How To Cut Tiles Correctly

3 ways to cut tile at home

Any ceramic tile laying process is not complete without cutting it. There will be a lot of it especially if you use some kind of non-standard layout, for example, diagonally. In the last article, we talked about which layout is better to choose in order to get uniform and beautiful cuts everywhere. Now we will talk about how to properly cut tiles at home.

As you know, the tile is made of baked clay, which is covered with glaze on top. It’s hard to break it with your hands, but if it lies on any unevenness, then it cracks easily from a small load. To simplify this process and make the required break line, you need to loosen the top layer of the glaze. that is, cut it, and therefore make efforts to break.

There are 3 main ways to do this:

- Special tool. manual, electric tile cutter or special tongs.

- Angle Grinder.

- Other handy sharp tools.

Let’s talk more about each tile cutting method.

- The tile is inserted into the tile cutter, and the markings on it are aligned with a special label.

- The handle is lowered and held away from you. It must be driven at the same speed and even pressure so that the roller cuts the glaze to the same depth. It will be enough to run the roller once. If driven several times, the breakage may turn out to be of poor quality.

- Next to the roller there are special paws that lower and break the tiles into 2 parts after a sharp push on the lever. In this case, all tile cutters have a metal tubercle on their platform, and soft pads along the edges. When you press on the edges of the tile with your paws, maximum stress will be created at the notch, if correctly aligned with the backing, and it will evenly break off.

It is difficult to explain it in words, so it is easier to look. Which shows how to cut tiles correctly with a tile cutter:

High-quality tile cutters allow you to cut even 10 mm thick tiles without any problems. And it doesn’t matter at what angle you cut it: at least 45 degrees, at least 30.

How to cut porcelain stoneware

It is believed that porcelain stoneware is the hardest material from which floor tiles are made. You can trim it in the same way as a regular tile.

Sometimes simple floor tiles are more difficult to cut than porcelain stoneware. There is a hardened tile on which, after cutting with a tile cutter, almost no notch in the glaze is visible. And even a diamond disc does not take it on an angle grinder. the cut turns out to be torn, like after a tractor. In such cases, you need to use an angle grinder, and file a 2-3 mm groove on the back side to mark the place of the break.

How to choose the right disc by tile

For cutting, metal discs are used with diamond dust on the edges. But they are different: for concrete, brick, stone. Tiled discs do not have any holes, the soldering on them is uniform and smooth. Discs for concrete have slots on the solder, and will chip when vibrated. If you cut ceramic tiles with them, then these chips can fly into the face.

Cutting tiles angle grinder

Sometimes there are cases when you need to cut a narrow strip of tiles 0.5–2 cm, and an ordinary tile cutter does not take it, because his legs are too wide.

In such cases, you need to draw a notch line with a pencil and make a washed down angle grinder with a diamond disc. But if you try to cut it off in one go, the narrow strip will break off in parts. Therefore, you need to smoothly and without pressure walk the angle grinder along the markings to get an incision with a depth of about 2 mm. You need to walk along the mowing line with the disc, and not directly along it, then the width of the already narrow strip will not decrease.

Using the same method, running several times along the same seam, you will cut a narrow strip. The second and next time you can drive the angle grinder faster, but try to press it to the opposite side, then there will be no chips.

It is better to do this work by weight, so the vibration will go into the hands. When you already see that the strip will soon fall, it is advisable to put something soft so that it does not break.

Tile cutting angle grinder with a special diamond-coated disc on tiles

Be sure to wear glasses when working with an angle grinder.

Tile cutter tongs

Tile-cutting tongs are the cheapest (200-400 rubles), and it is suitable only for small volumes of work with thin ceramic tiles at home.

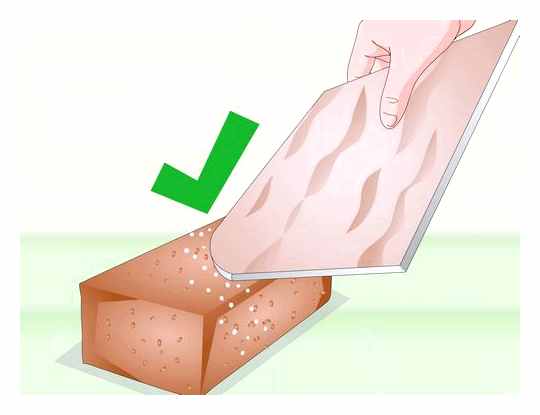

After notching, press down on the tile with a cracking pliers

- Make markings taking into account all gaps and seams (-5 mm).

- Attach a metal ruler to the mowing line and slide the cutter along the line once. The pressure should be moderate to form a visible streak. Lead him from the far end to you.

