How To Install Line On A Mower

Thick line

It is stored at the top of the trimmer body.

Spare coil storage space

It is very simple to install such a fishing line into the reel. according to the internal scheme inside the reel. We insert the center of the line with a metal mount in the upper part of the reel, and draw the ends of the line along the grooves and bring it out.

Trimming the line into the trimmer.

I want to devote today’s article to the sore subject of summer residents and gardeners of the entire post-Soviet space “How to fill the line in the trimmer.” Not many trimmer manufacturers answer this question in their instruction manuals. Therefore, it is also difficult for simple gardeners to figure out how to do it correctly.

I want to start with a brief description of the technical characteristics of the trimmers.

So, trimmers are electric and gasoline. The cutting element for trimmers can be a line and a knife. The line is ordinary, four. pentahedral and intertwined (in the form of a pigtail). Knives come in 2, 3 and 4 bladed knives. Knives also come in plastic and metal.

The line feed system from the trimmer is manual, semi-automatic and automatic.

Development engineers who create new models of trimmers accurately calculate the diameter (thickness) of the line and the number of knife blades, according to the power of the trimmers. Otherwise, the motor is overloaded, resulting in damage. And these are additional and significant costs.

Trimmers on the market today:

With one nozzle. only a line.

With two nozzles. a fishing line and a three-four-blade knife.

With one attachment. only three to four blades.

Our Kulibins long ago learned to improve any mechanisms. So, for example, some gardeners make successful, in their opinion, replacement of fishing line with a metal cable, or fishing line. But at the same time, they do not think about the safety of their own and their loved ones, because, like a cable with the power of a working trimmer, it can easily break out and not only injure the mower and others, but leave him crippled for life. The use of a fishing line can and gives a better effect, I have never personally tried it than a trimmer line, but this work has a number of inconveniences: when it comes into contact with hard objects, it loosens or it can simply be pulled out of the reel indefinitely.

So, what is called closer to the topic. Here is an example of how to thread the line into the trimmer (Trimmer BOSCH Art 30). Everything is very simple. Started.

After you have chosen the line for refueling, you need to cut off the required amount of line, because all the line in a skein will not be wound into a reel.

Cut off and start reeling.

Remove the coil and the protective cover from the coil.

They took it off. We fix one end of the line in the gap and carefully and evenly wind the line.

The amount of line should be such that the protective cover of the reel closes and the line on the reel unwinds a little by itself.

We put the other end of the line into the hole on the protective casing.

Next we take the coil and the protective cover of the coil. We squirt the end of the line from the reel into the metal hole on the protective cover of the reel. Tighten the line a little.

We put it all on the trimmer. Turn the coil clockwise until it clicks.

They fixed it. Now we connect the trimmer to the network. We put the trimmer in the starting position for work. We turn on the trimmer. Excess line length will be cut on the trimming blade.

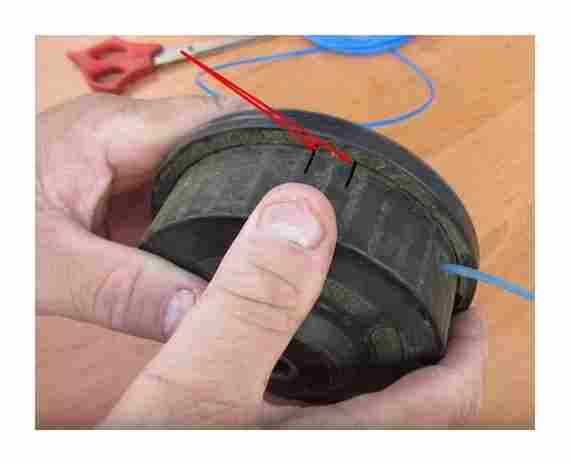

Coil in trimmer

Lawn Striping. How To Achieve The Best Stripes In Your Lawn

That’s all we start working.

In addition to the standard lawn line, my trimmer also has a thick line for cutting rough weeds. It has the shape of a pigtail, i.e. three lines are tightly intertwined. This line has its own spool.

Heavy-duty line in a reel

This reel is attached to the trimmer in the same way as a reel with an ordinary line.

How to load, insert, put on or wind, wind the line onto the trimmer spool?

Uncategorized

How to load, insert, put on or wind, wind the line onto the trimmer spool?

I went out into the garden, started the trimmer, worked for literally 5 minutes, and then the line in the trimmer spool ran out. What to do? In this article we will tell you how to properly wind the line on the trimmer reel yourself.!

