How to cut the angle of tile with a tile cutter. Safety regulations

Life hacks of the finisor. how to professionally cut different types of tiles

Tile work. work is not easy for beginners, requiring thoughtful preparation. In addition, it is important to find an individual approach to the varieties of material to reduce waste, and therefore the financial costs of the customer.

Tile cutting formula without prejudice to material

Considering the topic of how to cut tiles correctly, professional tiles are based on general principles.

The material must be carefully cleaned. It should not have traces of tile glue, dust.

The work involves dust formation, therefore they advise you to wear protective eyes for the eyes.

Using a hand tool, you can not overdo it. Otherwise, the broken tile is guaranteed. Having selected the power tool, you need to act confidently, clearly, but neatly.

For a spectacular resolution of the problem, cut tiles at home, the construction environment offers different modifications of tools.

That the main thing in the operation of different units associated with the tile sharp?

It is better to work with glass cutter. expert opinion

I answer, cut the tiles, first select the right glass cutter. It is presented in the market with three variations.

Roller glass cutter. is used most often. The advantage is a thin clear fishing line for a trimmer.

The oil type model works similarly, providing cutting without damage. Thanks to the clock, the task can be performed easily and quickly.

Diamond glass cutter is more intended for an experienced craftsman, since there is a great risk of getting uneven edges. In the case you will need a “strained” hand.

A competitive technical advantage of the means is the possibility of cutting not only in a straight line, but also figured cutting of tiles is quite aesthetic. Glass cutter is used when working with tiles, ceramics.

Recommendation! For porcelain tile, hand glass cutters, electrolobsics are better not to use. They can be used as an additional tool.

The tile must be placed on a geometrically even surface, removing small particles of dirt, glue. When performing the line, you need to make efforts. The outlined edge is removed with nippers.

Advice! Approaching the line planned by the glass cutter, the nippers should grab small fragments. If you use the “big step” plots in the department of the almost cut part, there is a risk of going beyond the edge of the line and ruin the appearance of the product.

An important point remains: cutting ceramic tiles you need to completely wrap the glass cutter and keep it strictly perpendicular. Sometimes the master can be difficult, because often such tools are more used by professionals for thin types of tiles.

At a construction site where the deadlines are running out, the foreman is in a hurry, the cutting of ceramic tiles is faster than the corner grinder is carried out. But you need to know certain tricks with her.

Basic methods of cutting corner granite grinder

This type of tile is the hardest. It is wear.resistant, suitable for public premises. Deciding to cut porcelain tiles should be based on two methods.

The evenness of the line when using a corner grinder depends on the correctly selected disk. Two paths are possible here when choosing discs.

Continuous discs are applicable in the case of “wet” cutting with water to cool the tool and reduce dust. It is appropriate to use them in working with tiles.

Deciding to cut porcelain tiles at home, it will be appropriate to contact a segmented disk that suggests a “dry” method of processing. But it is not recommended to cut more than 2 minutes. We need to take a break.

Using a standard corner grinder, representatives of the construction sphere do not advise buying disks with a thickness of less than 2 mm. Before each procedure, checking the state of the disk for the information appearance of the chip to zero is required.

The specialist marks the future cut with a marker, placing tiles on a prepared flat surface. It is better to fix it on a workbench. Cutting is carried out on the front side. In some cases, it makes sense to make a double cut. From the “face” to the product is slightly pressed, conducting a fishing line for a trimmer, the main cutting is carried out from the end part. This secret answers the question of how to cut the tiles of a corner grinder without chips, without losses for the owner of the room.

Proven methods of cutting ceramic tiles with a tile cutter

Ordinary ceramics for the bathroom, for example, is also cut with the participation of a corner grinder. Although at home it is often more appropriate manual tile cutter.

Minimization of the formation of dust, flaws on the tile.

The tool is light, contains a cutting video that relatively quickly carries out the task. The probability of marriage is reduced at times even compared to a corner grinder. Having placed the tile under the paw on the metal platform of the structure, in one motion it is possible to quickly perform the cut. There are several types of manual tiles.

Roller options are quite simple, suitable for standard tiles.

For more solid types of ceramic tiles, mechanical tile cutter with a hard carriage is advised.

