How To Cut Ceramic Tiles Correctly

How to cut with a manual tile cutter?

This tool is only used for making light straight cuts. With it, you can cut the tiles either evenly or diagonally. In this case, the direction does not matter. This equipment is very easy to use. At the same time, before cutting a tile with a tile cutter, it is necessary to have a general idea of its structure. The tool is a base where special tubular runners are fixed. A carriage with a hard alloy roller slides over them. After marking, the tile is laid on this base in the required way.

Here are the basic guidelines for using this tool:

- It is necessary to apply a roller to the tile and make a neat cut using a special handle. In this case, only one cut is needed. Don’t cut through the same spot two or three times. The result will be disastrous. the material will break completely in the wrong way. It is also because of this that you need to carefully monitor the sharpness of the cutting device. On specialized professional models, it is removable, so if necessary, a dull roller can be easily changed.

- It is worth noting that in order to obtain high-quality tiles when working with such a tool, you also need to be able to correctly break the material. On the basis of the equipment, in the course of the cut, a small tubercle is provided, which lifts the edge of the ceramic product clearly above the cut and then releases its ends. It is thanks to this that the tubercle, together with the slot on the tile, acts as a guide for breaking. In addition, the product also breaks with the help of a movable T-shaped heel, which is located in front of the roller. This heel must be set exactly in the middle of the cut so that when the lever is pressed, it presses on the blade. Also, this tile cutter can cut diagonally.

How to cut tiles with an electric tile cutter?

If you plan to work with very hard and large-format tiles, then it is best to use professional equipment. an electric tile cutter. To work with such equipment, certain professional skills and abilities are required. In particular, since the cutting process is rather complicated and time consuming. However, nevertheless, if you are interested in how to cut ceramic tiles as quickly and accurately as possible, even with very large volumes, then an electric tool is the best choice. Such equipment is quite expensive, but it pays off with repeated use and can serve for several decades. The design of the electric tile cutter is almost identical to the modern circular saw. The main differences are the discs used and the presence of water trays.

Another feature of these machines is the ability to perform a neat bevel cut. This is very useful when covering outside corners. In this case, the need for aluminum or plastic corners completely disappears. The product, which is docked in a corner with a 45-degree cut, looks very interesting.

We present to your attention a short instruction manual:

- Pour water into the bath so that it overlaps the disc by 2-3 centimeters;

- We measure out the part of the tile that needs to be cut off and put it on the machine;

- Then we press our canvas to the machine and slowly bring it to the disk. It is not recommended to apply strong pressure on the disc, as it may stop;

- Now you need to make a cut along the second line. To do this, carefully lift the tile and do a similar procedure.

Working with a glass cutter

The simplest, cheapest and easiest tool for processing ceramic products is a glass cutter. It can be of two types: with a small diameter roller and with a diamond tip. There are practically no special differences in work between them, however, the first tool is more convenient to use. In addition, cutting tiles with a glass cutter is no different from cutting glass.

Let’s consider a step-by-step instruction for working with this tool:

- Firstly, before cutting the tile with a glass cutter, you need to accurately mark the cut line with an erased marker or pencil on its glossy side. For this, it is also advisable to use corners or metal rulers. With a ruler on the mowing line, you need to run the glass cutter only once from the far edge of the ceramic to you. over, trying to distribute the force as evenly as possible when pressing the tool. Thus, you will get an absolutely even line. a depression that weakening the strength of the canvas.

- Secondly, you need to position the tiles on the table so that the line of the notch on the product and the edge of the table completely coincide. Further, gently holding part of the tile on the table, you need to press on its other edge: the product will break gently and precisely. The edges after all work can be sanded.

How to cut ceramic tiles correctly: 4 ways

Ceramic tiles are a very durable and attractive facing material in all respects. However, the tiling process is not as easy as it sounds and requires patience and preparation. In order to successfully install this material on the floor, on the wall, around the edges of the room, around electrical appliances, window frames, pipes or various protrusions, it is necessary to use specialized equipment. However, before starting directly to work, you will definitely need to decide how and how to cut ceramic tiles.

