How To Insert Line Into A Bosch Trimmer

Thick line

It is stored at the top of the trimmer body.

Trimming the line into the trimmer.

I want to devote today’s article to the sore subject of summer residents and gardeners of the entire post-Soviet space “How to fill the line in the trimmer.” Not many trimmer manufacturers answer this question in their instruction manuals. Therefore, it is also difficult for simple gardeners to figure out how to do it correctly.

I want to start with a brief description of the technical characteristics of the trimmers.

So, trimmers are electric and gasoline. The cutting element for trimmers can be a line and a knife. The line is ordinary, four. pentahedral and intertwined (in the form of a pigtail). Knives come in 2, 3 and 4 bladed knives. Knives also come in plastic and metal.

The line feed system from the trimmer is manual, semi-automatic and automatic.

Development engineers who create new models of trimmers accurately calculate the diameter (thickness) of the line and the number of knife blades, according to the power of the trimmers. Otherwise, the motor is overloaded, resulting in damage. And these are additional and significant costs.

Trimmers on the market today:

EASIEST WAY TO STRING YOUR WEED EATER

With one nozzle. only a line.

With two nozzles. a fishing line and a three-four-blade knife.

With one attachment. only three to four blades.

Our Kulibins long ago learned to improve any mechanisms. So, for example, some gardeners make successful, in their opinion, replacement of fishing line with a metal cable, or fishing line. But at the same time, they do not think about the safety of their own and their loved ones, because, like a cable with the power of a working trimmer, it can easily break out and not only injure the mower and others, but leave him crippled for life. The use of a fishing line can and gives a better effect, I have never personally tried it than a trimmer line, but this work has a number of inconveniences: when it comes into contact with hard objects, it loosens or it can simply be pulled out of the reel indefinitely.

So, what is called closer to the topic. Here is an example of how to thread the line into the trimmer (Trimmer BOSCH Art 30). Everything is very simple. Started.

After you have chosen the line for refueling, you need to cut off the required amount of line, because all the line in a skein will not be wound into a reel.

Cut off and start reeling.

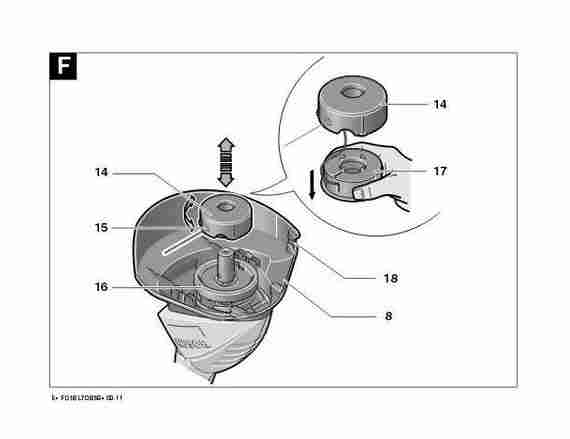

Remove the coil and the protective cover from the coil.

They took it off. We fix one end of the line in the gap and carefully and evenly wind the line.

The amount of line should be such that the protective cover of the reel closes and the line on the reel unwinds a little by itself.

We put the other end of the line into the hole on the protective casing.

Next we take the coil and the protective cover of the coil. We squirt the end of the line from the reel into the metal hole on the protective cover of the reel. Tighten the line a little.

We put it all on the trimmer. Turn the coil clockwise until it clicks.

They fixed it. Now we connect the trimmer to the network. We put the trimmer in the starting position for work. We turn on the trimmer. Excess line length will be cut on the trimming blade.

Coil in trimmer

That’s all we start working.

Spare coil storage space

It is very simple to install such a fishing line into the reel. according to the internal scheme inside the reel. We insert the center of the line with a metal mount in the upper part of the reel, and draw the ends of the line along the grooves and bring it out.

In addition to the standard lawn line, my trimmer also has a thick line for cutting rough weeds. It has the shape of a pigtail, i.e. three lines are tightly intertwined. This line has its own spool.

Heavy-duty line in a reel

This reel is attached to the trimmer in the same way as a reel with an ordinary line.

How to replace line in any trimmer

How to replace line in any trimmer

So, first unscrew the nozzle. This should be done by rotating the drum to the right. Here we have a drum with the remnants of an old fishing line in our hands. We open it. Most often, the lid is closed with latches that can be opened with a screwdriver, threading it through the holes and slightly pressing. Or you need to squeeze the latch and turn the cover in the direction of the arrow. In this case, the lid itself must be held, since reels with automatic line feed have a spring that, when straightened, can throw out all the inner parts of the drum. Gently pulling out the reel, remove the scraps of fishing line from it.

