How to cut plastic at home

We cut plexiglass with a cutter

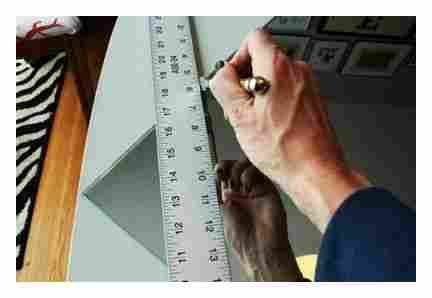

The methods for cutting plexiglass at home can be completely different. Someone uses a hacksaw for metal, and someone uses a cutter. Basically, this tool is a saw with just one tooth. To cut the plexiglass, you need a metal ruler of a certain length. This tool must be placed on the sheet of material where you want to split it. After that, you need to draw a cutter along the ruler.

When the cut reaches ½ the thickness of the sheet, you can stop and then gently break the material. If defects have appeared, they can be smoothed out. To do this, sand the edge of the plexiglass with sandpaper. If desired, the cutter can be made independently from an emery cloth. Some experienced craftsmen use pieces of glass to cut plexiglass. This method requires reliable hand protection.

Plexiglas laser cutting

How are plexiglass products made in production? Typically, a laser is used to cut this material. This is the most convenient method. However, it is simply impossible to apply it at home. Thanks to the thin laser, a precise incision can be made. In this way, even small details of future products are usually cut out. However, this cutting method has certain limitations: the laser beam creates a high stress on the material. In the future, it is simply impossible to glue individual parts together.

Plexiglass products can only be cut in an industrial environment. If necessary, you should seek assistance from the appropriate organization. The main thing. make all the drawings in advance. It is also worth picking up an experienced master.

A hacksaw for metal will help out

If you need to cut plexiglass at home, you can use a metal hacksaw. This is the most affordable tool. However, this method has a serious drawback: the cut site remains rough and rough. To eliminate such a defect, additional processing is required. To smooth the cut point, sandpaper or a file is usually used.

Plexiglass: what to cut?

In some cases, the use of a saw is allowed. It can be tape or disk. The last type of saw is designed for straight cuts. At the same time, the seam is neat and clear. As for the band saw, it is suitable for making blanks. Cutting clear edges with such a tool is unlikely to work. To make the surface smoother, it is recommended to use a cutter.

It is worth noting that this method of cutting plexiglass can be used not only in production, but also at home.

How to make hot knife cutter Acrylic, Plexiglass, Plastic, PVC and Foam Cutter

Special equipment

Plexiglass products are cut with a high-speed tool. This allows you to get an even and high-quality seam. The speed of such equipment can be up to 4 thousand revolutions per minute. After that, the plexiglass undergoes additional mechanical processing.

However, do not forget that this material has a low thermal conductivity. Cutting at high speed can quickly heat up the edges. Some instruments have a Plexiglas mode.

Material features

Not everyone knows what plexiglass is. How to cut it at home and what features does it have? First of all, plexiglass has the performance characteristics of durable plastic, and also looks like ordinary glass. This material is transparent. However, unlike glass, it does not break.

Thanks to these properties, plexiglass has become popular. How to cut it in everyday life? In this case, not everything is so simple. The material itself is quite durable. Plexiglas is widely used. Indeed, in some cases, using ordinary glass is dangerous and problematic. The material can be processed by almost all available methods. However, there are some nuances that should be considered when working with plexiglass.

Plexiglass: how to cut at home

At home, cutting plexiglass is rarely required. Typically, this work is carried out by specialists in the workshops. However, this skill can be useful in everyday life as well. After all, sometimes there is a desire to make a vase, an aquarium or a small decorative table with your own hands. So, the subject of our review. plexiglass. How to cut such material?

Using simple tools

If cutting plexiglass with a laser. is an expensive pleasure for you, then you can cut the material with scrap materials. Very often, a nichrome thread is used for such work. Before starting cutting, it must be heated. This will require a transformer with a power of 24 W.

As a result of simple manipulations, you can carefully cut the plexiglass. The heated nichrome thread simply melts the material. This allows you not only to cut plexiglass, but also to cut curly details.

Also, some craftsmen use a slotted screwdriver. This option is suitable for cutting plexiglass at home. A screwdriver is usually pressed against the material with the butt end. In this case, the tool must be held by the very edge of the handle. After that, the screwdriver blade is heated with a soldering iron, the power of which is 25 W.