Ceramic cutting tool

The quality of the cladding will depend on how the ceramic material is processed. If you are interested in how you can cut ceramic tiles, then, first of all, pay attention to the following tools:

- Manual tile cutter;

- Glass cutter;

- Electric tile cutter;

- Angle Grinder.

Using this equipment, you can perform both standard cutting operations and rather complex procedures. For example, cutting rectangular and circular holes, trimming edges. Each of these tools is used for a specific amount of work. In addition, it has its own functional features that must be taken into account when starting the process of processing ceramics.

We cut ceramics angle grinder

The angle grinder gives very great opportunities for cutting. it can easily and accurately not only cut along even lines, but also make curly cuts. If desired, using an angle grinder, you can cut a beautiful round hole with a diameter of 70 mm in the tile. In order for practically no chips to remain on the glossy surface, it is necessary to use only a new diamond wheel and cut from the back of the product. Therefore, before you cut the tile with an angle grinder, you need to make sure the quality of the wheel and its functionality. We do the markings, draw the disc along the markings and break off the long part. Break off the rest. Corners can be smoothed with pliers or the same angle grinder.

An angle grinder equipped with a diamond disc is essentially a universal tile cutter. In order to increase the efficiency of the tool, the equipment can be equipped with a special cooling system. Of course, this increases the cost of the tool, but at the same time increases its productivity. It is thanks to its efficiency that the angle grinder has become quite widespread today.

How to cut with a manual tile cutter?

This tool is only used for making light straight cuts. With it, you can cut the tiles either evenly or diagonally. In this case, the direction does not matter. This equipment is very easy to use. At the same time, before cutting a tile with a tile cutter, it is necessary to have a general idea of its structure. The tool is a base where special tubular runners are fixed. A carriage with a hard alloy roller slides over them. After marking, the tile is laid on this base in the required way.

Here are the basic guidelines for using this tool:

- It is necessary to apply a roller to the tile and make a neat cut using a special handle. In this case, only one cut is needed. Don’t cut the same spot two or three times. The result will be disastrous. the material will break completely in the wrong way. It is also because of this that you need to carefully monitor the sharpness of the cutting device. On specialized professional models, it is removable, so if necessary, a dull roller can be easily changed.

- It should be noted that in order to obtain high-quality tiles when working with such a tool, you also need to be able to correctly break the material. On the basis of the equipment, in the course of the cut, a small tubercle is provided, which lifts the edge of the ceramic product clearly above the cut and then releases its ends. It is thanks to this that the tubercle, together with the slot on the tile, acts as a guide for breaking. In addition, the product also breaks with the help of a movable T-shaped heel, which is located in front of the roller. This heel must be set exactly in the middle of the cut so that when the lever is pressed, it presses on the blade. Also, this tile cutter can cut diagonally.

How to cut tiles with an electric tile cutter?

If you plan to work with very hard and large-format tiles, then it is best to use professional equipment. an electric tile cutter. To work with such equipment, certain professional skills and abilities are required. In particular, since the cutting process is quite complicated and time consuming. However, nevertheless, if you are interested in how to cut ceramic tiles as quickly and accurately as possible, even with very large volumes, then an electric tool is the best choice. Such equipment is quite expensive, but it pays off with repeated use and can serve for several decades. The design of the electric tile cutter is almost identical to the modern circular saw. The main differences are the discs used and the availability of water trays.

Another feature of these machines is the ability to perform a neat bevel cut. This is very useful when covering outside corners. In this case, the need for aluminum or plastic corners completely disappears. The product, which is docked in a corner with a 45-degree cut, looks very interesting.

We present to your attention a short instruction manual:

- Pour water into the bath so that it overlaps the disc by 2-3 centimeters;

- We measure out the part of the tile that needs to be cut off and put it on the machine;

- Then we press our canvas to the machine and slowly bring it to the disk. It is not recommended to apply strong pressure on the disc, as it may stop;

- Now you need to make a cut along the second line. To do this, carefully lift the tile and do a similar procedure.

