How To Cut The Countertop Under The Sink

How to make a sink hole correctly?

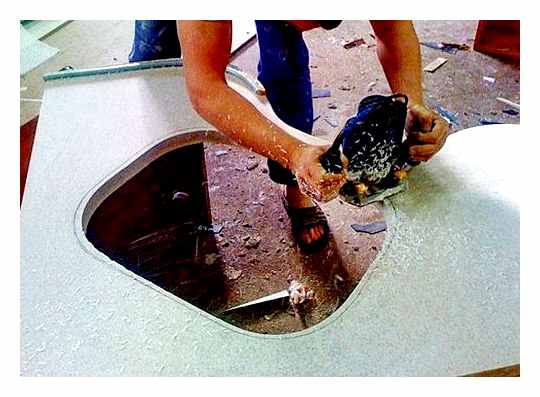

An electric jigsaw is required to make a hole in the countertop. It is suitable for wood and chipboard worktops. If the tabletop is made of durable materials, then the jigsaw will not cope. First, 4 holes with a diameter of 1 cm are prepared at the corners of the rectangle, without crossing the marking line. Then a file with the required tooth length (2 mm) is put on the jigsaw. To avoid chipping on the front surface, choose the opposite direction of the tooth.

Holes are made to the left and right, and then the wooden plank is pulled with self-tapping screws across the sawn lines so that the cut part does not fall prematurely under gravity. The cut out part is carefully removed, and the exposed edges of the hole and irregularities are coated with liquid silicone.

How to embed a sink into a countertop

How to quickly and accurately cut a hole for a sink

Immediately, we note that with a household tool, you can cut a hole only in a chipboard or solid wood countertop, regardless of the type of coating. Stronger materials such as silicon agglomerate require specialized cutting tools and attachments.

First, you need to drill several holes with a diameter of 10–12 mm in the table top near the mowing line of the marking, but without crossing it. Usually 4 holes are drilled at diametrically opposite points of the contour or at the corners of a rectangle. It is imperative to start drilling from the front side so as not to pull out a large section when the drill comes out.

To cut a hole for a sink, you need an electric jigsaw with a file at least 8 mm wide and a tooth length of about 1.4–2 mm. It is better to choose the opposite direction of the tooth so that no chips form on the front surface during sawing. And although the sink rim covers a strip 12–20 mm from the edge, some countertops behave unpredictably and give a rather long crack.

First, a hole is cut on two opposite sides, then a small strip of chipboard or wood is laid across the cutting lines. It is attracted by self-tapping screws to the cut-out part of the tabletop and keeps it from falling at the end of the cut. After installing the strip, it is necessary to complete the cutting of the fragment and remove it. An open cut, all chips and unprotected edges are abundantly treated with transparent silicone, leaving a layer of at least 0.5 mm, and allowed to dry.

How to embed a sink into the countertop with your own hands?

How to properly and easily embed a sink into a worktop? This question is faced by everyone who started repairs in their kitchen. We will tell you in an accessible and detailed way how to do the installation correctly and quickly.

Installation of a sink and its connection

Almost all sinks are equipped with tape seals, but they are quite hygroscopic and accumulate moisture in themselves, creating conditions for the development of mold. Instead of standard seals, manual sealing with silicone sealant is required.

With an indent of 1–2 mm from the edge of the hole, a silicone flagellum is extruded onto the tabletop in a circle, the thickness of which is 2–3 mm greater than the height of the sink rim. Another flagellum is applied at a distance of 10 mm from the first. The silicone should be left for 30-40 minutes, until its surface no longer sticks to your hands. Then the sink is installed in the hole, its edges are carefully pressed down, giving the silicone the desired shape. The sink must adhere tightly to the worktop along the entire perimeter, otherwise it may unscrew a little when tightening the fasteners. After 5-10 minutes, the sink must be removed and make sure that the silicone has not burst or leaked. Thus, a double continuous rim is formed on the worktop, excluding the ingress of water into the interior, while the sink can be easily dismantled.

Before the final installation and fixing of the countertop, it is necessary to mount fittings on it, access to which will be difficult by the bowl, that is, the mixer and the overflow hose, if any. But the siphon or shredder is much more convenient to attach to the installed sink, so that it can be held during installation by the open drain hole.

To secure the sink, it has steel hinges located along the contour of the bowl in an amount of 4 to 10 pieces. They are threaded with screw clamps in the form of paws, the edges of which should be oriented outward. After that, the sink is lowered into the hole and finally leveled, then the screws are tightened, tightly pressing the sides to the tabletop.