- Place the tongs with their feet along the mowing line of the crowbar near the edge. The sponges should be on top of the glaze and the straight part on the bottom. the line of the break should run right in the middle between the edges of the upper lip.

- Press gently on the handles to break off the tiles. At the same time, do not lift it high, otherwise after falling it will break.

We make a drink at 45 degrees

Ceramic pencil skirting is best for protecting the sharp outer corners of tiles

If you are using a professional electric tile cutter, the tilting platform there makes it easy to make a 45 degree angle on the tile bevel, but not everyone has such a tool. It is easy to make such an angle on your own using the same angle grinder “by eye”. The disc is guided along the line of the cut, with the disc tilted slightly inward.

Cut tiles at 45 degrees

Electric tile cutter

If you have a large amount of work, then the fastest and highest quality cut comes from an electric tile cutter. They use a diamond wheel and supply water to the cut to cool and remove dust. The cheapest types of amateur class can be found on sale for 3-4 thousand rubles.

How to cut a tile with the letter “G”

Since the tile cutter can only cut the tiles straight, many have difficulty with L-shaped cutouts. The easiest option is to divide this tile into 2 rectangular elements, but then you get an extra ugly seam that will catch your eye.

But this can be avoided by trimming the short side with an angle grinder and then cutting the long side with a tile cutter.

Step-by-step instructions on how to make L-shaped cuts on tiles

The second method: by any method available to you, a cut is made on the glaze, and the excess is gradually broken off with pliers. Irregularities are sanded with sandpaper. This option will even allow you to get a rounded incision for abutting the risers.

How to properly cut tile, tile cutting

When tiling the walls and floors of a kitchen, bathroom or toilet, you have to not only cut the tiles into pieces, but also make round cutouts for pipes in them, as well as corner and other curly cuts necessary when fitting the tiles to the surfaces to be coated. The simplest are straight cuts (photos 1-7), the more complex are the corner and side semicircular cuts (photos 8-13), and the most difficult are the cuts inside the tiles (photos 14-19).

Tile cutting methods

First of all, you need to find the tools. In the selection process, it should be borne in mind that each method implies a different amount of work to be done. In addition, a wall tile cutter is not always suitable for cutting floor tiles. If you are faced with the task of radial cutting of building material, you will need to use a special cutting technology.

Tiles are often used for wall cladding. This type of tile has a softer structure, so cutting it is less difficult compared to dense types of tiles that are used for flooring.

How to cut tiles correctly?

Tile is a building material that is used for cladding various surfaces for decorative purposes, so it has a fragile structure and must be handled with extreme care. When working with tiles, it is almost always necessary to cut them. This process can be carried out in several ways. over, each method implies the use of different tools. How to cut ceramic tiles is detailed below. It is useful to know the features associated with performing this procedure.

Electric cutter cutting method

An electric tile cutter is a good choice for productive and quality cutting. It is a special machine powered by the mains, which includes a motor and a platform where the tile cutting element is attached. Material processing is carried out thanks to a diamond-coated cutting wheel and a water tank.

Certain models involve partial immersion of the wheel in water, but most often the edge of the cutting element only touches the edge of the water. This is required to reduce the likelihood of dust formation and protect the tool from cracking, which significantly extends its service life.

The electric cutter is considered a professional piece of equipment for cutting tiles, so it is versatile. It can be used to cut tiles of any degree of hardness. In this case, the cuts are perfectly straight and smoothed. The tool is able to cut fragments less than 5 mm wide. It is well suited for creating small holes and can be cut at a 45 ° angle.

The only drawback of the electric cutter is its high cost. It should only be purchased for permanent use.

How to cut tiles with a glass cutter?

Scheme for cutting tiles with a glass cutter.

This tool is most often used for cutting tiles, since it is quite simple to handle. The roller glass cutter is ideal for cutting small quantities of tiles as it can be finished in no time.

Before starting work, you need to spread the tile on a flat surface and mark the desired areas with a marker. Take the glass cutter in your hand just as you would hold a simple ballpoint pen, and gently roll it towards you, gently pushing down on its base. A noticeable line on the marked mowing line will indicate a successful result. Then you need to put the tile on the bump (match or nail) and gently break the smaller piece, holding the larger part with your other hand.

Using an oil-type glass cutter, it is much easier to cut tiles, since a small container is built into its handle, where a mixture of technical oil and kerosene is poured. In the process of processing the building material, the liquid flows down to the base and softens the interaction of the tool with the tile surface.

- High cutting speed;

- Low cost of the tool;

- Easy to operate and maintain.

The disadvantage of the tool is the difficulty of cutting a huge amount of tiles, since each tile must be carefully cracked after processing. In addition, it is not adapted for frequent use and can quickly fail.