Ceramic cutting tool

The quality of the cladding will depend on how the ceramic material is processed. If you are interested in how you can cut ceramic tiles, then, first of all, pay attention to the following tools:

- Manual tile cutter;

- Glass cutter;

- Electric tile cutter;

- Angle Grinder.

Using this equipment, you can perform both standard cutting operations and rather complex procedures. For example, cutting rectangular and circular holes, trimming edges. Each of these tools is used for a specific amount of work. In addition, it has its own functional features that must be taken into account when starting the process of processing ceramics.

Working with a glass cutter

The simplest, cheapest and easiest tool for processing ceramic products is a glass cutter. It can be of two types: with a small diameter roller and with a diamond tip. There are practically no special differences in work between them, however, the first tool is more convenient to use. In addition, cutting tiles with a glass cutter is no different from cutting glass.

Let’s consider a step-by-step instruction for working with this tool:

- Firstly, before cutting the tile with a glass cutter, you need to accurately mark the cut line with an erased marker or pencil on its glossy side. For this, it is also advisable to use corners or metal rulers. With a ruler on the mowing line, you need to run the glass cutter only once from the far edge of the ceramic to you. over, trying to distribute the force as evenly as possible when pressing the tool. Thus, you will get an absolutely even line. a depression that weakening the strength of the canvas.

- Secondly, you need to position the tiles on the table so that the line of the notch on the product and the edge of the table completely coincide. Further, gently holding part of the tile on the table, you need to press on its other edge: the product will break gently and precisely. The edges after all work can be sanded.

We cut ceramics angle grinder

The angle grinder gives very great opportunities for cutting. it can easily and accurately not only cut along even lines, but also make curly cuts. If desired, using an angle grinder, you can cut a beautiful round hole with a diameter of 70 mm in the tile. In order for practically no chips to remain on the glossy surface, it is necessary to use only a new diamond wheel and cut from the back of the product. Therefore, before you cut the tile with an angle grinder, you need to make sure the quality of the wheel and its functionality. We do the markings, draw the disc along the markings and break off the long part. Break off the rest. Corners can be smoothed with pliers or the same angle grinder.

An angle grinder equipped with a diamond disc is essentially a universal tile cutter. In order to increase the efficiency of the tool, the equipment can be equipped with a special cooling system. Of course, this increases the cost of the tool, but at the same time increases its productivity. It is thanks to its efficiency that the angle grinder has become quite widespread today.

Processing angle grinder

An angle grinder is a tool that gives you a lot of possibilities when cutting. It is a versatile tile cutter and can be used in almost all applications. With this device, you can perform large amounts of work, because if necessary, the angle grinder can be equipped with a special cooling system. Naturally, this increases its cost, but at the same time significantly increases productivity.

Pros of an angle grinder:

- Performs large amounts of work.

- It can cut holes of any shape, from cutting ceramics along a straight mowing line to beautiful oval cutouts.

- Availability: sold everywhere.

The disadvantages of the device are:

- Low precision and uneven cut.

- The quality of work directly depends on the experience and skills of the master.

- The cut edge often crumbles.

- Large amount of dust during operation.

Work process:

- The first step is to make sure that the diamond wheel of the angle grinder is suitable for the job. This is a necessary measure to help keep the surface of the glossy tile from chipping after cutting. Then we mark the product, cut it with a disc according to the marking.

- After that, we equal the corners of the product with tongs or an angle grinder.

Working with a manual tile cutter

Manual tile cutter. the simplest tool for cutting ceramic tiles, used most often at home, because of its low productivity.

Pluses of the tool:

- Use does not require special skill.

- Low cost.

Cons of the tool:

- Used only for small volumes of work.

- It is almost impossible to cut thin strips of the product.

