How To Cut Decorative Plaster Stone

Surface and material preparation

For work, you need to prepare all the necessary materials and tools to speed up the process of installing stone elements. Would need:

- artificial gypsum stone (you should buy the entire amount of material that is needed for finishing at once);

- tile glue or special gypsum composition;

- priming materials;

- measuring instruments, building level;

- putty knife;

- hacksaw;

- metal brush;

- brush or roller;

- narrow scapula for filling the joint (6-8 mm).

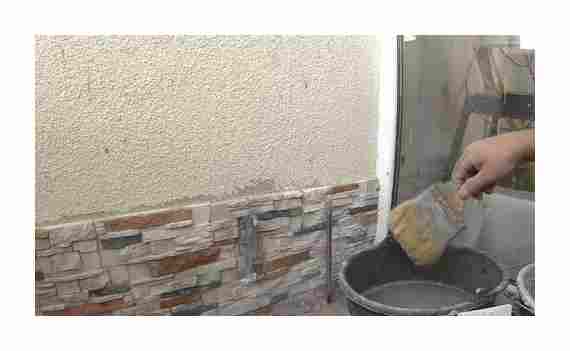

Work begins with the preparation of the base: it must be leveled and rubbed, eliminating strong differences in surface height. Small irregularities can be filled with glue during the installation of each element, so the alignment is done on its own, without calling professionals:

- remove the old coating from concrete, plastered surfaces and eliminate potholes, after drying, treat the wall with a metal brush;

- glue a fiberglass reinforcing mesh on a wooden wall;

- apply a primer solution according to the manufacturer’s instructions, observing the drying time of the composition.

How to paste on the wallpaper?

A fashionable way of decorating walls, combining the use of wallpaper and fragments paved with plaster stone tiles, requires special rules. It is not recommended to glue the tiles directly on the wallpaper: a lot of parts can tear the panel off the wall.

To properly finish, glue a decorative stone on the wall in combination with wallpaper as follows:

- align the wall and mark its parts where different materials will be mounted;

- stick wallpaper in the traditional way, leaving exposed areas intended for stone;

- if the wallpaper is already glued on and does not need to be changed, remove part of this coating in the right places;

- when gluing or removing part of the wallpaper, the line of combining the textures should go 2-3 cm onto the pasted surface, then the joint of different parts will be invisible;

- it is necessary to prime the wall and glue the decorative gypsum stone according to the principles described for the installation of such tiles, slightly winding the edges of the parts onto the wallpaper.

If you have to change the wallpaper after the stone has been laid, it is recommended to join the edges, making an overlap of the panel over the tile (3-5 cm). In this case, it is important to glue the junction well. After gluing with a sharp knife, cut off the excess right along the edge of the stone. If necessary, the edges are glued, and a decorative molding (plinth) can be attached to the straight joint.

Advantages and disadvantages of decorative stone

Despite its low cost, gypsum stone differs little in strength from other types of wall coverings and has the following advantages:

- ease;

- easy installation;

- the ability to absorb and release moisture, while maintaining an optimal indoor climate;

- incombustibility;

- absence of volatile and harmful substances in the composition;

- color fastness and long service life.

During operation, gypsum materials can be damaged by strong mechanical impact (impact with a hard object). The advantages of using tiles can also be attributed to the ease of repairing the coating: it is enough to remove the damaged element and glue in its place a whole.

There are practically no drawbacks to plaster imitation of stone surfaces. Tiles are not recommended for facades, but during interior work they compete with facing bricks and clinker, tile or ceramic tiles.

How to glue decorative plaster stone

Decorative gypsum stone is a modern finishing material, a kind of wall tiles. Manufacturers offer a wide selection of textures and shades of products that allow you to create a coating that imitates chipped and torn stone of different breeds, flagstones, as well as brickwork from facing or antique material.

Gluing instructions

It is necessary to glue the artificial stone on the wall in compliance with the requirements for the installation of coatings of this type. There should be no voids or irregularities under the tiles, since a thin layer of gypsum above them will be especially vulnerable to impacts. The gluing technology is simple and does not require special skills and abilities.

How to glue a decorative stone with your own hands?