Now you need to take 5 meters of new line and fold it in half (to find the middle). In the middle part of the reel there is a notch (in some designs. a hole), for which we need to hook our fishing line. There is also an arrow on the spool showing the direction of winding. An important detail. if the reel has two compartments, then one half of the line should be wound in one direction, and the other in the other. When finishing winding, you need to leave 15-20 cm of fishing line free. There are also two notches on the top ring of the coil, through which these free ends need to be passed. We dealt with the winding itself.

The last step in the line replacement process is to assemble the drum. First you need to install the spring and washers in their place. Then, holding the reel with one hand, with the other you need to thread the ends of the line into the corresponding holes on the sides of the nozzle. After that, install the coil in its place, pulling the line and being careful not to dislodge the spring. When all the internal elements of the nozzle take their places, you can close the drum with a lid. You just need to make some effort to ensure that the latches fall into place. Voila! The mowing head is ready for use!

When choosing a fishing line for your motor scythe (gasoline or electric), you should dwell on some points, which we will talk about in detail.

Line diameter.

Engine power determines which maximum line diameter can be used for a given braid. For example, the manufacturer of an electric trimmer with a power of up to 1 kW recommends using a line of ø2 mm, and at values of about 500 W. only ø1.5 mm. Also, the manufacturer of any heavy duty curved bar trimmer recommends using a ø2mm line.

A gasoline engine is more durable than an electric engine, so you can install thicker line there, which means stronger line, which allows you to cut more grass and work longer.

For grass cutters with a straight bar, you can select the line according to the following simple algorithm: the diameter in millimeters corresponds to the engine volume in tens of cubic centimeters. For example, for a Husqvarna 128R lawn mower with an engine capacity of about 25 cm3, use a line of ø2.5 ± 0.2 mm. For more powerful hedge trimmers with volumes of more than 40 cm3, only the geometric dimensions of the outlet openings of the mowing head. no more than 4 mm are the limitation of the diameter of the line.

So, a thin line (about 1.5 mm) cuts well cultivated lawn grass, and a thick one (for example, 3.0-3.5 mm) successfully destroys weeds and even young shrubs.

Line shape.

The simplest and cheapest to manufacture is a round line. However, the requirements of ergonomics and environmental protection limit its use. due to its physical properties, it creates an unacceptably high level of noise (which is comparable to the noise of the engine itself). This is the classic Husqvarna round line or Oregon RoundLine or Chipmaster.

To reduce the noise produced by the line, it is given a special shape. they make it spiral like Oregon DuoLine Plus (noise reduction by 15 dB) or with special transverse grooves like Husqvarna Whisper (-8 dB).

Following the school laws of physics, the “working” part of the line during the mowing process is only the end surface, not the side surface. However, to increase the “sharpness” of the line, i.e. to increase efficiency, the cross section is changed from round to faceted: star-shaped, square or square with teeth. Oregon StarLine, Nylsaw or Flexiblade.

For example, according to the calculations of experts, the Oregon Nylsaw line, due to its square profile, is 27% “sharper” than its round counterpart, which clearly affects the increase in cutting speed.

# replace # any # diameter # shape # trimmer # lawn mower # for # spool # mow # repair # lawn mower # replacement

Video How to replace the line in any trimmer of the O T V E R T K A channel: the home master’s channel

Types of trimmer lines

First of all, in order not to resort to frequent replacements, it is better to use a denser line. The number of its types and manufacturing firms is simply amazing. The main parameter of the trimmer line is its diameter. It varies from 1.6 to 3.2 mm. The most common type is 2mm line. However, its selection must be made depending on the type of trimmer you have.

There are several options for the section of the line. So, it can be round, square, in the form of a star with sharp edges. The last option is the most effective. However, it should only be used on powerful braids and at the same time you need to know how to thread the line into the trimmer spool. Therefore, we can conclude that the more powerful your lawn mower, the thicker the line should be.

A process such as winding a fishing line on a trimmer is not difficult, but it has its own characteristics. First, you need to choose the right fishing line, the diameter of which is prescribed in the device’s passport.

First, unscrew the spool cap. Be careful as the thread can be left or right. The left-hand thread is necessary so that the head of the scythe does not unwind during operation.

How to thread the line into the trimmer spool and which one is better to use for this?