Work process:

First, the product is marked and the cutting wheel installed on the tongs is carried out along the marked lines. At the same time, the circle in this device is larger than on the glass cutter (up to 15 mm), which contributes to the creation of a deeper cut in the workpiece. After that, the breaking of the tiles is smoother and of better quality. The lips of the tongs are put on the edge of the tile, then their wide plate, forming a small angle, is placed on top of the front side of the tile, and the central part along the mowing line is bent clearly above the marked groove. The gradual squeezing of the lips of the forceps of the product leads to a neat break off of the excess part.

Working with an electric tile cutter

The electric tile cutter is the most reliable and most efficient ceramic tile cutting machine. This professional tool is used everywhere.

The advantages of the device are:

- The ability to process different types of ceramic products with different strengths.

- Doing a huge amount of work.

- Possibility of connecting water cooling.

- There is probably only one wide range. this is its cost. It is the most expensive power tool on the construction market.

There is probably only one minus of this device. it is its cost. It is the most expensive ceramic tile cutting tool of all of the above. However, the price justifies the quality. With the help of an electric tile cutter, you can perform work of any complexity and bring products of different strengths and sizes into the desired form. Such devices are made for real professionals, have a long service life and are used in large industries everywhere.

That’s all. Now you can decide on the choice of one or another tool for processing ceramic tiles. Finally, I would like to give advice: when trying to cut tiles for the first time. buy it a little more, because it is possible that while you acquire the necessary skill, some part of the material will be spoiled. However, with a little practice, you can achieve the desired effect and independently prepare ceramic tiles for laying in your home.

Tool

In construction work, depending on their complexity and volume, several types of tools are used for cutting ceramics:

- Angle Grinder.

- Glass cutter.

- Manual tile cutter.

- Electric tile cutter.

Using this tool, you can perform both standard and complex tile processing operations. With the skill of working with these tools, you can cut round and rectangular holes, as well as trim the edges.

It is worth noting that the further quality of the cladding depends on the choice of this or that equipment in most cases. Therefore, first of all, you should familiarize yourself with the specifics of the work of each of the listed tools, determine the amount of material at which they are used, as well as functional features. All this you need to know when starting cutting. Only by highlighting all these issues, it will be possible to determine with confidence: the better to cut ceramic tiles.

How to cut ceramic tiles (tile)

Ceramic tiles are a durable and effective cladding material in every sense. However, the installation process is not as easy as it seems at first. Before tiling the floor, walls, edges of the room, bypassing pipes or other protrusions, you need to use the necessary equipment and skills. But before that, more painstaking work should be done: prepare the tile for cladding, namely: cut it into the necessary parts.

Using a glass cutter

Using a glass cutter to cut tiles is the simplest option.

Pros of a glass cutter:

- Requires no special skill to complete the task.

- Doesn’t need a lot of money.

Cons of glass cutter:

- Only suitable for processing glazed tiles with low hardness.

Cutting process:

- The tiles are placed on a flat and non-slip surface. There should not be any bumps under it, otherwise it will crack.

- Use a ruler and a marker to indicate the cut line.

- Holding a ruler on the marked mowing line, carefully draw a tool along it. In this case, the groove from the glass cutter must pass evenly over the entire area of the tile.

- After that, the tile must be positioned on the surface so that the line of the cut coincides with its edge. You can also place a corner under the workpiece along the scrapping line. After that, with the help of careful tapping, the tiles are broken exactly along the mowing line. In this case, the product should burst clearly along the marked mowing line.

In the construction markets, cutters-cutters are sold specifically for these purposes, combining the functions of a glass cutter and tongs. When buying such a tool, you need to make sure that it is equipped with a diamond cut or a high-quality cutting wheel.

This shows several ways to cut ceramic tiles:

The following material will tell you how to make the cut edge of a tile even, without chips:

How to cut ceramic tiles with a cutter?

If you need to work with large tiles and cut in a straight line, a dedicated cutter will do. Every builder usually has such a knife, and it will not be difficult to rent it. But this option is only suitable for straight cut lines and a small number of tiles.