When choosing a method for interior decoration, take into account the need to leave a gap between the elements. Distinguish:

- Installation without jointing. They are used for finishing under a torn or chipped stone, trying to make a uniform surface without joints. Masonry elements are installed close to each other.

- Brickwork with jointing. It is used to imitate a brick wall, paving with flagstone or cobblestone, pebble mosaic, etc. Between the individual stones there is a gap of 0.5-1 cm, which, after gluing the coating, must be filled with grouting mixtures.

In addition to these differences, the laying of decorative gypsum stone is carried out according to the general principles:

- Open several packs of stone from the purchased batch. The material may differ slightly in shade, and mixing different elements will allow you to get a coating with a soft color transition, like a natural stone. It is advisable at this stage to lay out the outline that will be on the wall. This will help fit the tiles together so that they best resemble staggered brickwork or uneven geological texture. You can cut off part of the plate with a hacksaw for metal (with small teeth).

- Wipe the back of each tile with a wire brush and cover with the primer used for the wall. Prepare the glue in advance if the manufacturer of the mixture recommends insisting it before use.

- Adhesives are applied depending on their type. A putty or gypsum-based tile adhesive is smeared on the seamy surface of the part with a notched trowel. Sealants and liquid nails are used according to the manufacturer’s instructions: they are applied in dots or in stripes, waves, etc. Cement-based mixtures are applied to the wall with a layer of up to 6 mm (in separate sections of 1 sq. M).

- The tiles are glued with a pressing and rotating motion. If any compound other than cement is used, it is better to glue from the upper corner, gradually lowering to the floor. It is more convenient to fix the tiles on the cement-sand mortar applied to the wall, starting from the bottom. If a seamless technique is used, the elements are rubbed close to each other. To simulate brickwork, you can use thin, even sticks, placing them in the joints. They will allow you to make the seam even.

- After finishing the finish, the wall must be dried according to the instructions for the glue (most often about 24 hours). Then, grouting compounds are applied to the masonry with jointing, filling the gaps between the tiles with them. A wooden spatula 6-8 mm wide will help to rub the composition into a narrow seam. For seamless masonry, grout is not used, since the space between the tiles is often filled with excess glue during installation. If they squeezed out, you need to remove the composition immediately, before it hardens.

After drying, the walls in a room with high humidity (kitchen, bathroom) must be treated with moisture-proof varnish. A glossy or matte finish is sometimes used to decorate a wall in a room with normal humidity.

What glue is used when working with decorative stone?

Depending on the material of the surface to be trimmed, you can use different types of glue:

- putty, tile or cement-sand mixtures. for brick, concrete, plastered walls;

- PVA, acrylic, Bustilat. For installation on drywall under putty;

- liquid nails, thickened paint, sealants and mastics. for fastening to metal, plastic and similar partitions and architectural elements.

When choosing an adhesive, you need to pay attention to its suitability for use on existing surfaces. The manufacturer indicates this information on the packaging. Adhesive for brick-like gypsum tiles can also be used for filling joints.

Drying and processing

When the mixture hardens, the workpieces are removed from the dies. To do this, cover the mold, for example, with a sheet of cardboard, turn it over and place it on a hard surface. The matrix is removed by gently pulling back its edges. The resulting tiles are left to dry for 24 hours in a warm room. During drying, do not allow direct sunlight to hit the gypsum tiles. The form, freed from finished products, it is advisable to immediately clean it. wipe it with a dry piece of cloth or a sponge.

To smooth out possible imperfections (fingerprints, excess gypsum) and give the blanks a finished look, they are processed with sandpaper.

The texture of a tile imitating a brick or stone can be enhanced with a chisel. make deeper grooves, add chips. Products will become more resistant to moisture if they are first opened with acrylic primer, and after it dries with acrylic varnish.

Gypsum tiles without the addition of color are white. To give it the desired color, a water-soluble or dry coloring pigment is introduced into the solution before pouring into molds. In this case, a uniformly colored tile is obtained. If you add liquid color to the mixture already poured into the matrices and make several chaotic mixing movements with a thin brush, then the finished product will be with colored stains.

