How to cut drywall on slopes.

DIY slopes from drywall: three main installation methods

The finish of slopes with drywall to make it yourself quite easy. The method belongs to the most popular type of design of the entrance, interior door, as well as for the window.

Installation is simple, and after installing drywall, the openings are beautiful, even and strong. There are other ways of design, but the use of GCL is easier and cheaper, especially if the seam on the window walk the doorway is large.

Properties of drywall

When going to make window slopes from drywall with your own hands, you need to learn about the pluses and properties of the material. The first thing to note is the ability to do work with your own hands, without the use of the help of masters. The final result will please, and meet all the requirements of the repair.

After facing, the material can be sheathed, the opening of the opening and other finishing materials, for example, use staining or pasting with wallpaper. The main properties of drywall when decorating slopes are presented in the table:

| A decent level of sound insulation and thermal insulation: | If you need a window opening and a windowsill, you can not only sew it with a plasterboard, but additionally lay a layer of insulating materials to enhance the design and the quality of isolation. |

| A light weight: | Due to the small mass of drywall for installation, it will not be necessary to use special technologies, installation is carried out on a metal profile from which a metal frame is created or on adhesive mixtures. |

| Ideal plane: | Plasterboard sheets are perfectly smooth, due to which the slopes on the windows and doors will be even, which significantly facilitates the process of finishing with putty, and also accelerates the creation of slopes. |

| Air permeability: | The slope due to its property does not allow to deform, even if there is a strong temperature difference or in the rooms there is a high humidity in the rooms. |

| Environmental friendliness: | Although the drywall sheets can be with additives, the material can be environmentally friendly and slopes can be done in children’s rooms. Drywall does not secrete toxic substances. |

| The minimum amount of garbage: | During installation work, waste, dust and other garbage from drywall material, there is almost no. |

For window slopes from drywall, it is necessary to choose the right sheets that will have certain types of additives and other additives:

- For the design of slopes in an ordinary environment, in a residential building or apartment, standard drywall is used, which can withstand humidity to a mark of 70%.

- When using drywall from the side of the street or in the bathroom and other moist places, a moisture.resistant drywall is used, the material additionally includes antifungal and hydrophobic impurities.

- To reduce the likelihood of fire, for slopes of windows and doors, fire.resistant material is used, in which there are already impurities of mineral wool and fiberglass. This type of drywall sheets is rarely used, but it is very durable in itself.

Important! Drywall. breathing material, due to which it can absorb moisture and, if necessary, release it into the atmosphere without changing the forms.

Is it possible to do on PVC structures?

External slopes are not made from GVL, GCL, even waterproof, however, as well as from gypsum plaster. The reason does not need to be particularly explained: gypsum absorbs moisture and deforms, lags, slides, cardboard bubbles. Such products, unlike cement-sand mixtures and plastic panels, are not designed to withstand the conditions of a street environment.

There are reviews that the GKLV stained with an external slope of about 10 years without much Комментарии и мнения владельцев. Perhaps there are such cases, since the material is protected by the finish, but, it is unlikely that experts will guarantee a quality service in such an environment.

Important! There are two exceptions for gypsum decoration, lime (GVL, GCL, plaster), even if they are positioned as moisture.resistant: outer (street) environment and wet, with increased (above 75%) humidity.

Hypsum plasterboard slopes near the PVC focus are made only by internal. The owners of the premises make such an external (external) decoration only at their risk and fear, it is too highly likely that after a short time it will become unusable. Plastic linings or cement-sand plaster are designed for the street.

Drywall is also undesirable in the rooms not wet, but where there is a strong influence of steam, other fumes, for example, in kitchens with intense work processes (although, if the regime is ordinary, then there are no warnings).

The standards and technical conditions of some large construction organizations specifically prescribe this restriction:

Requirements

When arranging slopes from drywall, the surface preparation is less labor.cost. Let’s list the requirements:

- When landing on the glue, the panel is inserted into the groove in the mounting foam. It is necessary to very carefully remove the protruding tubercle of this substance near the PVC-water frame and make a sample (5 mm) for the stove. Any voids and cracks near the subsequently adjacent end of the sheet should be absent.

- It is extremely recommended to make compensation seams or at least install a vapor barrier membrane. At a minimum, update the foam, choose the old one, more thoroughly and denser to blame the gaps between the frame and the wall.