If you use a trimmer frequently, you should already have a spare line prepared. In case the reel runs out of line. To select a line of a suitable diameter, refer to the trimmer datasheet for the diameter recommended by the trimmer manufacturer. The line diameter ranges from 1.2mm to 4mm. Also pay attention to the shape of the line, for example:

For one threading of the reel with line, you will need 2 meters of line. Buy a line recommended by the manufacturer, quality line does not wear out as quickly!

So, let’s get down to disassembling the coil! Remove the spool of line from the trimmer, in order to get to the line, you need to open the spool. On the coil body, press the latches and, holding the latches, turning the cover, remove it. Opening the spool, you will see that it consists of these parts: the spool body, the spool core where the line is wound, a metal spring, two metal washers and a spool cap. Fold the prepared piece of fishing line in half: so that one end of the fishing line is 10 cm longer than the other. We fix the place of the bend of the fishing line, putting it into the groove, in the dividing side (core). We twist the core of the reel so that the line winds in the direction of the movement arrow. We fix the ends of the line in the holes on the body.

Now, put the coil together. Place the first iron washer in the coil body. We put the second iron washer inside the core with the fishing line, and then insert the spring there so that it does not fall out. Now we plant the core inside the coil body, with the spring down. We stretch the free ends of the line into the holes on the reel body. We tighten the ends of the line outside the body so that the core sits inside the coil. We close the coil body with the coil cover, paying attention to the latches. they must match! Scroll the cover until it snaps into place. Install the reel with the line on the trimmer, pull the ends of the line to the desired length.

Everything is ready to go! You can also watch a video on this topic on our YouTube channel.!

Hand winding the line to the reel

Winding Experiments

For reels made by Daiwa and Abu Garsia, as well as the inexpensive Cobra, well-known in Ukraine, the winding style is formed by the taper of the spool. Shimano went with a peculiar way of adjusting the profile thanks to the washer pad under the spool.

The disadvantage of the system with washers is the impossibility of using it in more well-known and convenient reels with a rear brake. Any winding profile can be set at the time of backing up.

Line winding device

Consider a line winding device. It consists of the following elements:

- nail;

- and a circle of rubber with a thickness of 7.5 mm.

The nail is taken of such a size that it would go into the spool hole almost closely. It would be nice to have a stem from such coils (only faulty ones). In the absence of such, you can rivet the nail itself a little, creating a slightly elliptical configuration for it along the hole in your spool. We pierce the rubber with a nail in the center.

Then we insert it into the spool, and take an electric drill or screwdriver and clamp this device in the drill chuck. In order to better bond and increase the friction force between the rubber band and the spool, we slightly tap on the nail, drowning it in the rubber (you can also use a “micro pore”). We knit the fishing line on the spool with a self-tightening knot, and then we tighten the knot, we wind it clockwise, we hold the reel with the fishing line in one hand, by the central hole, we take the drill in the other hand and, adjusting the revolutions of the cartridge, we wind.

It is not necessary to reel the forest too much, we only control the uniform laying of the fishing line along the spool, leading the fishing line up and down

We fill almost the entire spool, leaving a collar of 1.35. 2.35 mm; with a tighter winding of the wood, it can sometimes slip off the spool. With such a winding, twisting of the line does not occur. On the water, the line looks aesthetically pleasing and even, and in this case it serves much longer.

Winding profile and casting distance

The reel designers have experimentally found a definite improvement in casting performance in relation to the winding profile.

- The narrowing of the winding towards the tulip (front cone) is embodied in the Long Cast spool, which really increases the casting distance and is used in carp, float and feeder fishing.

- The narrowing of the winding to the handle (rear cone) is made in the ABS spool from “Daiva”, which increases the casting distance, and most importantly, greatly reduces the possibility of dropping loops, as well as “beards” when fishing with a spinning rod with jerks. For spinning players who fish with twitching, jigs and jerking, such a winding of the line on the reel is simply a must. Apply such a winding on a braid with a diameter smaller than 0.2 mm. From tapered windings, direct winding gives similar results.

How to wind a fishing line on a reel: diagram

In this article, we will look at how to wind the line on a reel. On a standard reel, 100 meters of 0.3 mm line is wound. It is calculated that the winding of the line on the spool, as a rule, is wound 2 mm below the edge of the bobbin collar.

than the edge of the side, the winding of the fishing line on the reel is not performed; at the time of casting, the line is guaranteed to break the turns and form a beard. The lower the winding of the line on the reel is done, but the lower it is, the shorter the casting distance.