It is easier to paint tiles already laid on the wall with liquid paint. To give the hand-made tiles an interesting texture, you can paint the shape from the inside before pouring the plaster mass. Products will be colored unevenly, with alternating bright and dull stripes, which will give them a greater resemblance to natural wood or stone.

Cleaning the tile mold

Before re-pouring, carefully inspect all cells and remove adhering gypsum residues. Since silicone or polyurethane cells are flexible, cleaning is easy. Dry pieces of gypsum dough will easily come off if the plastic is slightly bent in the place of contamination.

How is gypsum tile processed after cutting

You can drill the necessary holes in the plaster using a drill. A drill of standard sizes is suitable for this purpose.

Typically, plaster tiles have uneven edges. This circumstance makes it difficult to lay it. When joining two tiles, you will have to cut a layer of a certain thickness. This can be done using a regular chisel. After performing the manipulation, the cut site will need to be cleaned. To complete the task, you will need sandpaper.

Advantages and disadvantages

To improve the quality of the cut, you need to use a hacksaw for metal. Such a tool helps to avoid post-processing of the material. However, cutting gypsum tiles using this method takes a long time.

The sander allows you to speed up the cutting process. But it dusty the surrounding space. So later you will have to spend a lot of time cleaning the room from dust.

Making decorative plaster tiles for stone and brick with your own hands at home

The room, decorated with relief tiles, looks very solid. A finished tile usually costs a lot of money, but if you wish, you can replace it with a budget analogue. do-it-yourself gypsum tiles at home.

Processing, painting, varnishing

An untreated gypsum surface is not very practical. It is difficult to keep it clean. On a white background, any pollution is striking, the tile looks untidy. This problem can be solved by painting and applying a protective coating.

You can paint plaster in two ways. At the first, paint is applied to an already cast and dried product. For brick-like staining, you can use acrylic paints and even simple watercolor. With this method, it is easier to choose the desired tone or to make the tiles multi-colored. However, it has significant drawbacks: fading and a high probability of damage to the top color layer.

It is better to paint dry plaster mix before mixing. At the same time, the gypsum becomes colored not only outside, but also inside, due to which the places of scratches or chips are practically invisible. Iron oxide powders are well suited for coloring the gypsum mixture, and they cost little. Depending on the composition, they are yellow, orange, reddish, brown or black. They can be used to paint gypsum bricks in any of these shades.

When planning to paint in this way, it must be borne in mind that after drying, the gypsum dough brightens by several tones, and the resulting shade may differ from the intended one. Experienced finishers advise to paint a small portion first and let it dry completely. This will help to avoid mistakes when tinting the bulk. At the final stage of finishing, the tiles are covered with a transparent acrylic varnish that protects against moisture and dirt.

How to cut plaster tiles with your own hands

Most people decorate their walls with gypsum tiles. It has a decorative function. However, with cutting the material, certain difficulties may arise. For this purpose, the following tools are used:

1) With a hacksaw for metal.

2) Grinding machine.

3) With a hacksaw for wood.

Each of the above methods has its own advantages and disadvantages.

What is required during the installation process

To install gypsum tiles, you need to arm yourself with the following tools:

1) Hacksaw for wood.

2) Rubber spatula.

4) Wet sponge.

Plaster Coving Installation. Balancing A Mitre

How to make a decorative brick or stone with your own hands

How to make decorative styrofoam brick

How to make decorative drywall brick

How to make a decorative plasterboard stone with plastering

How to make a decorative plaster stone in a homemade form

How to make decorative plaster brick in siding

How to make a decorative gypsum stone without a shape

Wall decoration will cost several times cheaper than with purchased tiles.

How to do

- Decide on the size of the tiles. A standard brick has a side surface of 250 × 65 mm, but it is not necessary to tie to it: the dimensions can be arbitrary.

- Using a level and a pencil, mark the size of the future tiles on the EPSS sheet.

- Use a sharp knife to cut the material into pieces along the line. This can be done both by level (if you need to get perfectly smooth edges), or simply by hand (if you want more naturalness).

- Cut the pieces into thick pieces to make two thin tiles each. The expanded polystyrene is quite dense, so it is convenient to use a knife with teeth and cut through the pieces in several passes.