How to cut a floor tile?

This type of tile is characterized by a higher degree of hardness, therefore, floor tiles require a special approach. When choosing a suitable tool, it is recommended to pay attention to the options that are discussed below.

How to cut tiles with a manual tile cutter

Tile cutting scheme angle grinder.

If you are faced with the task of processing a large number of tiles, a manual tile cutter will become an indispensable tool in this matter. It is a base with shaped tubes and a cutting element.

To cut the tile, you need to push it under the profile tubes and, applying slight pressure, push the cutting element away from you. For the most effective result, try to maintain a stable level of pressure on the handle. At the end of the tile cutting, you will need to press the handle and break the tile.

The advantages of a manual tile cutter:

- Comfort during work;

- The handle reduces the need for physical force;

- The tiles are cut with high precision.

Among the shortcomings, it should be noted that the tool is limited: it cannot be used to cut fragments less than 5 mm wide. In some cases, the edges of the cut area are uneven, but this can be corrected by hand grinding.

Tile cutting angle grinder

If you are not well versed in how to cut tiles, it is recommended to resort to using an angle grinder. This tool is considered a household tool, so it is ideal for people who do not have professional knowledge and experience in cutting tiles.

Tiling tools.

Cutting tiles with an angle grinder is very simple: you need to connect the device to the mains, start it with the power button and wait for the wheel to pick up the required speed. Cutting should be done away from you without unnecessary effort. In this case, do not forget to pre-mark the desired areas on the surface of the tile.

For sawing tiles, it is recommended to purchase a tool where the speed of rotation of the circle is regulated. When working with tiles, the rotation speed should not exceed 3.5 thousand rpm. If the speed goes beyond this value, there is a risk of chipping on the tile surface. At the same time, a lot of shavings and dust are formed in the radius of work, since they fly over a long distance at high speed.

When choosing a wheel, you should focus on cutting elements designed for processing concrete surfaces (diamond). The use of wheels for processing metal structures is unacceptable.

The angle grinder is excellent for work related to sawing tiles, since it has a low cost and the simplest operating principle. However, this tool has its drawbacks. As mentioned above, during the work process, a large amount of debris and dust is generated. In some cases, the edge of the cut fragments is uneven, so it must be sanded by hand with sandpaper and a file, removing sharp protrusions with nippers.

It is worth remembering that working with an angle grinder presupposes extremely careful and careful handling of the tool, as it poses a danger to human health.

In addition, the angle grinder must be held firmly while cutting the tiles. Make sure you have enough free space to not harass yourself while you work.

This guide covers the most effective and popular cutting methods for wall and floor tiles. Having studied all the nuances, choose the most suitable method for yourself.

List of required tools

Tile cutting tools.

To cut the tile, we need:

- Angle Grinder;

- Diamond blade for working with concrete and stone materials;

- Protective glasses;

- Roulette or ruler;

- Marker or pencil;

- Diamond glass cutter;

- Smooth bar for applying the mowing line with a glass cutter;

- Pliers for nibbling rounded cut lines;

- Sandpaper for edging cut tiles.

How to cut tiles correctly?

If you are making repairs yourself, then at the stage of laying the tiles, situations will surely appear when the tiles need to be adjusted in size and shape. And then the question arises: how to cut the tiles? Of course, there are special machines for this purpose, but the purchase of such a tool is not very justified if the volume of work is small and only a few cuts are required.

Tile cutting scheme.

You just need to purchase a special disc and, taking into account some of the nuances, carefully and accurately do the job.

Correct tile cutting angle grinder: steps

Angle grinder device diagram.

- When cutting in a straight line, it is necessary to ensure a perfectly flat edge, as this affects the overall appearance after laying and joining, and any irregularities will be conspicuous. Even if you have a steady hand and have perfectly walked the angle grinder over the mowing line, small but noticeable chips may remain on the edge on the face side. To avoid them, do the following: place a flat bar and run the glass cutter once along the marked mowing line, pressing it firmly and confidently. Now, pressing the tile to the edge of the table or securing it to a workbench, slide an angle grinder with a diamond disc close to the line from the cutter, which will not allow the edge to crumble, and the cut will be perfect on the face. The next pass completely cut off the excess part of the tile. Do not forget about safety, protect your eyes by wearing safety glasses.

- To cut tiles correctly, first of all, you need accurate markings. In order to avoid errors during installation, you should not mark all the tiles in advance, but immediately each one before gluing in its place. If this is a straight line, then simply measure the desired size and trace the line on the front of the tile with a pencil or a marker under the ruler. If it is a curve, for example a cutout for an outlet, then you need to attach the tile to the place where it is glued and make marks. Make them on the left or right edge of the tile and on the top or bottom, applying the tile, respectively, first to the side of the outlet, and then above or below. By connecting the horizontal and vertical mowing lines from the marks, you will get points along which you will draw the cut line.

