How To Disassemble The Elty 18 Volt Screwdriver

How to disassemble a screwdriver: cartridge, battery

Innovative technologies in construction are developing every day, it is no longer a secret that a screwdriver is an indispensable assistant for both an experienced specialist and a novice craftsman. Thanks to him, you can easily tighten all kinds of screws and self-tapping screws when assembling furniture structures, as well as when repairing equipment and living quarters.

- How to remove a chuck from a screwdriver

- How to revive a screwdriver battery

- Repair of the gearbox and screwdriver button

- How to change the chuck for a drill

The fact that any equipment fails over time is no longer news to us, so it becomes possible to disassemble the screwdriver and try to fix it with your own hands. But only without fanaticism, be careful when disassembling, especially such models as: interskol yes 12er 01, interskol yes 18er.

How to disassemble a screwdriver in general

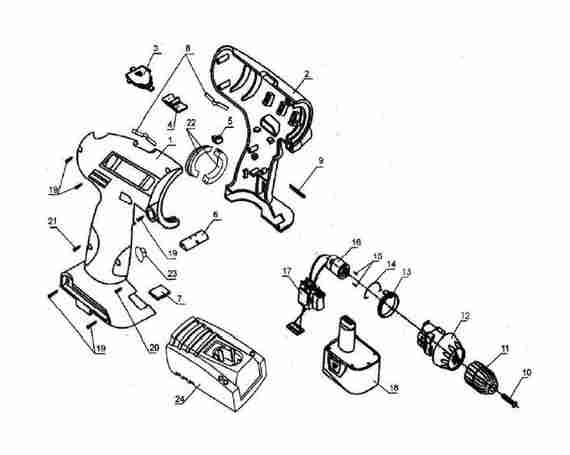

Let’s analyze the disassembly, an example is a Makita screwdriver:

- We remove the block housing where the battery is located.

- We remove the screws that combine the two halves of the case with a Phillips screwdriver.

- We take out everything that is contained inside the tool body.

- Disconnect the reverse button.

- Dismantle the speed switch.

- Disconnect the engine and gearbox.

How a screwdriver works?

What problems can you fix at home? How to recognize this or that breakdown? To give specific answers to the questions asked, let’s first understand the internal mechanism of the tool. The main protruding element is the power button. Used to start the device and to change the speed, direction of rotation of the working part. the chuck.

The setting of the revolutions is carried out thanks to an electronic device based on a transistor. The RPM is directly proportional to the force at which the button is pressed. The reverse is started by replacing the polarity of the electric current at the terminals. Traditionally, the screwdriver is equipped with single-phase collector-type motors that operate on continuous current. The motor includes a body, magnets, anchor and brushes.

Rotation from the motor goes to the gearbox. Further, it converts high engine speed into reduced cycles on the shaft, a cartridge with active bits is fixed in it. The gearbox can be used classic, as on a conventional drill, and including planetary. Recently, the classic gearbox is almost never used, so we will not stop and go further. The planetary gear includes:

- Ring gear

- Sun gear mounted directly on the motor shaft

- Satellites

- two or three carriers

Then comes the force stabilizer with sixteen positions. These positions give a specific voltage to the self-tapping screw, so as not to spoil the material with which they are attached. The last component is the cartridge.

How the cartridge is disassembled

If the fixation of the cartridge is conical, then it is removed simply. by gentle blows with a hammer on the block body. If the fastener is threaded, the following steps are required:

- In the clockwise direction, unscrew the screw with the left-hand thread.

- We squeeze the hexagon in a vice, put the key on it and make blows with a hammer. Likewise, the chuck should move from its original position. You can choose another option:

- Place the screwdriver on a flat surface such as a table.

- Turn it on.

- Observe if the cartridge has moved off the table. when hitting a hexagon.

It also happens that all of the above methods do not work, and then one thing remains. to disassemble the screwdriver, after which:

- Remove the gearbox and spindle;

- Place the assembly in the vise clamps;

- Take the pipe wrench and then detach the chuck.

And if debris is found in the gearbox, then you need to do so.

How to disassemble the battery

- Detach the screws at the bottom of the box.

- Open box.

- Check and reject components.

- Replace and reassemble.