Very often, those people who personally own dachas and vegetable gardens are faced with the need to care for the lawn on the site. In such cases, you simply cannot do without the usual manual braid or trimmer. The first is slowly fading into the background, and the number of people who use it is getting smaller and smaller. The trimmer works automatically and does not require a lot of effort. over, you don‘t need a special skill to use it.

How the trimmer works?

The principle of operation of such a device is that the grass is cut by a special fishing line installed on a fast-rotating head. The number of revolutions per minute can reach 8000. For a short time, the line becomes unusable, more precisely, it is erased. Then summer residents have a question: “How to fill the line in the trimmer coil”?

Threading the line into the trimmer

Before threading the line into the trimmer spool, measure 5 m from the skein (this is the average amount of line installed on trimmers). Then fold it in half to find the middle. The resulting center must be inserted into a special slot located on the spool. After that, wind the line in the direction of the arrow on the head.

From the above, it follows that the process of replacing the fishing line itself is not difficult. Having carried out such a manipulation as winding a fishing line on a trimmer reel several times, you will bring this process to automaticity. The only thing is that you need to constantly monitor the condition of the line in order to avoid breaking it at the time of work on the site, when a spare coil may not be at hand.

Now you know how to thread the line into the trimmer spool, and you can do it yourself without much effort.!

How to wind the line on the BOSCH ART 23 SL grass trimmer

Help me choose a reel with a line for the BOSCH ART 23 SL trimmer Yuri. | Topic author: Peter

Disappeared on sale, maybe someone knows for which models the electric.

Nikita Look for the whole head assembly suitable for the thread and do not suffer.

Stepan 642,00 rub clck.ru/BUq2i

Tags: How to wind the line on the Bosch art 23 trimmer

How to wind the line on the Bosch art 23 trimmer

Trimmer BOSCH ART 23 EASYTRIM | Topic author: Internet

Trimmer BOSCH ART 23 EASYTRIM Trimmer BOSCH ART 23 EASYTRIM Buy 1, 970.00 р. Trimmers (Electric) Weight only 1.5 kg Longest rod in its class (100 cm) Tangle-free “Pro-Tap” trim head Additional handle for comfortable adjustment. electroplus.su Power

280 watts

Battery type

straight one-piece

Handle shape

bottom

Cutting tool type

line

Max. line diameter

12 months.

Gross weight

2.42 kg

Net weight

1.5KG

Country of origin

Malaysia

Trimmer Bosch ART 23 Easytrim

The Bosch ART 23 Easytrim trimmer with a 280 watt motor and a working width of 23 centimeters is perfect for working in small areas. This model is incredibly lightweight, well balanced and has an extra handle for comfortable and fatigue-free use.

Technical characteristics of the trimmer Bosch ART 23 Easytrim

Power: 280W

Processing width: 230 mm

Net weight: 1.5kg

Powerful underfloor engine

Weight is only one and a half kilograms

Good balance and ergonomic design

Longest bar in its class (100 cm)

Tangle-free “Pro-Tap” trim head

Additional handle for comfortable work

Practical cable holder on the pole

Description of trimmer Bosch ART 23 Easytrim

Trimmers from Bosch make lawn maintenance a pleasure. The lightest and most compact trimmer of all models offered by this long-established manufacturer is the Bosch ART 23 Easytrim. With this trimmer, you can quickly trim small lawns or successfully add finishing touches to a lawn mowed lawn by trimming edges, edging and hard-to-reach areas for large garden equipment. This trimmer is powered by a 280 watt engine. This power may not seem too big, but it is quite enough for all everyday tasks. The lower engine position improves tool balancing, making it much easier to work with these trimmers.

The Bosch ART 23 Easytrim trimmer has been designed to be as comfortable as possible to work with. This trimmer has the longest barbell in its class (in the fixed barbell class). The 100-centimeter bar length allows you to work without bending over and minimizes back muscle tension. Good balance and a weight of only one and a half kilograms make it easy to use the trimmer, and the additional handle makes it comfortable to work in a variety of positions. In addition, the Bosch ART 23 Easytrim trimmer is quite functional. Thanks to the easy rotation of the trimmer cutter head, this model can also be successfully used as a trimming tool. This model uses the “Pro-Tap” trimmer head for cutting equipment, which feeds the line comfortably and prevents tangling when changing. Another small but undoubtedly useful feature of this trimmer is the practical cable holder located at the top of the boom.