- You should always start by checking your rig. There are a lot of design options like a cutter, but the principle of their work is approximately the same: you put the tiles on the work surface and then carefully and confidently make an incision with a knife. To check the working condition of the rig, take one tile, preferably broken or chipped.

- Before cutting ceramic tiles, be sure to draw with a pencil on the back of the cutting line.

- Then lay the workpiece face up. We expose it and check the correct location relative to the intended mowing line. Controlled with lines or markings on the edges of the tiles.

- Please note that the tile cutter usually has a special scale. Which can also be safely used to control.

- Now let’s consider the process itself, how to cut the ceramic tile: we will move the carriage with the blade along the lower edge, which is located closer to you. Place the blade near the edge of the tile and apply downward force. We move in this way along the mowing line.

- Always check the reliability of fixing the workpiece: if the tile is not firmly clamped and walks, the edge will be uneven, and there is a possibility of splitting.

- Always slide the blade all the way down and smoothly to get the smoothest cut possible. If you are planning to use such a device for the first time, buy a few additional tiles, since it will definitely not be possible to cut exactly from high-quality the first time.

- This equipment allows you to make diagonal cuts. For these purposes, we install the tiles accordingly. It is important here to align the position so that the ends are symmetrical.

- Otherwise, nothing fundamentally new happens: you press on the cutter and slide it to the very end with the blade.

How to cut ceramic tiles?

This material will be useful to those who are going to start laying tiles in an apartment on their own. No matter how you position and calculate your work, you cannot avoid cutting ceramic tiles. For these purposes, there are several special devices, depending on the complexity of the work and its volume. As a rule, such instruments are available for free sale, and sometimes they are rented. And to make the work a joy, let’s first get acquainted with the basic rules of how to cut ceramic tiles.

Cutting ceramic tiles into small pieces

For creative people, even the tile on the wall becomes a work of art. Many people prefer to use the mosaic technique instead of the usual method. It involves pre-cutting the tiles into small squares or other small pieces. How to do this, we will consider below.

Using a hole saw

If you want to make circular cuts in your tiles, a tile cutter and a tile hacksaw cannot help you. You will need a hole saw that allows you to drill holes of various diameters in the tiles. The hole saw fits onto the drill and allows you to work quickly and effortlessly. The cutter does not cut straight mowing lines very well, but can easily function as a wire cutter. Such a tool is expensive but can be used for a wide range of home renovation jobs.

Straight cut

The straight cut is the most common type that is used for sizing and covering edges (small gaps between a full ceramic row and a plinth or wall corner). The tile cutter allows you to make straight cuts by hand, which is convenient when you have to cut a small number of thin tiles. The angle grinder is also a handy tool for making straight cuts in tiles. The electric tile cutter allows you to cut straight or cut only part of the tile. This gives an advantage in precision and speed.

Using a water-cooled saw

Accurate cut lines are produced with a water-cooled saw, but experience is required to use it. If you are looking for a tool that can handle large volumes of work, get a better professional.

The principle of operation is based on the ability of water to cool the surface of the cutter, which allows you to reduce friction and increase the quality and accuracy of the cut. In this tool, water is sprayed directly onto the diamond saw blade. Inexpensive options do not have pumps, but can work when submerged in water. It is recommended to cut outdoors due to dust and splashes that result from work. If you want to work indoors, be sure to have a splash guard or shroud over the tool blade.

The best type of blade that can be used when cutting ceramic tiles. It is smooth with a diamond tip, without any notches or nicks. Serrated blades are designed for porcelain and natural stones. Once you have the correct tooling, make sure it is securely attached to the mill using the supplied mill sharpening tools. Vibration cracks ceramic tiles, so the disc must be firmly tightened into the grooves.