Professionals suggest winding up to 250 meters of braid, but it is easier to reel in additional line to solve the problem. both cheaper and more effect (see the article: “How to choose a braid?”). At first, I tried to compose different formulas to calculate the length of the winding line, but, firstly, it did not work out to calculate with the required accuracy, and secondly, this length is determined automatically when the fishing line is experimentally wound on a reel.

| Read more about choosing a spinning rod in the article: → “How to choose a spinning rod: choosing a reel, rings, rods and firm”. |

How to reel fishing line

Fishing is really exciting and exciting business. Beginner spinning players, of course, want to quickly join it and finally get a sensible result. The reservoir where you are going to fish has been selected, all the necessary accessories have been bought. There are rods, reels with lures and lines. too. However. even a slight, but still tangible nuisance can wait right on the shore, which sometimes completely disrupts the whole fishing.

Her name is the winding of a fishing line on a reel. Each coil seems to be equipped with an instruction with a basic diagram. But the fact is that with such an attitude, it will not be possible to catch a lot for sure. If the loop is wound incorrectly, the loop can be thrown off, and instead of removing the fish from the hook, then you will have to bother with untangling a lump from the fishing line with your own hands.

They start using spinning most often with tackles that are shorter (both reels and rods). The caliber of the bobbin in them is two to three thousand (that is, a hundred-meter line is not more than a third of a millimeter thick in this case, the limit). The winding structures can also be very different: this is a chaotic winding in a chaotic arrangement of Chinese samples (more or less suitable for monofilament, but completely inappropriate with braided line), and more professional formats such as a straight cylinder, straight and inverted cone. And from the very beginning it is better to get used to those types of styling that are more serious, because this is not a whim, but a higher efficiency. Having saved a few hundred rubles in passing, you will then begin to curse everything in the world, when, instead of casting and biting (well, or just casting and waiting), fishing turns into a continuous struggle with “beards” and other overlaps of the line. Such a catch has never brought joy to anyone.

How to quickly wind a line on a spinning reel

The main, fundamental rule is that the equipped line must be flat, like a ruler. For cylindrical winding, a straight line is optimal, and if a cone is chosen, then an inclined one. But in any case, remember firmly, only the line without bends.

How can this leveling be ensured in practice? First of all, we attach the bobbin to a stationary rod-shaped object on which it should scroll easily and freely. Pencils and knitting needles, fountain pens and screwdrivers, small metal tubes without sharp edges, and even a smooth and well-polished stick can act as a rod. As a last resort, find someone who agrees to hold.

Pull the line through every single rod ring. Tie a knot at the extended end. Now you can start threading the line to the surface of the reel. First, we fasten it on top of the bobbin in a circle, having previously lifted up the arc of the line stacker, and when another knot of the “Arbor” type is tied and tightened, the arc can be lowered.

Braided line loves to slip very much. This can be avoided by prying a piece of rubber under the attachment point (for example, cut from an unusable fingertip or worn out glove), in extreme cases. support it with an adhesive plaster, if there is no rubber.

And now comes the turn of the line winding. Rotate the handle on the spool neatly and evenly. Make sure the line is tight all the time. It is imperative to support it, but only in tight gloves.

When winding up, avoid, as much as possible, ending it at the level of the bobbin collars. If you do not follow this rule, then self-resetting of loops or their eerie entanglement becomes very likely. To avoid such an outcome, pay attention to at least a millimeter or two of the fishing line that is not swept up to the side. On the other hand, exceeding the gap of five millimeters can make long-range casting impossible. Backing is a prophylaxis (in fact. winding the main line of the auxiliary line from below, no thicker than three tenths of a millimeter, otherwise an even laying will become unattainable). Please note that almost all threads work well in backing, except for long-drying cotton and nylon.

See useful how to properly wind the line to the reel

Determining how much fishing line to throw on backing is possible only by experiments, there are no ready-made formulas and theoretical provisions on this matter. Another bobbin is required. We wind the main forest on it, then backing (do not forget about the gap from the side). Next, we attach the main mount, to which we are already introducing the lines in the reverse order. Visit our website and read more useful tips for fishermen.

All About Replacing the Line on the Trimmer Head

How to change the line on a lawn mower: detailed instructions

In 1971, American entrepreneur George Bollas invented a lawn mower that used a line as a cutting knife. Much time has passed since then, the drive has become more powerful, a modern trimmer can easily damage the bark, so the idea itself has transformed into mowing grass around obstacles without damaging the mower cutter itself. For a neat cut around obstacles, a smaller line head can be used and can be easily changed from large areas to delicate mows. However, the cutting tool itself needs to be replaced periodically. We will tell you how to disassemble the head of a lawn mower (trimmer) and reel in a new line.