How to change the line on a lawn mower: detailed instructions

In 1971, American entrepreneur George Bollas invented a lawn mower that used a line as a cutting knife. Much time has passed since then, the drive has become more powerful, a modern trimmer can easily damage the bark, so the idea itself has transformed into mowing grass around obstacles without damaging the mower cutter itself. For a neat cut around obstacles, a smaller line head can be used and can be easily changed from large areas to delicate mows. However, the cutting tool itself needs to be replaced periodically. We will tell you how to disassemble the head of a lawn mower (trimmer) and reel in a new line.

All About Replacing the Line on the Trimmer Head

Choosing a line for the trimmer head

There are many types of heads available to suit different types of line. The latter is also available in several diameters: from 1.0 mm to 3.2 mm. over, its cross-section is round (including with a special groove to reduce the noise level), square, twisted and in the shape of a star.

There are no clear preferences, this explains the wide variety of shapes and diameters on the market. The round shape is usually stronger, but has the worst cutting ability and also produces a characteristic sound when rotated. Therefore, sometimes an acoustic groove is made on it, however, the use of this fishing line makes sense only on battery trimmers, in cars with a gasoline engine and a network drive, the sound level of the drive itself practically drowns out the sound from the fishing line. The square has a good cutting ability, and despite the fact that such a line is less strong than a round line, on average it is consumed less. Square fishing line quite easily cuts off the growth of the same willow up to 1 cm in diameter. The star has the maximum number of cutting edges, mows the best and is consumed the fastest.

The next nuance when choosing is rigidity. The fact is that in the production of nylon, a modifier (often maleic anhydride) is added to it, which improves its strength and prevents tearing. However, modifiers are not the cheapest component, they are trying to save money on it. Therefore, a seemingly good line, which remained for the winter, unexpectedly behaves in a completely different way in spring. it breaks, stops coming out of the reel normally. There is a recommendation to soak the fishing line in water before work, but I do not see much point in this, maleic anhydride interacts with water, but if it is not enough in nylon, then there will be nothing to interact with. Therefore, it makes no sense to stock up on fishing line for a long period of time, breaking or constantly breaking fishing line, which, moreover, does not want to leave the reel itself, can significantly complicate the work.

Preparation. remove and disassemble the spool

On most electric and petrol trims, you will need to remove the spool to replace the line. The FUBAG tool lets you skip this step. To make the instruction universal, we will still consider it in detail:

Secure the shaft. Insert the locking element into the corresponding hole. It can be a thin screwdriver or a metal rod.

Unscrew the bobbin case. In our example. strictly in the clockwise direction.

Unscrew the cover according to the direction indicated on the body.

Remove the coil for winding.

The preparatory stage has been passed. You can proceed to winding the fishing line.

How to properly wind the line on the trimmer reel. Step-by-step guide VIDEO

How to wind the line onto the trimmer spool

Winding Algorithm

Insert the resulting loop into the groove.

Lay the line in the direction indicated on the element body.

Insert the short end into the slot on the side of the spool.

Secure the long end in the opposite groove.

Place the spool of coiled line into the spool body.

Pull the line out of the locking grooves.

Put on the cover and fix.

Trim the ends of the line, leaving 10 to 15 centimeters.

The replacement of the line is completed and now it remains only to screw the bobbin onto the trimmer and you can work.

How to choose a fishing line. length, diameter, restrictions

IMPORTANT TO REMEMBER! Do not use fishing line or metal cables for the trimmer. This replacement is ineffective and dangerous. The rope can injure not only the mower himself, but also those around him.

As for the length, you should rely on the estimated frequency of use of the trimmer. The more often, the more it costs to stock up expenses.

Information about the possible line diameter can be found on the body trimmer spools. Most likely, the range will be indicated there. The thickness varies from 1.2 to 4 mm. Choose the appropriate option, taking into account the characteristics of the cultivated area. The larger the diameter, the easier it is to mow tough grass.

ATTENTION! Typical line problems

No wonder they say: “Forewarned is forearmed“. Knowing about possible problems and the causes of their occurrence, you can prevent them in time. We recommend to remember or leave a memo.

| Problem | Cause | Decision |

| Line break | Stones, branches and solid objects in the grass | Avoid collision |

| Poor cord quality | Replace with a quality analog | |

| Wear of outlet holes in the head | Complete replacement of part required | |

| The line is unwound | The spring in the coil is weakened | Check spring and replace if damaged |

| The line is sticking | Poor line quality, due to which it can melt under the influence of temperature from the heating head | Reel in less line or replace with a better line |

For a better understanding of the mechanism of the process of changing the line in the spool with a video guide prepared by FUBAG specialists:

How to properly wind the line on the trimmer spool

Many, having worked out the factory line on a recently purchased trimmer, try to wind a new one, but they cannot, because they do not know how to properly wind the line on the spool (bobbin) of the trimmer. It seems that there is an instruction, but it still does not work. Let’s try to deal with this issue in this article.

