How to cut corners on plastic ceiling skirting boards

Product features

For the manufacture of decorative elements, the same materials are used as for the panels. polyvinyl chloride (PVC).

- It differs from the usual mounting L-shaped profile only in the decorative part, in the form of a classic concave skirting board.

- Unlike standard fillets made of polyurethane or polystyrene, plastic skirting boards have a fastening element in the form of a groove into which the edge of the panel is inserted. When installing the ceiling, this additional part allows you to tightly fix all its elements.

Advice! It is not necessary to fasten the panels only by means of grooves. the structure will not be strong enough. In the middle, they are additionally attached to the crate.

Minuses

- During installation, all the unevenness of the walls will be noticeable, due to the difficulty of bending the plastic;

- Cannot be repainted;

- Afraid of fever;

- The small width of these decorative elements. For example, foam products are much wider;

- Installation of the ceiling, when using only plastic skirting boards, is quite complicated. it is very difficult to put the last element in place, because of the geometry, so you have to be sophisticated;

Advice! Such inconvenience is not caused by the installation of separate skirting boards, in which the decorative part is inserted later on the latch.

The standard length of products is three meters, which should be taken into account when calculating their number per room.

Tip: Due to their small width, such elements should not be used in rooms with high ceilings. They are best suited for the bathroom and kitchen, as shown in the photo.

A clerical knife or a hacksaw for metal with fine teeth is used for cutting, which makes the cut more accurate. Better cutting of parts at an angle will help you get a miter box.

Solution advantages

- They are easy to clean using a sponge and a non-abrasive detergent;

- Over time, products do not turn yellow;

- After installation, the plastic ceiling and skirting boards make up a more complete picture compared to other types of finishes;

- Absolute moisture resistance;

- Low price;

- Large range of colors;

- Light weight.

How to make a plastic ceiling skirting board. it’s about installation, not production

How to make plastic skirting boards? Their main purpose is to decorate plastic ceilings, which are quite popular for decorating rooms where there is high humidity.

When assembling, there is always a small gap between the ceiling and the wall, or there is a not very neat joint. In this case, the best option is to install a plastic skirting board with your own hands, which will hide all defects, and sometimes serve as a fastener.

How to fix

Before fixing the strips, it is necessary to properly cut the corners for plastic ceiling skirting boards, or use factory fittings, among which we can distinguish:

- Internal corners for ceiling skirting boards are placed in the corresponding corners. They do not always look neat, since the actual angle may differ from the right one.

How to make the corners of a plastic skirting board in the absence of special decorative elements with which they are made?

- Purchase a special wort.

- Trimming the edges of the skirting board must first be done in one direction, placing the edge of the part in the miter box. In this case, the angle of inclination on the element should be 45 degrees.

- In a plastic skirting board, the groove should not be completely cut out, but about 0.5 centimeters should be left, this will avoid the formation of a gap in the corners. How to do everything correctly will tell the video.

Tip: Keep in mind that the next plank will be trimmed under the same degree, but in a different direction.

This will make it possible to connect all the workpieces at the corners in such a way that they do not have ugly gaps that may appear due to small errors.

Tip: If gaps form after joining the frames, they can be sealed with a special silicone sealant. When planning the decoration of corners with decorative fittings, a careful fitting of the skirting boards is not required.

- Products are installed.

- They are attached to the protruding edge using self-tapping screws or construction brackets.

- Further, cut along the length of the plinth are inserted into the grooves.

Advice

How the ceiling plinth, the angle for it and other fittings are attached is not very difficult to figure out, even if you have never done such work with your own hands before. The main principle is accuracy. attention should be paid to precise cutting of parts.

Outside corner

- Measure the length of the plinth from the nearest wall to the outer corner, leave the fishing line on the wrong side with a pencil, indicating the desired length. It should be noted that the edge (its upper part) should protrude slightly outward.

- The plinth is moved to the miter box and cut off.

- The adjacent bar also needs to be measured with a margin and cut off in a mirror image to the first part.

Trying on the ceiling plinth: the joining of the parts should be perfectly even. If the result is not achieved and there are irregularities at the joints, you can trim the edges with an ordinary knife to a perfect fit.

