easier to cover small gaps with a putty, which, after drying, must be treated with sanding paper. As for the inner corner, it is much easier to arrange it.

The procedure for how to cut the ceiling plinth in the corners of the interior type is very similar to the one described above. The first step is to determine the side that will be adjacent to the ceiling. It is placed at the bottom of the miter box. The reverse side leans against the near wall. After sawing off the plinth on the ceiling, the resulting fragments must be applied dry to the corner, checking the quality of the joint. Fitting is carried out if necessary. After that, one and the second skirting boards are installed on the assembly structure. Small gaps in the corner can be filled with a special putty.

Cutting without tools

How to cut a corner of a skirting board without a miter box? It is possible to perform the calculation and cut manually.

By attaching the product to the place where it will be mounted, you can immediately take into account all the errors on the walls.

How to cut ceiling plinths in corners with and without a miter box?

The procedure for installing fillets on ceilings seems to be quite easy, but it requires specific techniques to successfully complete the repair. Often we cut the corners of the ceiling plinth completely incorrectly, which leads to a reduction in its service life and poor quality of repair work. Correct joining, evenly fixed edges is a completely achievable result, if you use the recommendations of experienced specialists.

Angle slicing

How to cut ceiling skirting boards in the corners? The secret of a high-quality incision is in making cuts both on the outside and on the inside. The inner cut matters if we make the outer corner.

Usually they use professional equipment. miter saws or industrial electric rotary hammers. But home renovation advocates can get by with conventional tools. The main requirement is that at the end of the work, the result should be a clearly visible texture for the cornice, reflected on its front or back side.

Installation of finishes: features

Many owners of houses and apartments, in the midst of renovation work, are often puzzled by the question of how to properly cut the ceiling plinth in the corners. The problem is that it is not technically possible to make an incision at a 45 degree angle. To perform such manipulations, it is important to correctly dock at the boundaries of the outer and inner corners of the web, which is quite problematic.

Specificity of the ceiling option. not only in the vertical position of the web.

For the most accurate cutting, a special corner element is used, which is inserted into the edge of the skirting board. it will help to hide cutting errors. This element will emphasize the corners in the room; the choice of such a detail must be approached responsibly.

Corner slicing technology

So, at what angle to cut the ceiling plinth and where does the formation of an angle begin with the help of home remedies??

First you need to measure the angle that is between the walls. for this you can take pieces of foam from the technique. Usually the angle is 90 degrees. a strict perpendicular. In this case, you need to trim the edges of the product at an angle of 45 degrees.

In the event of irregularities and mismatched joints in the gap between the ceiling and walls, you need to divide the corner radius in half. In this case, do not confuse the details. The baguette for the left side is notched on the right, and the one on the right is the other way around.

Before cutting the ceiling plinths in the corners, form a corner inside the material in the upper space. this decision is based on the fact that the lower side protrudes above the upper one. When performing an outer corner, the procedure is reversed. The texture of expanded polystyrene materials helps to smoothly and accurately adjust the details. If wooden or plastic elements are used for the baguette, then you will have to work with them more carefully.

Varieties of finishing products

This material is intended for decorative finishing of the ceiling area, visually separating it from the walls and covering the joints of various finishing elements. Almost any option for decoration, interior design involves the use of such details. Otherwise, the room will look unfinished.

Fillets are used to fix this part, which are attached to the ceiling with glue.

The choice of mounting option depends on the type of product:

- PVC. the cheapest, but also the most brittle, prone to defects, but easy to use, it can be cut with a knife.

- Expanded polystyrene is also inexpensive, brittle, requiring a hacksaw for metal, although it is easily cut. Another option is slightly more expensive. from extruded polystyrene foam, it is more difficult to cut it, but it crumbles less.

- Polyurethane is the most expensive and moisture resistant, durable and elastic. It is more difficult to work with it, it deforms at high temperatures.

- Wooden. dense and heavy material, cut only with a hacksaw.

Cutting method with miter box

The most popular mounting option is using household tools. The miter box is a renowned carpenter’s assistant to help you cut at the right angle. Usually it is a tray, wood or plastic, with vertical slots for the blade at angles of 45 and 90 degrees. How to cut the corners of a ceiling plinth with a miter box?