- If you have experience in cutting glass, then straight cuts can be made without an angle grinder, simply by pressing the tile to the edge of the table, break it off along the mowing line drawn with a glass cutter. But if you’re dealing with a thin strip, an angle grinder will make it easier.

- When working with curved lines, the technology will be slightly different. There are 2 options to consider here: cutting from the edge of the tile and cutting a hole in the middle, for example, for a rosette. In the first case, make an angle grinder cuts from the edge to the marked mowing line at an interval of about 1 cm, resulting in something like a comb. Then use pliers to break off the resulting teeth.

- When it is necessary to make a full round hole for the outlet, then first make an angle grinder 2 cuts crosswise, dividing the marked circle into 4 sectors. Then, with the next 4 cuts, connect the extreme points of the previous 2, thereby obtaining a cut out square inside the marked circle. To select the remaining 4 segments, make cuts as described above and break out the teeth with pliers. Of course, in this case, the edges have irregularities, but ideality is not required here, because the hole will be closed with a socket. Although to obtain smoother edges, after all types of trimming, the ceramic tile is processed along the edge with sandpaper.

- After trimming the ceramic tile, attach it to its place and make sure everything is done accurately, if necessary, correct the tile with an angle grinder, cutting off excess. Now mortar can be applied and glued.

To master this process, 1-2 training cuts are enough, you will feel the contact of the diamond disc with the ceramic and will be able to hold the line. Practice right away on the part of the tile that will not be useful to you later and will be thrown away. Do not be afraid to try and you will be able to achieve a good enough result.

List of required tools

Tile cutting tools.

To cut the tile, we need:

- Angle Grinder;

- Diamond blade for working with concrete and stone materials;

- Protective glasses;

- Roulette or ruler;

- Marker or pencil;

- Diamond glass cutter;

- Smooth bar for applying the mowing line with a glass cutter;

- Pliers for nibbling rounded cut lines;

- Sandpaper for edging cut tiles.

How to cut tiles correctly?

If you are making repairs yourself, then at the stage of laying the tiles, situations will surely appear when the tiles need to be adjusted in size and shape. And then the question arises: how to cut the tiles? Of course, there are special machines for this purpose, but the purchase of such a tool is not very justified if the volume of work is small and only a few cuts are required.

Tile cutting scheme.

This can be done with a diamond cutter and an angle grinder, also called an angle grinder.

You just need to purchase a special disc and, taking into account some of the nuances, carefully and accurately do the job.

What and how is the easiest way to cut tiles: expert advice

Ceramic tiles are durable and convenient material in many ways. But the installation process requires some preparation, accuracy and patience. In order to tile a working wall or a floor in a kitchen beautifully and with high quality, it is necessary not only to be able to lay, but to know how to cut a tile. When decorating a kitchen apron with tiles, whole tiles are not always stacked. To veneer ledges, window frames, electrical outlets and edge switches, tile cutting or drilling is often necessary.

How to cut tiles correctly

How to cut ceramic tiles

Wall tiles or glass tiles can be cut with a conventional roller glass cutter. Mark with a marker or pencil before cutting. Tiles designed for flooring are thicker and stronger, so a glass cutter will not be enough.

In such cases, a tile cutter (tile cutter) is used. It differs from a roller glass cutter with a wheel, which is much larger in the tile cutter, so the cutter can puncture the tile to a greater depth. The tile cutter resembles tongs in appearance, with its help you can not only cut, but also break the tile after the cut. The tile breaking mechanism consists of a metal tooth corner on the bottom of the forceps and a special corner on the top.

Electric tile cutting machine

If floor tiles are to be cut, the corner on the top of the pliers should only be made of metal. Therefore, if you decide to purchase a tile cutter, choose a tool with a metal corner rather than a plastic one. The plastic corner tile cutter is only suitable for wall tiles. Most cutters are equipped with a metal ruler with a stop, which is designed for serial cutting. if you need to cut tiles to the same size (for example, for a curb).

Ceramic tiles can also be cut with an angle grinder with a diamond wheel. it is best suited for working with tiles. But this method is the noisiest and most dusty, so you can use an angle grinder only when it is impossible to saw with a tile cutter or other tool.

The main difference between the tile cutter is the larger wheel, which can be used to cut a greater depth, and the presence of a mechanism that, after the cut, allows you to break the tile. Electric tile cutters, also available on the market, cut the tiles very neatly, the edges are smooth and slightly rounded.

Before cutting the tile, it should be soaked in water for 30-40 minutes, and then mark the part intended for cutting by applying the cutting line with a marker or pencil.