- The surface of the slope is cleaned of garbage, dust, any adhering substances (old building materials, paint, etc.). It is important to do degreasing if fat spots are noticed or there is reason to assume the presence of such substances in these places. This is especially true if adhesive fixation is used.

- The slopes are influenced by moisture, temperature changes, condensate, therefore the surface is treated with moisture resistant, antiseptic, antifungal primer, preferably in 2 layers. For porous walls, deeply penetrating strengthening means are used.

- For an adhesive method, more desirable alignment of the base with putty (moisture.resistant). But special accuracy, as when finishing slopes by plaster, is not required, the main thing is that there are no irregularities that can raise or lower the plate along its entire length, that is, it is necessary to ensure that its edges are at the same level.

Reference! For smooth walls of the slopes of slopes for drywall, there are no such strict requirements as for plaster. The sheet is installed with some gap filled with adhesive composition, insulation.

Disadvantages, roughness, of course, will not appear. That is, even quite overall irregularities at all will not affect the evenness of the panel, moreover, it will hide them.

Gypsum cardboard sheets are also called giper (GP). Gyproc is not the name of the material, it is a foreign trademark of a manufacturer using its technology, sometimes it is considered better, but it is a separate topic, for example, the same Knauf is sometimes better.

Why it may be required?

The need to cut a drywall sheet during the construction of the walls is usually due to the presence of angles, communications, sockets, switches and other obstacles that interfere with the successful installation of sheets. Also, the reason may be the desire of the owner of the object to “dilute” the standard of the partitions, adding curly lines to the directness of the surfaces.

In order to cut a drywall sheet without any problems exactly according to the specified sizes, the following tools will be required:

- Knife. The simplest and cheapest option is a universal installation. However, to improve the quality of processing, it is recommended to choose a special tool: a knife with a trapezoid or disk blade.

- Hacksaw. With its help, holes and figures of different complexity are cut in the sheet. The best option is a scabbard for metal with a thin blade.

- Electric. The best choice for drunk rounded figures. When using a metal for metal with small teeth, you can exclude the risk of chips on the ends of GKL.

In addition, it should be noted an electric drill, which allows you to cut holes in the drywall cavity without unnecessary problems. If large gaps are needed, special nozzles and feathers will be required.

Important! For cutting GKL, it is not recommended to give preference to circular saws. When using it, a large cloud of gypsum dust is created and all this is accompanied by a powerful noise.

Standard tools are doing well with their task, while the cutter experiences much less inconvenience, so it is better to dwell on the list indicated above.

What other devices are needed?

In addition to cutting tools, in the process of processing sheets of drywall, other devices may be required. For example, for applying markings to the material you will need:

In order to qualitatively process the edges of the GCL after completion of work, there is a need for shirts: pendant and to remove the chamfer.

When using tools for cutting, do not forget about protection. Before work, it is necessary to prepare glasses and a respirator to prevent dust from entering the eyes and respiratory organs, as well as gloves from hard material so as not to damage the hands with cutting devices.

Marking

The result of the work largely depends on the correctness of the marking. The standard instructions for applying cutting lines on the side of the sheet include the following steps:

Important! When performing marking, it is not recommended to use a handle or markers, since when making an error or after installation, getting rid of them will not work. It will be possible to erase such marks only when using potent fluids, which can adversely affect the characteristics of GKL.

The main technological techniques for the cutting of drywall and processing of workpieces

The cutting of drywall itself is completely simple. But in order to work it was convenient, and the marking and cuts are accurate, it is necessary that the room where the cutting passes is well.lit and quite free.

The main technological techniques for cutting drywall sheets and processing of workpieces are shown in the instructions below:

Several useful tips from experienced masters

I would like to give some tips that will help to cope with the task without making incorrigible errors.

- Do not cut drywall with a “corner grinder”, since there will be not only a lot of noise, but also a cloud of gypsum dust, which will add problems with cleaning the room. And there is no sense at all in this approach, to be honest.

- If it is necessary to use a hammer when cutting the material, you can use only rubber. kiyanka, since a metal tool can seriously damage drywall. And, of course, carefully measure the force of strokes.