- With the blade at an angle, chamfer along the contour of the tiles. Trim the resulting halves by cutting off all unnecessary from them. Or, conversely, give the surface a rougher look.

- The finished elements are attached with a smooth surface to the wall close to each other or with a gap imitating a masonry joint. Then, if necessary, primed and painted.

What is needed

- Drywall of any thickness;

- sharp knife;

- level;

- pencil.

What is needed

- Basement siding;

- gypsum;

- PVA glue;

- fiberglass;

- putty knife.

Now reading

How to do

- The first step is to make a mold. To do this, find a suitable piece of chipboard or plywood. Take a thick oilcloth and cut it to the size of the base.

- Remove the covers from the cable channels and attach the boxes around the perimeter of the chipboard piece with screws, thus pressing the oilcloth.

- Cut the trunking covers into pieces that will fit the tiles. Install them in place, and then cut the boxes along them. Later, a spatula will be inserted into these slots to separate the bricks.

- Stir the plaster of paris with water in a cut plastic bottle until it becomes a sour cream and add fiberglass for strength. Instead, you can tousle a polypropylene bag and simply cut threads from the canvas.

- Pour the plaster mixture into the mold and distribute it evenly. Tap the edges lightly to avoid voids. When the casting dries up a little, stir it with a plastic trowel to give the texture of the stone.

- Divide the still uncured plaster into tiles. To do this, insert a long spatula into the frame slots and press down. Use a dish sponge to blot the casting to form a porous structure.

- Remove the frame on either side and remove the tiles one at a time. Gently pick them up with a spatula and, if necessary, trim along the joints with a knife.

- Next, the finished stones are primed and painted. Then they are attached to the walls using tile glue.

How to make a decorative plaster stone in a homemade form

Another method of producing tiles is by casting from a gypsum mixture. The production is even cheaper and easier. The simplest form with sides is made from a piece of chipboard, cable duct and foil. Stones and bricks are obtained with the correct geometry and texture, not inferior to purchased tiles.

Coloring recommendations

Correct painting of gypsum stone implies adherence to simple rules:

- parts are pre-dried within 1-2 days;

- the old material is sanded, otherwise the paint will crumble from it soon;

- impregnations are applied according to the instructions on the label. some solutions are applied before the painting procedure, some types are not compatible with certain paints;

- to make the product shine, a varnish coating is added over the paint, but it is not always appropriate. due to this, the feeling of the naturalness of the stone is lost.

When you follow these tips, it becomes possible to protect the decorative stone from negative influences, corrosion, and the paint layer will last for a long time.

Painting methods

There are several methods of painting the material: in bulk and surface.

The first method is used when making a stone on your own. The technology consists in adding coloring pigments to the plaster solution. as a result, the product is painted over from the inside. For painting with this method, mix 1/2 part of the color with 200 ml of water and the same volume of acrylic primer. Matt varnish is applied to the required surface of the stone after complete drying.

The surface method is very simple: the finished facing material is coated with a coloring agent from a spray gun. The advantage of this method is the ability to give the decorative stone the desired shade, to create a natural, natural look.

What to paint?

If unprocessed products are purchased for finishing, or the material is made independently, then the products need painting. The first step is to test the selected compositions in order to understand what color the result will be.

Painting is carried out using the following mixtures and solutions:

- Acrylic paint. this water-based solution is suitable for gypsum stone due to its resistance to external influences, good elasticity, due to which cracks will not form on the facing element.

- Vitriol. copper and iron vitriol acts as an impregnation and helps to increase the strength of parts. Copper sulfate gives the stone a blue tint, and iron. yellow.

- Stain is a monochromatic mixture used for painting cement-based materials, as well as gypsum stones. Decoration is carried out with acid stain or wood compound.

In addition, painting is done with other solutions: various varnishes and impregnations with a wet effect, paints that give the plaster stone a natural look.

The main thing is to determine the purpose of the material and, depending on this, select a dye.

Subtleties of painting decorative plaster stone

Sometimes there is a strong desire to change something in the design of an apartment or house. In this case, you can use gypsum stone, the painting of which is not as difficult as it seems at first glance. The use of decorative stone will allow you to transform any room, but first you need to deal with the intricacies of staining the material.

