How to cut plastic panels correctly

Home cooking recipes with photo National

Hello everyone! We continue to acquaint you with the recipes of everyone’s favorite Italian cuisine.

Design of a studio apartment 100 hundred ideas Houzz Russia

On the other hand, there is a wise saying: Whoever understands a woman, half is! And from ourselves we add: and who will please her.

Pampas grass 50 photos what is the Cortaderia cortaderia

What is cortaderia or pampas grass. The name of the cortaderia comes from the Spanish cortar court. cut.

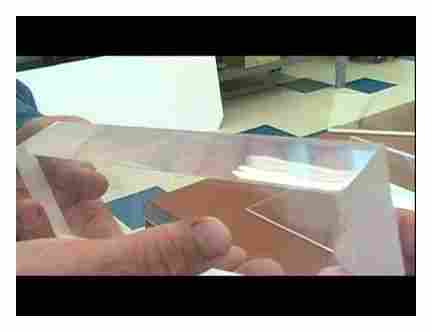

How to cut plastic panels at home

PVC panels. modern finishing material, which has successfully and deservedly gained popularity in the field of interior decoration.

It is necessary to cut correctly with the wrong side of the panel down, because during processing under the influence of the load, the profile of the strip changes and causes some inconvenience during the installation process. When processing plastic with a circle, the angle grinder turns on only at low speeds, which will avoid damage to the material due to melting of the edges. If you are cutting several panels that need to be the same length, you need to place them on at least two supports. And further from the tool, if we work with a hacksaw on a tree with a fine tooth, the main thing is to cut it without a jerk, the MDF is laid on a horizontal surface with reliable fixation (with a foot, for example). Among the variety of finishing materials used in construction, plastic panels occupy a separate category. To give the desired color in one tone, additional dry mixtures, and for drawing a picture. thermal printing, using an auxiliary roller heated to a high temperature.

To cut pvc panels, you can use different tools, each of which has its own advantages and disadvantages. Thinking about “how to cut plastic”, you can remember about a hacksaw, be it for wood or metal. On the one hand, the workpiece is cut at an angle of 45 degrees and sharpened, on the other hand, a handle is made of electrical tape for easy holding and safe use. A stationery knife is considered a more suitable tool for this, because using it, the material is not completely cut. Using a jigsaw is very convenient to cut stacks of panels, but you should make sure that their height does not exceed the length of the file installed in the tool.

Photos of new wallpapers in the interior of the kitchen

Washable wallpaper for the kitchen tips, how and what wallpaper to choose.

How to cut pvc panels how to cut correctly

To avoid chips, you need to use a high-speed tool, a circular saw is best for this. But it is possible, by installing thinner discs with small teeth, to work with plastic panels and laminated blanks. Most experienced professionals, whose tools are of a wide variety and are designed for high-quality processing of plastic, prefer to cut pvc panels using a special cutter. Thanks to him, an even cut is created without much effort on the plastic surface, which is characterized by the absence of chipping and chipping.

How to easily cut acrylic sheet

When choosing a tool such as a hacksaw, you do not need to overdo it with physical activity on the plastic panels. In addition, if you make an incision from the inside out, the front side can become covered with microcracks, which will manifest themselves only over time, finally ruining the design. The plinth is cut by cutting the floor plinth, but sometimes it is enough to cut the plastic plinths at a right angle. now a large number of various additional products for them have appeared on sale. In addition, before starting work, it is important to check the jigsaw on some unnecessary piece of plastic. How to avoid mistakes The main mistake when cutting sheets and working with plastic panels is not knowing that pvc sheets cannot stand low temperatures.

Recommended

I already wrote that I do not like to spend money on buying a new one, if the old one can still be repaired.

How to cut plastic pvc panels at home

These tools dramatically speed up the length change process and also provide a superior cut edge appearance. All these recommendations help to properly saw and cut the chipboard, but chips, nevertheless, cannot be completely avoided. How to connect mdf panels? A circular or electric circular saw is a powerful construction tool, the main task of which is to work with wood and materials similar in spirit.

All sheets that are made of polymers (plastisol, polydifluorionad, polyester, pural) can be cut with a jigsaw, angle grinder or a construction knife. You need to drive the saw with slight pressure, at an acute angle to the surface, constantly monitoring its position; for cutting chipboard and chipboard slabs with a jigsaw, the saw line should be scratched or even cut through. If you already know how you will cut pvc panels at home, you should also prepare a tool. This will significantly reduce the number of rejected and damaged panels, and save a novice craftsman from wasting time, money, and, above all, from injuries.