- So that there are fewer Zazubrins along the cutting line on the edges of the sheet, it is recommended to be a hacksaw or a knife at a right angle. the lower the slope of the blade, the larger the rags of cardboard will be obtained.

- All basic cuts are made before fixing the material on the crate. Since if the cut is made unsuccessfully, you will have to replace the sheet with a new one, and the spoiled can be used for inserts. The exception is windows and openings. it is better to cut out at the installation site, after fixing on the frame.

- It is not recommended to cut complex drawings with thin partitions in drywall in drywall, for example, openwork nets, since the material is quite fragile.

- If a whole sheet is cut, then most often this process is carried out on the floor. After the cut is made, the beam is placed on its line under the drywall. Then you need to press on both parts of the canvas, which will easily break on the cut line.

for a knife for drywall

From the above information, a logical conclusion suggests itself that there is nothing particularly complicated in the process of cutting drywall sheets. And anyone who has no experience in building an amateur can easily cope with this work. If there are any doubts, then you can try your hand at a small piece of material and make sure how simple everything is if you follow technological recommendations and wield a quality tool.

Find out how to make an arch from drywall with step.by.step instructions, from our new article on our portal.

At the end of the publication. a video in which masters clearly demonstrate the techniques of cutting drywall.

Instruments and consumables for installation

In order for the process of designing a window structure to go high quality, it is necessary to prepare the following tools:

- spatulas of several sizes;

- Construction knife;

- hacksaw or electric jigsaw;

- marker or construction pencil;

- roulette or other measuring tool;

- brush or roller for primer;

- The drill is nozzle.

- drywall (sheets);

- mounting foam;

- water;

- metal profiles;

- primer mixture;

- fasteners;

- supports;

- glue.

note. You will also need materials for thermal insulation of slopes.

Features of the installation

The process of arranging window slopes using drywall can be performed in several ways. There are also differences in the installation of cladding from the inner or outside of the structure.

Finishing inside

Sheets 1.2 cm thick are used inside the room. In rooms with high humidity, it is necessary to use a moisture.resistant appearance. Regardless of the decoration method, there are several actions that are performed in any case. For example, the preparatory stage:

- It is necessary to prepare the workspace. To do this, you need to remove furniture or other items that are near the window. If it is impossible to remove, then carefully cover from dust. Then clean the surface of the window opening of debris, dust, dirt and moisture. Clean everything with a brush and rinse with water.

- The purified dry base is thoroughly disconnected.

- Make measurements. It is recommended to measure the depth of the opening in each plane twice to exclude errors. In case of divergence of values, it is necessary to take the largest of them. The panels should be the same size.

- Perform the cutting of the material. Transfer the obtained dimensions to the GKL plate, draw a fishing line for a trimmer of cutting. Attach a ruler to it, draw a knife. Put a wooden beam, deliver several strokes along the edge (neatly) to break off the desired part. Cut the irrigation or hacksaw. Cut the bottom of the cardboard with scissors.

Then you can go directly to the installation, having previously selected one of the ways:

Adhesive method

The method looks very simple to execute, but requires attentiveness, accuracy and accuracy. It is recommended for those cases when it is necessary to maintain the initial size of the opening.

- Smear with glue sheets of GKL.

- Squeeze the element to the surface of the slope.

- Fix the panels using spacers installed on the floor or window sill.

- Full joints with an acrylic sealant, staining it in the desired color.

Pros. the speed of work, a minimum set of materials, before the final painting, it is enough to apply a layer of putty. Minus. you need to definitely follow the angles of inclination when stickering strips.

Using the frame

The technique will make the surface very practical:

- First should make a crate. For this, wooden bars or metal profile are suitable.

- From them cut the segments in accordance with the dimensions removed.

- Install the frame in the opening, insulate mineral wool.

- Squeeze the GCL sheets to the crate and fix with self.tapping screws.

Important! Self.tapping screws must be twisted without deepening.

This method is suitable if further cladding is carried out along with adjacent walls.

How to make slopes on drywall windows:

On the mounting foam

A very popular way thanks to the speed of work and simplicity. Foam can also be used when sealing small gaps. It is important not to make a mistake with the amount of material. When expanding foam, the deformation of the GCL sheets can cause deformation.

- Prepare the work surface.

- Shake the balloon with foam (it is better to take a design with a gun).

