How to Cut Foam Blocks at Home

Gas silicate blocks than cutting. A hacksaw, a reciprocating saw with a blade on aerated concrete, a saw

How to Cut Aerated Concrete Blocks. Xl-INFO.Ru

To build a house, they often began to choose such a building material as aerated concrete. However, how to saw aerated concrete blocks? These are porous, alas, strong blocks, which include cement, lime, quartz sand, gypsum stone, aluminum powder and water. A lightweight cellular material emerges from the combination of these components. When laying the walls, the blocks are chosen strictly in size, so as not to violate the strength and thermal insulation of the wall.

The composition of aerated concrete blocks includes: cement, lime, quartz sand, gypsum stone, aluminum powder and water.

Aerated concrete is simply processed, because aerated concrete can be cut at any angle. To get blocks of the right size, use various sawing tools. Aerated concrete is a fairly strong material, because simple saws are not suitable for it. It is best to use a tool with hardened blades and special solders from win. There are a number of types of such tools that differ in cutting methods.

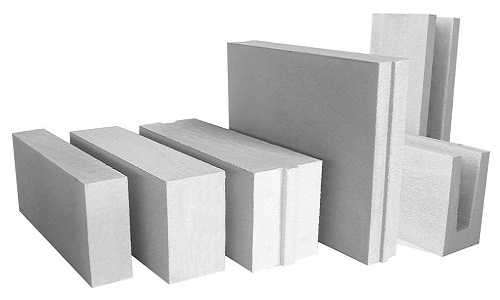

Varieties of aerated concrete blocks.

Aerated concrete is cut with a hand saw. Its design is the same as a conventional saw for wood, alas, the thickness of the blade is much more than simple, so that when sawing hard blocks to prevent deformation. Such a saw is mainly used when the volumes of work are small differently when laying corner places. It is also convenient to use it to fit the door and window gaps. For convenience, before cutting on the block using a ruler and a pencil outline the cut line.

The cutting blade is certainly made of hard metal. If the canvas is long, blocks have the option to cut both across and along. The teeth should be rapid as it is also called from a hard alloy of cermets. If there is a hard alloy soldering on each clove, this will greatly facilitate the work with it. Such a saw will have greater wear resistance, it will better bear the load when cutting aerated concrete. You will like such a saw with one handle or, for greater convenience, has two handles.

How to quickly cut a gas block?

This is also a hand saw, but it works from the mains. It looks the same as an electric drill, in which the cutting parts are required to be oriented forward. The blade travels in a straight line forward.

Properties of aerated concrete blocks.

Such a tool is used for medium volumes of work, special flat parts are used. To obtain a flat strip of cut it is also planned before cutting.

The stroke frequency during operation reaches 3 thousand per minute. The stroke length of the saw sometimes reaches 32 mm. You need to take care of it in the same way as for an ordinary electric saw. The saw blade has a special hole in which engine oil is sometimes dripped. The saw is cooled through the ventilation holes that are in the case. Such a tool allows you to quickly and correctly saw aerated concrete blocks of various sizes.

This is a multi-cutting tool, which is a radial ribbon of steel with teeth on one side. Such a tape is used in a special tape-saw type machine. Such a machine allows you to cut aerated concrete rather in comparison with a hand saw, alas, its price is high. The canvas is made of hard metal, the height of the working surface of the machine is adjustable. The tension of the cutting blade occurs automatically, which increases the accuracy of the cut.

The cutting blade is guided by ultra-precise rollers. There is an option to work continuously without stops, because the waste is rapidly removed through the lumen in the machine. The cutting blade is of course simple and quick to change if necessary. The machine is easily transported using wheels. For greater stability of the machine during operation use stops.

Scheme shtroboreza for cutting aerated concrete.

When cutting blocks from aerated concrete, it is very difficult to get a completely flat surface. To level the surface very much, a special plane is used when laying the walls. Segments from a saw with small carbide teeth are inserted into its wooden base. The segments are installed at an angle, which allows them to painstakingly clean the bulges on the blocks. If the teeth are dull, they can easily be sharpened using a trihedral rattle. Use it on each row of masonry, with all this there is an option to reduce the consumption of adhesive.