What to look for when choosing

It is clear that the choice begins with the color and pattern. But so that during the installation process there are no difficulties, during the purchase it is necessary to track some points:

- Examine the cut of the selected plastic panel. The thicker the lintels and the front and back resin layers, the stronger the finish will be. You can also focus on weight. the larger it is, the thicker the panels will be.

- The thickness of the plastic is the same everywhere, without thickening and thinner places. This is a sign of normal quality.

- Pay attention to the geometry. The cells should not be wrinkled, the edges should be absolutely even. Even if everything is packed, it does not interfere with unpacking and inspecting. so that there are no problems later.

- Examine the front surface. The drawing should be applied evenly, clearly, without smears.

- If you choose panels from different packs, but of the same color, carefully look at the colors. they may differ.

It is also worth checking the quality of the polymer used. It is necessary to take one bar so that it bends by about 30% and straighten it. Then examine it. If there is no damage to the plastic or pattern, everything is fine.

Wall decoration with PVC panels

During repairs, you do not always want to get involved with “wet” work. laying tiles, for example. There is a simpler technology. wall decoration with plastic panels. You can cope on your own, even without much experience in construction work, and in a day or two carry out repairs in the bathroom, toilet, on the balcony / loggia and in the kitchen.

Sizes and prices

In width, plastic wall panels are most often 25 cm and 37 cm, length. 2700 cm and 3000 cm. There are other non-standard sizes, but these are most common. For the price, you can observe a fairly strong spread. it depends on the thickness of the walls, the type of printing, the manufacturer, the complexity of the pattern, etc.

| Violet pink | 250 mm 2700 mm 8 mm | V-Plast, Russia | 120 rbl | |

| Kanamala | 250 mm 2700 mm 9 mm | lamination | Vivipan | 220 rbl |

| PVC Panel Mosaic Turquoise | 950 mm 480 mm 3 mm | Russia | 128 rbl | |

| Scarlet | 250 mm 2700 mm 8 mm | Cronoplast (Russia) | 215 rbl |

How to do without corner profiles

If the presence of skirting boards at the top and bottom of the wall is familiar to us, then not everyone likes the corner profiles. When decorating walls with plastic panels, you can do without them. You will need a sharp wallpaper or clerical knife. If you cut a strip of plastic from the back in the right place, the panel can be bent. From the front side it will not be visible in any way, and the torment with the last panel will be avoided. And outwardly, many like this way more.

Wall decoration with plastic panels: how to do without corner profiles

To correctly determine where it is necessary to cut, insert the penultimate panel, fasten it. We take a piece of a panel several centimeters wide, insert it into the already installed one and mark where the corner is. We take it out, cut out a strip of plastic in the marked place, try it on. If everything is ok, use this piece as a template, transferring exactly the place of the cut. This is also not according to technology, but such wall decoration with plastic panels looks, it seems to me, better. Especially if the color and texture of the corner profile is different.

Thin PVC Wall Panels

Above we were talking about products that consist of two layers of plastic, connected by jumpers. Along with a lot of advantages, they have a rather serious drawback: if you make enough effort, they can be pushed through. This is often the reason for not using them. Therefore, thin wall plastic panels have appeared on the market not so long ago. Their thickness is 3 mm and no cells. Only a layer of plastic with a pattern applied to the surface. Accordingly, there is nothing to push. Dimensions of this type of panels 950 480 mm or so.

Their installation method is different. they are glued to the walls. Due to the fact that this finishing material has a very small thickness, it is cut with scissors and, moreover, takes away from the room, sucking too little space. 3 mm.

What to make a crate

The installation of PVC panels on the walls according to the technology should be done on the crate. The crate is made from:

-

Wooden bars. The optimal section is 4020 mm. Before installation on the walls, it is advisable to treat the wood with antiseptic compounds. If wall decoration with plastic panels is planned in a damp room, then special treatment against mold is also required. The panels are attached to wooden planks with wood screws, nails with a wide head, staples from a construction stapler.