- Apply the composition to the back of the glued strips.

- Press the stripes to the slope and immediately tear back (traces of foam should remain on the surface of the opening).

- After 10 minutes, finally put the stripes.

There is a procedure for mounting the strips. first vertical, then ceiling (horizontal) and at the end the last vertical. Foam will freeze in a day. Then you can proceed to the finish of the slope. In this version, the focus performs the functions of glue and insulation.

Откосы из гипсокартона своими руками. Все этапы. ПЕРЕДЕЛКА ХРУЩЕВКИ ОТ А до Я #15

For putty

This method is considered the most reliable, it makes the slopes stronger.

- Prepare the surface.

- On the wrong plane of the sheet of GKL apply the solution.

- Moisturize the base of the opening with water.

- Attach a drywall strip and install spacers.

Important. Full hardening occurs in two days, then finishing is performed.

Outside

The installation process is not radically different. The street uses the mounting method for the frame. First you need to take measurements, prepare the surface and cut the sheets in size.

The mineral wool works well as a heater, and the surface of the installed slopes must be well plunged into 2-3 layers.

Then polish the finish layer, gnaw and paint.

Making slopes from GKL

The manufacture of slopes consists of such stages: preparatory, directly installation of drywall panels, finishing slopes. This article will talk about how to make slopes from drywall with your own hands and without much costs.

How geometrically correct the window is the opening of this stage depends on this stage. And this can significantly improve or worsen the appearance of the room.

Measurements of window opening and cutting drywall

It is very important to make the right window measurements. The window opening is neatly measured, it is advisable to make two measurements of the depth of the opening on each of the planes in order to make sure they are even. If not, then the width of the slope should be taken equal to the most great value. The width of all panels should be the same.

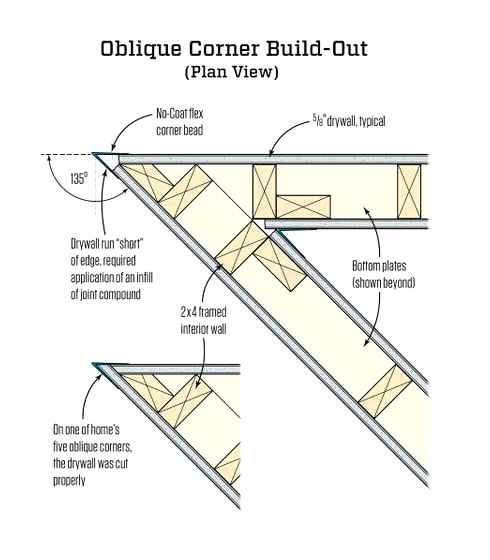

If the slopes go at an angle, then these corners should be equal on two sides. For the convenience and accurate installation of side panels, you can make a special template of this angle from drywall or polystyrene.

In order not to miss the size, the preparations of the panels can be made more than the width of the slope and cut it already in the place after installation. But, if the inner wall is curve, it is better to make the exact dimensions of the width of the slope. They will then serve as beacons to align the wall around the opening.

Pruning of excess drywall in place: with a knife we make an incision along the wall

Pressing slightly, bend the drywall: cut the paper with a knife on the back

In order to carefully make the upper angle of the slope, the upper panel iset on the side panels.

Preparation of window opening

Cut the mounting foam with a knife, which goes beyond the plane of the window frame. Clean the surfaces from the residues of foam, old plaster, paint. Be sure to get the plane of the walls for better stage with glue.

Installation of slopes

There are three main methods for installing slopes from GKL.

The first method is the use of an L-shaped profile to adjust to a plastic frame

The first method uses a plastic L-shaped profile. It is attached to the edge of the frame with self.tapping screws.

L-shaped plastic profile is attached to the frame. Self-tapping step 150-200mm

To fix the drywall sheet in the profile, squeeze the sealant. On the slope from the side of the window is attached (glued) insulation. It is convenient to use mineral wool, but you can take foam or polystyrene, giving them the necessary shape.

Glue for drywall is applied to the other part of the slope. Drywall is inserted into the profile and pressed to the edge of the slope. Tapping the panel, achieve its correct location. Check the level of installation with the level.