The plexiglass should start melting. With the tip of a screwdriver, simply draw the line in the place where the cut should be. After that, the plexiglass breaks easily. To get a straight line, you can use a metal ruler or a hacksaw blade without teeth.

In addition to the above methods, you can cut the plexiglass with a cutter or circular saw. The blade thickness in this case should be no more than 1 mm. It is worth considering that smoke may appear during the cutting process. In this case, the edges of the material often foam due to the increase in temperature as a result of friction. This can be avoided. It is necessary to cool the working surface of the tool.

How can PVC panels be cut

Plastic finishing material can be cut both lengthwise and across. Of course, the main blanks are cross-cut. When it is necessary for the sewn surface to be completely closed, then it is necessary to use a longitudinal cut. Before starting work, it is determined how to cut plastic panels at home or at an industrial facility. The number of blanks required for wall cladding is of no small importance.

Using many years of experience in the use of PVC materials in interior decoration, we highlight what can be used to cut plastic panels:

- construction knife;

- hacksaw for metal;

- Angle Grinder;

- jigsaw;

- cutter;

- hacksaw for wood.

The use of any of these tools will help solve the question of how to cut PVC panels, but each of them has features that must be taken into account when performing work.

Cutter

Such a device is convenient when speed and high-quality cut of the end face of the workpieces are important for solving the problem. The speed of such a tool is high, while the quality is better than any of the ones described above. But, when working, you need to carefully inspect the panel for possible chips and lay it inside out to the cutter, and face down to the supporting surface. This is due to the fact that the cutter can push the surface of the PVC workpiece by 2-5 millimeters.

The tool simplifies and speeds up installation work. Buying a cutter will forever close the question of how to cut off a plastic panel, and other methods will no longer be relevant. When using it, it is important to remember that such a tool will not be able to trim in place with such a tool.

Hacksaw

If, when performing finishing work, the question concerns how to cut the panels exactly, then for such a case, it will be correct to use a hacksaw. When the edge of the panels is hidden from the eye by the starting or corner finishing profile, then a hacksaw is used for wood. If the cut area remains in sight, then use a tool for metal.

When choosing what to cut plastic panels, attention is paid to the convenience of work. When using a hacksaw on wood, the workpiece will vibrate strongly and must be held firmly. And when using tooling for metal, the vibration effect will be little noticeable, but the tool will need to be held almost parallel to the plane of the workpiece. This is due to the thickness of the blade holder, which is larger than the blade.

In both cases, the panel is placed facing the cutting tool so that all chips and imperfections remain on the wrong side.

Construction knife

In any household, you can find a kitchen knife, sharpen it and use it to solve the problem than to cut off a plastic panel. But, to get a high-quality cut, it is better to use a construction or clerical knife. Replaceable blades, which are supplied with the tool, will allow you to get an even, smooth surface. Cutting with a knife is faster than using sawing devices. But, when you have to deal with the honeycomb structure of plastic panels, the use of such a tool becomes inconvenient.

When using a construction or clerical knife, the panel is marked out, then laid on cardboard or the cut part is left hanging. After that, pushing through the front and back sides of the finishing material, they separate the unnecessary parts. If a large area of unclaimed plastic part remains, then it is better to put or substitute a support under it, in order to avoid kinking or skewing the workpiece.

Angle Grinder

To carry out such work, it will be inconvenient to use a large-sized angle grinder, and it is useless. angle grinder of small size with a thin disc for metal (0.8-1 mm), will fit in the best way.

If it is necessary to cut a large number of panels at the same time, they are fastened, markings are applied. The cut is made from the front or back. The end quality is obtained without defects. Such a power tool allows you to cut a panel with high quality or several at once.

Jigsaw

When performing work, the place of the cut is first marked on the front surface, and then smoothly cut to the required size, passing the tool along the marking mowing line. Cellophane or other material is placed under the jigsaw support foot, which will prevent the possibility of scratching the PVC panel. In the case of simultaneous cutting of several blanks, they are fastened with plastic clamps or wrapped with transparent tape. At the same time, it is better to isolate the front surface from the adhesive tape (lay a sheet of paper).

How to cut PVC panels

Among the variety of finishing materials used in construction, plastic panels occupy a separate category. It is a modern coating that is used for interior and sometimes exterior walls. They are made from polyvinyl chloride by extrusion. Before performing installation work, it is important to decide: what is the best way to cut PVC panels. The range of tools and accessories offered on the market is full of offers, both general and special. Among all the inventory, you can choose what will cut the plastic panels.

