How To Discharge A Screwdriver Battery At Home

Restoration of the screwdriver battery

Recovery of lithium-ion and nickel-cadmium batteries in Bosch, Hitachi and Makita screwdrivers at home

How to repair and start a lithium-ion battery

For these types of batteries, you need to remember where the positive, negative and charging contacts are located. The voltage control board located on the batteries most often fails, or rather, their stabilizers and protective diodes.

The voltage at the output of the battery is checked, if the value is significantly less than normal, resuscitation is performed.

Restoration of the 18 volt screwdriver battery

18v is a common power that corresponds to 15 units. As a donor, you need to choose an electrical appliance with a voltage of 14.5 V, that is, a 12 V car battery will not work.

Battery does not charge

A screwdriver, after prolonged use, sometimes fails. Its working element may stop charging, which will lead to the impossibility of fulfilling the functional capabilities of the instrument, the instrument, roughly speaking, will “die”.

In order to extend the life of the instrument, so that you do not have to remove it from the field of view, you can try three methods in turn. Each subsequent one is considered more complicated and costly. They consist in:

- Restoration and increase of capacity after its reversible loss (memory effect);

- Adding distilled water to the electrolyte;

- Replacing some or all of the battery packs.

How to repair a battery for a screwdriver at home

The cordless screwdriver is a convenient mechanism that allows you to quickly deal with repairs. Instead of a heavy drill on a wire, it is better to take a lightweight screwdriver that can handle the same tasks without being tied to one place.

They have only one problem. Batteries fail. There are many reasons for this:

- Long downtime. Modern lithium-ion batteries require periodic charging and discharging. They drastically lose capacity if they are idle for a long time.

- Temperature drops. Li-Ion does not tolerate high temperatures. Therefore, there are recommendations for storing these batteries in the refrigerator. But they cannot work in such conditions.

- Overdischarge. The protection system can cause the batteries to discharge to zero and a large current must be applied to the input to resurrect them.

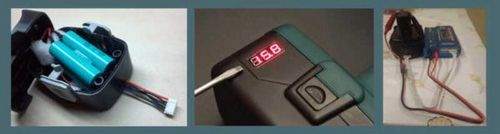

Replacing cans in the battery

How to repair a battery for a screwdriver? The easiest way to revive a battery is to replace one of the cans.

It is necessary to find a defective element with low voltage. To do this, you need to use a tester.

Instructions on how to check the battery of a screwdriver with a multimeter:

- A conventional multimeter has two test leads. Red and black. There are two contacts (plus and minus) from opposite ends of the can.

- The tester selection lever is set to “constant voltage” mode. If the multimeter has automatic selection of values, this is enough. If not, you need to put the lever in the “20” position.

- The probes are applied to the contact pads and the voltage is measured. The screen shows the real voltage. If there is a “-” sign in front of the numbers, then the probes need to be changed with each other.

- Each bank is checked using this algorithm.

When a broken element was found, it is simply soldered off and replaced. You need to use a powerful soldering iron so as not to overheat the jar.

Fault definition

The most common cause of failure is failure of only one element. They are connected in series, which means that even a drop in capacity on one battery will lead to a complete malfunction of the entire battery. In this case, we need:

- Screwdriver. Usually the body is connected with Phillips screws. Some models have foolproof protection and there may be vandal-resistant sprockets, triangles or even spunners.

- Multimeter. Any model is enough, even the cheapest DT-830. Since measurements are taken in millivolts, Soviet dial voltmeters will not work.

Next, you need to follow the instructions:

- The battery is disconnected from the screwdriver. It must be fully charged.

- The case is disassembled.

- Now you need to remove all the jars. There are more of them in Ni-Kd, since the rated voltage of one section is less.

- Voltage is measured at each bank. For nickel-cadmium, 1.2 volts is nominal. For lithium. The normal voltage is in the range of 3.6-3.8 volts.

- After measuring, you need to look at which banks the voltage is reduced. For example, if the voltage on two lithium batteries is 3.8, and on one it is 3.5, then it is she who is defective.

- The battery is assembled and installed in the instrument. Now it needs to be set to zero.