Choosing a line for the trimmer head

There are many types of heads available to suit different types of line. The latter is also available in several diameters: from 1.0 mm to 3.2 mm. over, its cross-section is round (including with a special groove to reduce the noise level), square, twisted and in the shape of a star.

There are no clear preferences, this explains the wide variety of shapes and diameters on the market. The round shape is usually stronger, but has the worst cutting ability and also produces a characteristic sound when rotated. Therefore, sometimes an acoustic groove is made on it, however, the use of this fishing line makes sense only on battery trimmers, in cars with a gasoline engine and a network drive, the sound level of the drive itself practically drowns out the sound from the fishing line. The square has a good cutting ability, and despite the fact that such a line is less strong than a round line, on average it is consumed less. Square fishing line quite easily cuts off the growth of the same willow up to 1 cm in diameter. The star has the maximum number of cutting edges, mows the best and is consumed the fastest.

The next nuance when choosing is rigidity. The fact is that in the production of nylon, a modifier (often maleic anhydride) is added to it, which improves its strength and prevents tearing. However, modifiers are not the cheapest component, they are trying to save money on it. Therefore, a seemingly good line, which remained for the winter, unexpectedly behaves in a completely different way in spring. it breaks, stops coming out of the reel normally. There is a recommendation to soak the fishing line in water before work, but I do not see much point in this, maleic anhydride interacts with water, but if it is not enough in nylon, then there will be nothing to interact with. Therefore, it makes no sense to stock up on fishing line for a long period of time, breaking or constantly breaking fishing line, which, moreover, does not want to leave the reel itself, can significantly complicate the work.

How to wind the line correctly: replacement features depending on the type of removable trimmer coil

To figure out how to thread the line into the removable trimmer head, the following recommendations and video instructions will help.

By size

Before you wind the thread on the trimmer spool, you should pay attention to its size. Most often, a line with a cross section of 2 mm is used.

You can choose a suitable diameter in the following ways:

- See the recommendations in the manufacturer’s instructions for the trimmer.

- Manufacturers often apply cross-section information to the bobbin.

- The section of the cord must match the diameter of the reel hole.

Important! The thicker the thread is tucked in, the harder the grass it can cut.

By quality

Before putting on the line on the trimmer, you need to pay attention to the section of the cord:

- round threads are the most common option. They cut the grass perfectly, even in difficult areas;

- Spiral line is suitable for thin grass. It is not very durable and is not suitable for old thickets;

- a cord with notches and sharp edges is chosen for mowing weeds;

- fishing line with a variety of geometric sections will help to mow the lawn more evenly, but the strength of the consumable is low.

Important! Most wear-resistant consumable is 2-piece round, reinforced internally.

The owner of the lawn mower should know that it is strictly forbidden to use metal wire, fishing thread and various strings.

Auto feed trimmer: how to wind the line into the removable reel

In some models of trimmers, a reel is installed, the line in which is refilled automatically. It is enough for the owner to fix the ends in the head, after turning on the equipment, the mechanism will perform all the winding manipulations on its own.

You should know this! The strengths of the automatic trimmer head include the ease of winding. The disadvantages of such equipment are frequent breakdowns of a complex mechanism and high cost.

How to wind the line correctly on the spool of the single-barbed trimmer

Most often, a thread up to five meters long is used. The procedure consists of the following steps:

- Bend the cord with a loop and insert into the groove of the head.

- Wind the thread in the opposite direction to the markings on the body. They indicate the direction of movement of the head.

- Leave the end of the thread up to fifteen centimeters free to increase centrifugal force.

- Thread the free end through the spool outlet.

- Assemble the trimmer head.

How to wind the line around the reel of the double barb trimmer

You can watch the video before work, and also take into account the following recommendations.

- If there is only one track, both threads are wound parallel.

- If there are two tracks, each piece is wound in a separate groove.

- Wind the threads in the opposite direction to the rotation of the head.

- The length of the free ends should not exceed fifteen centimeters.

- Thread the ends into the outlet holes.

- Assemble the head and check the trimmer performance.

Advice! If the loose antennae are of different lengths, do not worry. During work, excess ends will be cut.

What are the trimmers and features of their use

The trimmer is useful for mowing small or difficult areas, such as near hedges, between beds and along paths. Today, manufacturers produce a wide variety of gasoline, electric and battery models, which can be selected for any owner’s request.

A fishing line is used as a cutting element of the trimmer. In the process of work, sooner or later, its length will end, and then the owner will have a question of how to correctly replace and fix the thread tucked into a removable coil.