Basic rules for cutting

So that the efforts on cutting PVC panels are not wasted, and the result of the work meets expectations, experts recommend adhering to a number of rules for working with plastic. These little secrets will help not only to significantly reduce the amount of spoiled material, but also save the master from unnecessary financial expenses and injuries.

When carrying out work in the heated season, do not start cutting panels that have recently been brought into the room. The plastic should naturally warm up to room temperature, which is achieved in at least 12 hours. The fact is that at low temperatures the plastic panel becomes fragile, and therefore it can crack and break off in large fragments.

Regardless of the chosen method of processing the material, it should be placed with its front side facing you, which will avoid deformation of the panel and difficulties during its further installation. When cut from the seamy side, you can find microcracks on the front part, which will manifest itself over time and significantly spoil the interior.

It is necessary to mark in advance the straight line of the planned cut, which can be done with a simple pencil and a stationery ruler.

To speed up the process of preparing the material for installation work, you can cut or saw several PVC panels at the same time. To do this, it is enough to fold them in a pile and create a two-point support. It is best to rest the opposite edge of the stack against the wall, which will help avoid shifting the products, respectively, as a result, parts of the same length will be obtained.

Power tool

For quick sawing of PVC panels, a power tool at hand is best. For this purpose, you can use almost any device, which will help to significantly reduce the time spent on preparing for installation.

Often, cutting is performed using the following devices:

- jigsaw;

- Angle Grinder;

- circulars.

To work with plastic material, it is allowed to use only low speeds, because with significant heating it begins to melt and release fumes that are toxic to the human body, and in this case the cut will turn out to be torn.

Using a jigsaw will help make the process of preparing PVC panels for installation much faster than using a hand tool.

However, with this method of processing, the following nuances must be taken into account:

- even before starting work, it is necessary to turn off the pendulum stroke;

- a file with as small teeth as possible should be used;

- you need to set the lowest speed of movement of the file, which will avoid excessive heating of the plastic at the cut.

Using a jigsaw is very convenient to cut stacks of panels, but you should make sure that their height does not exceed the length of the file installed in the tool.

The angle grinder is recognized as the most convenient and practical power tool with which you can cut PVC wall panels. By installing a cutting disc, you can make not only straight, but also curly cuts on the surface of the plastic. When processing plastic in a circle, the angle grinder turns on only at low speeds, which will avoid damage to the material due to melting of the edges.

In the absence of more practical and convenient tools, PVC can be cut with a knife.

To solve this problem, the following types of cutting products are suitable:

- Kitchen knife. This tool is suitable for cutting multiple panels in the process of repairing or replacing them. For large-scale wall decoration, such a procedure is unnecessarily long and painful.

- Construction knife. Among hand-held cutting tools, such a device is one of the best options for achieving a straight cut with relatively little effort.

- Stationery knife. Using a wooden ruler or square, this tool allows you to achieve a perfectly even cut of the panel, therefore, it is often used to cut them.

Hacksaw

One of the universal devices for cutting any material is a hacksaw, which is sure to be found in the arsenal of any craftsman. It is she who will help, if necessary, cut the plastic wall panel. Such work will take longer than using a special cutter, but with significant volumes of cladding, this will not significantly affect the total repair time.

When using a hacksaw, you should listen to the following recommendations of experts:

- for working with plastic finishing materials, you should use a tool with small teeth, which is usually designed for working with metal or wood;

- to shorten the PVC panel, there is no need to apply strong physical forces, which can damage the material;

- you can cut several parts at once with a hacksaw by folding them in a pile and securing them to avoid bending or displacement.

To prevent the cut from being serrated, it is not recommended to use a tool with teeth set apart in different directions.

Choosing a cutting tool

Specialists in the implementation of repair work, who have to carry out the installation of PVC panels in their professional activities, know many secrets regarding the correct cutting of plastic materials up and down. After analyzing them, each owner who wants to make repairs on his own will be able to choose the most suitable professional tool for him or use the tools at hand.

The choice of a method for cutting panels usually depends on the tasks and capabilities of the master. Below are the types of cutting materials.

Material features

PVC panels are one of the modern types of finishing materials that are made by extrusion and are used both in the bathroom and in the living room. The main raw material in the production of such products is polyvinyl chloride, which is used to fill the mold. To give the panels the desired color, a certain amount of crushed natural chalk is added to their composition.