Cutting aerated concrete blocks of 10 centimeters

Shtroborez is another tool used to build a house from aerated concrete blocks. Thanks to its use, various grooves and grooves can be easily made in a porous material. In these grooves then they will hide the wiring or the pipeline. The tool has a double-sided cutter, bolted to the hand holders. The pressure on the cutters is distributed moderately, by 2 handles, and the work is performed faster, for sure.

Before cutting aerated concrete blocks, make the necessary measurements and use a ruler to mark the pencil using rulers on the aerated concrete block. For convenience, when moving the tool, a rail is placed under it. The cutting element is made of hard alloy with an additional diamond coating.

Stroboreza are manual and electronic.

The electronic tool has a rotational body with several incisors. You will like the rotary disk with a diameter of up to 150 mm; it is fixed in the same way as on a grinder. In order not to make great efforts, there are rubber rollers that move along the working surface. The rotation of the cutters occurs with the help of an electric motor, which is possibly of different power.

What is needed, the main tools with which you can immediately cut aerated concrete are considered.

Now there are more new tools. Alas, those listed are already tested and reliable. Using them, you can not doubt the high-quality result. The main thing is to make the right choice of a tool before cutting aerated concrete blocks.

How to Cut Foam Blocks at Home

How to cut aerated concrete blocks: the choice of tools

When building a house, they often began to choose such a building material as aerated concrete. But how to saw aerated concrete blocks? These are porous, but durable blocks, which include cement, lime, quartz sand, gypsum stone, aluminum powder and water. A lightweight cellular material is obtained from the combination of these components. When laying walls, blocks are chosen strictly in size so as not to violate the strength and thermal insulation of the wall.

The composition of aerated concrete blocks includes: cement, lime, quartz sand, gypsum stone, aluminum powder and water.

Aerated concrete is easily processed, so aerated concrete can be cut at any angle. To get the blocks of the right size, use all kinds of cutting tools. Aerated concrete is a fairly durable material, so ordinary saws are not suitable for it. It is best to use a tool with hardened blades and special victitian solders. There are several types of such tools that differ in cutting methods.

Hand Saw Application

Varieties of aerated concrete blocks.

Aerated concrete can be cut with a hand saw. Its design is similar to an ordinary saw for wood, but the thickness of the blade is much larger, so that when sawing hard blocks to prevent deformation. Such a saw is mainly used when the volume of work is small or when laying corner places. It is also convenient to use it to fit the door and window openings. For convenience, before cutting on the block using a ruler and a pencil outline the cut line.

The saw blade must be made of hard metal. If the canvas is long, the blocks can be cut both across and along. The teeth should be rapid or carbide. If there is a hard alloy soldering on each clove, this will greatly facilitate the work with it. Such a saw will have greater wear resistance, it will better bear the load when cutting aerated concrete. Such a saw may be with one handle or for greater convenience may have two handles.

Reciprocating saw

This is also a hand saw, but it works from the mains. It looks like an electric drill, in which the cutting parts are directed forward. The blade travels in a straight line forward.

Characteristics of aerated concrete blocks.

Such a tool is used for medium volumes of work, special flat parts are used. To obtain an even cut line, it is also scheduled before cutting.

The operating frequency reaches 3 thousand per minute. The stroke length of the saw can reach 32 mm. It is necessary to take care of it in the same way as for a conventional electric saw. The saw blade has a special hole in which engine oil is dripped from time to time. The saw is cooled through the ventilation holes that are in the case. Such a tool makes it possible to quickly and correctly saw aerated concrete blocks of different sizes.

Band Saw

This is a multi-cutting tool, which is a circular ribbon of steel with teeth on one side. Such a tape is used in a special tape saw machine. Such a machine allows you to cut aerated concrete much faster compared to a hand saw, but its cost is high. The canvas is made of hard metal, the height of the working surface of the machine is adjustable. The tension of the cutting blade occurs automatically, which increases the accuracy of the cut.