To cut the tile with a wet saw, first lay it on a smooth surface. If the tool is equipped with a pump, place the pump in the sump and fill it with water. Test it and make sure it is functional before cutting in such a way that it will flow water to the diamond blade. If the equipment does not have a pump, fill the container to a certain level to keep the blade submerged in the water. Now take a marker and mark the cut shape on the tile. To make straight mowing lines, place the tile on the tray out of the diamond disc. Turn on the saw, pressing the tile firmly against the tray, slide it and let the blade cut through the tile. To make corner cuts, switch to protractor mode and cut the cuts by making small parallel cuts about 3 centimeters apart. Grab a tile scissors and finish the job by finalizing the cut.

Using a tile cutter

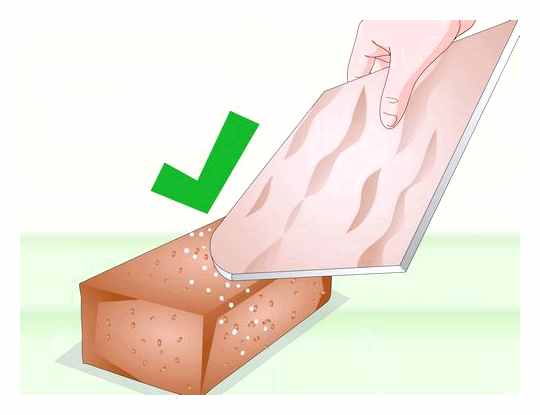

First you need to mark the cut line. After marking, press the tile firmly against the front guide of the tool. Lift and pinch to get straight line.

After that, click on the tool handle to split the tile in two.

The manual tile cutter allows you to make very accurate straight cuts and usually without damaging the enamel (or glaze) of your tile. Some ceramic cutters are capable of cutting up to 48 inches in length and at 15, 30 and 45 degrees. The only drawback of this tool: it requires more skill and experience. Depending on the type of ceramic you will be cutting, this tool can be more difficult to work successfully. For all wall tiles and a large proportion of floor tiles, the ceramic cutter is the most efficient tool both in terms of accuracy (line and less than 1mm width) and speed (it takes about 5 seconds to cut). The slice principle is to draw a line at the top of the tile and then split it, just like you would with glass.

The tool consists of a wooden or metal base and a movable carriage that drives the cutting disc. The cutting takes place in two stages: first, the tile is scratched, and then it is cut using a wheel that moves along an axis. In the second step, the handle is lifted to break the tile along the cutting axis. Only a few incisions are required to achieve a good result. Cutting sizes: from 30 cm to 120 cm in length. Cut types: tiles can be cut either in width or diagonally. Types of tiles for cutting: cuts tiles of small thickness and medium strength. Ideal for cutting most earthenware, sandstone and terracotta. Options: quick-change systems, anti-vibration and anti-slip handles for maximum precision. Two rails rather than one can better guide the tile cutting process.

Using tile scissors

In case you want to make an indirect cut along the edges of a tile, it is more efficient to use a tile scissors, since a regular saw or cutter cannot make an irregular cut. This tool is used to make cuts up to 5 centimeters from the edge, making the cut with the cutter line. Scissors are also used to make tiny cutouts. The best part about them is that they are relatively cheap. The disadvantage is that, unlike the first tool, the cuts made with them are not as straight.

To make a cut with a tile tong, first use a line cutter.

After evaluating, slowly bite off pieces of tile around the marked perimeter. Removing large chunks will destroy the entire tile, so you need to exercise moderation and patience.

Rounded cut

The rounded cut allows the ceramic to be reshaped to accommodate piping or a switch or electrical outlet. For cutting large quantities of ceramics or thick and resistant ceramics, use a dedicated machine. Rounded pliers or circular saw allows you to manually make rounded cuts. They allow precise processing of thin tiles. The hole saw mounted on the drill allows you to drill large holes in the center of the tile. It is very convenient for circular cutting.

7 methods for cutting ceramic tiles

To facilitate the procedure, it is recommended to use three different instruments. However, it should be remembered that cement, stone, terracotta and certain types of porcelain stoneware should only be cut with a water-cooled saw. Here is a list of the tools you can use to cut:

- Manual tile cutter;

- Tile scissors;

- Water cooled table saw;

- Angle Grinder;

- Hole saw;

- Jigsaw;

- Electric drill.

