How To Install a Blade On a Scroll Saw: a Step-By-Step Guide. Scroll saw blade holder

How To Install a Blade On a Scroll Saw: a Step-By-Step Guide

Scroll saws are interesting tools that perform some of the most specialized kinds of woodworking.

Anyone who has much experience at all with scroll saws knows that blade life on most scroll saws measures in minutes.

Knowing how to install a blade on a scroll saw becomes almost second nature to the experienced scroll saw operator.

For the not so experienced, learning how to install a blade on a scroll saw is an important skill.

This step-by-step guide should give any scroll saw user a general understanding of the steps required to install or change a scroll saw blade.

How to install a blade on a scroll saw: a step-by-step guide. Installing a blade on a scroll saw is dependent on the type of blade used in the saw and the manufacturer’s design. Generally, the steps in changing a scroll saw blade are:

Each manufacturer’s design will vary, which may require different intermediate steps or special tools.

The first thing you should always do when performing maintenance on any tool is to consult the user manual that came with the tool.

Before You Begin Installing the Blade

The first step in changing the blade on your scroll saw is to be thoroughly familiar with the recommendations of the manufacturer of your saw.

These recommendations are part of the user manual that accompanies your saw.

If you can’t find your user manual, most manufacturers now make the manuals available online as a free download.

You should locate and have at hand any of the special tools that came with your saw that are required to change the blade.

Having the correct tool in the appropriate size will make the job of changing the blade on your scroll saw much easier.

Once you are familiar with the recommendations from the manufacturer, you have the proper saw blade in hand and the tools for the job, you are almost ready to install or change the blade on your scroll saw.

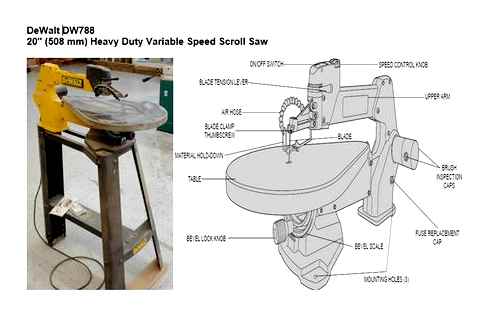

Need to Know Terminology and Parts

If you aren’t familiar with the parts of your scroll saw, this is a good time to begin learning.

Knowing the correct terminology and where to look for the parts on your scroll saw will make understanding these step-by-step instructions for changing or installing a blade on your scroll saw much easier.

Some manufacturers may use different terminology for the parts of their scroll saws.

Don’t despair. With a little work, you will be able to identify the parts readily and do the translations without any problem.

Upper Arm

The upper arm of your scroll saw is the topmost portion of the saw.

The upper arm has the upper blade mount attached at the forward end of the arm.

I should also have the material hold down the foot and a blade guard attached as well.

Some scroll saws may also have accessories attached to the upper arm assembly, such as a sawdust blower hose and a work light.

Many saws will also have the on/off switch and the variable speed control located on the upper arm.

Most manufacturers locate the blade tensioning device on the upper arm.

Lower Arm

Beneath the worktable is the lower arm assembly.

The lower arm is the driving arm of the saw and, with the attached motor, causes the blade to reciprocate up and down.

Attached to the fore-end of the lower arm assembly is the lower blade mount.

Tensioning Device

All scroll saws have a means of adjusting the tension between the upper arm and the lower arm.

This tension is what keeps the blade cutting straight and true. An improperly tensioned blade will wander, vibrate, and break much sooner than normal.

The type of tensioning device and its location varies from one model of scroll saw to another. Some have knobs while some use levers, usually located on the upper arm assembly.

The knob or lever may be at the front or back of the upper arm assembly and should be easily identifiable.

Table Insert

Most scroll saws have a larger opening in the worktable that is necessary for the blade to operate.

A table insert comes with the saw and fills in this opening to make a work surface that allows the material to be supported as close to the blade as possible.

The table inserts are removable to allow easier access to the lower arm assembly and the lower blade mounts.