The mounting screws on the underside can vary from four to six. Often unscrewed with a Phillips screwdriver. The screws are available in various lengths. This must be taken into account so as not to confuse them during assembly. On some modifications, you can find a non-separable case. Then examine the entire surface and find a special strip along which the factory gluing passes. Next, you need to take a strong knife and insert it into the groove, slightly shaking to the sides. If the case broke into the upper and lower parts, the autopsy was successful. Not a problem if it happens past the groove. All discrepancies can be glued with good superglue. The upper part of the case contains several parts for the battery. On each of these components, the voltage is measured, which must certainly be in the range of the optimal level. If the difference is more than 10%, such a battery needs to be replaced.

Each manufacturer strives to create a tool that will be as convenient as possible in the workflow, creating an extensive range of models. from basic screwdrivers to professional samples.

Hitachi screwdrivers prioritize excellent build quality as well as the practicality of their tools. The Bosch range of cordless screwdrivers is virtually indistinguishable from its brethren, which have a cord for connecting to 220 V. Equipped with mode switches, as well as a shutdown button and an accelerator option, Bosch screwdrivers are an excellent solution for home and professional use. In addition, such brands as Interskol, Makita, Cmi, Zubr have proven themselves to be excellent.

How to choose a new cartridge

The chuck for the screwdriver is chosen based on a number of aspects. When choosing a suitable part, you need to be guided by the following recommendations:

- if the bits have to be changed frequently, it is better to prefer quick- or self-locking cylinders; otherwise, work will go slower;

- gear-crown design. the choice of those who strive for maximum chuck reliability; if the priority is one hundred percent fixing the bit, it is better to purchase a key cartridge;

- when choosing a part, it is necessary to take into account its characteristics; parameters are regulated by the corresponding GOST; the larger the clamping cone, the larger the number with which it is marked;

- it is necessary to take into account the country of origin. alphanumeric designations of foreign models differ from domestic ones.

If it is difficult to independently determine the type of “clamp”, it is better to consult a specialist.

HOW TO FIX CORDLESS SCREWDRIVER | Motor Not working | DIY | Disassemble

The wrong choice is tantamount, at least, to the incorrect operation of the tool.

In the worst case, not only repeated spending on a new cylinder is possible, but also the replacement of the entire screwdriver.

How the cartridge is disassembled

If the fixation of the cartridge is conical, then it can be removed simply. by gentle blows with a hammer on the block body. If the fastener is threaded, the following steps are required:

- In the clockwise direction, unscrew the screw with a left-hand thread.

- We squeeze the hexagon in a vice, put the key on it and make blows with a hammer. Likewise, the chuck should move from its original position. You can choose another option:

- Place the screwdriver on a flat surface such as a table.

- Turn it on.

- Observe if the cartridge has moved off the table. when hitting a hexagon.

It also happens that all of the above methods do not work, and then one thing remains. to disassemble the screwdriver, after which:

- Remove the gearbox and spindle;

- Place the assembly in the vise clamps;

- Take the pipe wrench and then detach the chuck.

And if debris is found in the gearbox, then you need to do so.

Device and malfunctions of the screwdriver

All screwdrivers are similar. They consist of the following functional units:

- start button;

- pulse width regulator;

- electric motor;

- transistor;

- planetary reductor.

All components of the device are in a durable and aesthetic case, which has a rubberized handle, control and adjustment buttons, as well as a slot for installing a battery (if the screwdriver is designed only for operation from a 220 V network, it does not have a battery).

When you press the start button not completely, the screwdriver may squeak. It is normal for DC motors to operate at startup and at low rpm.

To disassemble the cartridge, you need to remove the plug at its base. The plastic plug is gently pushed off with a knife. Metal. knocked out by hammer blows on the base of the chuck:

BOSCH Upgrade Battery / Change Old Dead Li Ion Cell / GSR BAT411

- Take a large bolt, insert it into the chuck and squeeze slightly to center. The head of the bolt should protrude two to three centimeters above the chuck.

- Hit the bolt head with a hammer. The cartridge will pop out of the case.

How to disassemble the elti 18 volt screwdriver

Innovative technologies in construction are developing every day, it is no longer a secret that a screwdriver is an indispensable assistant for both an experienced specialist and a novice craftsman. Thanks to him, you can easily tighten all kinds of screws and self-tapping screws when assembling furniture structures, as well as when repairing equipment and living quarters.

The fact that any equipment fails over time is no longer news to us, so it becomes possible to disassemble the screwdriver and try to fix it with your own hands. But only without fanaticism, be careful when disassembling, especially such models as: interskol yes 12er 01, interskol yes 18er.