Installation of a sink and connection of communications

This will require liquid silicone again. Having stepped back a couple of millimeters from the edge of the hole, we apply silicone with a flagellum in thickness just above the sink rim. Departing from the first one more centimeter, we apply another flagellum.

After half an hour, the silicone will dry and stop sticking to your hands. Then the sink needs to be inserted into the hole and the edges are well pressed so that the silicone strands take the shape of the sink, and leave for a few minutes. The sink is then removed and the silicone tested. If it is not violated, then everything is in order, and the sink will have a reliable additional side.

We attach fittings to the table top for installing a mixer and a hose. It is more convenient to attach the siphon to the installed sink. Many sinks have special loops for screw clamps in the shape of the feet. They help to tighten the sides to the table top.

Performing markup

This is a rather crucial stage. Place the sink in the center of the countertop. Remember that the gap from the edge of the worktop to the edge of the sink must be more than 50 mm. If this distance is less than 50 cm, then the sink must be deepened.

The distance from the corner plinth should be more than 30 mm so as not to create problems when cleaning. If the dimensions of the countertop allow, it is better to leave a little space from both sides for household chemicals and a sponge.

If the manufacturer encloses a template for the sink insert, then the task is much easier. The template is glued to the worktop and facilitates the marking.

In the event that the countertop is without a template, it should be installed on it, turning it over, and the sink should be drawn around the contours with a washable marker. If there is a sink and a drying compartment or a waste tray in one block, then one common hole is cut.

Required tools

In this article, we figure out how to embed a sink into the countertop, and if you joined us, it means that you have a change of scenery in your kitchen, and I would like to try myself as a master. Well, we will try to consider in detail all the pitfalls in order not only to carry out the installation, but also to ensure the durability of the new acquisition.

How to install a sink in a worktop: a simple algorithm

Hello, friends.

In this article, we will consider one very serious operation, which greatly affects the quality of the kitchen set.

It’s about the sink sidebar. We will consider this whole process from start to finish with all its nuances.

Before you embed a sink, you need to decide in which part of the countertop it should be located.

To do this, the countertop must be placed on the lower modules of the kitchen, and the box in which the sink should be placed, from the inside, circle with a pencil (along the countertop) to determine the internal space for it.

After that, the table must be put upside down, and mark the place for cutting the hole. This is done as follows:

First, the location of the sink itself is determined (it should not go beyond the inner border of the box, otherwise, to insert it, it will be necessary to cut not only the countertop, but also the sides of the box

- When the position is determined, it is outlined with a pencil along its contour

- Then, with a tape measure, you need to measure the distance from the edge to the ear, into which the fasteners are attached

- After that, in case the sink is round, the center of the drawn circle is located. It is located as follows: on the circle, anywhere, a point is placed to which a straight part or ruler is attached. To this straight line, you need to attach another piece (or square) with a right angle. In the area of the center, a line is drawn. Then the second point is taken and the same is done. The intersection of two lines will be the center of the drawn circle (yes, sometimes knowledge of geometry can be very useful)

- Mowing lines (type, diameters) are drawn through the center of the circle. They are needed in order to measure along them, from the edge of the circle, the distance we measured from the edge of the sink to its ear for fasteners.

- Having made 8-10 such “serifs”, through them, using the same sink, we draw curves (in parts), which form inside the circle we have drawn, another circle, the radius of which is less than the radius of the main circle at the distance from the edge of the sink to its ear. This will be the circle that needs to be cut with a jigsaw.

- We make a hole on the inside of this circle with a large drill (usually, this is a drill with a diameter of 10 millimeters).

- We insert a jigsaw file into this drill, and cut a hole. Do not forget, when the hole is almost cut, support the cut out part of the countertop, as it can break off, breaking the plastic from the front.

When the hole is made, the inside of it needs to be covered with silicone, since this place is the most problematic place in the kitchen. It should be protected as much as possible from moisture getting inside the countertop, since in this case, the countertop can simply “break” from moisture. and this is its complete replacement.

So, after the hole has been “siliconized”, we begin to prepare the sink for the insert.

To do this, you need to stick adhesive tape on its inner surface, which is always included in the kit (plus fasteners and plus, plastic pipes for draining).

Please note before you buy a sink: Sticky tape (which needs to be glued inside) should not be stuck on it. It should be included. Almost all sinks in which adhesive tape was previously glued, it was not glued correctly.