It is recommended to start with the top panel. For a more correct installation of the upper sheet and its fixation on the lateral surfaces, you can set special beacons and latches. You can fill the guide rails on the wall, which will serve as a template for the correct placement. During the staining of the glue under the panel, put supports. For better fixation, you can fix drywall to screws.

Side panels are installed similarly. A plastic profile is put on the lower edge of the side panel, so a neat joint with a windowsill is obtained.

The second method is direct adjustment

In this method, drywall starts up for the profile of the frame. For ease of installation of the sheet, it is recommended to make small grooves in the mounting foam, into which drywall will be inserted. The rest is similar to the 1st method.

Third method. installation on the mounting foam

Sloping can be “put” just on the mounting foam. Thus, the foam will serve as glue and insulation. This is appropriate if the gap between the frame and the wall is small and the slope itself is shallow. You can also replace mineral wool with foam. When planting a slope on a foam, it must be borne in mind that it has the ability to expand and correctly dose its number when damping. To fix the panel in this case, it is better to fix it on screws.

Tip: Before applying foam or glue of the surface of the wall, it is recorded with water.

Materials and tools:

Gypsum cardboard sheet

For decoration of slopes with drywall, the sheets can not be bought, but use scraps left after, for example, devices of partitions, leveling walls or manufacturing a suspended ceiling.

Glue for drywall

Plasterboard sheets can be glued to any construction mixture sold in a dry form, on the package of which there is a mention that this mixture can be used to glue drywall sheets. Typically, such mixtures are sold in packages of 25, 30 or 50 kg, but recently you can find packages and 5 kg. In addition, the finish gypsum putty can be used as glue for drywall, if the volume of work is small and the thickness of the adhesive layer is less than 2 cm. And drywall can also be glued to the wall with cement.containing tile glue. However, tile glue, as well as the finish gypsum putty, is undesirable to apply more than 1.5-2 cm. It is quite difficult to calculate the required amount of glue, and 50 and 15 kg of glue can leave for one window or door. Why is this so, it will become clear from the further description.

Halog

Drywall. One of the few building materials for cutting which is enough any sharp object. This is usually done by a simple stationery knife:

But no one forbids the use of an electrician or a hacksaw on wood for this purpose, though garbage and dust will be much larger.

Glue

Despite the apparent insignificance, this is a rather important point. The container should be convenient to knead the glue. If there is no desire to buy a bucket for 8-12 for this purpose in the construction store, then you can use the old metal basin in which the grandmother cooked jam (but the granny does not need to talk about it).

Glue

But the spatula can be almost any, t.e. have a width of 4 to 10 cm and can be not only metal, but also wooden or rubber. With small volumes of work, the spatula is also used to knead the glue, with large volumes it is better to use a drill with a nozzle.

Building level

for marking drywall and checking the correctness of plasterboard setting. In principle, when decorating slopes with drywall without a building level, it is quite possible to do without a flat wooden bar or one of the metal profiles for drywall. But working with the level is still more convenient.

Primer

By and large, instead of primer, you can use ordinary water. 20-30 years ago, when performing plaster work, this was quite enough, however and the result of this we can observe in photo 1. Club of plaster with brickwork was very weak, as a result of which the plaster was dismantled when the old wooden doors collapsed. Glue for drywall and even starting gypsum putty have much more adhesion than cement-sand plaster, however, the use of primers when working with drywall has already become a common place. You can apply a primer to the surface as you like, at least with a brush, at least a roller, at least a spray gun. I usually use a trimmed plastic bottle and an old shabby brush for this purpose.

Complexation sequence:

At first, an excess foam is cut off with a clerical (wallpaper) knife. The more acute the blade of the knife, the easier it will be to cut the foam, however, when pruning the foam, the tip of the knife will definitely touch the brickwork and dull from this, so the tip must be periodically cut off for better cutting of the mounting foam. At the same time, the length of the blade decreases and it becomes not so convenient to cut off the foam, especially if the foam has performed a lot, but still, one blade is usually enough to cut the foam on one door or window opening. It is advisable to trim the foam no earlier than a day after the foam is blown away. Of course, you can cut the foam and 5-8 hours after the blowing, but the thicker the layer of foam, the more likely it has not yet froze, and therefore the risk of getting into an still unforgettable foam, spoil the blade and cowing your hands very high. In this case, foam was blown by professional installers, which means that the foam was consumed minimally and there was nothing especially to cut off here (see. Photo 1).