First, you should attach the material to the ceiling, install its bar in the miter box.

Holding the working material with the right hand, select the position of the hacksaw at 45 degrees and cut.

Recommendations of the masters

Experienced carpenters, joiners and builders know best how to cut ceiling plinths in corners. Most advise you to make cuts on the side and try on the strips to the ceiling, if necessary. cut in the direction of the part adjoining the surface.

Having made a rough docking, the finally finished fillets are screwed to the wall. The seams are sealed. the installation of the skirting board is complete.

How to make an inner corner of a ceiling plinth

Most often in the home they deal with the inner corners. Cutting is pretty easy.

- To begin with, the material is placed at the junction of the wall and ceiling in the position in which they are going to be fixed in the future. Mark the desired length on the product.

- The ceiling plinth is placed in the miter box in the same position, that is, that part of the fillet, which is mounted on the ceiling, should be facing upwards, and facing the wall should be adjacent to the wall of the device. The edges of the products are aligned with the extreme angle mark of 45 degrees.

- The blade is turned at an angle of 45 degrees and the excess fragment is removed. The knife should be sharp, and ideally it should be cut in one motion. The second part is prepared in the same way, but on the other side.

Cutting skirting boards for ceilings without miter box

You also need to figure out how to glue a ceiling plinth without a miter box. this tool is far from always available. One of these methods involves marking the skirting boards on the ceiling. Perhaps the only drawback of this method is the fact that it is not very convenient to keep the bar motionless while applying the markings. Otherwise, the method is quite reliable. the measurement accuracy is higher, since when the plinth is applied to the place, all errors become noticeable.

Another method is associated with corner trimming of the baseboard. The edges of the two joining workpieces are cut at right angles. One of the planks is applied directly to the corner, after which a fishing line is applied to the ceiling along the contour of the plinth. The same operation is repeated with the opposite skirting board.

The point at which the two separate mowing lines intersect is the mark at which the skirting board will need to be cut. The workpieces are again applied to their places in turn, the cut mowing line is marked on them. A straight line is drawn from the mark to the opposite edge of the part. The skirting boards are cut in accordance with the markings applied to them and are joined in place. This method is an excellent answer to the question of how to connect the corners of the ceiling plinth without a miter box, especially when it comes to internal corners.

Pruning with a miter box

To give the plinth the required angle, a special tool is used. a miter box. Structurally, this tool is a tray made of wood, metal or plastic. In certain areas of the miter box, there are vertical slots that allow you to cut various parts at an angle of 45 or 90 degrees.

complex devices can be found on the market, in which, in addition to the angles already described, there is the possibility of a 60-degree cut. There is also a professional miter box equipped with a swivel mechanism. This tool differs from the simplified one in that it has the ability to fix the cutting blade at any angle. You need to know how to properly glue the ceiling plinth in the corners so that everything looks beautiful.

Decorative corners for ceiling plinths

Cropping wide varieties is much more inconvenient. The product is difficult to fit into such a compact tool as a miter box, and complex relief can be ruined.

For such models, special corners are produced. You can find this option only for PVC, foam or polyurethane products. The elements have the same design, their dimensions are easy to adjust, since a material as light as foam is easy to cut.

The technology is very simple: the corner is fixed in the joint, and fragments of the ceiling plinth are attached to it.

How to cut a ceiling plinth in the corners without a miter box the first time

How to cut the corners of a ceiling plinth. Photo 1

Probably everyone who at least once carried out repair work with their own hands faced the problem of cutting out the outer and inner corners of the ceiling plinth. Ceiling skirting board, also called fillet, is used in repairs in order to hide the uneven border between the wall and the ceiling and to give the interior completeness. How to cut a corner of a skirting board without a miter box? We will talk about this in our article.

How to cut a ceiling plinth in the corners without a miter box? If you don’t have a miter box on hand, it doesn’t matter. You can cut the outer and inner corner without a miter box.

Fillets on the market today are available in different sizes, shapes and colors, with or without relief patterns. The material from which they are made is also different. These are mainly: polyurethane, expanded polystyrene, polystyrene and polyvinyl chloride. But recently, the most popular in the repair work has become a wooden ceiling plinth. Its aesthetic appearance allows you to add elegance and rigor to the design of the room.