Blade Clamps

The physical connectors that hold the blade securely to the arms of the scroll saw as the blade clamps.

The style of blade clamp is a function of the style of blade you scroll saw is designed to use and the technique for attaching the clamp to the blade.

On some saws, the blade clamps are removable and, after being attached to the blade, snap back into holders on the upper and lower arm assemblies.

In some cases, the blade clamps are fixed to the arm assemblies.

A few scroll saws offer combination blade mounts that will allow you to use either style of the scroll saw blade.

Styles of Blades

Scroll saw blades come in two types, pinned and pinless.

Pinned blades have a small circular pin fitted crossways through the top portion of the blade and at right angles to the cutting edge.

These pins fit over a blade clamp holding the blade into a groove or notch on the blade clamp.

Pinless blades have smooth ends that slip into a blade clamp, which tightens with a wrench or thumbscrews.

The clamp blocks squeeze and grip the ends of the blade.

On scroll saws designed to use either style of blade, a set of blade adapters come with the scroll saw.

These blade adapters are screw-type blade clamps, which then fit into the pinned blade holder on the scroll saw, effectively turning a pinless blade into a pinned blade.

Related Content: Why do scroll saws vibrate so much? Is it just normal?

Understanding How a Scroll Saw Cuts

One thing that you must always remember is that there is an up and a down on a scroll saw blade.

Scroll saws cut on the downstroke of the blade.

For the scroll saw to operate properly and safely, the scroll saw blade must install into the saw in the proper direction.

On most scroll saw blades, this is easy to determine by looking at the blade.

The rake of the teeth, or the angles at which the teeth set on the blade, should point downward.

On some reverse tooth blades figuring out which is up and which is down may be harder.

Many blade manufacturers will print the blade information on the top portion of the blade.

The blade label is often a good indication of which way a reverse tooth blade mounts in the scroll saw.

Below is a short video about how the types of scroll saw blades:

Saws by the very nature of what they do are dangerous.

The blades themselves are incredibly sharp and require handling with care.

- Always wear proper safety equipment when working around power tools. Eye protection is an absolute must, as is a good work apron. When operating large power equipment, hearing protection is a must as well.

- Disconnect the power before doing any maintenance or blade changes on your scroll saw. Nothing can ruin your day faster than to inadvertently bump a power switch when your fingers are in contact with a sharp blade.

- Keep your workspace clean and orderly, especially the floor around your scroll saw. Loose wood scraps and even sawdust are trip hazards under the right circumstances.

Step 2 Release the Tension On The Blade

Using the blade tension device, release the tension on the blade according to the manufacturer’s instructions.

Your saw may have a lever or knob located somewhere on the upper arm assembly.

Your user manual that accompanied your saw will help you identify exactly where the tensioning device is and how to work it to remove the tension from the blade.

Step 3 Remove the table Insert, blade guard, and other safety equipment as directed in the user manual

Remove the table insert to make accessing the lower blade mount on, the lower arm assembly easier.

Follow the manufacturer’s instructions on removing the table insert.

If equipped, you may also need to remove the blade guard and any other guards that cover moving parts of the saw.

Your user manual will have explicit instructions on what to remove to access the blade mounts.

Step 4 Remove the old blade

You may need to refer again to your user manual to understand exactly how to remove the blade from the blade mounts.

The pins on pinned blades usually ride in a v-groove or slot of some sort on the blade mounts on the upper and lower arm assemblies.

The tension on the blade keeps the pins in the slots or grooves as the blade reciprocates up and down.

Some pinned blade mounts are depressed to allow the pin to slip from the grove or slot.

Some may have thumbscrews that open the blade mount to allow the pin to slip free of the mount.

Your user manual is the best reference on the exact method of releasing the pinned blade from the blade mount on your scroll saw.

Step 5 Insert the New Blade.

Installing the new blade is the reverse process of removing the old blade.

Be sure the blade is right side up and that the teeth are facing downward so that they cut on the downstroke of the blade.

The pins must fit into the grooves or slots on the blade mount.