The cutting blade is guided by ultra-precise rollers. You can work for a long time without stops, as the waste is quickly removed through the lumen in the machine. The cutting blade can be easily and quickly replaced if necessary. The machine is easily transported using wheels. And for greater stability of the machine during operation, stops are used.

Planer and Stroborez

Scheme shtroboreza for cutting aerated concrete.

When cutting blocks from aerated concrete, it is very difficult to get a perfectly flat surface. To level the surface as much as possible, a special planer is used when laying the walls. Segments from a saw with fine carbide teeth are inserted into its wooden base. The segments are mounted at an angle, which allows them to thoroughly clean irregularities on the blocks. If the teeth are dull, they can be easily sharpened with a triangular file. Use it on each row of masonry, while it is possible to reduce the consumption of adhesive.

Shtroborez is another tool that is used in the construction of houses from aerated concrete blocks. With its help, you can easily make different grooves and grooves in the porous material. In these grooves they will then hide the wiring or piping. The tool has a double-sided cutter, which is bolted to the hand holders. The pressure on the cutters is distributed evenly, due to two handles, and the work can be done faster, with high accuracy.

Before cutting aerated concrete blocks, make the necessary measurements and use a ruler to mark the pencil using a ruler on the aerated concrete block. For convenience, when moving the tool, a rail is placed under it. The cutting element is made of hard alloy with additional diamond spraying.

Stroboreza can be manual and electric.

The electric tool has a rotational body with several incisors. The rotary disk can be up to 150 mm in diameter, it is fixed in the same way as on a grinder. In order not to exert much effort, there are rubber rollers that move along the working surface. The rotation of the cutters occurs with the help of an electric motor, which can be of different power.

So, the main tools with which you can cut aerated concrete as quickly as possible are considered.

Nowadays, more and more new tools are appearing. But those listed are already verified and reliable. Using them, you can be sure of a quality result. The main thing is to make the right choice of tools before cutting aerated concrete blocks.

How to cut aerated concrete blocks, aerated concrete?

Block cut with a hand saw

Aerated concrete is a new generation of building material, which is intended for the construction of durable and warm buildings with minimal labor and costs and in the shortest possible time. To obtain a lightweight cellular aerated concrete block, aluminum powder, lime, cement, gypsum stone and quartz sand are used. Depending on the construction project, blocks of various sizes are used, which are cut with tools with special victorious solders and hardened blades. In this article you will learn how to cut aerated concrete blocks.

We cut aerated concrete with a hand saw

For small amounts of work, a hand saw with a thick blade of hard metal alloy with teeth made of cermet alloy or rapid is used for cutting blocks. To make a high-quality smooth cut of an aerated concrete block, in addition to a hand saw, a corner is used.

On the block, the required fragment size is marked, then a corner is applied and the block is cut. To ensure good adhesion with glue, the cut side is treated with a grinding grater. For convenience, choose a saw with a long blade and with two handles.

We use a reciprocating saw

During construction work of medium volumes, a reciprocating saw is used instead of a hand tool. This is almost the same hand saw, only with an electric motor. The principle of cutting a block is no different from working with a conventional saw. Marking of the cut lines is made, a corner is set and a cut is carried out. It’s worth noting. That for the proper operation of this tool, you need to periodically add engine oil to a special hole.

Aerated concrete cutting with a band saw

With large volumes of construction work, the use of simple tools for cutting aerated concrete blocks becomes ineffective. Therefore, tape-type machines with circular steel tape with teeth on one side are used. Automatic stretching of the working blade significantly increases the accuracy of cutting of building material. Ultra-precise rollers are used to guide the cutting blade.

Stroborez for cutting blocks

How to cut aerated concrete, if you need to make an incomplete cut, and the usual shallow groove or grooves? For these purposes, use manual or electric chippers. The double-sided cutter is made of durable hard alloy with diamond coating. The block is marked. To make it convenient to work, a rail is placed under the tool.