The first way is with a miter box

Professional miter box with rotary hacksaw

The miter box usually looks like a tray with vertical holes for a hacksaw. It can be made of wood, metal or plastic. This tool is the oldest and simplest carpenter’s tool for cutting wood pieces at 90 ° and 45 ° angles. There are types of such a device for professional work, with a rotary mechanism, in which the cutting tool can be rotated and fixed in any position.

How to cut a ceiling plinth correctly

Ceiling corners are divided into internal and external, the method of joining on them is slightly different.

If necessary, you can make a miter box with your own hands. To do this, you need three trims from plywood or boards of the same size. First, they are applied in the form of an inverted letter “P” and the corners are marked. Then, according to the marking, slots are cut out for a hacksaw almost to the very bottom, and the boards are twisted.

Method two. no additional tools

For the inner corner, you can use the simplest way of perfect joining. by marking on the ceiling. Another example of how to cut a corner nice and even.

- Apply a fillet to the ceiling, firmly pressing its even edge into a corner.

- Draw a line along the long side of the plinth on the ceiling.

- The same action is done with the adjacent part on the other side.

- Mark the point of intersection of lines.

The end result is an even 45 ° angle when you draw the line from the point of intersection to the edge of the part. Note that the above marking method works only for perfectly flat corners.

Inner corner

- Making the right measurements.

- We install the plinth strip in the miter box so that this position exactly coincides with the placement on the ceiling.

- The plinth should be firmly pressed against the opposite wall of the miter box. Hold and press with your free hand.

- We put a hacksaw at an angle of 45 ° in a special hole and cut off the part.

- The adjacent part must be cut in the same way, only in a mirror image, as shown in the photo.

When cutting soft materials (PVC, expanded polystyrene), use a metal hacksaw or an ordinary construction knife. Then the work will be neat and with smooth edges.

How to cut the corner of a skirting board evenly

A beautiful and neat edging of the ceiling hides the joints between the coverings and is an additional element of the room’s decor. But in order for the ceiling plinth to look really beautiful, you need to be able to qualitatively join its corner joints. How to cut the corners of the ceiling plinth evenly can be found in our article. Related article: how to properly glue the ceiling plinth with glue and putty.

other methods

With a good eye and accuracy of hand action, you can use a homemade template that resembles an imitation of a miter box. To do this, take a thin board or thick plywood and draw a layout in the form of a horizontal rectangle. Using a protractor, mark 45 ° on the right and left sides of the rectangle. Draw mowing lines connecting opposite edges. You can now cut off the ceiling plinth using this layout. The actions are simple and similar to the description above in the first option. Only the ceiling parts should not be inserted, but placed on the drawing and the hacksaw should be combined with the layout of the layout.

Special accessories for docking

Installation of PVC skirting boards

Installation of a skirting board for PVC panels involves the installation of a frame made of wooden strips or metal profiles. The frame elements should be fastened at a distance of about half a meter from each other. If the wall is flat, then the profiles are fixed with dowels. On walls with defects, it is recommended to use self-tapping screws, making gaskets under the frame in the places of the depressions.

The outermost elements of the frame will act as a base for fixing the ceiling plinth for plastic panels in corner joints. The main part of PVC skirting boards is fixed with self-tapping screws or construction brackets. The joints are decorated with special inserts, which allow faster and more accurate installation work. Installation of PVC panels on the main part of the ceiling is quite simple, there are grooves on each skirting board that do not allow the panel to move to the side.

Preparing for installation

Before starting the installation of plastic ceiling skirting boards, it is necessary to determine what materials will be required for work, and in what quantity.

In particular, you need to prepare the following:

- Skirting boards and accessories, e.g. PVC skirting board corner.

- Adhesive composition.

- Required fasteners.

Before installing the ceiling skirting boards, measure the areas where the skirting boards are to be attached using a tape measure. Then the number of skirting boards is determined, for which the resulting total length is divided by the standard product size, 3 or 6 meters. If the result is a fractional number, then it should be rounded up.

Various inserts and corners for PVC skirting boards can be used as accessories. It is necessary for decorating the corner joints of the skirting boards and building up their length. Corner elements can be internal and external.

It is very important to choose the right adhesive for the skirting boards. Among the suitable formulations, several popular options can be distinguished:

- Moment glue. The composition is characterized by a fairly fast setting, but has one drawback: getting on the front of the product, it can cause irreparable defects.