Decorating PVC panels can be done in one of the following ways:

- staining;

- thermal printing;

- offset printing.

Thermal printing is applied to the plastic surface using a special roller heated to high temperatures, which presses the film to the surface of the product. Thanks to this technology, it is possible to quickly and clearly apply a pattern without losing the brightness of the image. The panel itself does not need additional varnishing. Offset printing is used much less often due to its high cost.

How to cut PVC panels?

- Material features

- Choosing a cutting tool

- Cutter

- Hacksaw

- Power tool

- Knife

- Basic rules for cutting

- Safety regulations

PVC panel is one of the most popular materials for interior decoration. Its use in the interior attracts not only by its appearance, but also by its affordable price, ease of maintenance and installation. Due to the listed characteristics, many people prefer PVC panels, rather than tiles, when decorating personal hygiene rooms.

Cutter

If necessary, this tool can be independently made from available tools, for which it is enough to adhere to the following recommendations:

- it is necessary to prepare a metal strip, the thickness of which is at least 2 mm, and the width is 1 cm;

- then one of the edges of the workpiece should be cut off at an angle of 45 degrees;

- it is necessary to sharpen the edge of a homemade product using a grindstone;

- the opposite side should be wrapped with electrical tape, which will allow you to protect your hand from damage during work.

A professional cutter for plastic has a relatively low cost, so its purchase can serve as a profitable investment, because thanks to such a tool, the process of cutting PVC panels becomes not only more convenient, but also quite fast.

Safety regulations

Like working with any building materials, processing PVC panels requires compliance with several safety rules. These recommendations are especially relevant if you plan to work using a tool that is connected to the power supply, for example, a jigsaw or an angle grinder. When cutting plastic with a power tool, there is a great danger that debris and sawdust can fly off the panels. Therefore, experts recommend purchasing safety glasses and gloves in advance, which should not be removed until the end of the work. These seemingly simple personal protective equipment can help keep your hands and eyes safe from injury.

These tips should help you decide on the choice of a tool, as well as create an interior of your own dreams and avoid most mistakes, because with a little effort, you can achieve the desired result, saving a lot of money.

How to easily and clearly cut a plastic panel is described in the video.

Power tool

If someone asks a question about how to cut plastic wall panels, and there is an electric jigsaw in the middle of the tools, then you can drop all doubts and apply it specifically.

After all, this is one of the power tools that comes up for this task. But first you need to test to cut an unnecessary piece. And all in order to realize which side will be cut neatly. There is also an important detail: the file must be with a small tooth, and the pendulum stroke is disabled. So, paying attention to all the tips, you can cut the panels without difficulty. over, this method significantly saves time, because with the help of an electric jigsaw, you can cut several panels at once by simply folding them together evenly.

But often for those who are thinking about what to cut plastic PVC panels, the choice falls on a hacksaw for alloy or wood, but in principle, that the teeth are small in size.

The advantage of this method is that you can cut several panels at once. You need to cut with the front side, at a small slope and try not to press hard on

The smoothest method to cut bottles at home

Then your voice for Strizhenova’s video changed so much that a squirrel came to her! Eckhardt Gunther Trio for Flute, Oboe Clarinet, op. 57 First Moveme ANS DVR Setup Most Relaxing Music for Ayurveda Massage | Spa Relaxing Music Milling Cutter, Boring Machine from Angle Grinder.

How to cut plastic at home

What to cut?

It is not extremely comfortable to even deliver one home. You need to cut them into pieces.

An angle grinder is a tool that is suitable for cutting PVC panels, it leaves the cuts clean, which is important for almost everyone. Obviously, this is an extremely ubiquitous tool, but not everyone has it in stock.

What to do in such a situation? In this case, an electric jigsaw can help to cut the plastic panels. A jigsaw blade should be chosen with a small tooth, having tasted in advance on an unnecessary piece to make sure of a suitable result.

The ease of cutting panels is that several panels can be cut at once, saving time and effort.

What to do if neither one nor the other instrument is at hand? In this case, there is no reason for frustration. After all, PVC panels can be cut even with an ordinary knife. Opening with an ordinary knife is quite difficult to do. Naturally, a construction knife is more suitable, but you can also make it yourself. To do this, you can take a piece of alloy, approximately 3 to 5 mm. and sharpen one edge at an angle of 45 °, and simply wrap the other edge with electrical tape. But the most common option for cutting plastic panels is a clerical knife.