Wooden planks for lathing under PVC panels

Metal profiles (galvanized)

How to cut hard plastic best trick

This is how the mounting strips for PVC panels look

Of the three materials listed, plastic is the best choice for installing plastic panels in the bathroom. It reacts little to temperature changes, does not react in any way to changes in humidity, does not rot and does not crack. Galvanized steel feels good in a humid environment, but it must be of good quality, otherwise it will rust anyway. The most unimportant material is wood, but they, with appropriate processing, also cost years. And to keep it that way, follow the recommendations for application on the antibacterial composition exactly. In some cases, it is enough to smear a couple of times with a brush, in others. soak for a while and then dry.

Types of plastic panels for wall decoration

This type of finishing material is made of PVC. polyvinyl chloride. In a semi-liquid state, this polymer is extruded into a mold. A drawing is applied to the finished panels. It can be first printed on foil, then glued and varnished (laminated panels). over, these panels may not have a flat, but a textured surface. The drawing applied using this technology retains the paint for a long time, but such materials cost about two times more.

Several samples of PVC laminated panels for wall decoration

Another technology is to apply the pattern directly to the plastic, and then cover it with two layers of varnish. Cheaper technology, but the service life and quality of the pattern is lower.

Ceiling and wall

There are two types of plastic panels. for ceilings and for walls. Those intended for the ceiling have a thickness of 5 mm and thinner partitions, and the wall ones. from 8 to 10 mm and a greater thickness of the walls and partitions. You can determine which view is in front of you by looking at the cut. This type of finishing material differs in that it has a flat surface and with tight joining the seams are not very noticeable.

Plastic panels for wall decoration

There is another standard size, which is also called plastic lining. with a thickness of 10 mm, the panel has a width of 10 cm and shaped edges, which are more characteristic of plastic lining. If you trim the walls with this material, the surface will not be even, but embossed, similar to a wooden lining.

Plastic panels: what to cut?

It is worth noting that such a building material is quite simple to process. You can cut the plastic panel with almost any tool. Usually, a hacksaw for wood or metal is used for such work. In this case, the size of the teeth on the tool should be taken into account. The smaller they are, the better. The main advantage of this method is that, if necessary, you can cut several panels at the same time. In this case, the facing material is recommended to be placed with the front side up, at an angle. The panel is cut very easily. However, strong pressure should be avoided.

If you decide to use a wood saw to cut plastic panels, then you should choose a tool for mixed or cross-cutting, with undivided teeth. The result will be a neat and even edge.

Plastic panels: how to cut and how

Today, a variety of materials are used for wall decoration. Their choice is so great that it is difficult to decide. over, each material has certain properties. They are worth considering. In some cases, only plastic panels are relevant. How to cut such material, not everyone knows.

The use of power tools

So how to cut plastic panels? For such purposes, many use a jigsaw. However, during the cutting process, it is necessary to strictly monitor the pressure. Otherwise, the material may not withstand the pressure and break. To speed up the installation of such panels, many use circular saws and an angle grinder, but experts do not recommend using such a tool. Plastic itself is fragile and can easily break if handled carelessly. In addition, the material may become hot during the cutting process due to the high speed of the blade. As a result, the edges of the panels may melt. In addition, when heated, such material begins to emit toxic substances.

Installation features

So what’s the best way to cut plastic panels? It all depends on the condition of the surface being trimmed. This is the whole complexity of installation. If the surface is flat, straight and smooth, then you can immediately cut the finishing material by adjusting all the details, as well as cutting the required number of panels.

If the surface has irregularities, and also requires curly cuts, then the process of installing the finishing material will be somewhat complicated. In some cases, a wall can include architectural features such as ledges, doors, windows, and so on. In this case, the plastic panels will have to be cut during installation.

What are plastic panels

Plastic panels are an irreplaceable material for surface finishing in bathrooms, garden houses, loggias, toilets. After all, it has several advantages. So what is the difference between plastic panels? How to cut such material and how? Among the advantages of the panels, it is worth noting their resistance to moisture. In addition, they are classified as low-flammable materials. It’s easy to mount them. In addition, plastic panels are resistant to abrasion, so they last a long time and are relatively cheap.

Can I cut with a knife

You can also use a utility knife to cut plastic panels. To do this, an incision is made on the surface of the material using a ruler. After that, the panel simply breaks. It is not recommended to use a regular knife. This cutting method is much better than those described above. However, cutting panels with a cellular structure with a knife is almost impossible.

How to cut plastic panels

Hacksaw

This tool is present in any home workshop. For those who are not ready to spend money on purchasing a cutter, using a hacksaw may well be an option for solving the problem of cutting panels.