To process a particularly durable material up to 16 mm thick, the model on bearings will be the best solution.

To perform a large amount of work, this tool with a system of air and water cooling is useful. What are its advantages?

It is possible to cut tiles at an angle of 45 degrees for the design of the angles between the walls.

Ability to cut a stone, porcelain stoneware.

In the process, the head depth plays a role. Recommended value. 3 cm. The length of the cut, equal to 50 cm, matters. And the power of the motor. Before the execution, you need to make sure that the wheel is fixed, checking its degree of wear.

What useful tips should be taken into account more?

The end of the tile material is sometimes cut at an angle. Using a corner grinder, you should choose a continuous disk designed for tiles. High.quality cutting of tiles under 45 degrees will turn out when installing the product on the rib, starting to grind the rear clay part. Having discovered irregularities, it is allowed to repeat the operation.

Get a smooth edge conveniently contact diamond “turtles” or sandpaper. Professionals also advise using a corner grinder with adjusting speeds to avoid burning of the edge.

The trick from the pros! For maximum aesthetics of the angle, it is not recommended to reach the icing part by about 1 mm. Filigency of skill is determined by the experience of the operator. Passing on the glaze with a tool, the edge is not very beautiful.

How to cut tile easily. How to Use a Manual Tile Cutter. INGCO. Cheap manual cutter

How to work with manual tiles?

Before using manual tile cutter, test it on the serviceability of the standard functionality. All its components ideally do not have visible defects acquired in the work, as well as factory flaws. Roller tile cutter for home use works without a clip of video. The surface of the roller is normally does not have notches, potholes and chips, its shape looks right. it is always round, without distortion. The carriage moves without slipping and stuck.

To exclude whirlwinding, flooding of the video, a ball.bearing kit is fixed on the torque axis. on both sides of the tool. The tile cutter should not be deformed, divided by rust to a noticeable thinning of steel walls and so on. Finally, both the video and the bed should not be dirty before cutting tiles and tiles.

The step.by.step process of cutting tiles or tiles is as follows.

- Mark the surface of the tile with a construction marker or pencil. according to pre.selected dimensions.

- Place a fragment of the tile on the tool frame so that the fishing line for the trimmer cut off on the fishing line for the trimmer of the brown node with the cutting roller. Make sure that the distance from the cut line to the extreme edge of the fragment of the tile or tile was 1 cm or more. Otherwise, the incision will turn out with chips. at least it can be with unfinished areas, but it happens vice versa: chips capture extra areas, and the fragment may be spoiled.

- Draw a brown component along the cut line with some effort. The main thing is not to overdo it: the glazed surface of the fragment should be cut to the entire thickness. You can not repeat the cut twice and more than times. the section will be imperfect.

- Turn the handle of the tile cutter so that the tool is again ready to work. Carry out a strong pressure. the unnecessary part of the fragment will break off.

Ceramics are kept in water before cutting. Using a few drops of industrial or engine oil, apply it along the cut line. This will prevent the flight of small fragments, ceramic dust in different directions.

Manual tile cutter has a significant drawback: it is not recommended to work with thick and particularly hard tiles. use motorized tiles.

How to cut tiles with an electric device?

Use of a motor tile cuttry when cutting floor tiles. a harsh necessity. The instruction manual of this method allows you to get even edges even with a significant thickness of fragments of tiles-2-3 cm. A visual difference. the lack of too pointed edges after cutting hard and thick tiles. The distance from the edge of the fragment of the tile to the cut line reaches 4 mm. you can not worry about the possible unevenness and randomness of the new edge.

The step.by.step guide looks as follows.

- Mark fragments for cutting, put one of them on the subject table of the tile cutter along the calibrated guide.

- Before turning on the diamond cutter, water cooling is activated at the cutting site. Then move the fragment towards the rotating disk.

- Do not overdo it. pressing the diamond disk from the side of the fragment should be small. Excessive effort at the beginning of cutting can lead to cracks and chips of a fragment. At the end of the incision, reduce the force to the same low level. rush will lead to the appearance of chips on a fragment.

- Having completed the cut, stop the disk and water cooling.

The fragment is cut. Go to cutting the next.