Tools

To create a decorative element that attracts attention with your own hands, you need to use the tools thanks to which the painting is performed.

The main devices include:

- airbrush or spray gun;

- brushes and rollers;

- sandpaper or sander.

Most often, an airbrush is used for painting.

Wall design / how to make a stone wall from decorative plaster

Its advantage over a brush is that it sprays the composition, and does not smear it, as a result, an even color is obtained without too dark unnatural areas.

With the airbrush, you can give the stone different shades by simply adjusting the flow of paint and the distance from the tool to the working surface. A conventional airbrush with a compressor equipped with oil cooling and an automatic pressure regulator is suitable for painting the material.

It is very rare to paint the entire facing stone with a brush, because the device leaves streaks and ugly spots. The brush is a great tool for highlighting areas.

Preparation and painting

Preparation for staining is carried out depending on the type of material: a previously used stone or a new one. The old corrosive layer is carefully removed from used products. The stone is then sanded to eliminate large surface differences. Facing elements are blown by a compressor and impregnated 2-3 times. due to this, during finishing, the consumption of coloring compositions will be significantly reduced.

The new stone does not need to be ground and rubbed. it is enough just to wash it and soak it 2 times. In this case, painting will take much less time.

There is no need to use high-precision tools and special technologies to paint the material. First, a composition is prepared from a dry powder, filled with the required amount of water indicated on the instructions from the manufacturer. If everything is done incorrectly, then you can get an overly liquid or thick solution. it will be rather inconvenient for them to paint textured gypsum stone.

In the process of work, you need to paint over all the details, without getting too far beyond the boundaries of each element. As it dries, the paint on the plaster will fade slightly. The surface should be varnished to provide protection. Decorative gypsum stone is painted with water-soluble paints, so the varnish is chosen with the same characteristics: alkyd, matte, pentaphthalic.

Decorating

There are several ways to paint the surface of a decorative plaster stone in an interesting way, with the help of which you can achieve an unusual look of the product:

Thanks to these tips, preparation for painting a decorative gypsum stone will be productive, and the result of the work will be of high quality and long-term.

One of the ways to paint decorative gypsum stone is presented in the following video.

Stone Cutting Tools

According to the degree of hardness, decorative stones can be divided into two groups: harder. porcelain stoneware and cement-based stone, and less hard. acrylic stone and gypsum stone. To cut them in the conditions of finishing work at a construction site, two types of tools are used.

A decorative stone of high hardness is cut with a rapidly rotating disc mounted on an angle grinder, colloquially referred to as an “angle grinder”. There are two types of discs: abrasive, reinforced inside with a fine mesh mesh and metal with diamond coating. Diamond discs are significantly superior in resistance to abrasive discs. Allows you to work faster and do not change the disk longer. They cost significantly more.

Plaster and acrylic imitation of decorative stones is noticeably softer. Therefore, they can be cut with a fine-toothed saw. The saw blade can be installed in a hacksaw for metal. A more productive tool is an electric jigsaw. The file in it must also have a fine tooth, which ensures the removal of a thin layer of material in one pass. Small thickness of the removed layer, reduces the load on the cutting tool, increases the cleanliness of the cut and makes the work more productive.

You can also cut these stones with an angle grinder, but the gypsum is very dusty. In addition, since the “stone” made of gypsum is fragile, it can be broken, like glass, by first holding a deep risk in the right place. In this case, homemade cutters with a sharp hook-shaped end are used as a tool. The question “What to cut?” allows multiple answers. The answer to it is given by the finisher at a specific workplace, based on the prevailing conditions and personal experience.

Technology and instructions for cutting stone

Since decorative stone can be cut with two types of tools, each of them will have its own technology. At the same time, the beginning and the end of the processes are the same, so let’s combine them into one instruction:

- Before starting work on cutting a stone, you should make sure that the safety requirements are met.

- Carefully mark the cutting line.

- Clamp the workpiece securely. Make sure that the cut off part of the stone, separated from the main massif, does not pose a threat to the worker and others.