Working with a manual tile cutter

With a tile cutter, you can make an incision at a given desired angle. In this case, the markings are applied using a square with divisions. the cutting line on the tile is located at least one cm from the edge of the tile. Align the mark with the pointer on the cutter when using the tile cutter. The tile is fixed at the same level, and the cutting element is moved away from itself. Move the cutter very slowly to the edge of the tile. So you can avoid overheating of the tile, the appearance of cracks and chips on it.

It is very important to break the notched element correctly. Using a tile cutter, apply pressure evenly to avoid breaking or deviating from the markings you applied. If you are using a manual tile cutter, you will not be able to cut strips less than 5 mm wide.

If the amount of work with tiles is small, it is quite possible to do without a special machine for cutting tiles, using a conventional roller glass cutter (diamond). Cutting ceramic tiles with a glass cutter is done in the same way. First, the tiles are soaked in water for 30-40 minutes. After applying the marking with a marker or pencil on the front side, the tiles are laid on a flat board or plywood. The incision is made with strong pressure. just once. Pressing evenly on the tool, roll it in the direction from the far edge of the tile towards you so that a groove appears on the surface of the enamel. To make a break along the formed mowing line, place a nail, match or thin wire under it, and press on the tile from both sides at once.

Cutting tiles with a glass cutter

It is quite difficult to perform a large amount of work with a glass cutter, since the process takes a lot of time and requires concentration. After all, you need to constantly monitor that the incision is in the right place. And of course, you can’t cut thick floor tiles with a glass cutter.

If you get sharp, jagged edges, use wire cutters or pliers to level them. The uneven edge is bite off, and the chips are leveled with a round file. The edges of the tiles are treated with coarse sandpaper.

If cutting ceramic tiles is done with this tool, it is very important to observe safety precautions. Wear protective eyewear when working with an angle grinder. In addition, the instrument must have a protective sheath that absorbs most of the ceramic tile splinters. A protective cover is also needed in order to ensure your safety if a disc suddenly breaks at high speeds.

Tile cutting with an angle grinder is carried out using a diamond wheel. Before starting work, make sure that the circle is securely fastened, then turn on the tool and cut along the previously marked mowing line. Remember that this method of cutting tiles is the most dusty and noisy, so use the angle grinder only in emergencies, for example, when you need to cut porcelain tiles. an angle grinder is also needed to level the edges of tiles when an angle cut is required (for joining tiles on ledges).

Tile cutting angle grinder with diamond wheel

Such tiles resemble natural stone in texture. Modern technologies make it possible to give a ceramic granite surface almost any color. wood, volcanic solidified lava, rough hewn stone, aged stone. The properties of porcelain stoneware tiles stem from the specifics of the raw materials that are used to make this finishing material. Unlike ceramic tiles intended for interior decoration, porcelain stoneware tiles can be used for both interior and facade work. After all, the components of the tile during the production process interact at the molecular level and are sintered so much that they form a monolith. Therefore, cutting porcelain stoneware tiles is a laborious process that can only be facilitated by an angle grinder.

How to properly cut tile, tile cutting

When tiling the walls and floors of a kitchen, bathroom or toilet, you have to not only cut the tiles into pieces, but also make round cutouts for pipes in them, as well as corner and other curly cuts necessary when fitting the tiles to the surfaces to be coated. The simplest are straight cuts (photos 1-7), the more complex are the corner and side semicircular cuts (photos 8-13), and the most difficult are the cuts inside the tiles (photos 14-19).

1. Use a cutting machine to cut the tiles in a straight line.

2. Place the carbide wheel in the cutting place on the edge of the tile and pull the cutter handle without interruption to the end of the tile while maintaining even pressure.

3. The machine is equipped with a kind of anvil to break the tiles according to the cut strip. Therefore, as soon as the wheel enters the tile, just press the handle to break the tile.

4. The traditional cutting technique is to set the tile along the cut with a pencil and, holding with both hands, break it.

5. After the cut, the edges are sanded with an abrasive mesh.

6. To break off a thin strip, use pliers.

7. Cutting diagonally is carried out by the machine in the same way as in a straight line.

8. The electric jigsaw, equipped with a file for cutting tiles, allows you to cut ordinary faience or terracotta tiles.

9. Cutting in an arc of hard, especially floor tiles is easier to do with an angle grinder equipped with a concrete disc.

10. Finish the cut by grinding the edges of the tiles with a grinding wheel using an angle grinder.

11. A small corner cut in the tile is made according to the risk drawn with a carbide cutter.

12. The inner part of the tile sector to be removed is divided with a cutter into small squares.

13. Break off small pieces of tiles with curved jaw pliers.

14. To make a round hole for the passage of the pipe, the tiles are laid flat on a wooden or chipboard support and a small hole is slowly and forcefully drilled with a carbide drill on the drawn contour of the hole.