How to use manual tile cutter

First of all, it is necessary to consider the design of the tool so that it is clear how to use it correctly. So, its design includes a bed, on which two brackets are attached. They are located on two opposite sides of the base. Between them are installed guides made of tubes.

A carriage should be moved on these guides, on which a diamond wheel is installed, located below. In some models of manual tile cutters, a handle is attached to the carriage, with the help of which the direction of movement of the cutting tool is created. On the bed on one of the sides is a ruler that determines the length of the cutting of ceramic tiles, as well as the emphasis in which this tile should rest so that the tile material does not occur during cutting.

Some models are equipped with clamps so that again there is no displacement, although the tile itself is supported by hands. Often you can find tiles in which there are mechanisms of the broken part. That is, you can choose a tool with which you can cut the tile easily and quickly. As practice shows, this usually takes no more than one minute.

Attention! Manufacturers of cutting tools today offer tile cutters that can be cut on a tile hole.

So, before cutting the tile with a tile cutter (manual), it is necessary to check it for compliance with the technical condition. All visible parts of the structure should be without visible damage, the wheel should spin easily and without play. The last defect can be quickly fixed if you twist the fastener, which holds the wheel in the carriage. If the backlash has not passed, then it is better to replace the wheel.

Check how the carriage moves. Its move should be soft and smooth. Stanin before starting work should be cleaned of pollution. After which we can assume that the tool is ready to work.

Ceramic cutting technology is carried out below the next algorithm.

- Marking with a marker or pencil is applied to the tile.

- The tile is installed in the tile cutter so that the applied fishing line for the cutting trimmer is exactly under the cutting wheel (roller). To do this, the line is put on the line that determines the width of the cut part. It must be borne in mind that with a hand tool you can qualitatively cut the tile material if the cut line is located at a distance of at least one centimeter from the edge of the tile.

- Now it is necessary, driving the handle, to advance the carriage along the line applied by the marker. It is very important to consider pressure on the surface of the tile itself. The main thing is to cut the glazed layer of cladding. If the pressure is large, then there is always a chance that the tile will break. If, on the contrary, the pressure will be insignificant, then the layer of glaze may not work out to cut. But most importantly. the incision should be carried out in one pass. It is better not to carry out this operation again, because a fishing line for a trimmer cut can be a curve.

- Next, you need to do a break on the place of the incision. Why should the handle be returned to the working position and click on it. The result is an even fracture of the tile.

There are many recommendations that simplify the process of cutting ceramic tiles. For example, first lower the material into the water or drop on a wheel or on a fishing line for a trimmer cut a drop of technical oil. Such lubrication makes it possible to easily enter the glazed surface. We add that the porcelain tile with a hand tiles cannot be cut, this facing material is too hard and durable too hard and durable.

How to use an electric tile cutter

In principle, this power tool greatly resembles a circulation saw. In the same way, its design includes a cutting disk, which is fixed to the electric drive shaft. The latter is small in size an electric engine. Typically, electrical tiles are manual or stationary models operating from an alternating current network with a voltage of 220 volts.

One of the modifications of electrical tiles is a tool in which a tape with diamond spraying is installed instead of a cutting disk. By the way, most often strip models are manual. The high speed of rotation of the cutting working body creates between it and ceramic tiles the force of friction, which causes high thermal energy release. The latter negatively affects diamond spraying, therefore, the design of the tile cutters includes a container with water, with which the edges of the working organ and the tiles are cooling and the edges of the working body are made. Water is brought to stationary equipment to hoses.

So, how to correctly cut ceramic tiles with an electric tile cutter. As in the case of a manual tool, a stationary device must be checked for the technical condition. The most important thing is that the cutting disk does not have a backlash. It can be adjusted by clamping a clamping nut that attaches the disk to the electric motor shaft. If after that the backlash was re.found, you will have to replace the disk with a new.

Now the sequence of operations.

- Tile marking is made.

- The guide is tuned, along which the tile will be displaced along the cut line.

- Tile material is laid on the device table.

- The electric motor and water is turned on, which is supplied to the place of the incision.