Recommendations for the home master

- Experienced builders recommend cutting the planks from the side and trying them on immediately on the ceiling. If irregularities are found, you can cut the baguette in the direction of the product adjoining the ceiling;

- After preliminary fitting, the finished cornices are attached to the wall and to the ceiling. Seams and corner joints are sealed with silicone sealant;

- Before cutting wide skirting boards, make a few test cuts on short skirting boards to help you avoid making mistakes when finishing cutting;

- At home, a table pushed against the wall can serve as an accurate miter box:

- To mark the inner corner, the length of the bar is counted from the corner;

- To mark the outer corner, the baguette should protrude beyond the corner of the room by its own width;

- The skirting board should be cut on a flat, hard surface, unmarked surface downwards;

- Ceiling products are glued or screwed after cutting both strips;

- Small errors when joining wooden, aluminum or PVC baguettes are removed with a file. The curvature of the foam fillets is leveled with a sharp knife or cutter;

- If a small gap still remains, it is masked with Knauf, ABC finishing putty, or white silicone sealant.

How to make a miter box template yourself

In the absence of a miter box or unwillingness to buy it, it is not necessary to purchase a special tool in order to use it once or twice in the entire history of repairs. You can make a homemade template with the same capabilities. it doesn’t take much time. As a blank for an impromptu miter box, take a board, thick paper or cardboard, and mark the required cuts on them.

Then draw two parallel mowing lines on the template, locate the center on the drawing, and use a school protractor to set any corners. This simple technology gives very accurate results, while you can draw and cut any angle greater or less than 90 0.

The technology for working with a homemade miter box is no different from operations with an industrial product. The baguette should be attached to one of the lines, put the hacksaw at the selected angle, and cut off the workpiece. If you do not plan to spend money on miter box pr

Outside corner cutting

In the case of external corners, the cutting technology will look like this:

- For greater accuracy, it will be better to start with the inner corners, and only then proceed to the outer ones. If this is not done, then the length of the plinth in the end may simply not be enough.

- The part is attached to the ceiling, and marks are made on it in the right places. Then the plinth is placed in the miter box, held with the left hand near the near wall and cut off at the desired angle using a hacksaw.

- The opposite bar is laid near the near wall of the miter box, but is held by the right hand. The hacksaw is at a 45-degree angle and the workpiece can be cut off. Finished planks need to be docked with each other to make sure that the cut is correct.

Cutting skirting boards with a miter box is only suitable if the walls and ceiling are at right angles to each other. If there are any irregularities, it would be better to use another method.

How to dock the ceiling plinth in the corners: step by step instructions

How to fit the ceiling plinth in the corners is one of the main questions that are asked when repairing ceilings. When installing skirting boards, difficulties arise when it is necessary to adjust the joints of individual elements. And, if on straight sections it comes out to glue the fillet the first time, then you have to tinker with the corners. Therefore, a reasonable question arises, how to dock the ceiling plinths in the corners so that the connections turn out invisible.

Correctly joined inner corner

How to join ceiling skirting boards in straight sections

After the corners are finished, the easiest part of the job remains. gluing friezes on flat areas. If the edges of the planks are uneven, trim the baguette at right angles on both sides.

When the plinth is ready, coat the segment with glue on the back side, attach it to the end corner strip, press down. Glue the next part from a different corner.

At the end, a piece of plinth is installed in the middle. There will be no questions with this part of the work. To get a perfect fit, sand the cut sides of the frieze with sandpaper or a file. When you attach the fillet to the wall, press it with the edge of your palm, then the shape of the baguette will not suffer. Remove excess adhesive with a cloth.

When the skirting board is glued on, inspect the result again. The resulting cracks at the joints are putty or sealed with a sealant.

You can leave the baguettes as they are, or paint to match the rest of the finish. Painting is carried out both before attaching the skirting boards to the wall, and after installing them.

How to properly join ceiling skirting boards: getting ready for work

For work you will need:

- plinth;

- glue;

- stationery knife;

- a hacksaw for metal with small teeth;

- ruler;

- roulette;

- pencil;

- miter box;

- sealant;

- dry clean cloth.