Using an angle grinder

Another tool you can use. This is a stone disc angle grinder. Cuts will not be as clean as when using a water cooled saw, although they will still be of decent quality. Thanks to this tool, you can make rough cuts of doorways and vents quite easily.

The cutting procedure for an angle grinder consists of several steps:

- Draw mowing line to mark the area to be cut

- Stick the tape parallel to the cut line to prevent chipping.

- Gently pull the trigger of the angle grinder and cut along the surface of the drawn lines

- By holding the blade horizontally to the edge, you can make rounded cuts

- By keeping the blade vertically at the edge, you can make straight cuts

Never operate a power tool without appropriate protective equipment. While a dust mask is sufficient to protect against large particles as well as work gloves. Wear a long-sleeved shirt and work pants so you don’t accidentally cut yourself from the ceramic shards that break off during the sanding process. Hold the tool firmly with both hands as you cut the tiles.

Corner cut using an angle grinder

Use an angle grinder to make angled cuts:

- Draw the cut line with a marker, and a ruler Equip an angle grinder with a diamond disc.

- Nail two wooden guides on a wooden board: the distance between the two guides should match the drop of ceramic.

- Place the ceramic between the two guides to keep it from moving while cutting.

- Tilt the grinder slightly and start the ceramic, hold the grinder with both hands.

- Move back and forth to cut the ceramic. Follow the lines that you drew.

- Sand the edges of the cut ceramic tile to remove any unevenness due to cutting.

How to cut ceramic tiles at home

Ceramic tile is a wear-resistant material that is why it is used for cladding walls, roofs, countertops and other surfaces. In cases where it is used as a building material, most of us are faced with the need to cut it. Life would be much easier if there was only one way to cut, however each power tool is best suited for different types of material, so it is important to know the requirements of each sample before purchasing a tool. This article aims to help you successfully cut all kinds of tiles.

Working with small to medium sized ceramic tiles requires careful measurements, the right tools and attention to detail. Only a combination of these factors will achieve good results. If you just need to cut a few pieces, a ceramic glass cutter is for you. However, if you need to cut a large amount, it may be more convenient to use a more serious tool. Knowing how to cut the tiles yourself can save you a lot of money and ensure that your parts come out exactly the way you want them.

How to cut ceramic tiles

In any case, special tools will be needed for the work. The simplest of them is a glass cutter, a manual tile cutter has a higher performance, for professionals it is recommended to opt for electric tile cutters. When you acquire a certain skill, the tile can be cut with an angle grinder, and a diamond string can be used to make art products.

Glass cutter

It is the simplest and cheapest ceramic tile cutting tool. It has a different design:

- Cutting element. small diameter wheel;

- Diamond stylus;

- Roller glass cutter with oil reservoir in the handle. Grease flows down a narrow groove and makes the notch easier.

Glass cutter cutting elements can be replaced as the edge is seamed. How to cut ceramic tiles with a glass cutter? On the front side, a cut line is drawn with a pencil or marker. Holding the ruler on the mowing line, draw the glass cutter towards you from the far edge of the tile. The goal is to draw a uniform depression that reduces the strength of the tile.

Then place the tiles on the edge of a table or other flat surface. the line of the cut should line up with the edge. Holding the edge of the tile on the table with one hand, with the other gently press on the edge that is suspended. The tile should break at the notch. Its edges are sanded with a file for ceramic products.

It is advisable to use a glass cutter for small amounts of work. It allows you to make straight cuts vertically and diagonally. Not suitable for cutting floor tiles, porcelain stoneware tiles and tiles over 5 mm thick. It is problematic to cut a strip less than 20 mm wide with a glass cutter.

Other ceramic tile trimmers

What is the best way to cut ceramic tiles if you need non-standard edge shapes? There are various devices for this.

- Nippers. Used to bite off small pieces, corners and semicircles. Leaves behind an uneven edge that must be trimmed with an emery wheel.