After that, a primer is applied to brickwork to improve adhesion (sticking). While the primer dries, you can cut drywall and knead the glue. In this case, it was necessary to block the distance of 5-6 cm, so the drywall was glued in two layers (just so convenient for me), but no one forbids to stick drywall and in one layer. For the first layer, taking into account the fact that the door mount (see. Photo 1) prevented the plasterboard of the plasterboard, and pieces were cut. For the first layer, it is not necessary to try hard when cutting drywall, all the same, the second layer will block everything. After gluing the first layer of drywall, the slope looked like this:

Photo 2. Type of slope after the sticker of the first layer of drywall.

Gluing drywall into two layers undoubtedly requires more time, but this method has advantages. When you glue drywall with one layer, the glue should be more thick with a thick layer thickness 3-5 cm, which means that it will be more difficult to set drywall into a design position. In addition, the concept of “slope” implies that the angle between the surfaces of the wall in this place will not be straight, but dumb, therefore, to create such a corner, a different thickness of the adhesive layer will be required, and this also complicates the work when performing slopes in brick and block houses. Well, the last point is in favor of 2 layers: drywall sheets are not always perfectly even, and if cutting plastone trimming is used not in proper conditions for finishing the slopes, then even more so even even more so. Therefore, when the second layer is glued, then to put a drywall to the design position, sometimes you have to additionally fix the sheets to the wall. If the drywall is glued into one layer, then for fastening you have to drill holes in the wall with a with a pen and driving into these dowels, and when the first layer of drywall is already glued on the slope, then the holes are enough in the drywall sheet of the second layer and you can screw these sheets with screws to the sheets to the sheets first layer.

In order for the glue of the first layer to dry from 5 to 12 hours, depending on the thickness of the adhesive layer. At this time, you can put up the remaining slopes, well, or stick drywall into one layer on these slopes. After the glue of the first layer has dried, you can glue the second layer. It is advisable to cut a drywall sheet for the second layer more carefully, then this will save time on putty and immediately create a slope angle. For the second layer, however, as for the first, the glue is not applied to the excessive, but by the so.called “stands”:

Photo 3. Application of glue for drywall.

This allows you to set drywall to the design position with the least labor costs. The thickness of the rally should be 1-1.5 cm more than the future thickness of the adhesive layer. After the glue is applied to the slope of the slope, a drywall sheet is pressed. The position of the sheet can be controlled by eye, but it is better to use the building level for this (in photography 3. left), profile from drywall or any other even item. As already mentioned, drywall sheets are often slightly curved, the fact is that drywall actively absorbs moisture from the atmosphere, even waterproof, and if storage under the influence of its own weight can be slightly curved. Thus, when gluing drywall, sometimes there is a need to “pull up” the sheet to the wall a little:

Photo 4. Setting a plasterboard sheet by level.

In the photo 4 you can see a black screw hat (near the level), with the help of which the sheet was put to the design position. Another self.tapping screw was screwed from below, but it is not visible in the photo. Of course, you can seer the slope at once with one sheet of drywall, but in this case, gypsum plasters were used to finish the slope and therefore the second layer consisted of two pieces of drywall. The final type of slope before putty was this:

Photo 5. Slopted by drywall before the finish putty.

As you can see in photo 5, I had to stick several pieces of drywall and on the main wall, so that later there was less work when putting down.

In panel houses, where the slope shape is immediately set by the surface of the reinforced concrete panel, usually one layer of drywall is enough. How to stick a drywall on a slope in one layer, you can see in the next

When replacing old balcony wooden double doors with a box of a box of about 130 cm, sometimes there is a desire to save, t.e. Put an ordinary door with a box width 80-100 cm. At the same time, the remaining space can be laid with brick or various kinds of blocks, but it is much easier and more efficiently and more effective in terms of thermal insulation by gypsum plasters. True, in such cases you can’t stick drywall, here you have to make a frame:

What you need to work?

First of all, you need to prepare the drywall sheets suitable for such work. The best option is moisture.resistant material 12.5 mm thick.