How to make a miter box with your own hands

As for the miter box, in the absence of one, it is easy to make the instrument yourself. Take three sanded boards and connect with self-tapping screws in the shape of the letter “P”. Now make the cuts so that the skirting board is easy to cut at the desired angle. Usually, the middle line is cut at an angle of 90 °, and the outer ones. 45 °. The cut should reach the point where the side walls of the miter box are attached to the lower base. The side walls are made of both wood and aluminum. Metal tools will last longer.

Before starting work, the ceiling surface and walls at the place where the skirting boards are attached must be prepared. They are cleaned of dust, old finishes, leveled with putty and primed. Any water-based paint that improves the adhesion properties of the glue is used as a primer.

On a note! Fillets are best fixed to the wall surface, not wallpaper. So the skirting boards will hold more securely.

Choose glue on an acrylic or silicone base. Alternatively, you can use putty, then, in addition to gluing the frieze, it will be possible to eliminate irregularities on the wall surface. Glue is used to fix the baguette to the wallpaper, the putty to the walls.

No Tape Measure Needed! Drywall Trick- Easiest way for cutting electrical ceiling boxes wall outlets

Ceiling plinth adhesive

“Liquid nails” cannot be used for plastic fillets, since they contain solvents that deform the plinth.

If you want, you can make your own glue. To do this, mix the putty and PVA glue in a 1: 1 ratio, let the substance sit for 5-10 minutes. The solution must be worked out in 2 hours, as it hardens quickly. Styrofoam, gypsum and wooden fillets are fixed on such glue.

To make it easier to work, beat off the control line with a paint cord under the ceiling.

With strong irregularities and distortions of the walls, the plinth will only highlight imperfections. However, this rule also works in the opposite direction. Even with uneven corners, the situation can be remedied with a properly glued ceiling frieze. The main thing is to follow the sequence when working. Attach the first element from the corner closest to the entrance to the room. During installation, try to form as few joints as possible.

How to join the corners of ceiling plinths: external and non-standard

Despite the fact that outer corners are less common in rooms, knowing how to join ceiling plinths in them will not hurt. To cut the fillet, proceed as follows:

- press the friezes crosswise against the wall. This will tell you where to start and end the cut;

- outline the line along which you will cut the frieze;

- cut the baguettes along this mowing line, check the docking by aligning the skirting boards in the corner;

- the cut should have straight edges. If defects are obtained, trim the cutting line with a knife or file with a file.

Sometimes even craftsmen have to face difficulties when fitting skirting boards. For example, if the room has non-standard corners. In this case, the skirting boards are cut into small pieces (5-10 cm), which are alternately docked with each other and glued to the wall. In order not to get confused in the sequence, the order of each element is outlined with a simple pencil on the reverse side. After the parts are glued, remove excess glue or putty, continue to work further.

Preparation of skirting boards for work is carried out before applying the markings.

How to join ceiling skirting boards and what you need to know about fillets

Skirting board is a decorative element used in the interior to indicate a smooth transition between the ceiling and walls. If a stretch ceiling is installed in the room, the fillet will hide the gaps formed during the work. Often the evenness of walls and corners leaves much to be desired, therefore, ceiling baguettes are also used to mask such defects.

Another task that designers assign to skirting boards is to act as a kind of niche for mounting decorative lighting. This idea has been used in interior decoration for several years. The light from the tape located on the inside of the skirting board gives a soft diffused glow, filling the room with a cozy and comfortable atmosphere, creating the effect of a decorative ceiling floating (floating stretch ceilings).

Ceiling lighting around the perimeter

Polyurethane or polystyrene is used as a material for the production of fillets. A special extrusion method makes it possible to obtain light and flexible friezes, with the help of which it will be possible to bypass uneven walls. Baguettes are also made from plaster or wood. In this case, the surface of the decorative element is completely smooth, with patterns or deep relief. The most common type is white friezes, which can be painted to match the color of the interior.

The figure shows fillets with relief

The decorative plinth is combined with plastic panels, foam tiles, textured wallpaper. The ceiling gets an interesting look when products are combined with stucco elements.