- Adhesive composition “Titan”. Refers to safe materials, but hardens a little slower compared to other adhesives.

- “Liquid Nails”. The composition is based on an organic solvent, which contributes to the rapid hardening of the glue. However, after completing the installation work, it is necessary to thoroughly ventilate the room. The advantage of the material is the ability to use in rooms with high humidity levels and a sharp change in temperature.

- Acrylic “Liquid nails”. It is an environmentally friendly material, nose with slight imperfections. First, the glue dries for a long time. Secondly, it cannot be used at negative air temperatures.

- A special putty compound is used for working with overhead skirting boards.

PVC fillets are fixed with screws or special construction brackets.

Tommy’s Trade Secrets. How To Fit Coving (Internal Mitre)

Types of skirting boards for the ceiling

The ceiling plinth for PVC panels has several names: baguette, frieze, fillet. However, the purpose of all elements is the same, they are intended for masking and decorating corner joints of the ceiling and walls.

- Baguette, which in turn can be extruded, injection or laminated. In the first case, the material is characterized by carved indentations, the second option is decorated with embossed decor. In any case, they perform a decorative function.

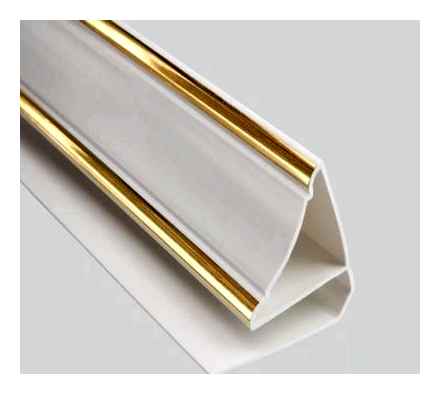

- The PVC profile has a triangular cross-section and is distinguished by the presence of an additional U-shaped profile. This design allows the use of elements for decorating individual areas and the simultaneous fastening of panels. In this case, first, the profile is attached to the wall, and then plastic panels are inserted into the grooves. The profile is fastened in accordance with the purpose: to fix the ceiling panels, the U-shaped profile is directed to the side, to hold the wall panels, the profile should be directed down.

Installation work

Installation of the skirting board for PVC panels on the ceiling is carried out depending on the type of element, therefore it is important to know and understand how to fix the ceiling plinth for plastic panels.

Overhead skirting board

This type of decorative elements is fixed on the surface as follows:

- With the help of special devices, the edges of the skirting board are cut at an angle of 45 0 to the front side.

- An adhesive composition is applied to the inner surface of the product.

- The PVC skirting board for the ceiling is applied in the surface and pressed along the entire length.

- It is recommended to immediately remove excess glue formed when pressing on the product with a soft cloth.

- The plinth is left until the adhesive is completely dry, after which the joints and gaps are sealed with silicone sealant or an angle is set for the PVC ceiling plinth. If you make the corners yourself, you need to know how to make the corners on the ceiling plinth so that the joints are even.

DIY Coving Cornice Cutting Tips for Beginners

How to install a ceiling plinth for PVC panels. fixing instructions

The use of PVC panels can significantly reduce the time spent on repairing walls and ceilings. At the same time, we can say with confidence that the quality of the work performed remains at the same level, subject to the sequence of actions and the correct choice of materials. However, there is one drawback of PVC panels: an even and beautiful connection of the ceiling and walls will not work. To solve the problem of such a plan, ceiling plinths for plastic panels allow. This element is able to emphasize the style of room decoration and hide minor imperfections that are formed when finishing surfaces with plastic panels.

Advantageous characteristics of PVC skirting boards

All products made of polyvinyl chloride have a large number of advantages, the plastic skirting board for the ceiling in this regard is no exception:

- Installing skirting boards is a simple job that your average home craftsman can handle. To change the finishing elements, it is enough to remove the old panels and skirting boards, and fix the new panels on the frame.

- Subject to correct operation, plastic products can last a long time, since the material is not afraid of moisture, heat and cold.

- PVC skirting boards are environmentally friendly materials, therefore they can be used as a finishing material in children’s rooms.

- A wide selection of colors and textures allows you to choose products for any style.

- The ability to complete the renovation of the premises as soon as possible.

Renovation of premises using PVC panels and skirting boards saves time and effort, beautiful and durable wall and ceiling decoration.