- Cut the workpiece according to the markings.

- If you have to cut a closed contour with a jigsaw, for example, an opening for a sink in a kitchen countertop, you should first drill a hole inside the contour, with a diameter larger than the width of the file.

- Unfasten the workpiece.

- After finishing work, clean the workplace.

How and how to properly cut decorative stone

Decorative stone is understood as materials of artificial origin, repeating the appearance and, in part, the properties of natural stones: granite, marble, tuff, sandstone, etc. The modern development of technologies allows not only to imitate any natural finishing material, but also to ensure its good workability.

It is important for a finisher on an object to know how to cut a decorative stone, how to drill it, how to assemble a solid object from separate parts. Solving these problems requires familiarity with the properties of such materials.

- Physical properties of decorative stone

- Stone Cutting Tools

- Technology and instructions for cutting stone

- Helpful advice from professionals

Physical properties of decorative stone

Four types of artificial stone are used in interior design:

- cement based;

- from plaster, as the main component;

- porcelain stoneware;

- acrylic stone.

Decorative stone on cement and plaster bases have an uncomplicated manufacturing process. It is not difficult to organize it in a construction site or a small artisan workshop. It boils down to mixing the prepared components, mixing the mixture with water and pouring it into molds, followed by drying. By introducing the appropriate dyes, the required shades of the material are obtained. Decorative cement stone is moisture resistant, durable and not afraid of moisture.

The continuation of the listed advantages is a relative disadvantage. the specific gravity is close to the corresponding parameter of natural finishing materials. It is used for external work: finishing the walls of the house with stone, laying paths, in small architectural forms and sculptures. Decorative gypsum stone has a lower weight compared to cement, it is easier to install on the walls of the house, but does not have high strength and moisture resistance. Indoor use.

Porcelain stoneware and acrylic stone are materials whose production is possible only in a large enterprise. The implementation of the appropriate technological processes requires complex expensive equipment, qualified personnel, a large stock of initial components and, as a consequence, a well-functioning system of sales of finished products. For the consumer, this is a positive moment in the relatively guaranteed quality of products. Large-scale production is forced to strictly control the compliance of its products with GOST and TU.

Porcelain stoneware, although it does not contain a single grain of natural granite, has properties that are very similar to it. It is made from a homogenized, i.e., a homogeneous mixture, white-burning clay, chamotte (kaolin), sand, feldspars, pegmatids and water. The material is molded and takes the required shape by semi-dry pressing followed by firing. Firing temperature 1200-1300 ° C. It is mainly used where the use of natural stone would be appropriate.

In appearance, acrylic stone is closer to marble, sometimes, in accordance with the design decision, to malachite. The composition includes mineral fillers. ground waste from the production of marble or granite, dyes and acrylic resins. After mixing the components, two technological methods are possible: extrusion or casting. The first way is more productive. The second. historically it was mastered earlier. is simpler in the composition of the equipment and allows you to get a product of almost any shape, and not just molding.

Acrylic stone is often used in kitchen equipment for countertops. an example of extrusion, and in bathrooms. for bathtubs. this is already casting.

Helpful advice from professionals

When cutting decorative stone, there is a set of unwritten rules for good and safe work. Here are some of them:

- work should be done in tight clothing that protects against small particles of material flying out from under the tool, eyes should be protected with glasses, long hair should be hidden under a headdress, closed shoes on the legs;

- cutting stone is a dusty process, so a respirator should be used;

- when cutting flat stones, it is more convenient to use not an angle grinder, but a special machine for cutting tiles with a diamond disc;

- dusting during cutting, significantly reduces the use of water, which moistens the processed stone and the cutting disc;

- mark the cutting path with a thin line, cut so that the marking line remains on the used part of the stone;

- from an angle grinder of three standard sizes: small, medium and large, it is preferable for an employee who does not have sufficient experience to choose a small one. This is easier and, accordingly, safer to work;

- when working with an angle grinder, it is recommended to hold the tool in such a way that if the cutting disc breaks, the debris does not cause injury;

- when working, hold the tool tightly, but not rigidly, as a caught bird is held: “so as not to strangle, but also not to let fly away”.