And correctly, it is glued so that there would be a small distance between it and the side of the sink itself (it turns out there, like a gutter), where the silicone is poured.

It turns out at the same time, two barriers: adhesive tape and silicone.

So, when all this is done, and the silicone is poured, the sink is inserted into the hole cut in the countertop (from bottom to top). If the tabletop is located, for example, on two chairs, then one of them can be immediately substituted under the sink, thus fixing it.

After that, fasteners are inserted into it.

I want to note that this is one of the most unpleasant moments when installing a kitchen unit.

The fasteners with which it is attached to the countertop are usually poor (meaning, poorly thought out). There are almost always problems with it (for this, you need to always have spare versions of this fastener for installation).

There are situations when he simply does not fix the countertop, but climbs to the sink (which happened at the installation, photos from which are posted in this article as an example).

As we did not bend the antennae of the fastener itself, he stubbornly jumped off the tabletop (and, of course, did not fix it).

The easiest way out of this situation is as shown in the figures: you need to insert a piece of chipboard, or something else, between the sink and the fasteners themselves. Thus, the fasteners are fixed, and, twisting, attracts the sink.

But, do not forget one detail: you need to exercise with the installation, if possible, not very long, since the silicone that was poured into the sink, when pressed against the countertop, partially “crawled” out. It should not have time to freeze, because in this case, removing it, you can remove part of the silicone under the sink.

When it is pulled against the worktop, you need to make sure that there are no gaps between it and the worktop. If they are, then it is badly attracted.

At the end of the insert, you need to wipe the silicone protruding from under the sink and the sink itself.

Stage # 3. edge treatment with silicone gel

The end surfaces of the resulting hole are sanded with a file and emery paper. After alignment, these places are lubricated with silicone sealant. over, this manipulation must be performed with special care, thus, it will be possible to avoid problems with leaks when using the sink.

The edges of the cutout must be carefully sealed

The sealant must be designed specifically for the material from which the countertop is made. If it is wooden or plastic, then the sealant should be alcohol-based.

Once the ends are filled with silicone, it’s time to insert the sink into the countertop. The fit should be very tight, if necessary, the product can be turned.

Now all that remains is to install the sink in the countertop

The installed fasteners are now tightened. The silicone that will be squeezed out in some amount when the sink is planted must be removed. The structure must be left to dry. Everything, we can assume that the sink under the countertop is finally mounted. But this is not the end of all the work, because the drain fittings still have to be connected.

Installation sequence for a recessed sink

Of course, the most interesting is a detailed consideration of how to install a sink in a fully recessed countertop. In principle, there is nothing incomprehensible in this procedure, it is not divided into several stages:

Stage # 1. marking the installation site

The correct marking will be ensured by the template that comes with the sink

The place where the sink for the bathroom with the countertop will be installed is determined. In this case, three conditions must be met:

- The sink cannot be flush against the wall;

- The sink should not be at the very edge

- Absolute usability must be at the forefront.

So, the meaning of this work is that the sink should not fall into the created hole, but it must be firmly and conveniently placed on the countertop. The sink under the countertop is turned over and laid on the surface. The outline is outlined. For this, a pencil is used, which is easily erased. Then measurements are taken to determine the distance from the fastening lugs to the edge of the sink.

The resulting size determines the distance that deviates from the mowing line of the previously outlined contour inward. Based on the dimensions obtained, a new marking of the inner contour is performed. You can do it even easier: just step back 1.5 cm along the entire outline inside the contour and draw a new reduced contour. Even a person without artistic talent will perform these simple actions correctly. But the resulting inner “figure” is to be cut.

And if such assistance is not provided by the manufacturer, then you need to act according to the technology described above.

Stage # 2. cutting along the outlined contour

Cutting a hole with a jigsaw will turn out faster and more accurately

Before the undercounter sink is installed, a hole is prepared. For cutting, ideally, you need to have a jigsaw on hand. Although you can use a simple hacksaw, but then you have to trim the edges. If a hacksaw is used, a hole is first drilled inside the outlined contour close to the mowing line of the marking. It must be large enough to fit the hacksaw blade. Then the unnecessary part is carefully cut out. In this case, it is necessary to minimize the pressure on the decorative coating of the countertop, since when performing this work, chips may appear.

What tools are required to work?

To do this work, nothing special is needed, all these items are always in the household:

- Electric jigsaw or hacksaw;

- Drill;

- Screwdriver;

- Pliers;

- Clamps;

- Spatula, brush;

- Sealant.

It is worth adding to the same list: a ruler, a pencil, a rag.