An incision is made on the back side, and then the panel itself breaks down. Using knives to cut the panel is even easier than using power tools.

Plastic panels have a number of advantages that make them irreplaceable for quick and cheap repair of bathrooms, toilets, loggias and garden houses. The panels are impervious to water, are low-flammable, resistant to mechanical abrasion, have a long service life and are relatively cheap. They can be used for finishing both walls and ceilings.

The development of the installation of plastic panels is simple and does not require preparatory surface preparation.

One of the essential steps in the installation of plastic panels is their cutting to the required size. The laboriousness of this step depends on the state of the surface being trimmed: if the wall, for example, is flat and even, then you can prepare the entire size of plastic panels required for it in advance. If the wall has different heights, complex shapes, or includes building elements (windows, doors, ledges, etc.), then you will have to cut the panels along the way, which, of course, significantly increases the installation time.

How to cut plastic panels? 4 tools to choose from to help

Someone may object and remember at least a tile, as one of the most common finishing for bathrooms.

Yes, tiles are a classic and a tradition. But PVC is installed easier and rather, they require much less maintenance, since they do not collect soap and precipitation from the water for themselves, in case of damage they are simply replaced.

In a word, the tile is still inferior to the 1st position to plastic panels. And if you need to quickly and superbly sheathe services, now almost everyone chooses specifically panels.

First of all, they fell in love with the people for the availability of self-installation. It causes the only difficulty: the usual length of a plank of 3 meters is very large for most apartments. In addition, the height of the ceilings may vary. both due to the errors of the builders, and due to the flight of the owner’s design thought.

So the finishing must be shortened, which means it must be trimmed.

How to cut plastic panels has long been invented. And these methods. both folk and modern technological ones. are quite diverse for us to choose: either the method that seems most comfortable, or the one for which there is a suitable tool on the shelf. Let’s take a closer look at a couple of more popular ways in which this process is carried out. And let’s take a closer look at each of them.

Construction markets provide a plastic cutter at a very affordable cost. from 10 to It may be completely needed and then, when the paneling is finished, so you can go broke and buy.

Such a cutter at the exit gives a completely flat cut, does not require special muscular efforts and does not take up much space in the pantry.

- And those who are completely economical can make such a cutter on their own.

- A scrap of iron sheet is taken mm in 2 wide. Band width. about a centimeter.

- One of the edges is trimmed at a 45 degree angle.

- The resulting knife sharpens perfectly.

- The opposite end is wrapped with electrical tape so that it does not put pressure on the hand.

- The cutter is ready, you can start measuring the panels.

comforte in use is an alloy tool, but a hacksaw for wood is also suitable, only with small teeth for cross cutting.

In this case, the teeth should not be divorced, so that the cutting edge is less shaggy. The advantage of this method is that with a hacksaw, you can cut several panels at once (if the walls are straight and everywhere of the same height), folding them in a stack.

- Planks are facing up, with a slight slope.

- You should work with a hacksaw without powerful pressure, so as not to break parts.

- PVC is quite easy to cut, so cutting problems are not expected.

Significantly speed up the process and give a fairly smooth cut.

Virtually irreplaceable with longitudinal separation. Like a hacksaw, they can process a stack of panels. if only its height does not exceed the length of the working surface of the tool.

There is one “but”: at high speeds, the panel begins to melt, because of which the edge comes out wavy, and unpleasant smelling and poisonous substances are released into the air. So the work is carried out only at low speeds.

In addition, you need to carefully dose the efforts, since all three tools are quite heavy and, so to speak, aggressive. Their very active use leads to panel breakage. Taking into account these shortcomings, almost all professionals advise using an ordinary, not electric, jigsaw for cutting.

It divides the panels slightly rather than a hacksaw, the cut comes out without creases, it is longitudinal cutting and is safe to use.

There is such and such a tool in any house! But its application has its own subtleties.

- An ordinary kitchen knife is more unsuitable for the pursued purpose. Even when perfectly sharpened, it has a very large blade for cutting plastic. It will turn out like Ilf and Petrov: “Saw, Shura, saw.” You can cut off one bar, but if there are a lot of them, cutting your time will take you more than the installation itself.

- A stationery knife is most suitable: it will not cut the panel to the end, but this is not required.