Drywall End Joint Finishing Hack for a Smoother Ceiling

If the drywall mounting method is selected on the frame, buy the corresponding UDs and CD profiles. Perform profile fixation using screws and dowels. In the case of using the pasting method, buy a special glue for drywall. 1 m 2 gypsum cardboard leaves an average of about 5 kg of adhesive composition. The specific value is determined individually in accordance with the brand of the binding agent and the state of the cut surface.

UD and CD Profiles glue for drywall PERLFIX 30kg

Additionally, you will need a sealing tape.

The set of tools is standard. Prepare the following devices:

- Corner grinder. Need to cut a metal profile. In the absence of a corner grinder, you can do with scissors for cutting metal;

- Peorator;

- knife for cutting sheets of drywall;

- metal square;

- measuring roulette;

- building level.

Preparatory events

First of all, remove all the measurements. In the process of preparing sheets of material for decorating slopes, leave minor allowances.

It is extremely difficult to provide an absolutely even base in places of installation of the finish, so it is better to take material with a margin and further cut off the excess than to find that parts of the sheet are not enough to cover the entire surface of the slope.

Regardless of the selected method of finishing slopes with drywall, perform preliminary preparation of the decorated surface. Be sure to delete the existing layer of plastering coating.

In the case of applying the laying method, the surface must be thoroughly leveled. To do this, you can use ordinary putty.

When using the frame method, in most cases, you can refuse preliminary leveling. It is enough to get rid of the crumbling sections of the plastering coating.

Process the base of the antifungal agent.

After performing all preliminary measures, you can proceed directly to the fastening of drywall sheets according to the selected method.

How to cut drywall?

Different operations may require their improvised means. Since it can cut drywall with several tools, it is better to consider the use of each of them separately. The main conditions are a continuous incision with the subsequent collapse. But this is not always possible to do, especially if the fishing line for the trimmer of the cut is very long.

Installation knife

This simple tool is ideal for the same simple work. It is used to cut large longitudinal pieces of drywall sheet. After the measurements made on the material, draw a fishing line for a trimmer for a cut. Then apply a ruler or profile, firmly fix the tool on the line with the hand, carefully cut the cardboard, deepening (maximum) by half a centimeter.

If the cutting occurs on the table, then the plate is shifted so that the incision goes beyond the edges of the countertop 10-15 mm. On the protruding part of the sheet, they are neatly tapped from below until the core breaks. Then the plate is turned over with the other side, the material is cut into the fracture line. To get the perfect docking of elements, the edge is processed with a shirt.

There are several knives suitable (or special) for cutting drywall sheets:

- Universal mounting knife. the most affordable option. It is simple and convenient to operate. It is possible to install blades of various thicknesses. Cons. slight reliability, blades that go very quickly.

- A plasterboard knife with a trapezoidal blade. This is already a professional who has an ergonomic handle, a non.combustible blade. The lack of the best “gypsoprofi” is “indecent” high price, however, even the most budget models of such knives guarantee the quality of the cut.

- Disk blade. These knives are favorites, since cutting cardboard is much easier for them. Any type of work is possible: both simple cut and curved. The pluses of knives. a reliable blade, the same depth of penetration along the entire length.

- Flight for drywall. This design has two discs that allow you to cut the sheet simultaneously on both sides. The peculiarity is that this tool is used only to obtain small stripes, their maximum width is 120 mm.

- Double.sided magnetic cut. Blade Runner. This is a leader if you evaluate the tools in speed and convenience. Therefore, he is in high esteem with professionals. A knife consists of two separate parts that are held by magnetic clamps. The disadvantage of the miracle cut is one: this is the price.

The most undesirable option is the clerical knives, too low-power and fragile (flimsy) to work with any sandvich material. Therefore, before the choice of the model, you need to evaluate the front of work, the forms of future blanks, the necessary accuracy of connecting elements. Very expensive cutting tools for beginners are not the best choice, since in this case, buying itself is unlikely to justify itself.

Hacksaw

This tool cut holes. square or rectangular. The thinner its canvas, the more carefully the work will turn out. To cut the “window”, on the back of the drywall, the form of the opening is first marked using a pencil and ruler. In one of the angles of the drawn figure, a hole of such a diameter (8-10 mm) is drilled with a drill so that the canvas of the hacksaw can be freely placed in it.