15. If you do not use effective, but more expensive special core drills for tiles, then drill a series of holes along the mowing line of the pipe circumference.

16. In one of the holes insert a jigsaw blade called “rope”. a steel cable coated with tungsten carbide.

18. Jigsaw cut through the jumpers between the holes.

19. The edges of the resulting round hole are processed with a belt sander with a remote blade.

Based on materials from the Sam magazine.

Correct tile cutting angle grinder: steps

Angle grinder device diagram.

- When cutting in a straight line, it is necessary to ensure a perfectly flat edge, as this affects the overall appearance after laying and joining, and any irregularities will be conspicuous. Even if you have a steady hand and have perfectly walked the angle grinder over the mowing line, small but noticeable chips may remain on the edge on the face side. To avoid them, do the following: place a flat bar and run the glass cutter once along the marked mowing line, pressing it firmly and confidently. Now, pressing the tile to the edge of the table or securing it to a workbench, slide an angle grinder with a diamond disc close to the line from the cutter, which will not allow the edge to crumble, and the cut will be perfect on the face. The next pass completely cut off the excess part of the tile. Do not forget about safety, protect your eyes by wearing safety glasses.

- To cut tiles correctly, first of all, you need accurate markings. In order to avoid errors during installation, you should not mark all the tiles in advance, but immediately each one before gluing in its place. If this is a straight line, then simply measure the desired size and trace the line on the front of the tile with a pencil or a marker under the ruler. If it is a curve, for example a cutout for an outlet, then you need to attach the tile to the place where it is glued and make marks. Make them on the left or right edge of the tile and on the top or bottom, applying the tile, respectively, first to the side of the outlet, and then above or below. By connecting the horizontal and vertical mowing lines from the marks, you will get points along which you will draw the cut line.

- If you have experience in cutting glass, then straight cuts can be made without an angle grinder, simply by pressing the tile to the edge of the table, break it off along the mowing line drawn with a glass cutter. But if you’re dealing with a thin strip, an angle grinder will make it easier.

- When working with curved lines, the technology will be slightly different. There are 2 options to consider here: cutting from the edge of the tile and cutting a hole in the middle, for example, for a rosette. In the first case, make an angle grinder cuts from the edge to the marked mowing line at an interval of about 1 cm, resulting in something like a comb. Then use pliers to break off the resulting teeth.

- When it is necessary to make a full round hole for the outlet, then first make an angle grinder 2 cuts crosswise, dividing the marked circle into 4 sectors. Then, with the next 4 cuts, connect the extreme points of the previous 2, thereby obtaining a cut out square inside the marked circle. To select the remaining 4 segments, make cuts as described above and break out the teeth with pliers. Of course, in this case, the edges have irregularities, but ideality is not required here, because the hole will be closed with a socket. Although to obtain smoother edges, after all types of trimming, the ceramic tile is processed along the edge with sandpaper.

- After trimming the ceramic tile, attach it to your place and make sure everything is done accurately, if necessary # 8211; adjust the tile angle grinder by cutting off excess. Now mortar can be applied and glued.

To master this process, 1-2 training cuts are enough, you will feel the contact of the diamond disc with the ceramic and will be able to hold the line. Practice right away on the part of the tile that will not be useful to you later and will be thrown away. Do not be afraid to try and you will be able to achieve a good enough result.

We cut tile at home

During renovation work at home, it is often necessary to cut the tiles. The choice of tools is huge, today both modern electric devices and manual ones, which have already become a kind of classics of the rifling business, are equally successful. In the article we will consider all the available options, and understand the rules in detail.

Sliced fragments are an integral part of any facing work

Tool selection

All devices are divided into two groups: manual and electrical. The first ones are good because they take up little space, are easy to use, there is practically no dust, hands are not in danger. But with sturdy tiles, not all fixtures will work. This category includes glass cutter and manual tile cutter.

There are electrical analogues of these instruments. Despite their size and risk of injury, they provide a quick process, excellent quality and the ability to process a large amount of material of any strength. angle grinder and jigsaw are irreplaceable devices in the implementation of figured cutting.

Angle Grinder

This tool cuts any material up to metal and porcelain stoneware. To do this, use a diamond-coated nozzle with a suitable grain size.

The most popular and used fixture

How to cut tile with an angle grinder:

- Attach a dry cutting blade to the tool, check the connection.

- Mark the line on the tile.

- Only work on the front side to avoid chipping.

- Secure the tile to the work surface so that it doesn’t move, but nothing gets in the way.