If the blade mount has a thumbscrew or set screw lock, retighten it according to the manufacturer’s specifications.

If the blade mounts have thumbscrews or set screws, tighten them properly before the blade is re-tensioned using the tensioning device on the saw arm.

Step 6 Replace the Table Insert and any other safety equipment or guards previously removed

Replace the table insert, making sure that it is facing the right direction and has the proper side up.

Some table inserts can be placed in the table backward or upside down.

An improperly placed table insert is a safety issue.

Never operate your scroll saw with any of the safety equipment or guards out of place.

Removing guards and shields is an open invitation to an accident.

Step 7 Re-Tension the Saw Blade

Tensioning a scroll saw blade properly is as much an art as it is a mechanical problem.

Start with the recommendations and specifications in the user manual that came with your saw.

As you gain experience, you will begin to learn to feel the blade for proper tension or even listen to the blade.

Many experienced scrolls saw users can strum or pick their blade and listen to the sound made by the blade.

The sound will tell them when they have the correct tension on the blade.

Many say that a properly tensioned blade will emit a musical note when strummed or plucked.

Step 8 Check the Saw

Before you go any further, now is a good time to check your scroll saw.

Keeping your scroll saw clean and in good working order will ensure that you get the best possible performance.

Check for loose or missing screws and, if the manufacturer recommends, lubricate any moving parts.

Once you have performed the routine maintenance on the saw and are sure that everything is as it should be, you should finish up your blade install and move on to the next step.

Step 9 Reconnect the Saw

Plug the power cord of the scroll saw back into a properly sized and grounded plug.

Test the scroll saw by turning it on briefly and making sure that everything fits properly, is adjusted, and that all safety guards are back in place.

Step 10 Make a Test Cut

Using a scrap of the same material you are cutting for your project, make a few test cuts with your newly installed blade.

If you notice anything amiss, stop and re-tension the blade and try another test cut.

When you are satisfied that everything is operating properly, you are ready to continue with your project.

How to Install Pinless Blades on a Scroll Saw

Installing or changing pinless scroll saw blades can be a bit more challenging.

The style and design of each saw manufacturer’s blade clamping mechanism are slightly different.

While the overall concepts are the same, differences in tolerances and specifications call for careful attention to the manufacturer’s instructions.

These step-by-step instructions for changing or installing pinless scroll saw blades are, by necessity, generic.

Step 1 Safety First

We can never emphasize safety enough when talking about maintenance and the use of power tools.

Observing proper safety protocols in your woodshop will mean long years of accident-free projects.

One of the biggest safety issues is lack of concentration.

Failing to keep your mind on the job at hand leads to careless mistakes that can be disastrous.

Please follow the basic safety rules in your woodshop:

- Always wear all your safety equipment. Hearing protection when running power tools is strongly suggested. Don’t forget eye protection and we always suggest a good quality work apron.

- Unplug any power tool when not in use and especially when you are performing maintenance or a tool change. An unplugged tool is inherently safer than one that is still powered.

- Practice good hygiene in your shop. Keeping a clean workspace prevents trips and other sorts of accidents. Working in a clean and orderly environment is not only safer but much more enjoyable.

Step 2 Release the Tension on the Blade.

Use the tensioning device on your saw to release the tension on the scroll saw blade.

The blade tension device may be a lever or knob. In general, these blade tensioning devices are on the upper arm assembly.

For more precise instructions, consult the user manual that came with your scroll saw and follow the directions given by the manufacturer to release the tension on the scroll saw blade.

Step 3 Remove the Table Insert, guards and safety equipment

Follow the manufacturer’s instructions on removing the table insert, guards, and other safety equipment to access the lower blade clamps on the lower arm assembly.

Set the table insert and other parts aside for the time being.

Step 4 Remove the Old Blade

The actual means of removing the old pinless blade from the blade clamps is determined by the style and design of the blade mounts on the scroll saw.

There are several varieties of blade mounts, and these can vary even between models made by the same manufacturer.

Some models of scroll saws are fitted with thumbscrews and don’t require any tools to loosen the blade mounts.

Loosening the top and bottom thumb screws will allow the blade to slip from the blade mounts.

Other models employ set screws to hold the blade in place in the blade mounts.

Some types use only one set screw on the side of the blade mount. Another type used two set screws, one on each side of the blade mount.

If your scroll saw uses set screws, use the right size tool. Ideally, you will have the tool provided with the scroll saw by the manufacturer.

If not, size the tool properly to prevent damaging the set screw.

Slip the old blade from the blade mounts and dispose of it properly.

Step 5 Place the New Scroll Saw Blade in the Mounts.

Follow the reverse steps to install the new saw blade in your scroll saw. Check the saw blade and make sure it is right-side up.

Pay attention to the placement of the scroll saw blade in relation to the table.

Pinless blades can be adjusted up and down to a certain degree in the mounts.

Setting a blade too low or too high can cause the blade to break or cut improperly.

If your saw has thumbscrews or a single set screw on the blade mount, tighten the thumbscrew or set screw as recommended by the user manual.

The proper tightness on the blade mounts will ensure the longest possible blade life.

The blade mounts that use two set screws are a bit more ticklish to use and adjust.

The blade must center between the set screws and the set screws then carefully tightened.

Under-tightening the set screws will result in a loose blade and over-tightening can cause early blade failure.

Failure to center the blade between the set screws can cause blades to wander or cut erratically.

Step 6 Put the Table Insert and Other Safety Equipment Back in Place

Replace the table insert into the worktable of the scroll saw. Pay attention to the proper placement of the table insert.

In improperly placed table insert can be a safety hazard when using the saw. All other guards or equipment removed to access the blade mounts before the next step.

Operating any power equipment without the proper guards, shields, and safety equipment is dangerous and should not become a habit.

Step 7 Reset the Scroll Saw Blade Tension

Follow the manufacturer’s directions on tensioning the scroll saw blade on your model of saw.

There are several methods of checking the scroll saw blade tension.

Always start with the method recommended by the manufacturer of your scroll saw.

You can then check for proper tension by physically moving the saw blade to check for tension and tightness.

As you become more experienced, you will develop a feel for proper tension on your scroll saw.

You may even begin to hear the sound made by a well-tensioned scroll saw blade when it is strummed or plucked.

Whatever method you use, the better the tension on the scroll saw blade, the better it will cut, and the longer it will last.

Step 8 Check the Saw

Anytime you change a blade or adjust the saw, it’s a good idea to perform a few routine other checks of the saw.

Look for any loose or missing screws or parts. Make sure that all the safety equipment such as guards and inserts are in place and adjusted correctly.

A little pre-emptive action can prevent mishaps and accidents down the line.

Step 9 Plug the Saw Back into The Power Outlet

Check that the on/off switch is in the off position and reconnect the power cord to the outlet.

Test the connection briefly to make sure the saw is operating correctly.

Step 10 Do some Test Cuts

Use a scrap piece of the same material you are using for your project and complete some test cuts.

Check the blade for vibration and blade wander. Turn off the saw and check the blade tension one more time before you continue with your project.

Combo Scroll Saws

Changing or installing scroll saw blades in a scroll saw that has the capability of using either style of blade usually involves a set of accessory blade mounts.

These accessory blade mounts clamp to the ends of the pinless blades and essentially act like pinned mounts.

The accessory blade mounts attach to the pinless blades in much the same fashion as the pinless blade mounts on the saw.

Thumbscrews or set screws tighten against the blade ends and clamp the blade securely to the accessory mounts.

Once the accessory blade mounts are securely attached to the blade, they are slipped onto the pinned mounts on the upper and lower arm assemblies just like a regular pinned blade.

The accessory mounts have a bar or pins that fit into the grooves or slots on the mounts and fasten to the pinned blade mounts in the normal fashion.

Follow the step-by-step directions for installing a pinned scroll saw blade after you have attached the accessory blade mounts to the pinless scroll saw blade.

explicit instructions for your model of saw are in the user manual that came with the saw from the manufacturer.

Don’t Get In A Hurry

We are all guilty of trying to cut corners to save time.

In the end, cutting corners may save a few seconds but cost more in damaged equipment and ruined projects.

Replacing a scroll saw blade might seem like an easy and trivial matter until you miss a step or fail to perform a check and needlessly break blades, ruin a nearly finished project, or, in the worst scenario, injure yourself.

Having a routine, a step-by-step approach to even the simplest job around the shop can be the difference between successful and enjoyable projects, and frustration at failure.

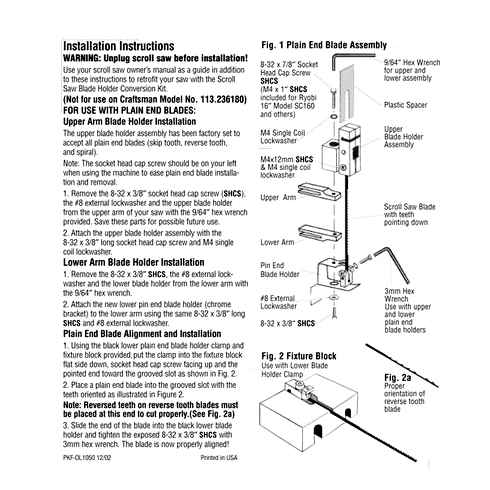

How to Install Plain End Scroll Saw Blades

Have you been wondering exactly how to install plain end scroll saw blades? Well, wonder no more!

This guide will walk you through all the steps you need to know in order to install plain end scroll saw blades successfully!

A scroll saw is an essential power tool to have in your woodworking arsenal.

Because of their narrow blades, scroll saws are useful for cutting accurate thin cuts such as joints, curves, slopes, and profiles.

Scroll saws come in two blade types, the pinned blade, and plain end scroll saw blade. As its name implies, the pin end blade has two pins at either end that sit on a blade holder.

Scroll saw beginners. Change your blade when you see this!!

The blade holder can then be tightened to give appropriate tension to the blade to prevent it from falling off when in use.

The pinless blade, (plain end blades) don’t have pins at their ends and are held together by a blade clamp instead.

Depending on the scroll saw you use, these clamps can be part of the scroll saw or may come off when installing the pinless scroll saw blades.

Plain end scroll saw blades are easier to find, and they come in many varieties, making them a better option to choose when working with a scroll saw.

But, as with any tools with reciprocating blades, these, too, dull with use and require replacement.

Here, we’ll look at how to install plain end scroll saw blades correctly so your machine keeps working at its best to give you accurate cuts every time.

How to Install Plain End Scroll Saw Blades

Safety First

Safety should be your priority whenever using or maintaining a power tool. They hold a host of stored energy which, if released at the wrong time, can lead to deep cuts, lacerations, lesions, and in severe cases, death by electrocution.

Unplug the power plug for your scroll saw before changing its blade. If multiple people use the machine, make sure that you leave a note tied to the machine’s main switch or circuit breaker to prevent accidental startups.

Wear protective gloves when maintaining your scroll saw as you’ll be handling the blade.

Getting the Scroll Saw Blade Assembly Ready

The assembly for plain saw blade scroll saws is going to depend on the brand you use. Account for all the components required.

In most cases, there will be the clamps, the blade, and an Allen key.

Some clamps already have a key on them and don’t require the Allen key, but if yours does, make sure it’s the right size for the clamp screws.

Inspect the clamps and blade, making sure they are in good condition and don’t have any signs of rust or damage, as this will impact your saw’s functionality and is also a safety hazard that may cause the blade to fly off.

Clamping the Scroll Saw Blade

- Grab your blade and one of your clamps. Guide one end of the blade through one of the openings on the clamp that runs between the two hex screws, ensuring that the cutting edge is in the correct orientation.

- Ensure that the end of the blade runs through both of the screw surfaces but doesn’t go out from the other end; otherwise, you won’t have enough blade length for the other clamp.

- Screw the blade in place by tightening the hex screw with an Allen key or the tightening screw on the clamp, ensuring that the blade is held firmly in the middle of the two screws.

- Don’t over-tighten the screws, as this may damage the threads. You can consult your scroll saw’s manual on tightening guides. Generally, half to one rotation should suffice when tightening.

- Hold the blade and clamp upright and make sure that the blade runs straight down the clamp. Significant deviations from the normal may cause the blade to kink and break when in use, so make adjustments if necessary.

- Install the other clamp in the same way on the other end of the blade and inspect again for straightness. Some scroll saws come with a guide on their upper arm where the whole blade assembly can be placed for accurate blade installation.

Installing the Blade Assembly in the Saw

Depending on the type of scroll saw you have, it may have a removable throat plate for inserting the blade assembly or may have a slit for guiding the blade assembly through the table.

In either case, a clamp-holding mechanism should be under the table where the clamp hooks onto or snap-in.

Find that lower inner hook and place one arm of the clamp onto the hook.

Keep medium to low tension on the upper clamp before hooking it onto the upper clamp holder above the table. Tighten the blade using the blade tension adjustment knob.

Adjusting the Tension

After you’ve installed the blade with its assembly, your work isn’t over yet.

Plug your saw back into the mains supply and run the saw for a couple of minutes, and you’ll see that the blade loosens.

That’s because the blade tends to stretch the first time the saw is turned on.

Workshop: 2 Quick Scrollsaw Upgrades

You must account for this phenomenon and adjust the tension again using the tension adjustment knob or a lever on the upper clamp holder.

And there you have it! Your new blade is installed.

Wrapping it Up

It is worth mentioning that not all scroll saws are created equal. Some are only manufactured to hold pinned blades, some only for plain, and some can hold both blades or may have an aftermarket attachment that allows them to hold both.

For the scroll saws that only hold plain blades, their clamps may not require coming off from the upper and lower arms, and the blade requires clamping by tightening it between the clamps.

You should consult your owner’s manual if you’re still unsure about this process. It’ll definitely have a section on how to install plain-end scroll saw blades.

If your scroll saw still doesn’t function properly, the chances are that the blade you replaced was dull, the motor inside the saw is damaged or has dull contact brushes, or the threads in the clamp(s) have broken off.

Maintain a check sheet where you regularly maintain your scroll saw, checking to see its motor and other peripheral parts’ performance.

This will improve its longevity and give you consistent cuts every time.

Hopefully, this guide showed you how to properly install a plain end scroll saw blade!

JET 727201 JWSS Lower Blade Holder (set of 3)

Most orders over 299 ship for free | See Details

Have a Question?

Need this Product for a Specific Application?

Use our handy finder to find the exact model for your needs.

JET 727201 JWSS Lower Blade Holder (set of 3)This set of three holders make it easy to pre-load a variety of blades for use during scroll saw projects.

Features:

Attaches quickly and securely into placeComes in a set of 3Will work with JWSS-18 JWSS-22

Specifications

JET 727201 JWSS Lower Blade Holder (set of 3)This set of three holders make it easy to pre-load a variety of blades for use during scroll saw projects.

Features:

Attaches quickly and securely into placeComes in a set of 3Will work with JWSS-18 JWSS-22

Specifications

Scroll Saw Blades

When you start looking for the answers to your questions, this subject can start to get very confusing. I hope this will make it less confusing and help to answer these and other questions that you may have about the different types of scroll saw blades.

When I first got my scroll saw several years ago, I just picked up a few packages of blades that were on the rack at the store. My saw also came with a few assorted blades in the box, so I used them. These blades worked okay for the first few days; however, the more research I did, the more I realized that I should get some better blades. So I ordered some good blades and while I waited for them to arrive, I continued to use the stock blades until I eventually broke them all. When the new blades arrived, it was surprising how much better they really were. They were so much better I never went back to the cheap blades.

In this article, I have included links to several of the websites that have been very helpful to me with this hobby. These are links that I have used to find the information that I am sharing with you.

Two Styles of Scroll Saw Blades

The first thing you need to determine is what kind of blade your scroll saw requires. There are two different styles of blades that are available: “Pin End” and “Plain End.” Some higher-end scroll saws do not accept pin end blades and some older scroll saws do not accept plain end blades. Some scroll saw can use both.

Pin End or Pinned

Pin end blades use a pin at each end of the blade to attach it to the blade holder. A limiting factor of using pin end blades is how small of an internal cut you can make because the hole may be smaller than the pins on the blade.

Most modern higher-end scroll saws do not accept pin end blade types. Also, some older or lower end scroll saws only accept pin end blade types.

If you have a scroll saw that only accepts pin end blade types and you want to do some of the work that requires a plain end blade, do not worry. The Olsen company has created the AC49610 conversion kit. This conversion kit allows most older 16-inch scroll saws to accept plain end blade types.

Plain End or Pinless

Plain end blades lack the pins that attach it to the blade holder. Because there is no pin, they must be held in place by clamping each end to the blade holder. This type of blade is much more popular than its pin end cousin and there are more blade configuration options available. Since there is no pin you can use it in very small internal cuts as long as the hole is slightly larger than the diameter of the blade itself.

Types of Scroll Saw Blades

There are several types of blades that perform different roles. Scroll saw blade manufacturers make their blades with different configurations and will call some of them by different names. They all will be some variance of the following types:

- Spiral – Spiral blades have teeth on all sides of the blade due to the blade actually being twisted. Because of this twist, they are sometimes difficult to attach to the blade holder. For this reason, some blade manufacturers design them with flat ends, making it easier to attach to the blade holder. Spiral blades are very useful for multi-directional scrolling since it allows you to cut in any direction without turning the piece of stock. This is a great benefit for people who have smaller scroll saws if they want to cut a larger project. I find these types of blades hard to use. There are many people that prefer spiral blades over the straight blades because of the maneuverability they provide. If you look at it closely, it resembles barbed-wire. Spiral blades are only plain end or pinless type.During my research, I have found that pin end spiral blades may have existed at one time, however, they appear to be very rare and mostscrollsaw blade manufacturers do not make them. I was unsuccessful in finding them.

- Standard – The teeth all point downward. This is how scroll saw blades were originally configured going back to the 18th century.

- Skip Tooth – Skip tooth blades will have a gap between each tooth. This allows the sawdust to be extracted which will keep the blade running cooler and will help prevent burning.

- Double Skip Tooth – Similar to a skip tooth blade except it will have two teeth and then a gap between the next two teeth. This allows even more sawdust to be extracted allowing the blade to run cooler and prevent burning. This added benefit of a smooth cut with less burning does come with the cost of a slower cut.

- Reverse Tooth – The teeth on the top portion of a reverse tooth blade point downward, and the teeth on the bottom portion of the blade point upwards with a blank space in between. This reason for this is to prevent tear-out on the bottom of the project.

- Crown Tooth – Crown tooth blades have teeth pointing in both directions so it cuts on both the upward stroke and the downward stroke. This allows a smooth finish with less burning. Also when it starts to become dull, you can flip the blade over and use it just like a new blade.

- Manufacturer Specific – Ultra reverse is an example of a manufacturer-specific type of blade. It is similar to a reverse tooth blade, except it adds more teeth pointing in both upward and downward directions. For instance, it will have several teeth pointing down, then every third tooth, pointing up. It will repeat this pattern for the length of the blade. Another manufacturer-specific type is the Modified Geometry by Pegas and Mach Series blade by Olson.

- Puzzle – Puzzle blades are very thin blades and specifically designed to make jigsaw puzzles. Puzzle blades can usually be found where regular blades are sold.

- Sanding – Olson calls them sanding files. Sanding files look like regular blades however, instead of teeth, they have sanding material on it designed for shaping and sanding.

- Other – Some manufacturers produce blades that are specifically made for metal, glass, and other materials.

What Size of Scroll Saw Blade Do I Need?

The blade size that you need will depend on the project that you are doing. For instance, if you require an internal cut for a fretwork pattern, you may need to go as small as #3/0; however, for a larger project or thicker materials, you may be able to use a blade as big as a #12.