- Now with your hands you need to push the tile to the cutting disk. Great efforts should not be created until the disk crashes into tiles. Further, the force can be increased. When the disk exits the tiles, the pressure must be reduced again.

- After which the equipment is turned off.

Please note that during cutting, the equipment works with a small vibration. This is a natural process, therefore it is very important that vibration does not acquire a large amplitude. This can cause a breakdown of the facing material.

If you use a manual tool for cutting, then the process is carried out on the floor or even horizontal plane. To do this, the stands are laid under the tile so that the cut.off part remains a canopy. Now the tool is turned on and is brought to the place of the applied line. Cut the tiles exactly along the line, the main thing is a solid hand that moves the tool without pressure.

Here are some recommendations from specialists how to properly cut the tiles with an electric tile cutter.

- Press the tile with both hands.

- Move it exactly along the guides.

- Periodically, you need to change water in the tank, because it falls dust and small pieces of cut off material.

- Pay attention to the cutting disk, it should always be clean without adhering dirt and waste from ceramics.

How to cut the tiles Telingrease electric

How to learn how to cut tiles with an electric tile. the question only looks complicated. The unit is intended for a significant amount of work to create direct cuts and angular lines. They will not be able to get rounding.

Apply for 1-2 units-inappropriate. It is optimal to use this analogue of the circular saw for large.scale repairs and construction. Provided quality. accurate and even cut the first time.

Cutting tiles with such a tile cutting is well shown on many videos. The process is as follows:

- preparation and consolidation of the workpiece;

- marking;

- Preparation of the tool in full accordance with factory requirements.

Before cutting tiles with a tile cutter. you need not to forget to remove unweated persons from the dangerous section. The inclusion and operation of the power tool is an increased danger to others due to the rotating blade. Of great importance are safety and personal protective equipment (glasses and gloves. first of all).

Preparation includes filling with water of the cooling tank and other measures. The work of this apparatus is distinguished by the need for constant cooling of the blade.

Excessive pressure on the tool is fraught with failure.

How can you cut the tile if not Tiles cutter

How to cut tiles with a tile cutter with a manual or other way, you can watch on the video. But what to do if there is no special tool? What can you do, how to cut the tile without tile cutter ?

Coating processing for even and not only cut is also performed by the following tools:

The latter can be performed with a fairly wide scale. For this, a variety of discs are available: steel (with segments or continuous), with spraying (more often than others, diamond), simple detachment (for gross work). Smooth, diagonal, curved and curly lines, as well as holes with a size of a diameter of the circle are formed.

How to cut tiles with a tile cutter. Stage and with photographs.

About how to cut the tile with a mechanical tile cutter. It has already been briefly told and shown on this site.

At first glance, there is nothing complicated in this. But in any business, there are details. A damn, as you know, lies in details.

Cut in a straight line does not cause particular complexity. The need to cut the tile with the letter “g”, leads to some confusion.

So you usually have to cut tiles on slopes and near various hatches, doors.

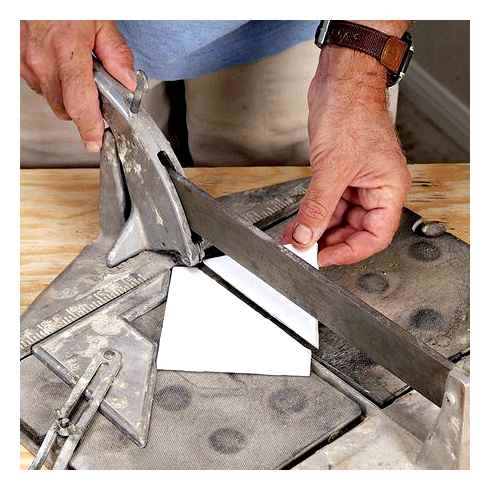

Stage cutting a piece of tile.

Previously, with the help of a square and a marker, it should be noted 3 angular points, a cut piece. Sometimes for marking a fairly short wedge and pencil. (Video at the end of the article).

Draw a tile cutter with a cutting wheel of two lines, according to the marking.

Cut the corner grinder short fishing line for a cutting trimmer. The cut.out circle should be designed for cutting ceramic tiles (this is always indicated on the pack package). The cut.out circle, during cutting, should not be located along the line outlined by a tile, but along the edge, on the side of the cut off (unnecessary), a piece.