Then the operation is repeated in the remaining corners. The hole is cut out with a hacksaw, which is necessarily kept so that the blade is always perpendicular to the surface of the sheet. In this case, the edge will be almost perfectly flat. After cutting the part of the edge of the drywall is aligned with a shirt. If the hole is too small, then it is treated with a file.

Lobby

This electric tool is considered the best assistant for working with GKL, since cutting drywall with a jigsaw is faster and more convenient. Another advantage is universality. Having one electric one in hand, you can cut holes of any shape. Thanks to the special sole holding the blade perpendicular to the sheet, the edges are almost perfect. Minus of the power tool. dust flying around the room.

The stove is drawn, put it on two stools so that the place for the cut is exactly between them. The electric canvas is installed, not including. Begin to cut along the line, acting smoothly, slowly. To cut a large round or oval figure, first also used a drill, which makes a hole for the canvas of the jigsaw. The edges, if the work is not very large.scale, after this tool you can easily be cleaned even with sandpaper.

For door or window openings, it is required to cut drywall with the letter “g”. In this case, it is advisable to use two tools at once. The short part is sawn with a hacksaw, a long. with an assembly knife. In this case, it is possible to work with a sheet already fixed in place.

Round holes for a socket or a circuit breaker are made with a drill (at medium speeds) with a nozzle, an electrician or a narrow hacksaw. The first option is preferable, since the operation takes place as quickly as possible. The nests are also advised to cut out after the installation of drywall on the frame.

Recommendations for the success of the operation

Since the first pancake often turns out to be a lump, you need to know all the pitfalls that may meet on the path of a novice “drywall”.

Basic

- Strong and even base. the ideal for working with GKL. However, for such a overall product, it is often unattainable. In this case, the “improvised” furniture becomes an assistant. tables or stools. If the latter acts in the role of the working surface, then it is necessary to ensure that the distance between them does not exceed 300 mm. Otherwise, any pressure can lead to the fact that the sheet will crack.

- When working with a knife, it is necessary to monitor the pressure of the blade on drywall. Excessive pressure is useless, since the goal of the operation is one. to make only an incision. cut only one layer of GKL. Trying in one fell swoop to “end” with a whole sandwich. You can probably do this, but the edge of such a blank will be very inaccurate. Another result of the use of the “heroic power”. a blunt blade.

- Cut processing also does not imply a strong press of a rubbish. It is enough to remove the irregularities resulting from cutting. Removing the chamfer at the joints of the GCL, which become partitions, usually do after installation on the frame. Acting otherwise, there is a chance to damage the edges of fragile material.

- If there is a drill, but there is no crown of a suitable diameter, then the hole for the switches and sockets is cut out differently. First, the circle is outlined by the circul. Then a large number of holes of small diameter are drilled along the drawn line. Then the circle is knocked out or cut out, and irregularities are eliminated.

The last option with knocking out guarantees ugly edges, they will have to put them in order for a long time. Another method of obtaining a round shape is the use of a jigsaw or a hacksaw after drilling a hole with a hole for their canvas.

Additional

- It is better to cut a whole drywall sheet on the floor. First, a cut on the material is made on the horizontal surface, then the beam is laid under this line. In this case, they press immediately on both parts of the sheet. So it is easier to break it strictly by cutting.

- Corner grinder is not the best tool for working with GKL, since cutting drywall with this tool does not make a big sense. The master will receive a room with clouds of gypsum dust at the output, and the “loudness” of the corner grinder is unlikely to appeal to the households, she will not please the neighbors.

- If the use of stubborn material requires the use of the hammer, because the blows do not help with the hands, then the best option is rubber kiyanka. In this case, the master will have little chance of damaging drywall, if you do not apply excessive strength.

- Elements designed for door and window openings, as a rule, are already cut out on fixed GCLs. Circles for switches and outlets too. In other cases, cutting of blanks is recommended to be done before installation.

- It does not matter which side of the sides to start cutting drywall. But some masters recommend marking and start working on the side that will come into contact with the frame, wall or ceiling.

GKL cutting is not too puzzling, since cutting drywall is quite easy. Any beginner master can cope with this work if he has a minimum set of tools, as well as the desire to do everything high.quality, extremely neatly. But practice will not hurt. When there are doubts, they will only be dispelled by training in a small piece of material. If there is a desire to see the techniques of cutting with “strangers”, then you can get acquainted with the video: