How to find out the size of the chain for a chainsaw

How to choose a chain for a saw with a gasoline engine step by step

Chain pitch is measured in inches. It is indicated on the product and affects the quality of the cut. The higher the saw power, the more you pick up the step. For non-professional instruments up to 2500 W, standard 0.325 ” pitch.

The chain pitch must match the pitch on the drive sprocket of the engine and tire. If you change it together with the tire, replace the engine sprocket with a collapsible one and install the drive ring on it with the desired pitch.

What size chain does my chainsaw take?

How to choose a chain for a chainsaw in the shape of a cutting tooth

The choice of chain for a chainsaw should take into account the shape of the cutting tooth. When viewed along the tooth, the cutting edges form a similarity to the number 7. The rounded tooth is called Chipper, with an acute angle. Chisel.

Chisel teeth are characterized by high productivity and cutting speed, because their configuration reduces the contact area of the tooth with the wood during operation. A serious drawback of the “chisel” tooth is that it quickly becomes blunt on wood contaminated with grains of sand. Resharpening such a tooth requires very precise adherence to all standard angles and parameters.

The Chipper tines have a larger cutting area with the wood and therefore lower cutting speed. But this drawback compensates for the undemanding quality of regrinding. The rounded corner of the “chipper” will tolerate sharpening errors more easily and shows itself well in working with contaminated wood.

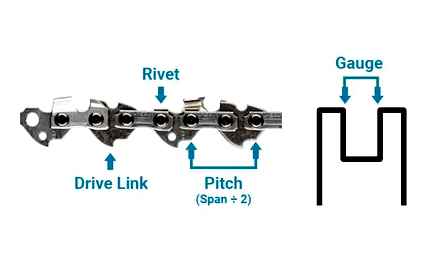

How to choose a chain for a chainsaw according to the thickness of the shank

The shank is the part of the chain link that fits into the guide bar. Its thickness must strictly correspond to the groove of the tire so that the chain moves as smoothly as possible, the cut is smooth and there is no excessive tire wear.

How to choose a chain for a chainsaw in length

Its total length is determined by the number of links that make it up (it is also equal to the number of shanks). The chain for one bar may not fit on a bar of the same length on another saw. Therefore, see what length the manufacturer recommends in the instructions for the saw.

Leave your opinion and wishes to the article “How to choose a chain for a chainsaw: types, sizes, nuances”

Required tools

Chainsaw manufacturers say that shortening the chain at home is unrealistic, because the very development of their production is very difficult and requires high-precision equipment. I will say right away that at least in the chainsaw chain and how to measure and choose the step, size, length of the chain. Practice, however, indicates that nothing is unrealizable. In order to shorten the chain, you will need:

Connecting links

If all the characteristics of the chain are mixed with the parts of your chainsaw, then you can start connecting the links. We connect the links to a rivet, pressing their side parts tightly. It will no longer be possible to rivet the protrusions, because they are grinded flush with the links. We’ll have to use electric welding. For this you need to take an electrode with a smaller diameter.

Determination of chain wear: a. wear of teeth, b. installation of an additional fixing plate on the key link.

It is not recommended to immediately start welding, because this is a very narrow job. how to sharpen a chain sharpening a saw chain from a chainsaw on a machine bought in. Practice doing this on other details first. So you will at least roughly understand at what current you need to cook and what welding time to choose. Well, the electrode will become shorter, which will allow you to weld more accurately. A very short period of time is enough to “grab” a rivet. After training, we weld the rivets to the lateral parts of the link. It remains only to grind off excess metal on both sides with a file and the chain can be considered ready for use.

Negative consequences of improper chain repair

The considered option of repairing the chain is not the most reliable, because no one guarantees the highest quality of the final product for you. The subsequent consequences of such a repair are likely:

- During welding (especially at a low current), unnecessary heating of parts of the circuit was produced, which became a prerequisite for the configuration of the physical parameters of the metal. Soft metal will allow the chain to stretch not along its entire length, but at the point of welding. The chain guides will shift, and other elements of the chainsaw (sprocket, tire) will rapidly fail.

- The welding depth is greater than planned. The inner part of the rivet was welded to one (or several) parts of the link, which became a violation of the mobility of the links. The consequences will be the same as described in the first case.

- Welding quality is poor. In this case, a circuit breakthrough may occur during its operation. The fact is that the chain in operation experiences very high lateral loads, therefore unreliable welding will rapidly “work out”. The possibility of injury will be very high.

The chain came out to disconnect. Do not rush to throw out the rivet removed from the chain. It may be that you cannot find a suitable substitute for it. Chainsaw manufacturers do not imply that an independent repair of the chain will be carried out, therefore they do not release such rivets on the market.