All these difficulties are needed so that the cut.out circle does not leave chips on enamel.

If the tile of a “very budget option”, as in the picture, the enamel bounces even when cutting a new wheel and an expensive tile cutter.

5 Ways to Cut Tile. Everything You Need to Know for Your First Tile Project

After a short cut of an angular grinder was made, the tile must be installed with a long side on a tile cutter, exactly along the line previously drawn by the wheel wheel, and break off the handle with a red tile.

Lever (with a cutting roller) for breaking tiles, it is necessary to install first or at the end of the tile, retreating from the edge of the tile 2-3 cm.

Installation of a tile cutter lever when pressed on a fishing line for a cutting cutter

In this way, you can cut the tile with a thickness of up to 12-15mm. But not every tile.

Cheap tiles, with two pipe guides, bend and cannot break, often, ordinary porcelain stoneware. The tool shown in the photo can cut the tile up to 18 mm. Only at the same time, it is necessary to make cuts on both sides of the tile.

After a piece of tiles is broken off, it is necessary to finalize the angle with a detachable circle.

The whole process completes the whole process, cut off the edges, with sandpaper. This operation is especially important when the cut part of the tile is not covered with anything.

Когда нет возможности установить плиткорез на стол или верстак, то им работают прямо на полу. With a significant amount of cutting, the knees begin to hurt. This can be avoided if you put a 5 centimeter sheet of foam next to the tool. This will not only create comfort to the knees, but also help pruning large tiles.

“Small tricks” when cutting tiles with a tile cutter

Small video how to mark and cut the tile with the letter “G”

Questions from letters and consultations in Skype:

How to cut off corrugated tiles?

Electric tile cutter is most suitable for trimming corrugated tiles. This is the case when it exceeds mechanical (my opinion).

With insignificant tile tuberosity, the last version of the tool is quite suitable.

But the larger the relief of the tile, the more difficult it breaks the lever along the line of the cutting of the video. Therefore, the cutting wheel should draw the most possible fishing line for a trimmer of all bumps. Then there is a chance that the tile will break along the cutting line.

And the smaller the cut off, the less chance for a successful cut. The video below shows that half of the tile always breaks successfully.

Cutting tiles with corner grinders

This video shows the general principle of operation with a corner grinding, including grinding the edges of the fault.

However, it is worth understanding: for such filigree work you need a good skill. In addition, quite often when cutting a disk. both in a straight line and a curve. chips occur. To cut the tiles of a corner grinder without chips and other problems, the masters recommend gluing a masking tape along the cutting line and make markings along it. By the way, it is convenient to do it with a normal pencil.

To simplify the work, it is better to fix the tile or porcelain tile on the desktop.

It is convenient to do this with special clamps-beasts. At the same time, the depreciation of the support surfaces of the clamps and at least the minimum depreciation of the desktop is mandatory. this will help to avoid unwanted vibration leading to chips on the tiles and its uneven fault.

It is recommended to lay a foam, foamed polyethylene and other similar materials on the table.

Sometimes it does not go out to get an even section, in this case you can “choose” the corner grinder the material to a certain circuit, and then smooth the edge with an abrasive.

If you need to make a rectangular neckline or cut the tile along the broken contour, straightforward cuts are performed.

Unfortunately, it is difficult to avoid cuts in the corners.

Corner grinder is also convenient to polish not quite even edges of the tiles after cutting. For this, special flexible abrasive circles are used.

What is needed to cut tiles without tile cutter?

In addition to the already mentioned corner grinder or angle grinding machine, glass cutters (otherwise wet cutting) are used. You can cut the tiles at home along the line of any complexity, but the problem is the need to apply a strictly defined (and quite large) effort to carry out the cut and fault of the tile. over, the more complicated the fishing line for the trimmer of the incision, the higher the risk of uneven fault.

The easiest way to work with direct contours.