- Start from yourself. Hold the tile with one hand. Drive the disc slightly away from the line mowing line.

Jigsaw

It is difficult to cut a tile figured, for example, in a semicircle. For this purpose, it is recommended to use more maneuverable tools. Of course, you can try to do the job with an angle grinder or glass cutter, but it’s better not to risk the integrity of the material and use a jigsaw.

Shape sawing tool

How to properly cut tiles at home using a jigsaw:

- Draw the line with a pencil. If the tile is too dense, it is recommended to first soak it in water and then wipe it dry.

- Install a diamond file on the jigsaw.

- Start moving smoothly to gain a foothold in the furrow.

- Guide the tool along the markings, but do not press hard. Until you cut through the tile, do not move it forward, otherwise you risk breaking the cutting part.

- Smoothly bring the jigsaw to the edge, at this moment it can go to the side, so hold it in the correct position.

Tile cutter

There are two types of tools: manual and electric. The first option is smaller and the majority have it on the farm.

Ideally, the tile is cut with a specially designed tool.

How to use a manual tile cutter:

- Wet material with water.

- Mark the line of the break with a pencil. Apply oil to the area to facilitate the movement of the cutter.

- Lower the tool handle. Press the cutting edge firmly enough to create a deep groove without damaging the tile itself.

- Pull the handle by activating the roller cutter. The movement should be smooth and confident.

- Split the tile in two along the mowing line.

How to cut tiles with an electric tile cutter:

- Mark up the face of the tile.

- Fix it to the working surface of the tool.

- If the design of your device provides for the presence of a reservoir with water, pre-fill it and install the container in place.

- Switch on the device.

- When working with tiles with an electric tile cutter, do not exert significant force when moving the tiles. Press it against the table just to secure it.

- Smoothly move the tile towards the working disc, holding on both sides, if possible.

- When the cutter comes to the edge, slow down a little to avoid a rough chip.

Glass cutter

Most people are in no hurry to purchase expensive and very large equipment for home use. An ordinary glass cutter comes to the rescue.

A hand tool can easily handle tiles

How to cut the tiles:

- Soak the material in water for a short time to soften its structure, this will facilitate the process, less effort will be required.

- Mark with a pencil the place of the break.

- Take the tool in your hand, with the other press the tile to the work surface and hold the ruler. Run a clear, straight line in one go. Press hard enough to create a deep, chip-free furrow. Work on the face of the tile.

- Tap the tile with the tool handle along the groove on both sides.

- Slide the element to the edge of the table and push in with your hand, it will split in two along the cut line. Or knock on the edge, the piece will fall off on its own. So the probability of formation of teeth is less.

The main nuances of work

How to properly cut tiles with such tools? Let’s highlight a few points:

- Be sure to mark up the material;

- Water will soften the tiles and facilitate the cutting process, reduce the amount of dust;

- Work is carried out on the front side;

- The pressure on the material should be moderate, and the movement should be confident, but smooth;

- It is impossible to break the tile by force;

- Notches along the edges are cleaned with sandpaper.

Other methods

One of the non-standard, but quite effective ways to cut tiles is to use a simple nail. It should be sharp at the end and large enough to comfortably grip and apply the necessary pressure to the material. The principle of the glass cutter is used. Make a furrow on the tile according to the markings and then break it in two. The chip turns out to be even and quite neat if done correctly and clearly.

Remember that an expensive tool is not always a guarantee of quality. For the most part, it all depends on the master himself, so before working with the finishing material, it is recommended to practice on unnecessary fragments.

Electric ceramic cutter

The electric tile cutter is based on a diamond disc that allows you to make even and beautiful cuts.

This device has a diamond disc as a working tool and will cope with tiles of any thickness.

When working, you get even cuts with rounded smoothed edges.

Such a machine can be used for any amount of work, it is used when cutting various ceramic and stone slabs, with the exception of those coated with carbide chips, which can damage the diamond disc.

They work on this device like this:

- A cut line is applied to the tile with a pencil;

- The marked tile is placed on the working platform of the machine, and tightly holding the plate with both hands and pressing it to the base of the device, slowly move the material under the blade of the diamond disc;

- When working, special glasses are used to protect the eyes and the level of cooling water in the machine pan is constantly monitored;

- The liquid is periodically changed. during operation it becomes clogged with ceramic chips;

- Do not try to increase the speed at which the tile is fed under the disc. it may crack.

How to cut a tile with a glass cutter or angle grinder?

With a glass cutter, you can make a straight cut in the material quite quickly. To do this, perform the following operations:

- Mark with a pencil (felt-tip pen) the line along which they are going to cut the tiles;

- Press the square of material to the table with one hand, and with the other, directing the glass cutter towards yourself and holding it at an angle of 90 °, hold the tool with pressure along the intended mowing line;

- The cut plate is placed on a wooden block (or on the edge of the table) and with a blow of the palm, break the tile along the mowing line of the cut.