It is also more profitable for traders to sell chains in their finished version than small parts for repairs. For certain reasons, it will be very difficult to find a suitable rivet with a suitable geometry. Making it at home will be even harder, because you will have to use an old rivet.

As you already guessed, the chainsaw chain will have to be disconnected two times. Do not forget to calculate with all this, so that the number of guide lugs on the inner side of the chain and the distance between these lugs are combined with the leading sprocket of the chainsaw. If you are shortening an unusual chain, then this is not necessary. And if this is a chain from another model of a chainsaw, then everything needs to be measured and calculated very well. Carbide chains for chainsaws. How different links look faster to count. A deviation in the chain pitch (even a small one) from the characteristics given by the design will lead to the fact that the chain will stretch again in the shortest possible time (in the best case) or break the chain saw sprocket. The tire will come to an end, as the driven sprocket will rapidly overheat.

Buying a tire is not easy

When buying a tire that is good from a unique model, there is a great possibility that the ancient chain with the newest tire will not fit together in any way. The best option is to try on all three main components. the tire / chain pair and, in fact, the gasoline tool itself. The length of the chainsaw bar is the length of the saw bar, as it is important when choosing a chain. An insignificant difference, from time to time not even noticeable to the eye, just one link may turn out to be critical for the entire assembly: the chain either does not wear at all, or it sags.

Subsequent point: different chainsaws are designed for different widths of tire grooves, respectively, and the drive links are designed for implementation with different tires. The wide grooves of the chainsaw are invented for a chain capable of withstanding significant loads, characterized by the highest quality of performance and efficiency of work. When choosing a chain, in principle, check the probable width for a given model of chainsaw.

Chainsaw chain markers

In some situations, owners of chainsaws may have some confusion in understanding all the chain markings for these tools. As a result, this leads to unsuccessful purchases. The choice of chainsaws is often determined by just a few basic criteria, one of which is the chain pitch. This indicator helps to highlight the future capabilities of the tool, including its cutting speed, and also, according to the norms, must correspond to the level of engine power. How are chains marked? Let’s figure it out!

Chainsaw chain pitch. Table

Taking into account the step size, at the moment the chains are divided into several subtypes:

| No. | Distance between rivets | Chain pitch (width in inches) |

| one | 6.35mm | 1/4 |

| 2 | 8.25mm | 0.325 |

| 3 | 9.3mm | 3/8 (0.375) |

| four | 10.26mm | 0.404 |

| five | 19.05mm | 3/4 |

As you can see from the table, the chain pitch is designated as a regular number (3/4) and decimal. “0.375”. This division is due to the similarity of the decimal values - “0.325” and “0.375”, since the difference of one digit created confusion when choosing a saw. Therefore, at one time it was decided to establish two different designations: decimal and ordinary fractions.

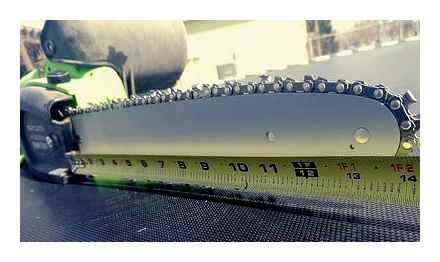

How to Measure a Chainsaw Chain

The pitch is stamped in the area of the special cut depth stop on each tooth.

The pluses of chains with a large pitch include:

- high level of productivity due to wide cut;

- the ability to perform complex work (felling large trees).

But it should be borne in mind that a wide cut requires the use of a more powerful engine, which in turn significantly increases resistance.

The advantages of small pitch chains are:

- low vibration;

- smooth movements when cutting;

- cleanliness of cut.

Benefits are achieved due to the large number of teeth and the small distance between them.

All known classification of circuits is based on the features of their marking, depending on the step, which is designed for specific needs and is produced for a specific power of electrical equipment. For a better understanding of each type of step, they should be considered separately.

Step and its dimensions

A step is an intermediate distance between three rivets, which are located side by side. To correctly calculate the chain pitch, measure the distance between the axes of three rivets placed close to each other. In the form of a formula, it looks like this:

Where, L is the step length, which in chainsaws characterizes the degree of distance between two teeth in relation to each other;

S. the value of the gap between the two extreme rivets of three.

The step size can also be equal to the length of the distance between two adjacent shanks.

Regularity: the greater the distance between the cutting teeth, the deeper they will enter the material being cut

By increasing the chain pitch, it becomes possible to increase the performance of the chainsaw. However, in such a case, the amount of force applied to rotate the drive sprocket changes. And the higher the chain pitch, the greater the power of the motors must be and the more physical forces are expended to pull it when cutting materials.

The main parameters of the chains

Applying the marking of the chain assumes the presence of the following parameters:

- Step:

- “0.325” is the most common and minimum step size that is used in semi-professional and household chainsaws with low powers. The standard value of power for such a step ranges from “0.325” to “3hp”, but not higher than “3.5hp”. When working with this type of chain, the sawing is smoother, more comfortable, without “gusts” of the processed products.