To divide the panel, you need to cut the tiles without a tile cutter to the desired contour and carefully break off. As shown in the diagram above, a thin rail, nail, knitting needle and other similar item are placed under the place of fault. What is interesting: with glass cutting can be drawn one place several times, and you also need a fishing line for a trimmer of fault from the back of the panel. It can be sawn with a hacksaw for metal. Before breaking the tile, it is necessary to “tap” the entire fishing line for a trimmer, as when cutting glass, and then make a sharp breakdown. It is convenient to rest the tile at the place of fault on the edge of the table or another angle. The break is cleaned with an abrasive.

Another option is the use of a jigsaw, ordinary or electric. Of course, the electrician is more productive and due to a high cut rate gives a lower risk of incorrect tile break.

What is valuable. the use of an electrician practically does not give restrictions on the thickness of the cut material. The only restriction is the permissible depth of immersion of the peel of the jigsaw, and in most models it is at least 3 5 cm.

For work, files for metal are used, the cut is cleaned with an abrasive to a smooth surface.

What tile cutting for cutting

Choosing manual tiles, pay attention to the following characteristics:

- The mechanism of the carriage. There are two varieties: roller and bearing. The roller carriage of high.quality tile cutter initially moves easily, but soon loses its smoothness. Bearing tiles are more expensive, but have a number of advantages: they serve longer, cut more precisely and provide the carriage with a smooth move.

- The bed should have sufficient stiffness, which is provided by the ribs under the bed. The low.strength bed is bent under load and the tile breaks crookedly, not along the furrow.

- The thickness of the guides. The higher this parameter, the lower the probability of the appearance of the carriage play.

- The diameter of the cutting roller. There should be the more, the thicker the tile.

- The size of the bed. It is advisable to purchase a tile cutter with a fairly large bed, which allows you to cut large floor tiles and perform diagonal cuts.

- Manufacturer. A guarantee of the quality and durability of the tool are well.proven, time.tested brands: Sigma, First, Matrix, Rubi, S.A., Germans Boada.

- Additional opportunities. These are the ruler (allows you to evaluate the width of the cut off and the remaining parts) and the rotary bed (it is used to cut at different angles).

Before use, the serviceability of the tile cutter according to the following criteria is checked:

- The diamond video is sharply sharpened, there are no chips and potholes on the cutting edge. Otherwise, the tile breaks crookedly, you get a lot of marriage. The inferior roller is changed.

- There is no karetka backlash. In the presence of a backlash, it is eliminated by adjusting screws. If it does not help, the tile cutter is repaired or changed.

- The carriage moves smoothly. If you fuck, lubricate the guides. It is useful to lubricate and the video so that it rotates easier.

- Pure bed. Ceramics are like crumbs on it.

- The condition of rubber mats that prevent tile gliding. They must fit tightly to the base.

- The angle between the emphasis and the axis of moving the carriage is 90 degrees. Checked by the square.

Round and curly cut

Often the question arises, than cutting ceramic tiles, if you need to not reduce its length/width/divide by diagonally or at an angle, and make a round hole.

For these purposes, a coronet drill or, otherwise, a diamond crown is best suited. This issue is considered here in more detail here. It is worth noting that the presence of a more rational version of drilling on a tile or separately, but for the sake of one hole, buy expensive drills on a tile and porcelain tile, of course, you should not. And to work with the ballerinka and for drilling, it is advisable to tap the future center of the hole. Successfully removes the problem of vibration, work with tiles laid on 3 5 mm layer of water in a form coinciding with its dimensions.

The combination of several sawdust, straight and round will help to make a more complex neckline. If the transitions of the curve along which the incision is performed is quite smoothed, or a broken fishing line for a trimmer is used, it is convenient to use an angular grinder and an angle grinding machine with an appropriate disk.

When you need cutting tiles?

You have to resort to such a tile processing in various cases when it is necessary to create a beautiful right angle. For example, when it is planned to put the tiles on the wall and on the floor, when you need to renew the ventilation box available at the floor or a deepening for pipes. In modern apartments, you can find various design features, which means that the variations of the use of tiles are significantly expanding.

Using such a sharpening method, the inter.seam guts look more accurate, and the edges of the tiles at the junction are more tightly closed by grout, which reliably protects them from moisture or random blows.

Cutting tiles at an angle of 45 degrees is performed if you want to put the finish in an unusual way, for example, diagonally. To do this, you can use both square and rectangular tiles. The latter will create unusual ornaments (and even the effect of the “parquet Christmas tree”).