Self-installation of the sink in the countertop. analysis of the installation technology

Setting up your own home is a creative process that has virtually no end. To create the perfect home, you have to invest a lot of money in the implementation of your creative ideas. Although you can always try to reduce them by doing some work without outside help. For example, with the right approach, self-installation of the sink in the countertop will not be a daunting task. It’s even interesting. with your own hands, two independent faceless objects to combine into a single logical composition.

Which sink is suitable for the countertop?

Before deciding how to attach the sink to the countertop, you should pay attention to the type of this sanitary ware. Today manufacturers offer the following sinks:

- Suspended;

- On a pedestal (tulip shell);

- Embedded;

- Consignment note.

In this case, we are interested in products of the last two types.

Option # 1. built-in sink

The sink built into the countertop is an integral part of bathroom furniture, and in particular the bedside table, which can be supplied complete with a mirror, lamp or other accessories. The sink is also built into kitchen furniture. To put it simply, the prototype of such a variant of installing a sink in a bathroom is the Moidodyr washbasin, known from Soviet times.

Option # 2. overhead sink

The installed sink on the countertop is a new word in the arrangement of the bathroom. In this case, the product is simply placed on the countertop, and any flat surface can play its role. Naturally, many special countertops are offered for sale, they differ from the usual ones in that they have recesses.

This sink installation has both pros and cons. So, due to the absence of joints, problems with water leakage are eliminated, and accessories and accessories can be stored on the surface of the countertop. This design can be easily placed over the washing machine. The pipe is fed to the sink in the same way as to the flat wall sink.

Stage # 4. final assembly of all elements

The mixer installation requires great care and meticulousness. Although if a hole for a mixer is made in the sink at the production stage, then there will be no particular trouble. If there is none, then it means that you will have to make this hole in the canvas of the countertop.

Naturally, this procedure is carried out even during the period when the holes for the installation of the sink are cut out. Hoses are installed in the mixer, then the product is inserted into the hole of the sink and fixed with special fasteners.

Some more helpful tips

Installing a sink into a countertop is both a complex and simple process. If the work is done poorly, then at least the appearance of the bathroom will be spoiled, and as a maximum, the tabletop will quickly fail due to the constant ingress of water into the sections.

Of course, you don’t have to rack your brains right away and invite a professional plumber to arrange the bathroom. this is the right of every homeowner. But making the work with your own hands is much more pleasant, and frankly speaking, installing the sink is the stage that everyone must go through on their own, because even the best craftsman will not do everything perfectly the way the homeowner does. In conclusion, we suggest watching a that shows how a specialist mounts a sink in a countertop.

How to embed a sink into a countertop. step by step guide

At first glance, the installation procedure is not complicated. However, there are a number of nuances that pop up immediately after the start of work. These nuances will be discussed. traditionally, in the form of illustrated step-by-step instructions.

We have already talked about the criteria for choosing a kitchen sink, we will only add that if you want to purchase a budget option, we recommend paying attention to the German Franke sink, made of stainless steel. It will cost more than Chinese models, but it is made of thin high-quality steel, and not from “thick foil”, as they are. It is such a sink that is installed in this example.

Kitchen sink Franke Pamira PML 611 3.5 ″

Almost all modern flush sinks are sold in a cardboard box, which additionally acts as a template for a countertop inset. This template is first and needs to be cut out for the subsequent installation of the sink.

Almost all modern models are sold in a cardboard box, which additionally acts as a template for a tie-in

Next, the cut template must be placed on the tabletop, and then aligned parallel to its sides. Then you should check if there are any elements under the chosen place that could interfere with the installation of the sink. When the optimal location of the product has been chosen, the template must be fixed with masking tape and outlined with a pencil.

The template is located on the table top

Now you can start cutting the template, for which it is convenient to use an electric jigsaw. But first it is necessary to drill initial holes in the countertop with a diameter slightly larger than the size of the jigsaw blade.

In order for the jigsaw to cut the countertop, you need to drill an initial hole in it for the jigsaw blade

It is also advisable to protect the perimeter around the future cutout with the same masking tape, otherwise the jigsaw can damage the tabletop. Directly during cutting, you should not rush, because the saw may deviate and the cut will turn out to be crooked.

The perimeter of the future opening is sealed with masking tape

When the opening is cut, its edges should be treated with sanitary silicone (this will make the cut waterproof). Then you need to wait until the silicone hardens.

In our example (as you can see in the image below), you have to cut not only the countertop itself, but also certain elements of kitchen furniture.

