How to Disassemble a Makita 18 Volt Screwdriver

Almost all screwdrivers operate on batteries. The average battery capacity is 12 mAh. And in order for it to always be in working condition, constant recharging is needed. To do this, you need a charger characteristic for each type of battery. However, they vary greatly in their characteristics.

Currently release 12–18 V models. It is also worth noting that manufacturers use different components for chargers of various models. To deal with this, you should familiarize yourself with the standard circuit of these chargers.

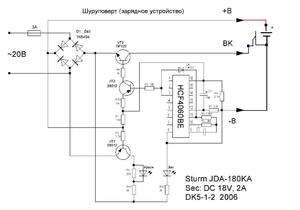

Standard Charger Wiring Diagram

The basis of the standard scheme is three-channel type chip. In this embodiment, four transistors are mounted on the chip, which differ greatly in capacitance and high-frequency capacitors (pulsed or transient). To stabilize the current, thyristors or tetrodes of the open type are used. Current conductivity is regulated by dipole filters. This circuitry can easily handle network congestion.

Circuit diagram

The purpose of power tools is primarily to make our daily work less tiring and routine. In home life, an indispensable assistant in the repair or disassembly (assembly) of furniture and other household items is a screwdriver. Autonomous food The screwdriver makes it more mobile and convenient to use. The charger is the power source for any cordless power tool, including a screwdriver. For example, get acquainted with the device and circuit diagram.

For the concepts of the chargers of 18 V screwdrivers are used transistors several capacitors and a tetrode with a diode bridge. Frequency stabilization is carried out by a grid trigger. The conductivity of the charging current at 18 V is usually 5.4 μA. Sometimes, to improve conductivity, chromatic resistors are used. The capacitance of the capacitors, in this case, should not be higher than 15 pF.

Screwdriver Battery Design

The “banks” of the battery are enclosed in a housing that has four contacts, including two power plus and minus for discharge / charge. Top control pin switched on via thermistor (thermal sensor), which protects the battery from overheating during charging. With strong heating, it limits or disables the charge current. The service contact is switched on through a 9 kΩ resistor, which equalizes the charge of all elements of complex charging stations, but they are usually used for industrial devices.

Standard and individual characteristics of the Interskol charger

- Interskol brand chargers use high conductivity transceivers. Their maximum current load reaches 6 A, and in new models and higher. The standard charger of the Interskol screwdriver uses a two-channel microcircuit, 3 pF capacitors, pulse transistors and open type tetrodes. Current conductivity reaches 6 μA, with an average battery power of 12 mAh.

- Quite often, the Russian manufacturer Interskol uses a battery charging circuit with transistors of the IRLML 2230 type. In this case, 18 V chargers use a three-channel type microcircuit and capacitors with a capacity of 2 pF, which tolerate network loads well. The conductivity index in this case reaches 4 μA. When choosing a screwdriver, you need to take into account its power, which affects its life. The higher the power indicator, the longer the tool will last.

Power Supply Elements

How to Disassemble a Makita 18 Volt Screwdriver

The battery is the most expensive part of the screwdriver and is approximately 70% of the total cost tool. When it fails, you will have to spend money on acquiring a practically new screwdriver. But if you have certain skills and knowledge, you can fix the breakdown yourself. To do this, you need some knowledge about the features and structure of the battery or charger.

All elements of a screwdriver, as a rule, have standard characteristics and sizes. Their main difference is the energy intensity, which is measured in A / h (ampere / hour). Capacity is indicated on each element of the power supply (they are called “banks”).

“Banks” are: lithium. Ionic, nickel. Cadmium and nickel. Metal. Hydride. The voltage of the first type is 3.6 V, others have a voltage of 1.2 V.

Battery malfunction determined by a multimeter. He will determine which of the “cans” is out of order.

DIY battery repair

To repair the battery of a screwdriver, you need to know its design and accurately determine the place of failure and the malfunction itself. If at least one element fails, the entire circuit will lose its performance. The presence of a “donor”, in which all the elements are in order or new “banks” will help solve this problem.

A multimeter or a 12 V lamp will tell you which element is faulty. To do this, put the battery to charge until it is fully charged. Then disassemble the housing and measure voltage all elements of the chain. If the voltage of the “cans” is lower than the rated voltage, then you need to mark them with a marker. Then reassemble the battery and let it run until its power drops noticeably. After that, disassemble again and measure the voltage of the marked “cans”. Sagging voltage on them should be most noticeable. If the difference is 0.5 V and higher, and the element is working, then this indicates its imminent failure. Such items must be replaced.

Using a 12 V lamp, faulty circuit elements can also be detected. To do this, you need to connect a fully charged and disassembled battery to the plus and minus contacts on the 12 V lamp. The load created by the lamp will be discharge the battery. Then measure the parts of the chain and identify the faulty links. Repair (restoration or replacement) can be done in two ways.

- The defective element is cut off and a new one is soldered with a soldering iron. This applies to lithium-ion batteries. So how to restore their work is not possible.

- Nickel. Cadmium and nickel. Metal. Hydride cells can be restored if there is an electrolyte that has lost volume. To do this, they are flashed with voltage, as well as amplified current, which helps to eliminate the memory effect and increases the capacity of the element. Although the defect cannot be completely eliminated. Perhaps, after a while, the malfunction will return. A much better option would be to replace failed items.

Replacing the necessary circuit elements

To repair the battery for a screwdriver, you will need spare battery, from which, you can borrow the necessary details or the purchase of new chain elements. New “banks” must meet the necessary parameters. To replace them, you need a soldering iron, tin, rosin or flux.

- Unsolder the connections of the defective parts and replace them with new ones. At the same time, do not allow them to overheat, which can lead to damage to the battery. To do this, try to solder quickly without delay. In the process of soldering, you can cool it with the touch of a hand, with the voltage turned off.

- Make connections with your own plates (copper ones possible), otherwise overheating of the wires can put the necessary thermistor into operation, which controls the heating and turns off the charging system. When connecting, do not forget to observe the polarity. The minus of the previous element in series connection is added to the plus of the next.

- Align the potential of the circuit elements. It differs in almost all “banks”. To do this, put the battery to charge all night, and then leave it to cool for a day. After that, measure the voltage of the elements. Indicators should be very close to face value.

- Insert the battery into the screwdriver and give it maximum load until it is completely discharged. Do two complete discharge cycles. The result will give a complete picture of the effectiveness of repair work.

DIY universal charger

To charge the battery, you can do it yourself USB powered. Necessary components for this: socket, USB-charging, 10 ampere fuse, the necessary connectors, paint, electrical tape and adhesive tape. To do this, you need:

- Dismantle the screwdriver into parts and cut off the upper case from the handle with a knife.

- Make a hole for the fuse on the side of the handle. Connect the wire to the fuse and mount it into the handle of the unit.

- Secure the fuse with glue or thermal gun. Wrap the case with tape and attach the structure to the battery connector. The wires are mounted at the top of the screwdriver. The tool is assembled and wrapped with electrical tape. After that, the case is polished, covered with paint and the resulting device is charged.

As you can see, this the process will not take much time and won’t be too ruinous for your family budget.