So, in order to wind the line, you first need to remove the coil from the trimmer. this will be more convenient. The removal method will depend on the type of trimmer.

Removing the coil from the trimmer

On small, bottom motor electric trimmers (when operating near the ground), the reel usually has two buttons on the sides. Click on them and disconnect one half of the coil body from the second, which remains on the trimmer. Together with the first half, the inner part is also taken out, on which the fishing line is directly wound. When parsing, be careful: there is a spring inside that can fly out and get lost.

On electric and gasoline trimmers with a curved bar (there is still no way to put a knife on such trimmers), you need to wrap the coil body itself with one hand, and with the other hand you need to start rotating the lamb on it counterclockwise. It is he who attaches the coil to the trimmer bar. Having unscrewed the lamb, carefully remove the entire coil, trying not to lose the spring inside.

On electric and gasoline trimmers with a straight bar and a gearbox at its end (on such trimmers, in addition to fishing line, you can also install a knife), we look for a hole under the coil, insert, for example, a screwdriver into it, quietly rotate the coil until the screwdriver crawls even deeper, and the coil will lock. Now we turn the whole coil clockwise (since the thread is left-handed) and remove it from the trimmer. Then we disassemble the coil. It can be assembled using latches or twisted with a lamb. If the coil is on snaps, then press on the sides on the base of the snaps so that they bend and release one half of the coil body from the other. We just unscrew the lamb. There may also be a third type of connection of two halves of such a coil: with it, you need to grab the lower part with one hand, and the upper part with the other, and start turning them in opposite directions. When disassembling such a coil, you also need to make sure that the spring inside is not lost.

than 200 types of trimmers in one place at the lowest prices. Click and watch

Now, having removed and disassembled the coil, we proceed, in fact, to winding.

Winding process

If your coil is designed to work with only one tendril, then it’s simple. You need to unwind 2-4 m of fishing line (depending on the size of the reel), find a fixing hole for the line on the inside of the reel, insert one end of the line there and start winding the line in the direction opposite to the direction of rotation of the reel on the trimmer. On the inside of the reel, they usually indicate with an arrow in which direction to wind the line. After winding the fishing line, we leave a small piece of it unwound to expose it. We fix this piece in a special groove located on the inner part of the reel and designed so that the line does not unwind at the time of collecting the reel. If there is no such a groove, then you will have to hold the fishing line with your finger to prevent it from unwinding during the further collection of the coil. Next, we take the outer part of the coil and thread the outer piece of fishing line into the existing hole, assemble and put the coil back on the trimmer.

If the coil is designed to work with two antennae, then do the following. On the inside of the reel, we look at how many grooves there are for winding the fishing line. There may be one or two of them. If there is only one groove, then both tendrils are wound along this one groove. If there are two grooves, then each antenna is wound along its own groove. A reel with one groove should have a through hole through which the line is threaded. We unwind 2-4 m of fishing line, thread it through this hole so that it sticks out equally on each side of the fishing line. And we simultaneously wind both antennae of the fishing line in the same direction, opposite to the direction of rotation of the coil on the trimmer and coinciding with the direction indicated by the arrow on the inside of the coil. We leave a little of the fishing line unwound, fix the resulting ends in special grooves, and if they are not there, we hold them with our fingers. We pass both ends into the existing holes on the outer casing of the coil. We collect the coil and attach it to the trimmer.

If there are two grooves, fold a piece of fishing line 2-4 m long in half, insert the loop obtained at the place of the bend into the groove between the two grooves, and simultaneously wind both ends of the fishing line along its own groove. Further actions are similar to the previous option.

There are also reels in which the fishing line is threaded through a through hole on the inside. After that, the ends of the line, without winding, are threaded completely through the holes on the outer body of the reel, collect the reel and begin to rotate the button, which is usually pressed, in order to release the line during operation as it wears out. Rotate the button. the fishing line itself is wound inside. At the same time, it will not work to turn it in the “wrong” direction, since it can only rotate in one direction. If you get used to it, you can wind fishing line on such a reel without even disassembling it. you just need to combine the through hole of the inner drum with the holes on the outer body of the reel, and then thread the fishing line through them.

That’s all on this issue. Happy winding!