How to Cut Corners of a Wooden Skirting Board

The content of the article:

- Main varieties

- Installation tools

- How to cut skirting corners

- Domestic

- Outdoor

- Non-standard

- Installation instructions

The joining of the floor plinth in the corners is a responsible process, which is important to carry out efficiently, since precisely defined clear angles are pleasing to the eye and give the flooring a complete look. To connect the products and get a neat joint, you need to know the technology of trimming them and the existing methods of fixation. Before cutting the floor skirting, read the instructions and recommendations below.

The main varieties of floor skirting boards

Today, plinths made of the following materials are used for decoration: wood, plastic, MDF.

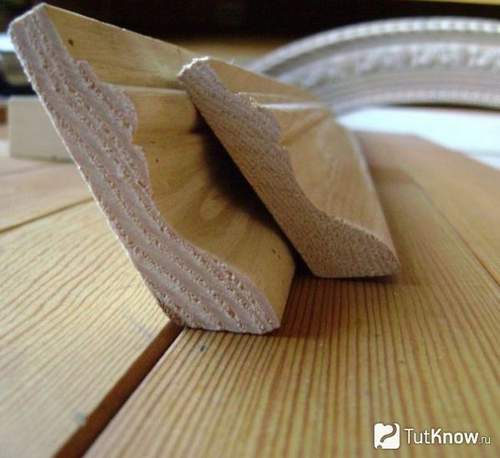

Wooden skirting boards are a traditional type of decoration. In old houses, only such were laid on the floor. Wooden skirting boards have a relief surface on the outside and special grooves for mounting wires and cables inside them. They are fixed with screws, less often nails. It is allowed to use sealant to fix them on the floor. If self-tapping screws are used for fixing, then dowels are pre-installed in the walls.

Among the advantages of wooden skirting boards should be noted durability, environmental friendliness, safety for humans and animals, the possibility of reuse.

However, their use does not always allow you to hide the wiring. In addition, after installing a wooden baseboard, it must be additionally puttied and covered with varnish, paint, stain. In addition, wood is an expensive material, and therefore, products from it will be of high cost. And before you cut the plinth to the floor, you will need to prepare special equipment.

Plastic skirting boards are simple and convenient products for finishing flooring. They are often thought out to the smallest detail: the design of the outer and inner corners, pockets for laying cables and wires, plugs for the ends, special mounts for fixing on the wall and floor.

Plastic skirting boards are distinguished by the speed of installation, a variety of color solutions, the absence of the need for putty and painting after installation, the presence of additional elements for sealing joints. This finish works well with any flooring material: parquet, carpet, tile, laminate, linoleum. Whatever coating you have, you can easily pick up a plastic baseboard for it.

However, plastic is a brittle material, and with a strong impact, chips and holes may appear on its surface. This will require a complete replacement of the whole product whip, at a minimum. Despite this drawback, modern builders prefer a plastic skirting board due to the large number of its advantages.

Mdf skirting boards are environmentally friendly and attractive. Dyed paper is adhered to their front side. Over, the process is carried out at high temperature and under pressure. This eliminates peeling of the decorative coating during operation.

A melamine coating is applied on top of the paper. It protects the skirting board from moisture and persistent contamination. Even in direct sunlight, the product will not lose its appearance for many years. Also, the advantages of MDF skirting boards include quick installation, easy maintenance, economy, a wide palette of shades.

Before joining the floor plinth in the corners, it should be remembered that MDF is characterized by increased fragility. In the process of installation and cutting of such a product, extreme accuracy is important.

Plastic or MDF, from which plinths are made, are lightweight materials that have a large number of color schemes. That is why the product is quite simple to choose for any decoration and design solution. Most often, when choosing the color of the skirting board, they are repelled from the shade of the floor covering.

Tools for installing floor skirting

The procedure for trimming and joining skirting boards from different materials is not much different. The main difference is that wood, plastic and MDF have different hardness and density, and working with wood, for example, is more difficult. If a sharp knife is suitable for cutting plastic, then a hacksaw is needed for wood.

To work with a wooden, plastic baseboard or MDF, you will need:

-

Miter box. A special joiner’s tray for a file, on the sides of which slots are located at different angles.

Tape measure and pencil.

Hacksaw, jigsaw or carpentry knife. Any of these tools are suitable for cutting. But only you decide what to cut the plastic baseboard for the floor. It depends on which tool is easier for you to work with.

Fine sandpaper.