How to quickly and easily remove the coil with your own hands

Before replacing the old line with a new one in the detachable trimmer spool, you must remove the head.

The process is completely simple, even beginners can do the job:

- Remove the upper fixing cover.

- Take out the removable spool.

- Get the spring out, if any.

- Unscrew the bolt with a screwdriver.

- Remove the housing from the shaft.

Mower on t 16 do it yourself

Tractor T-16 with mowing

Subscribe do not line)

Switch on the PTO tractor and run the mower for 30 minutes;

eliminate the noted shortcomings.

Transporting the mower

To transfer the mower to transport position: use the mower’s hydraulic cylinder to raise the beam and bar, manually push the boom from the tractor side. On the tractor side, install the transport bracket, fix the bar with a stop, tighten the transport bracket bolt.

Construction and operation of a lawn mower:

The mower is driven by a cardan drive from the universal joint shaft of the tractor to the power take-off shaft 8 (MWM) of the mower. A double-track drive pulley 3, rigidly connected to the VPM, transfers the rotation through the V-belts to the drive pulley shaft. An eccentric rigidly attached to the shaft of the driven pulley converts the rotational motion of the shaft into a reciprocating motion of the blade of the cutting device through the connecting rod.

The mowing process is as follows: when the tractor is driven with the mower in the field, the grass falling between the segments of the moving knife and the conflicting edges of the liner is cut. The cut plants are passed through the cutting device and placed on the surface of the field. At the same time, the stalk on the inner ski pulls the cut grass from the knife head slightly to the right, and the stem divider is installed on the outer divider and takes the cut grass from the left, providing free passage for the inner ski on the next track.

In addition, the rod is equipped with the best cutting device for the quality of inertial forces, the cutting power consumed and the total load on the segment blades, as well as the operational reliability is the slotted slot cutting device, with four liners, with the knife segments alternating with the notch up and down. This cutting device does not require daily adjustment of the clearances between the clamps and the segments. The segment is not rubbed with a clamp. High quality cutting of both vertical stems and dead stems, since the cutting of inclined stems is facilitated if the stems are cut with a knife, where the edge of the blade is at the bottom, that is, an inverted segment. This reduces clogging of the cutting device. Reduces the cost of repairing stamped fingers by equipping them with replaceable counters H 006.56.

Characteristics:

– Structural weight (dry) 120 kg

– Working width 1.8 m

– Productivity during 1 hour of main time is 1.25-2.5 hectares / h

– Working speed of basic operations is 8-10 km / h

– Transportation speed:

when the mower is raised and secured for a long journey, no more than 20 km / h

when the mower is raised for short-range movement in the field, no more than 10 km / h

Ground clearance, not less than 300 mm

– Dimensions:

– in working position:

length 1160 mm

width 3660 mm

height 875 mm

– in transport position (when driving on public roads with an MTZ-80 tractor)

length 4600 mm

width 1910 mm

height 3300 mm

Minimum cutting height 50 mm

– Cutting device:

segment to finger

knife drive handle

knife stroke 76 mm

service personnel 1 operator

Mower:

The main components of a lawn mower are:

coupling; bearing beam; cutting device; hydraulic lifting system of the cutting device; outer (right) divider; protective fence; transport traction; cardan mechanism.

DESCRIPTION OF MACHINE HERBAL FINGER KTP-1,3; KTP-1.4; KTP. 1.5; KTP. 1.8; KTP. 2.1

The lawn mower bundle is equipped with the best equipment for cutting quality, inertial forces, cutting power consumption and total segment blade load, as well as operational reliability is the stamped finger cutter. This cutting device does not require daily adjustment of the clearances between the clamps and the segments. The segment is not rubbed with a clamp. High quality cutting of both vertical stems and dead stems, since the cutting of inclined stems is facilitated if the stems are cut with a knife, the sharpening edge of which is sharpened in the lower part, that is, an inverted segment. This reduces clogging of the cutting device.

How to install a mower on T 16

Tractor t-16 rework mower

cast iron mower ks-2.1.

Telephone :

380680796990

Ukraine Zaporizhzhia Berdyansk

Mower tractor on T-16

Purpose of the lawn mower:

Tractor mower KTP-1,8 is designed for cutting grass and natural grasses with laying an inclined mass in a spray.

The KTP-1.8 mower is used in all soil and climatic zones.

The mower is combined with the T-16 tractor.

Preparing the mower for work

The complex of works on preparation of a new mower for operation includes:

preliminary assembly of mowers;

preparation of the tractor for assembly;

Mounting a lawn mower with a tractor.

Complete mower