Wood species and material thickness will be factors in determining the size and type of blade that you will need for a particular project.

The blade characteristics will be the width of the blade (kerf), TPI (teeth per inch), length of the blade, and the blade configuration such as skip tooth, reverse tooth, crown tooth, spiral, etc.

Taking all of these things into consideration, you may settle on just one or two blades that you become familiar with for most of your projects. I have become very used to a size #3 blade on probably 95% of the projects I do, including thicker hardwood.

The different types of blades come in a variety of sizes ranging from as small as #3/0 to as large as size #12. You can also get sizes that are outside of this range; although they are not very widely available.

Manufacturer’s Recommended Size of Scroll Saw Blades

There is a chart located on the Scroll Saw Woodworking Crafts website that shows the recommended blade size and configuration based on the project, the material, and thickness of the material.

Blade manufacturers will have different sizes for the different blade configurations as well.

For instance, at the following link, there is a chart available on Olson’s website that details the different blades they produce. You will see on page 1, the “PGT” blade size ranges from size 5RG to 9RG, while on page 2 the “Double Tooth” blade ranges from size 3/0 to 12.

Click the link below to view the Olson Scroll Saw Blade Selection chart. https://www.olsonsaw.net/wp-content/uploads/2016/01/2015-scrollchart.pdf

The chart in the link below is located at Bushton Manufacturing/Hawk Woodworking Tool’s website and includes three of the more popular brands of blades. They are Olson, Pegas, and Flying Dutchman. The chart lists the brand and the specifications of the blades such as TPI, pilot hole size, width, and thickness. Also listed in the chart will be the material and the pattern type that will be best suited for a particular blade.

Click the link below to view the Bushton Manufacturing Scroll Saw Blade Selection Chart.http://www.bushtonmanufacturing.com/ScrollSaw/ScrollSawParts/SS_BLADE_CHART_2-22-2013.pdf

The manufacture of the Pegas brand of blades has several downloadable charts for comparison available on their websites.

What Length of Scroll Saw Blade Do I Need?

Scroll saw blades are available in three, four, and five-inch lengths. Five-inch blades are the most popular with modern scroll saws.

Refer to the documentation for your scroll saw to verify which blade length may be required for your particular machine.

Brands of Scroll Saw Blades and Where Can I Get Them?

When I first began the scroll saw hobby, I only used blades from a handful of manufacturers. It was not until much later that I discovered there are many more brands of scroll saw blades available than I had originally thought.

In the link below I have listed all of the brands of scroll saw blades I could find. This list includes the website of the manufacturer if available and also where you can purchase that brand.

Some of the manufacturers make what they describe as fret saw blades as well. This is more common outside of the United States where scroll saws are sometimes known as fret saws. A fret saw can also refer to a hand-powered scroll saw that looks similar to a coping saw. The blades are usually interchangeable between the two tools.

Conclusion

Scroll saw blades come in either “pin end” or “plain end” style. Most modern scroll saws will accept plain end blades; however, to be certain, you will need to refer to the documentation that came with your scroll saw. Unless you have a specific need to use pin end blades, I would stick with plain end blades.

There is the AC49610 conversion kit if you require a plain end blade and your scroll saw only accepts pin end blade types.

There are a multitude of scroll saw blade manufacturers around the world. Scroll saw blades are available in a variety of configurations such as skip tooth, double tooth, and spiral just to name a few. There are even scroll saw blades for cutting metal and glass as well. Some manufacturers will have their own unique designs and names for their tooth configurations.

The type and thickness of material that you will be cutting are a few of the factors when determining the size and type of blade you will need.

An important thing to consider is that everyone has their own favorite blades to use. In order to find the right blade for your projects, you may want to experiment with some different types. This will help you determine which blades will be the best choice for you and your scroll saw.

I hope this has been helpful and you have enjoyed your visit. Let us know if you have any questions in the Комментарии и мнения владельцев section below. Subscribe to our blog so you will be notified by email when a new article is posted.