Scheme for cutting tiles with a stele cutter.

In addition, difficulties arise in its application when performing a curly cut mowing line. Now let’s look at how to cut the tile angle grinder.

To use it in facing work, you need to purchase a diamond disc, which allows you to use this universal tool for cutting tiles both along straight and curly lines. Compared to an electric tile cutter, an angle grinder is more mobile, but loses to it in terms of cut quality. After cutting the tile with this tool, you need to clean the sections with a file or sandpaper. Use an angle grinder like this:

- A cut line is drawn on the plate;

- The tile is fixed in wooden clamps, or it is pressed with the foot and an angle grinder is cut;

- The cut edges are cleaned with a file.

How to cut tile?

Cutting tools: A-tile cutter; B-crown carbide; C-angle grinder; D-manual tile cutter; E-pliers; F-glass cutter; G-hacksaw for metal.

On the market, manufacturers sell various fixtures and tools to accomplish this task.

Of all the offered variety, you can use the following for independent work:

- Manual slab cutter;

- Its electrical counterpart;

- Tile nippers;

- Conventional roller glass cutter;

- The so-called angle grinder;

- Metallic pencil with a victorious tip.

How to use these tools when cutting tiles will be discussed below.

How can you cut tiles with pliers?

Nippers are used to break off tiles.

This tool is used when it is necessary to cut tiles for holes in different places: for platbands, for water pipes, etc. Nippers do not cut in the literal sense of the word, but break off small pieces from the tiles along the mowing line of the cut. The pliers themselves have 2 carbide-coated clamps. the upper one cuts through the glazed layer on the tile, and the lower one serves as a support for the plate. Cutting pliers are used like this:

- The contour of the recess is applied to the tile;

- Insert the tile into the nippers so that the upper clamp is on the marked mowing line;

- Squeeze both halves of the tool and break the tiles along the markings. you cannot “bite off” large pieces, the edges will be uneven or the tile itself will crack;

- Having completely passed along the marking and removing unnecessary material, the cut on the tile is cleaned with a file or diamond sandpaper.

How to cut tile at home?

The production of works on covering the walls and floors of different rooms with ceramic tiles is not complete without cutting the tiles, since usually it is not always possible to use only whole plates and some of them have to be cut. How to cut a tile with your own hands? What tools should be used for this? How can you cut the tile so that the tiles have smooth edges, and the plate does not split?

When laying tiles, there is a need to cut them. Use special tools to keep the edges of the tiles even.

In order to cut high quality ceramic tiles, it is necessary to use special tools and devices. If the work to be performed is of a small volume, then hand tools are usually used. When covering large areas with tiles, professional equipment is used. Consider various methods and tools for cutting ceramic tiles.

The use of a manual machine at work

Tile cutting scheme with a manual machine.

Such a slab cutter is used to cut plates with a thickness of no more than 5-6 mm. The tool has a very reasonable price and makes it possible to relatively easily and quickly cut the required number of tiles. it is well suited for do-it-yourself facing work.

It is applied in the following order:

- With a pencil or felt-tip pen, mark the part to be cut on the tile;

- The material is installed on the base of the device so that the cutting line is under the impeller of the machine;

- Using the tool handle, carefully cut the cut with the impeller along the marked mowing line;

- The tile is fixed on both sides of the intended cut using the so-called wings;

- Lightly hitting the handle of the machine, separate an unnecessary piece from the tile.

If, after several such blows, the tile remains intact, then try to cut the next plate.

How to apply a metal pencil?

This tool is a steel rod 15-20 cm long and 10-12 mm in diameter. A pointed victorious tip is welded onto one end. They use it in the same way as a glass cutter, but the difference is that it allows you to cut the tile not only along straight lines, but also along curves of any complexity. In addition, it can be held at any angle when cutting the plate. Often, in addition to cutting, it is necessary to make holes in the tile. To do this, use a drill and drill of the following types:

- Lance-shaped;

- Tool with a victorious tip;

- Diamond drill.

The first 2 are used at low speed drills. The drilling process itself begins with the removal of the glaze layer or gluing it onto this place with masking tape. Materials and devices used for cutting ceramic plates.

- Tile;

- Marker or pencil.

- File and whether the skin.

- Diamond disc.

- Electric tool (angle grinder, drill, tile cutter).

- Hand tools (glass cutter, metal pencil with a victorious tip, slab cutter).

- Wooden block.

All the tools described above can be used to cut the tiles for tiling. They do not require particularly high qualifications from the worker and therefore are quite applicable for independent work.