- “0.375” (“3/8”). applied to chainsaws with a capacity of “4hp”. This chain is used when sawing wood of medium and small thickness.

The accuracy and quality of the created cut depends on the value of the step. In cases where it is not important to achieve high quality when working with a chainsaw, the accuracy of the cut is sometimes of particular importance. To do this, it is imperative to take into account the dependence of the step for the release of wood according to pre-applied markings.

- The thickness of the leading links (tails). When the chainsaw is working, its chain accounts for most of all the loads. Considering this, another main characteristic of the saw is the thickness of the link elements that enter the grooves of the bar. This parameter also determines the overall thickness of the fastening links, which is measured with a standard caliper. Standard thicknesses include:

- “1.1 mm” (“0.043”) and “1.3 mm” (“0.05”) are used in the production of entry-level chains, which are intended for small amounts of work. Often, with such values of the link thickness, the chain pitch length can be “0.325”, which implies the presence of low loads and a gentle mode of operation. Therefore, they are used in household and semi-professional devices;

- “1.5 mm” (“0.058”) is the most common thickness on the market for chainsaws and accessories. This value is able to ensure safe operation with a step size of “3/8”. The 1.5mm chain is not suitable for professional cutting;

- “1.6 mm” (0.063) and “2.0 mm” (0.08). designed for the most difficult work. Steel of special grades serves as the metal in the manufacture of such chains, and the characteristics of increased strength are laid in the design.

The greater the thickness of the link and the wider the groove of the tire, the higher quality the chainsaw is considered, since it is able to withstand heavy loads.

- The depth of cut is a distinctive feature of the chains produced and is characterized by the height of the profile of the cutting teeth. It is measured by the gap between the stops and the cutting top edge. Both high-profile (0.762 mm) and low-profile (0.635 mm) types of chain products can be presented on the market.

The higher the profile height, the higher the entry into the material (depth) and the cutting speed

High-profile chains are installed on chainsaws with increased engine power. Information about the height of the profile, as a rule, is written in the characteristic for the instrument.

The profile affects the occurrence of vibrations, which subsequently cause wear of the drive or problems when holding the tool in the hands. over, the higher the cutting parts, the stronger the vibration will be.

Household types of chainsaws are equipped with a low profile. In semi-professional devices, different variants of the types of chains can be combined. However, in most cases, they adhere to the principle:

In a chain with a large pitch, a low profile is set, and with a pitch of “0.325”. a high

Such variations increase the cutting speed not due to the step, but due to the change in the depth or height of the profile. Although in professional tools Accent is made to increase the step, explaining this by the fact that the chainsaw becomes more controllable.

- Cutting Teeth Geometry. Profile can be of two main types:

- chipper (popularly “sickle”). has a crescent shape and has a high performance. It is easier to sharpen during operation and does not require strict sharpening angles. Disadvantage: risk of high loads and deterioration of cutting performance;

- chisel (popularly “seven”). has a straight working surface in the form of the number “7”. They are used in chains with a pitch of “0.404” or “3/8” on professional saws. The main disadvantage of chisel links is the difficulty of sharpening the cutting elements and sensitivity to dirt.

- The number of cutting teeth is defined as the ratio of the number of teeth to the number of guides in the tire. Chainsaws of good production should combine two guide links in the cutting part of the tool.

- The type of link sharpening. directly depends on the type of future work. Classic types of chainsaws are used mostly for cross-cutting trees and are rarely used for longitudinal sawing. Taking into account the resistance of the tree in both cases, the chains can use a different angle of the links. On construction counters, you can now find chains with the following types of cutting links:

- longitudinal type of chain. involves sawing a tree along its fibers. The cutting angle reaches 5-15 degrees.

- transverse type. the cut is carried out across. The cutting angle in the chains is 25-35 degrees.

- Chain length. depends on the parameters and technical characteristics of the chainsaw itself: power, dimensions, etc. With standard or normalized chain tension, its length is most often indicated in the passport.

- The order of the links. the sequence of the links can be different:

- standard. there are two driving links for each cutting link in the chain;

- with a half-pass. every third link in the chain in terms of placement is replaced by the so-called connecting link;

- with a pass. at the locations of every second link for cutting, a connecting.

Why skip links in a chain? In the chains themselves, the most valuable is the quality of the cutting links, since they are manufactured using special technologies and are more expensive than connecting links. If it is impossible to shorten the chain, the only option to reduce the cost of the chain is to skip cutting elements. In operation, chains with skipped links show reduced performance and wear quickly.

In general, if you want to purchase a tool for cutting wood with maximum efficiency, do not be too lazy to additionally study the marking of chains for chainsaws, which is also indicated in the instructions for the tool.