Yes, this method will take a little longer, but with a small amount of work, this will not greatly affect the period of wall cladding.

It is important to note that a hacksaw for metal is best suited for cutting panels, and if you use a tool for wood, then the blade should have fine teeth. for cross-cutting.

Several options are possible here:

Simple kitchen knife

Although this tool is the least suitable for cutting PVC products, one or two strips can be cut in case of repair and replacement of panels. But with large-scale work, it is impractical to use it. the process will take a long time and painfully;

It is often used for cutting panels. Using a square or a flat wooden plank used as a ruler, it is possible to achieve an even cut.

How to cut plastic panels

The better to cut?

Different tools can be used to cut the panels. These include both special professional devices and ordinary hand or electric tools used in everyday life for various purposes.

Jigsaw and angle grinder

Using a jigsaw is a quick, but not too high-quality way. It is unlikely that it will be possible to achieve a perfectly even cut with its help, moreover, chips often form along the edge of the panel, so it is best to abandon this option, preferring the same angle grinder.

Using this tool will ensure an even cut, but only due to high speeds, the panel begins to emit an unpleasant odor and poisonous substances.

Cutter

This device is used by experienced craftsmen who are professionally engaged in finishing work.

The use of the cutter provides a perfectly smooth cut and allows you to shorten PVC strips without much physical effort.

Having bought such a tool, you can be sure that there will be no problems with high-quality cutting of panels.

How to cut PVC panels correctly?

To obtain a high-quality result when cutting, certain rules must be followed. Among them there are both general instructions and recommendations for working with a specific tool:

- It is unacceptable to work with material that was brought in from the cold. it must be warmed up before opening. Chilled PVC becomes brittle, leading to edge chipping.

- Wall panels should only be cut from the front side. Otherwise, the profile will crumple, and difficulties may arise during the installation process.

- The use of an angle grinder, jigsaw or hacksaw allows you to cut a bundle of panels at once.

In this case, they must be laid on two supports so that they do not sag, and not the cut edge must be resting against the wall. this will prevent the panels from moving during cutting.

When using a power tool, it is advisable to wear protective goggles, since the likelihood of being hit in the face by debris during work is quite high.

When working with a knife, it is worth using a guide on which the tool will rest during cutting.

This, as already mentioned, can be a square or a wooden lath. The guide is applied to the cut mowing line, the panel is cut and cracked, after which the material is cut from the back side.

That’s all. The main methods of cutting PVC panels have been considered and it remains only to determine the most optimal option, the choice of which depends on the personal preferences and capabilities of the master himself.

For a convenient way to cut PVC panels with a hacksaw, see the video below:

Hacksaw

A hacksaw is considered more practical to use, and it does not matter whether it is for metal or for wood. The only requirement when using a hacksaw for wood is the presence of small teeth, which should not be divorced, because this way the surface of the material that needs to be cut into pieces is destroyed. Such a tool is often used for crosscutting.

For convenience, when cutting, it is better to have the planks facing the contractor. When subjecting the length of the panels to a decrease, care must be taken not to apply enormous efforts when pressing the tool, because this can break the PVC sheets.

Due to the plasticity that the material possesses, it does not take much effort to cut off the excess part of the panel.

Application of panels

In the process of sheathing, it is necessary to initially decide on the tool used for cutting the plastic panels. This material is widely used for finishing balconies or bathrooms, because it has an excellent set of properties. We must also not forget about its practicality, which makes it even more popular. Plastic panels also attract buyers for their low cost and excellent appearance.

Each owner can independently finish the bathroom at home and at his discretion, because there are a huge variety of panel options that can be used for this. All PVC panels are manufactured with a standard length of 3 m.This is not always practical, because it requires cutting into pieces to obtain the desired size.

Currently, a huge number of tools have been created, thanks to which it is possible to shorten the length of a particular material. When working with plastic panels, it is necessary to take into account many factors, among which the main ones are practicality, cutting speed, surface quality, as well as ease of use.

How to cut PVC panels: tool selection

- Application of panels

- Cutting rules

- What is needed?

- Cutter

- Hacksaw

- Jigsaw, circular and angle grinder

- Knife

Undoubtedly, tiles are considered to be the classic material for finishing a bathroom, however, PVC panels have an increased installation speed, and additional maintenance of this material will not be required, because neither soap nor water is deposited on their surface. Initially, plastic panels worked well due to their ease of installation. To carry out such work, you will not need help from specialists and a complex tool.