Corner grinder for Wap

The usual corner grinder is in the arsenal not only for professional finishes, but also among lovers. It should be equipped with a diamond disk. Install the tile under the rib with the front side down. The tool should be adjusted, then it will be easier to achieve the right angle. At the same time, for starters, you need to set the minimum indicator so as not to melt the edges. When the desired angle is stood, go through it with a diamond disk again to polish it. Can be used for grinding a file, or sandpaper.

There are special nozzles for grinding. They are easy to replace. the base with Velcro is installed on the thread of the corner grinder. They are not as durable as diamond “turtles”, but they also cost cheaper. For those who are not engaged in repair on a production scale, this may be quite enough.

Many people prefer to use a mask or respirator when working with a corner grinder. This tool gives too much dust, which is not recommended to breathe.

How to use a corner grinder?

Let us consider in more detail how to use a corner grinder, working with tiles:

- The tile should stand in a vice vertically. Put a diamond disk, and then choose the operating mode of 1000-2000 revolutions per minute.

- Remove the corner part of the disk on which the notches are applied.

- The tool should be located at an angle of 45 degrees (relative to the front plane of the tile).

- Remove surpluses with smooth touches so that every time it goes along the finest layer from the surface, not reaching the edge of the outside of the corner.

- The edge with a thickness (about 2 mm) should remain untouched. This distance can be noted with a pencil.

At the second stage, a support plate is installed on the corner grinder. Circle with sandpaper is placed in the center of the support plate. Now you can bring the edge, and then create the most acute angle.

Wroked mosaics

Mosaic is the same ceramic tiles, it is also actively used today in the design of modern interiors, so sometimes it becomes necessary to perform a saw at an angle of 45 degrees on small modules. How to do it?

It is better to use an electric tile cutter for work, if there is experience in a corner grinder, it is also able to come in handy. If the tile cutter is used, as practice shows, cutting the mosaic by icing up is not very convenient. And all because the structure of the formed models is very mobile, it is constantly moving, so it is better to turn the tiles upside down, fix it on the back of the cutting disk and, supporting with your hand, perform a cut. Will have to suffer a little, but it will still be possible to perform the operation.

And here an important condition is preserved. when processing the edge, you do not need to reach the glaze layer. The mosaic processed in this way is most often used in the design of niches, boxes, under which engineering communications are hidden in the bathroom and in the toilet.

It will also be quite difficult to perform a corner grinder. This process is quite dusty, and it is necessary to be prepared for this. The mosaic in this case is also laid down the face down. During operation, the tile must be pressed to the surface of the base with something. You can use a flying fateful size for these purposes.

The saw is performed slowly, the clay is removed the layer by the layer. The diamond disk should work all the time at the smallest speeds. It will not be possible to perform a cut neatly with a corner grinder. Therefore, the cut will need to be finalized with a file or sandpaper.

Generalization

Recently, many, performing the facing of the walls of the tiles, refuse to use the plastic corner. The refusal sounds differently every time. One cannot choose the color of a plastic ceiling for the color of ceramic tiles, others prefer to use as few additional elements as possible in the decoration, others simply like to experiment and try something new.

The very idea is to make the tiles at an angle of 45 degrees and join the tile at right angles, not new. It was often used by builders in the lining of the marble of facade front elements. Now a similar technique began to be used in the design of niches, boxes, behind which engineering communications are hidden. It allows you to get a rather interesting solution. But using it, it is important to know that the angle on the tile, sharpened at an angle of 45 degrees has its technical disabilities.

Firstly, the angle becomes fragile, it is vulnerable, any strong blow will be able to destroy the tiled clatter. Therefore, this technique cannot be used when decorating surfaces located in the passage plane. It is enough to hook the angle with a metal bucket, and it cracks and crumbles, or covers with chips.

Secondly, such a decoration option significantly increases the complexity of the work, which means that the final cost of the repair will increase noticeably. The formation of a right angle by cutting requires the use of professional construction equipment. Therefore, wanting to experiment yourself in the described direction, you need to think carefully and weigh everything “for” and “against”.