- Diamond string. It is fixed in a conventional hacksaw for metal, used for curly cut. It cuts only wall tiles and requires some skill, since jerking chips form on the surface.

- Crowns are used to make round holes in ceramic tiles for sockets and switches.

- Ballerina. With the help of such a drill, holes of various diameters are made. The size is adjusted manually by changing the distance to the cutter. Up to 20 cuts can be made with one nozzle.

How to cut ceramic tiles

When working with tiles, the question arises: what is the best way to cut ceramic tiles? The choice of tool is determined by the amount of work and the properties of the tile itself. There are several ways to cut ceramic tiles.

How To Cut Ceramic Tile Angle Grinder

New wheels are used for dry cutting, diamond dusting or for work on concrete. an angle grinder is best used with adjustable speeds. At a rotation speed above 3.5 thousand rpm, the tile cracks, and the dust content increases significantly.

The angle grinder can be used to cut floor tiles, porcelain stoneware and wall tiles. With a certain skill, you can cut circles of 70 mm in diameter and make curly cuts.

The cut is made from the back of the tile, as small chips may remain on the surface. The canvas is laid on a solid and even surface, mark the line with a marker, draw an angle grinder around it and break off the part that is longer. The cut surface can be trimmed with the same angle grinder.

We cut ceramic tiles with an electric tile cutter

This tool belongs to the professional category and is quite expensive. With its help, a significant amount of work is easily performed, it cuts any tile quickly, accurately and beautifully. Allows you to cut less than 5 mm wide, make cuts at an angle of 45 degrees, recesses and holes. It is used for curly cutting. The cut has smooth and slightly rounded edges. In some models, the edge of the blade is immersed in water, in others, the surface at the cutting site is only wetted. During operation, all dust settles in the cooling water tank.

The design is very similar to a circular saw. Consists of a platform, a cutting disc fixed on it and an electric motor.

How to properly cut ceramic tiles with an electric tile cutter.

- Water is poured into the container so as to overlap the edge of the cutting wheel by 2-3 cm.

- Include tile cutter.

- Press the ceramic tile against the machine and slowly move it under the disc, focusing on the marked line.

- The blade is moved under the cutting element with a force depending on the strength of the tile. It is not recommended to apply excessive pressure on the knife, this may cause the tile cutter to stop.

- To cut a corner, the tile is gently lifted, unfolded and repeated.

It is necessary to monitor the condition of the cutting edge of the disc, replace it in time. Diamond wheels are commonly used. Also regularly, as it gets dirty, change the water in the bath.

How to cut ceramic tiles with a manual tile cutter

The tool allows you to cut strips from 5 mm wide, straight or diagonally.

It can be used to cut durable floor tiles and porcelain stoneware up to 15 mm thick. By design, it is a base, on which the carriage runners with a cutting wheel are fixed. It is slightly larger in diameter than in a glass cutter, which makes it possible to achieve a greater notch depth. The minimum size of the wheel is 1.5 cm.It is also removable, it can be replaced after a cycle of work.

On the base of the manual tile cutter there is a strip of hard material, with the help of which, after the cut, the tile is broken. There is a T-shaped piece in front of the roller on the carriage, which exerts pressure on the two halves of the tile.

The tile is placed on the base of the tool, after marking the break line, tightly clamped., The clamping corners must be metal in order to cut the floor tiles; plastic is enough for the wall. Pull the handle of the carriage, making an incision on the front surface of the tile.

The incision is made once. After the end of the cut, press the handle and the tile breaks. Edges will also have to be processed if they fall on a corner. If grout is used, then it will hide all defects.

And a few little tricks.

- It is recommended to soak the tiles in cold water for an hour before cutting.

- You can use a file, carborundum block, or an electric sharpener to trim the edges. Grinding is carried out in the direction from the front side to the base. Fine roughness is compared with sandpaper.

For a complete understanding of how to properly cut ceramic tiles, take a look.