Elements of kitchen furniture will also have to be cut.

If so, you need to use the cardboard sink template again, but this time on the inside of it.

The template is used again

Now you need to cut out the elements of the opening under the sink, and again, treat all the cuts with silicone.

Opening elements are cut

You can then try on the sink and see if everything fits. If everything is fine with this, you can proceed to further work.

Everything necessary for assembling the siphon (it must be purchased separately) should be unpacked and checked, then a careful study of the assembly instructions goes.

Preparing to assemble the siphon

There is nothing complicated in the assembly of the siphon, except that one of the tubes will need to be cut to size.

Next, you need to arm yourself with a wood crown in order to make a hole in the cabinet for a sewer outlet.

Drilling a hole for a sewer outlet

All communications must be connected before installing the sink. In our example, this is a gas pipe from a cylinder (it is orange) and water pipes (they are green).

Holes for water pipes should be made in the kitchen cabinet. The work should begin by marking the future location of the latter.

Pipe layout

All excess must be cut off with a jigsaw.

You need to cut in accordance with the markup

The next stage is another processing of the sections with sanitary silicone.

Cuts need to be treated with transparent sanitary silicone

Now you can lay water pipes (preferably, as in the example, polypropylene) to the sink and the water purification filter.

Laying water pipes

Here is the piping diagram under the kitchen sink.

Before installing the sink, you should install a tap for drinking water.

Preparing to install the mixer. To make a marking of the holes for it, you need to take a cardboard template in order to transfer their projection.

Preparing to install the mixer

In accordance with the projection, holes should be drilled in the sink through which the mixer will be attached.

The next step is directly attaching the mixer.

After that, you need to try on the fittings for the sink. According to German developers, for some reason, plastic latches will be enough to hold the product.

Factory plastic fasteners

An alternative option is to use strips of mounting tape (they need to be threaded into the “ears” of the fasteners).

Our solution for fixing the sink. strips of mounting tape threaded into the ears of the fixings

Also, before installing the product, the edges of the opening should be glued with a sealant.

Before installing the sink, the edge of the countertop is glued with a seal

The sink must be fixed with self-tapping screws through the mounting tape.

Everything, the kitchen sink is installed in the countertop! Now it remains to process all the gaps with sanitary sealant, and cut off the residues after the material hardens.

Kitchen sink cut into the countertop

Varieties of sinks by installation method

There are several technologies for installing a kitchen sink. The choice of this or that option depends, first of all, on the type of construction of the sink itself.

-

Overhead sinks. They are rightfully considered the cheapest and easiest to install. The installation itself looks like this: the sink is simply put on the countertop. The disadvantage of this method is that there are gaps between the cabinet and the sink.

Mortise kitchen sinks

It is not surprising that the representatives of the latter group are the most popular today. They, in contrast to overhead models, provide high-quality sealing, but at the same time they are much cheaper than under-table counterparts. In short, the best value for money.

Perfectly installed recessed sink

Key features of choosing a sink

Even before buying a sink and starting work, you must decide which product you will install. It is better to give preference to deep sinks and rather low faucets. in this case, splashes during washing the dishes will be minimal. A large depth of the sink is needed so that it is convenient for you to fold dirty dishes there or wash large pots.

In addition, pay attention to the material. it is much easier to embed a traditional stainless steel sink on your own. Although another good option is enameled steel.

Corner sink with two bowls attracts with shape and color

Installing the sink in the countertop with your own hands

Today you can install the kitchen sink you like. over, it is not at all necessary to contact a qualified specialist for this. usually, a procedure such as installing a sink in a countertop with your own hands can be done. But in any case, the kitchen sink has a truly strategic importance, and therefore its choice and especially installation should be approached with all responsibility.

Installing the sink in the countertop with your own hands

Kitchen sink prices

What is required for a kitchen sink insert?

To insert the sink into the countertop with your own hands, you must prepare the following materials and tools:

- Pencil;

- Electric drill, metal drill for it (1 cm in diameter);

- Roulette;

- Electric jigsaw;

- Building corner;

- Sharp knife;

- Crosshead screwdriver;

- Sealant (sanitary or universal);

- Self-tapping screws (dimensions. 4×30 mm).

Installation tools

Installation example without using a cardboard template

If such a template is absent for one reason or another, do not be discouraged, because the inset of the sink can be done without it. The procedure itself in this case, too, is nothing complicated, and a brief installation instructions are given in the table below.

Table. Workshop on installing a kitchen sink in a countertop.