Cutting rules

To carry out work safely, you must clearly follow the following rules:

- When working with panels that were brought in from the cold, you need to wait a short period of time. This action is necessary in order to warm the material. If you do not heed the advice, then the plastic panels will break during the cutting process, thereby losing their neat appearance. Often there are cases when cracks appear on the surface that is cut along.

- In order to obtain several planks of the same length, it is necessary to lay them on at least 2 supports. Thus, protection against sagging or displacement occurs. It is recommended to rest the edge of the element that is not pruned against the wall. Thanks to this action, you can secure against their shift.

- You can make the process easier by marking with a pencil or felt-tip pen.

- It is necessary to cut correctly with the wrong side of the panel down, because during processing under the influence of the load, the profile of the strip changes and causes some inconvenience during the installation process. Microcracks often appear on the front surface, which appear in the future.

- When using a power tool, you must use protective goggles and gloves that can protect against debris and sawdust flying in different directions during the cutting process.

Cutter

This tool has proven itself well due to its low cost. Perfect for home use.

The tool has excellent performance and the cut surface looks smooth. It should also be highlighted the fact that it does not require much physical effort to carry out the cutting. A huge advantage can also be called its compactness, in which it does not take up much space during its storage.

The disadvantage of the tool is the ability to cut only in a straight line of the mowing line, they will not be able to round off the edges.

Jigsaw, circular and angle grinder

These tools dramatically speed up the length change process and also provide a superior cut edge appearance. These devices have proven themselves perfectly if you need to quickly slit a panel longitudinally.

In no case should we forget that when working at increased rotational speeds of the cutting tool on the surface that is being processed, defects in the form of melted edges may appear. At the same time, unpleasant odors and substances harmful to health are emitted into the work area. It is necessary to decide which circle to carry out the processing. In view of this fact, at first all work must be done at reduced speeds. With an angle grinder, you can get not only straight cuts, but also curved cuts.

Experts recommend using a regular jigsaw to obtain a high-quality surface, as well as increased productivity, as a tool used when cutting. In this case, an excellent smooth edge is obtained, which does not have any creases, and is also very practical in the process of work. The tool has proven itself well both for longitudinal cutting and for cutting across the bar.

When using a jigsaw, you need to remember that you need to use a file with a fine tooth. Particular attention should be paid to the cutting mode. the minimum speed is selected and the pendulum stroke is turned off. This tool is excellent for cutting multiple panels at the same time.

This tool is perfect for cutting small quantities of plastic panels. Applying it, you just need to know some little things that can help and facilitate the process of changing the length.

The least suitable for such work is an ordinary kitchen knife, which can be found in any kitchen. Difficulties in working with this cutting tool arise due to the width of its blade. Even when perfectly sharpened, a kitchen knife will not cut through wall panels.

The performer will have to spend a lot of time if he does not have the opportunity to use another tool. In this case, the installation process will take longer.

A stationery knife is considered a more suitable tool for this, because using it, the material is not completely cut. After drawing along the front surface of the material, a groove is obtained. Turning over the bar and pressing on the edges, the PVC panel clearly breaks off along it, and the resulting small fringe, which covers the surface of the fracture, will absolutely not harm the appearance of the room in any way, because in any case it will be hidden either under the curbs or under the plinth.

a loaf knife made of ceramics can also carry out such work. It will do a great job with plastic panels due to the presence of a wavy cutting edge. Working with such a tool, it will not be difficult to obtain an element that will perfectly fit into the interior of the bathroom.

To cut PVC panels, you can use different tools, each of which has its own advantages and disadvantages. There are also specialized professional tools to speed up and facilitate cutting.

To learn how to cut a PVC panel using a clerical knife, see below.

How to cut plastic panels: features of working with material

The main advantage of any decorative panels is their easy installation, and if we talk about plastic panels, then you can add a very simple processing and adjustment. Plastic is a fairly soft material that can be cut with almost anything. I mean, almost every first cutting tool will do. Despite this, the issue of cutting plastic has its own subtleties and nuances, which, among other things, we will get acquainted with in this article, in which, together with the site stroisovety.org, we will deal with the question of how to cut plastic panels?