Bonding fillets. the finishing stage of the ceiling decoration. Baguettes are produced with a standard length of 2 m. Therefore, during the work, you will have to adjust the parts for joining in straight sections and in the corners of the room. Corner docking is the most difficult stage.

Ready-made corners for gluing skirting boards

How to dock the ceiling plinth in the corners: important nuances

Docking fillets in the corners is carried out in one of two ways:

- in the inner corners;

- in the outer corners.

As for the internal corners, they are in any room, their value is 90 °, external (270 °) are less common.

Features of trimming moldings in the corners are identical:

- when working with a miter box, the side of the frieze that is pressed against the wall of the tool when cutting the corners with the side part will be attached to the wall surface, to the base of the miter box. mounted to the ceiling;

- for internal corners, the lower side of the skirting board protrudes above the upper, for external corners. vice versa;

- measure the corners in the room with a protractor. If the value is 90 °, then cut the edges of the baguette at 45 ° angles. For non-standard angles, halve the measured value. Then the frieze located on the left side of the corner will have a right cut, on the right side. a left.

To cut the skirting board, fix the molding in the miter box to prevent slipping. After making the cut, join the two pieces together to check the result. Flaws are removed with a clerical knife or file.

If it did not work out perfectly to fit the fillets

It may well be that the first time not everything will go as smoothly as you would like. In this case, it is better that a gap remains between the adjacent elements of the baseboards, which can be masked with silicone sealant. To do this, carefully fill the gap with the compound, smooth out the sealant with your fingers, remove the excess mass with a wet cloth.

If the cut turned out to be less than necessary, and when trying to dock the plinths one of them “goes” to the side, take a clerical knife and cut the cut, or sand with fine-grained sandpaper.

Wooden

Models made of wood are the most common type of tool due to their good performance and the possibility of self-production. Wooden products have a classic structure and are represented by a structure of three boards, one of which acts as a base. The two side boards are equipped with paired grooves to cut different corners. Despite the low cost and ease of manufacture, wooden models have a big drawback: when working with a hacksaw for metal or with a saw, the grooves are gradually sawed, due to which, with regular use of the device, its service life is significantly reduced. However, for performing one-time work, for example, when carrying out repairs in an apartment, wooden models are quite suitable.

If you plan to use the wooden miter box more often, you can purchase a special saw that cuts only the plinth. This will protect the wood from sawing and significantly extend the life of the tool.

For self-production of a wooden miter box, they take a piece of board 10 cm wide and 50 cm long and use a protractor to measure angles of 45, 90, and if necessary, 60 degrees. Then the sidewalls are screwed on and the markings of the corners are transferred to them from the base. Next, the transferred marks are checked with a protractor. if everything is in order, then they begin to form the grooves. The cut is made until the hacksaw starts touching the upper surface of the base of the tray. The grooves should be formed in such a way that a hacksaw or saw can easily enter them, however, they should not be made too wide either. After the tool is ready, a trial sawing of the plinth is carried out at different angles, after which the blanks are removed and the angles are measured using a protractor.

How to cut an arbitrary corner?

Arbitrary corners are cut using a rotary or electric model. To do this, the plinth is placed on the work surface, fixed and laser markings are applied using the built-in protractor. Next, sawing is performed, after which the parts are combined as a control. Cutting corners with such tools is distinguished by the ideal shape of the sawing points and high measurement accuracy.

How to saw off the inner and outer corners?

When forming internal and external corners, there are some rules, having familiarized yourself with which, there will be no difficulties in cutting the plinth. The inner corner is formed as follows:

- The miter box is placed on a table or workbench with the side facing you;

- the plinth is placed, according to its left or right accessory, and close to the opposite wall of the tool;

- the left element should be placed in the miter box on the left side, and the corner should be sawed off on the right and vice versa: start the right parts on the right, and cut off the corner on the left;

- washed down without allowances, strictly along the outlined mowing line;

- after the left and right corners are sawn off, both blanks are combined and checked for tightness of the parts between themselves.

The outer corner is formed in a slightly different way, namely: the plinth is pressed not to the opposite, but to its side, after which the left part is installed not on the left, as it was in the previous case, but on the right, and the corner is sawn off. They do the same with the right fragment: set it to the left and cut off the corner. When working with a miter box, remember that in both cases the skirting boards are cut from the front side.