- The battery is disassembled and the voltage is measured again. If the voltage on the alleged element is much lower than on the others, then it is being replaced or repaired.

What is the purpose of the screwdriver battery discharge?

Before discharging a battery for a screwdriver, it should be understood for what purpose this operation is required. The answer to this question is very simple. In this way (by means of a three-fold discharge cycle and subsequent charge), you can improve the technical characteristics of the battery for some time.

As mentioned above, the difficulties of full discharge are inherent in nickel-cadmium batteries, while for more modern lithium-ion batteries, this problem is not relevant and such batteries are capable of self-discharge without additional manipulations.

The problem with nickel-cadmium batteries is that they have a so-called “memory effect”. And even a new battery can malfunction if charged incorrectly. So, if the nickel-cadmium battery is not fully charged (for example, up to 70%) and worked with a screwdriver, then with the subsequent late charging, such a battery will perceive 70% of the charge as full. That, accordingly, may subsequently negatively affect the battery resource and require its subsequent replacement.

In order to exclude such a situation, it may be necessary to completely discharge the battery of the screwdriver in order to erase the so-called “memory effect”.

By the way, the battery recovery method for a screwdriver can be found here.

How to discharge a battery for a screwdriver

The screwdriver is a very useful aid in many construction operations. However, in order for this tool to serve as long as possible, it is very important to follow all the recommendations for the operation and maintenance of this equipment. Well, in view of the fact that the most vulnerable link of a screwdriver is the battery, it is this unit that you should pay attention to, first of all (especially if your screwdriver is equipped with nickel-cadmium batteries).

How to completely discharge a nickel-cadmium battery

It should be noted right away that it will not be possible to completely discharge the nickel-cadmium battery for a screwdriver due to the long-term operation of the tool. Since even after the screwdriver stops working, a relatively large voltage (up to 7 volts) may be present at the battery terminals, since they hold a residual charge for a long time.

Therefore, it is more justified in this case to act somewhat differently:

- The battery is removed from the screwdriver;

- The battery is being disassembled;

- The block of cans is removed from the battery case (it may be necessary to unsolder the leads from the circuit elements);

- A load corresponding to the current and voltage indicators (most often 12 volts) is connected to the terminals of the cans block. It is not bad for these purposes to use an ordinary 12 volt car incandescent lamp;

- When the filament heats up, its resistance decreases and the entire charge remaining in the battery of the screwdriver is reduced to almost zero;

- The indicator of the complete discharge of the battery, and, accordingly, the end of the “erasing memory” process will be a completely extinguished lamp;

- After that, the battery is assembled in reverse order and the screwdriver can be used again for its intended purpose.

And finally, it should be noted that it is possible to restore the screwdriver battery in the proposed way several times, nevertheless, such manipulations negatively affect the performance of the battery and can cause its premature failure. Therefore, before using the screwdriver, always try to charge the battery to 100% and never leave the screwdriver battery in a discharged state for a long time.

How to discharge a screwdriver battery at home

Almost every battery in a power tool is the most expensive part. The screwdriver is no exception, because a replaceable battery can make up 30% of the total cost of the tool. After the device is discharged, it is necessary to purchase a new screwdriver, but to save finances there is another option. Restoration, which will extend its service life.

The battery on the screwdriver runs out quickly

The problem with fast self-discharge of the battery is quite common. It consists in fast charging, which takes about 20 minutes and the same short work.

This situation can be the result of incorrect operation of the thermal sensor located in the removable battery. This thermal sensor may not be installed as originally. You must return it to the place of purchase.

If the battery begins to discharge quickly after prolonged uninterrupted use, which could happen after a fall, you need to take on its repair.

Recovery of nickel-cadmium batteries for screwdrivers

The ni cd battery device is manufactured using the same technology, so any battery can be donated of this type.

Such devices are separate components. Blocks, with a nominal voltage of 1.2 V and an energy capacity of 1200-1500 MA / h. They are found in Interskol screwdrivers. Each unit affects the power, that is, with its value of 12 V, the number of units is 10, 14.4 V. 12, etc. After changing the battery, the power may drop for the first time, but then everything will be restored.