A groove is pressed on the front side, after which the bar breaks with ease. The remaining small fringe traditionally does not bother anyone. this edge is still hidden under the curbs and baseboards.

When using any tool, certain requirements must be made. At the same time, it is in your own interests, if you strive to do without industrial injuries and unnecessary marriage.

Before cutting the panels brought in from the cold, it is imperative to warm them up.

The main mistake of inexperienced finishers is to store the cladding on the balcony and bring it in as needed, immediately starting to cut it. PVC becomes brittle in the cold, and the cut comes out fragmented. Cracking is not uncommon along the entire length of the panel. So after the planks are brought into the room, they are left to stand at least overnight.

You can cut (again in any way) only with the wrong side down. If you place the panel incorrectly, its profile will collapse and cause difficulties during installation. The panels of some manufacturers may have the most significant violations: microcracks on the front surface, which do not appear immediately.

If you are cutting a stack of panels that need to be of similar length, place them on 2 supports so that they do not sag or move.

It is better to rest the end not cut off against something, at least against the wall. Otherwise, when the tool acts, the elements will be displaced and will turn out to be of different sizes.

And one more thing: when cutting, it is better to use goggles. Especially when using a power tool: the possibility of a fragment flying into the face area is quite high. And if scratches on hands are experienced phlegmantically by people, then eye injury is much more dangerous.

Naturally, it is up to the finisher to choose what to cut the plastic panels with. But before that, rather than preferring one tool to all others, you need to know what difficulties you can face when using it. We tried to cover them in full.

I tried cutting polystyrene with an angle grinder, but it heats up the plastic so that the edge comes out in waves. There is no PVC wire, the edge melts terribly. They say acrylic maybe I haven’t seen it myself and I don’t use it. A couple of seconds and you’re done, later just scratch with sandpaper to eliminate sagging.

You can also use a jigsaw, but when cutting, they need to strictly dose the pressure, otherwise the panels can simply be broken. If you use a saw for wood, it is better if it has teeth for transverse or mixed sawing, according to its ability, not divorced. such a saw will leave a smooth cut without scoring.

I cut the plywood clean at rpm on a tabletop circular with a laminate blade. The profile of a catfish that cuts the edge cleanly and does not shag the fibers. The largest thickness is 10 mm, more motor power is already small.

Stanley calls it concave for finishing work (this is about polystyrene).

It is comfortable for most plastics, you need a little habit, and do not skimp on a knife where to insert it, in cheap ones it does not clamp tightly, and this is the most basic thing. From acrylic, even with a jigsaw, split this size more than you cut it, that’s for sure. Such a narrow leg of the letter will be broken by 90% from vibration, and plus it constantly strives to start melting, the hemorrhoid is shorter.

Likewise. I cut both plastic and foam rubber with an ordinary knife with replaceable blades, only after every 10 cuts I break off the section so as not to wet it.

In the case of soft plastic, you can test using alloy scissors.

The advantage of this method is that they can cut several panels at once.

How to easily cut plastic sheets by hand

Cutting plastic and plexiglass at home. video

Polymers have firmly entered modern life, and there is not a single industry where they are not used, from the production of containers to space technologies.

Every year about a million tons of different plastics are made on the planet. Most of them cannot be decomposed into ordinary components without the help of others and disposed of without the help of others.

Make plastic at home with your own hands!

Sometimes you have to save money on the purchase of expensive systems, find the most affordable other options, or just put up with the lack of convenience.

If you want to organize a drainage system in your own garden, you can make small pebbles from plastic bottles.

Jigsaw

This tool can be called the main one. The jigsaw is good for everyone, it has a minimum of flaws. You can cut the panels up and down. You can cut shapes with ovals and other broken things.

The jigsaw has a twist. It tears the edge of the panel in places where it remains to cut completely slightly.

At this time, it is extremely common for the panels to burst (especially in cold weather).

Therefore, it is worth using the file with the smallest tooth. For ourselves, we have chosen a Bosch alloy blade with a 0.8 mm tooth. This file will greatly protect you from a torn cut.

If the jigsaw is operating at high speeds, it can be cut extremely quickly with such a file. This file is on an alloy, it does not blunt from cutting plastic products.

The main advantage of the jigsaw is its versatility. Cut PVC panels, you can both lengthwise and across.

In any spatial position.

The minus of the jigsaw is weight, the presence of a wire. With an incorrectly selected blade. a torn cut.