How to make a hole in a PVC panel photo

How to Make a Hole in a Plastic Panel: Hole Cutting Tool

Almost every time when it comes to decorating walls or ceilings with plastic panels, one has to deal with the issue of cutting holes in the panels for lamps or for sockets. separate tools are used for them, although in some cases some of those described above can be used. We’ll leave them for later, but for now we’ll figure out the most suitable options.

-

Hole saw. Ideal, but it is not always present at hand. Most suitable is a type-setting crown for drywall, which, by changing nozzles, can cut holes of various diameters. you can choose a file for both sockets and recessed ceiling lamps. This tool cuts very carefully, but you need to be careful at the end of the drilling. when the tool falls sharply through the plastic, the main panel can be damaged. At this point, the pressure on the tool must be significantly relieved.

How to cut plastic photo panels

This is with regard to solving the question of how to make a hole in a PVC panel for a lamp or a socket using the basic tools. in addition to them, as mentioned above, you can use the ones described above. For example, a knife. in order for the hole to be even, it must first be drawn with a marker or pen (unfortunately, a pencil leaves a barely noticeable mark on the plastic). In exactly the same way, according to a previously drawn mowing line, a hole can be cut with a blade from a hacksaw for metal, and with an electric jigsaw with a file with a fine tooth.

How to cut plastic panels: four tools and what to expect from them

What is most often found in the arsenal of any master finisher? Naturally, the most popular tool in the work. Among them there will certainly be a razor-sharp knife, a hacksaw for metal, for wood, and perhaps even an electric jigsaw. It is the listed tools that are most often used for cutting plastic panels. All these tools are cut in different ways, but be that as it may, they do it, and the quality of the cut is quite enough for wall decoration.

- Knife. Must be quite sharp and able to cut through one side of the panel in one pass. In fact, in the process of cutting the plastic with a knife, the master cuts only its front surface. then the panel simply breaks, after which the back side is cut off with a knife again. Everything is simple, but the cut itself turns out to be uneven and one side of the plastic is, as it were, bent, which makes it difficult to insert the PVC panel strip into the starting profile or connector. You have to trim everything and achieve a normal edge, spending time on this process.

- Hacksaw for wood. It has large teeth and in most cases does not cut plastic panels, but tears them along the edges. In general, the option is not very successful and it is better to leave it as a last resort, when nothing else is at hand.

How to make a hole in a plastic photo panel

By and large, if you are not confused by the melted edges of the panels, you can cut this material with an angle grinder. Alternatively, a circular saw is also suitable, but for this it will need to be equipped with a circle with a fine tooth. In general, anything will do, but you need to understand that some tools create ragged edges, while others make a clean, but not entirely even cut.

How to make a hole in a PVC panel: the secrets of cutting material

In working with each material, there are some peculiarities. so to speak, subtleties that are used by masters to achieve a particular goal. Regarding plastic panels, among such nuances, the following points can be distinguished.

- Cross cut. In the process of its production, the use of an angle will help create a cut at a clear angle of 90 degrees.

- Longitudinal cut. The simplest cut, since it is made between the internal reinforcing bridges. in most cases is done with a knife. First, the face of the plastic is cut, then the panel is bent and the back side is cut.

- Another interesting point associated with cutting plastic panels lengthwise is the possibility of facing the outer and inner corners without the use of special connecting elements. If the panel is cut from the back, it can be easily bent to form an inner corner. And if you remove the strip between the stiffeners from the back of the plastic, then the panel can be bent in the other direction, thereby forming an outer corner. The only thing to remember here is the fragility of plastic. with sudden movements, thin material can break. Before work, it is better to slightly warm the place of bending with a hairdryer. you can even use a household one.

How to bend a plastic photo panel

And the last point concerns the smooth slitting of plastic PVC panels. If you need to cut it clearly lengthwise, then it is best to make a cut between the internal bulkheads of the panel. first you can cut it as it goes, and only then trim it along the bulkhead. In principle, there is practically no need to make such precise and clear cuts. except when you have to hide the last strip in the starting profile. A clear cut without any burrs is important here.

topics than cutting plastic panels, I will say a few words about the quality of cutting. Do not underestimate the importance of a straight cut when installing plastic panels. you do not need to rely on the fact that the edges will hide behind the starting profile. The fact is that the cut curve is primarily a problem when installing the panel. It is much easier to insert a straight cut strip of plastic. over, when inserting a crookedly cut panel, you run the risk of damaging other elements of the cladding with the tool that you will use to insert the strip into the profile.