If, after cutting, there is a loose fit of the elements forming the corner, then with small flaws, the surface can be cleaned up with sandpaper, in case of obvious deviations, the work will have to be redone.

Tool features

The miter box is a specialized device designed for sawing floor and ceiling skirting boards at different angles. The device is made in the form of a box with missing end walls and without a cover. In the side surfaces, several pairs of slots are formed, which have a through design and are located at certain angles relative to the central axis of the base. The width of the slots allows you to freely place a hacksaw or a saw in them, provided there is a small set of teeth.

Some models of tools are equipped with a universal hacksaw equipped with a raised handle. This contributes to a special cutting accuracy and makes it easy to keep the hacksaw blade in a horizontal position.

If the miter box is not equipped with a cutting tool, then when choosing it, it is necessary to take into account the material for making the baseboards. So, when cutting plastic skirting boards and products from MDF, it is better to purchase a hacksaw for metal, for a wooden product. choose a saw for wood with frequent teeth, and for sawing foam or polyurethane baguettes. use a stationery knife.

During operation, the miter box is fixed on a workbench or table and securely fixed with a clamp. This does not allow the tool to move under the influence of the saw and makes working with it comfortable and completely safe. The process of trimming skirting boards with a miter box is quite simple and looks like this:

- a plinth is laid on the bottom of the tray and fixed in the desired position;

- then a hacksaw blade is inserted into the guide grooves that determine the desired angle and are located on opposite walls of the tray and the plinth is cut.

To prevent creases and chipping of the baguette, it is recommended to make a trial cut, during which it is necessary to determine the force of pressure and the intensity of movement of the cutting blade. This is especially true for ceiling plinths made of foam and polyurethane, which, if incorrectly cut, begin to crumble and crumple.

Joinery mills are classified according to three criteria: size, material of manufacture and type of construction. According to the first criterion, there are standard products designed for processing narrow and medium moldings, and large models that allow cutting high floor and wide ceiling plinths. The width of the slots in the overall products is no different from that of medium and small samples, however, the side walls of the tray and the width of its base are much larger.

According to the material of manufacture, joinery mills are divided into wooden, plastic and metal.

Features and tips for using skirting boards

- Tool features

- Views

- How to use?

- Subtleties of choice

The skirting miter box is a popular joinery tool that effectively solves the problem of cutting skirting boards. The high demand for the tool is due to its ease of use, low cost and wide consumer availability.

Made of metal

Metal miter boxes belong to the category of professional tools and are distinguished by a very long service life and high cutting accuracy. Alloy steel or aluminum is used as the material of manufacture for such models. Aluminum products weigh a little less than steel ones, so they are used by craftsmen much more often. No significant deficiencies were found in the metal tool. The only thing that can be attributed to the minuses is their price, which, however, is quickly justified by durability, cutting accuracy and ease of use of the tool.

The third criterion for classifying tools is the type of construction. On this basis, simple, rotary and electrical models are distinguished. The first are the classic version of the instrument and were discussed above. The design feature of the rotary model is the absence of one of the side walls, instead of which there is a rotary flap with a cutting blade installed on it. The base of the tool is equipped with a special holding device that reliably fixes the plinth when cutting. The use of such a tool makes it possible to form angles from 15 to 135 degrees and allows you to cut skirting boards for non-standard rooms, which cannot be done with a classic device.

The electric model, more commonly known as a miter saw, consists of a saw and a miter saw. The required angle is marked with a laser beam, which allows you to cut the skirting board very accurately. The device has a high productivity and is able to cut a large number of workpieces in a short time. The power tool is classified as a professional one, which, of course, affects its price and classifies it as an expensive device.

Made of plastic

Plastic miter boxes made on the basis of polyvinyl chloride are a good alternative to wooden models. The advantages of such products include their low cost and low weight. The tool is presented in a huge range of standard sizes, which allows you to purchase a model for almost any baseboard. There is only one drawback with plastic devices. it is the rapid expansion of the working grooves, which subsequently leads to large deviations from the required angle value and makes the tool unsuitable for further use. However, as in the case of wooden models, plastic miter boxes are perfect for one-time use.