Sealant or putty.

Fasteners (self-tapping screws, dowel-nails).

Before proceeding to the final finishing of the floor, it is necessary to correctly calculate the number of skirting boards. To do this, measure the perimeter of the room and multiply by the standard length of one product. Most often it is 2.5 or 3.5 meters. It is necessary to purchase finishing elements, caps, fasteners and docking tabs.

How to cut corners of a floor plinth

The acquired baseboard must be cut according to the perimeter of the room. To make this process faster and easier, you can draw a diagram of it on a piece of paper, marking all the outer and inner corners.

Cutting the skirting board to the inside corners

Despite the fact that the rooms most often have the appearance of a regular rectangle, the angles in them are not equal to 90 degrees. Such an angle is the dream of any builder and repairman. If you are still lucky and you have a classically correct angle, then to cut the baseboard you need to do the following:

-

We place a wooden or plastic cloth in the miter box;

We find a groove and a mark of 45 degrees on the side panel;

Focusing on it, we begin to saw the baseboard with a hacksaw;

When cutting the skirting board, remember which side it is on. When working with wood, an ideal angle will help to get a special putty.

If you are unlucky and your angles do not have 90 degrees, then you need to do the following steps:

-

We make a small markup on the floor. To do this, a pencil or washable marker is suitable. From one and the other side of the corner, it is necessary to draw the future border of the baseboard. In the corner you will get a kind of rhombus. Its diagonal is a fishing line.

After attaching the baseboard to the resulting rhombus, make a mark on its diagonal.

From the obtained mark to the corner of the plinth draw a straight line. This is your fishing line. Focusing on it, a hacksaw is cut.

Some experts recommend making a cut with a small increase. This will allow you to manually fit the skirting into the corner as accurately and tightly as possible.

At the end, it is necessary to insert a plug into the joint to form a neat inner corner of the skirting board for the floor. If this is a tree, then the joint should be puttyed and prepared for further painting.

Skirting the outside corners

If you have a classic external angle of 90 degrees, then the process of its formation is the same as the internal. When cutting, you must remember which baseboard you have on which side. After receiving the joint, it is necessary to close the ends with a special plug. If during the cutting process there are small flaws, they can be easily fixed with mastic, and then closed with a plug.

If you have non-standard angles, then cutting the skirting board comes down to the following steps:

-

We apply the canvas to one wall.

Using a pencil, mark its internal and external borders.

We do the same with another baseboard.

As in the case with the internal corner, we get a rhombus, only located outside. Its diagonal will serve as the cut edge.

With the help of a file and a miter box we carry out pruning.

We carefully clean the resulting ends and install the baseboard.

Your outer corner of the plinth on the floor is ready, and you can finally fix the product around the perimeter of the room using self-tapping screws or special glue.

Cutting skirting boards at custom angles

Modern design decisions in the decoration of premises often consist in the use of original forms. In this case, it is quite difficult to install the floor skirting in non-standard angles. After all, they are often simultaneously both internal and external. Sometimes the corners are completely rounded. That is why the docking methods described above are not suitable.

If you are dealing with a round corner, then you need to cut the skirting into 4-5 parts. Using plugs for connection, carefully lay out the entire corner in small parts. Do not forget to fix them with glue or putty. Thus, you get a neat rounded corner.

If you have an inside-outside corner in the room, then the following steps should be taken:

-

On one side we put a baseboard and draw its border on the floor.

Now apply the second half and make two marks: one. The intersection with the drawn border, the second. With the wall.

We connect the received points and make a cut.

If you use wooden plinths to decorate non-standard angles, then instead of plugs you will have to use putty. After it hardens, the resulting surface must be carefully sanded with sandpaper. And the principle of how to cut corners for a wooden floor skirting board remains the same.

Installation instructions for plastic floor skirting

We start the installation from the middle of the wall. To do this, we cut the end face at an angle of 90 degrees and carefully grind with sandpaper. This will allow for better grip between the two parts.

So that the skirting boards do not go away, it is recommended to use special glue or sealant for fixing. We also use special fasteners. Self-tapping screws, dowel-nails.

If you have sockets at the bottom, then carefully cut out the recess for them with a jigsaw. The resulting surface is carefully treated with sandpaper.

If you need to dock the baseboard with the door frame, then you should calculate the length of the canvas so that only the side cover can be placed between the end and the door jamb.

How to cut the corners of the floor skirting. Look at the: