How to make a drill from a chainsaw

How to make an ice screw from a chainsaw with your own hands?

An ice screw or a motor drill is a useful household device designed for quickly making holes of a certain diameter in ice or soil. The simplicity of the design and principle of operation makes it possible to make an ice drill for everyone, using a household chainsaw for this.

Preparing for equipment assembly

To make a homemade ice screw from a chainsaw, you need to prepare all the materials and equipment required for work. It is best to do this in advance, so that during assembly you do not waste time looking for the missing part.

To work you will need:

- durable metal drill without damage and corrosion;

- household chainsaw engine;

- gearbox. needed to transfer torque from the internal combustion engine of the saw to the drill;

- several solid steel pipes, from which the body will be made in the future;

- welding machine;

- machine for grinding metal surfaces;

- screwdriver or drill with a set of attachments for working with metal.

The work may also require a stationary lathe. With its help, the owner of the chainsaw will be able to fit any used part to the dimensions required for assembly.

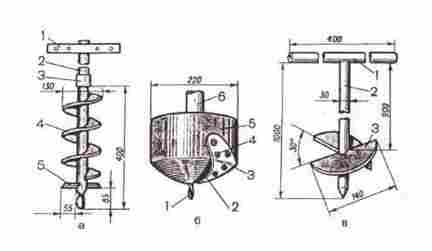

Before assembling equipment from a chainsaw, a diagram is also needed. It should describe in detail the dimensions of the parts used, as well as the method of their installation in the drill from the chainsaw.

After preparing the necessary equipment and studying the drawings, you can proceed directly to the assembly.

Self-made body

The ice drill attachment must be equipped with a sturdy housing. This element of the device will protect all internal parts of the equipment from mechanical damage, as well as the ingress of dust, debris and moisture into the structure. For the manufacture of the case, you need to use metal pipes on which there are no traces of rust or other defects. Pipes will need to be bent in the form of frames.

This is done in the following order:

- To begin with, you will need to measure a piece from the first pipe, the length of which should be equal to the perimeter of the planned frame. The optimal segment will be about 160 cm long;

- Then, on the surface of the prepared segment, it will be necessary to make cuts, the depth of which should not exceed 1/3 of the radius of the pipe used. These cuts should be located at the bends of the line. In order for the pipe to bend easily, in each place of its bend, 4–6 cuts must be made at a distance of 5 mm from each other. If, during bending of the pipe, it is not possible to obtain an even right angle, then the incisions made will need to be slightly ground off with an angle grinder;

- After bending the segment, all joints and corners will remain welded with a hand-held welding machine.

In the same order, you will need to make another frame, the perimeter of which should be about 40 cm.Then the two frames must be connected in such a way that the distance between their planes is about 35 cm.When assembling the frame, you need to make sure that the corners are installed pieces of metal pipes of approximately the same size.

The result should be a body with the shape of a quadrangular uniform truncated pyramid. Inside it, you will need to securely fix the engine from the chainsaw, as well as the gearbox and other elements of the drill.

Drill motor installation methods

The result of the previous actions was the previously removed engine from the chainsaw. as well as a reliable housing, inside which the gearbox is located. The existing elements will need to be connected together. To do this, you need to think over the method of connecting them.

If the motor in the future will be used exclusively for drilling holes, then a drill from a chainsaw for earth or ice can be made in the form of a solid structure. In this case, the used motor will not be removed, and its fastening will be more reliable.

If the motor is sometimes removed to mount it back on the chainsaw, then its mount will need to be made removable. This option is more practical to use, however, the motor mount in this case will be less reliable.

To make a removable mount, a large hole must be made in the manufactured housing to fix the motor. Its diameter must be the same as the internal combustion engine used. Next, you need to carefully consider the mount of the engine. It should be as reliable as possible and cost-effective in terms of time. It is best to use a few bolts and nuts to secure the motor. In this case, the owner of the drill will only need to unscrew the bolts, lift the housing cover and carefully remove the motor.

When planning the engine mount, provide free access to the fuel and engine oil filling containers. Also, the owner of the drill must have access to the valve, which is needed to regulate the pressure in the engine cylinder.

It is best to equip a fishing drill with an engine from an old chainsaw. This motor can be installed permanently, and not be removed during the entire service life of the drill. You will need a frame to mount the old engine. It should be at the top of the equipment. When installing the motor on the frame, you will need to remove the fuel and oil filler neck. An emergency switch must be installed in the same part of the device. This element is very important in cases where the drill will be used not only for ice, but also for land. The emergency switch will make it possible to turn off the equipment when the soil is too hard.

Most often, motors from Ural chainsaws are used to make a drill. These ICEs require minimal modifications. The only drawback is that only people of medium and tall stature will be able to work with these engines.

How to choose a gearbox?

First you need to choose a gearbox for a chainsaw for a drill. When buying an item, you should consider such important factors as the power of the chainsaw engine and the size of the drill. It must be remembered that the motors of most gasoline tools are powerful. If, during operation, the motor-drill from the chainsaw rotates at too high a speed, then it will be impossible to work with it. At the same time, if the gearbox transfers too low a rotational force to the used output shaft, then there will be very little benefit from using a gasoline tool. For these reasons, it is necessary to make accurate calculations of the gearbox parameters.

In most cases, in addition to the gearbox, a power take-off shaft is installed on the hole from the chainsaw. It regulates the speed of the engine’s crankshaft without loss of power. This makes it possible to make the drill more efficient and reduce the amount of fuel consumed by the motor.

How to make an ice screw from a chainsaw with your own hands?

A chainsaw drill is assembled in several stages. Each of them must be treated carefully. Otherwise, there will be a risk of rapid breakdown of one of the important elements of the device.

Self-fastening drill

The working nozzle of a homemade drill must be securely fastened. This can be done in several ways. The first is to use a pipe on which the gearbox and the drill to be used are mounted. An important advantage of this method is that, if necessary, the damaged element can be quickly replaced.

The second method is more difficult to perform, but it will make it possible to drill not only in the vertical, but also in the horizontal direction. This requires a frame made from a metal tube. In the future, you will need to weld another segment of the vertical pipe to the frame. Several metal rings must also be welded to the finished case. There should be no gaps inside the rings. When installing the drill, the rings must be put on the vertical pipe. After that, you can start operating a drill from a chainsaw.

There are two drawbacks to this method. The first of them is the increase in the weight of the equipment, and the second is the difficulties during operation due to the vertical pipe.

How to make an ice screw from a chainsaw with your own hands?

A chainsaw drill is assembled in several stages. Each of them must be treated carefully. Otherwise, there will be a risk of rapid breakdown of one of the important elements of the device.

Drill motor installation methods

The result of the previous actions was the previously removed engine from the chainsaw. as well as a reliable housing, inside which the gearbox is located. The existing elements will need to be connected together. To do this, you need to think over the method of connecting them.

If the motor in the future will be used exclusively for drilling holes, then a drill from a chainsaw for earth or ice can be made in the form of a solid structure. In this case, the used motor will not be removed, and its fastening will be more reliable.

If the motor is sometimes removed to mount it back on the chainsaw, then its mount will need to be made removable. This option is more practical to use, however, the motor mount in this case will be less reliable.

To make a removable mount, a large hole must be made in the manufactured housing to fix the motor. Its diameter must be the same as the internal combustion engine used. Next, you need to carefully consider the mount of the engine. It should be as reliable as possible and cost-effective in terms of time. It is best to use a few bolts and nuts to secure the motor. In this case, the owner of the drill will only need to unscrew the bolts, lift the housing cover and carefully remove the motor.

When planning the engine mount, provide free access to the fuel and engine oil filling containers. Also, the owner of the drill must have access to the valve, which is needed to regulate the pressure in the engine cylinder.

It is best to equip a fishing drill with an engine from an old chainsaw. This motor can be installed permanently, and not be removed during the entire service life of the drill. You will need a frame to mount the old engine. It should be at the top of the equipment. When installing the motor on the frame, you will need to remove the fuel and oil filler neck. An emergency switch must be installed in the same part of the device. This element is very important in cases where the drill will be used not only for ice, but also for land. The emergency switch will make it possible to turn off the equipment when the soil is too hard.

Most often, motors from Ural chainsaws are used to make a drill. These ICEs require minimal modifications. The only drawback is that only people of medium and tall stature will be able to work with these engines.

How to choose a gearbox?

First you need to choose a gearbox for a chainsaw for a drill. When buying an item, you should consider such important factors as the power of the chainsaw engine and the size of the drill. It must be remembered that the motors of most gasoline tools are powerful. If, during operation, the motor-drill from the chainsaw rotates at too high a speed, then it will be impossible to work with it. At the same time, if the gearbox transfers too low a rotational force to the used output shaft, then there will be very little benefit from using a gasoline tool. For these reasons, it is necessary to make accurate calculations of the gearbox parameters.

In most cases, in addition to the gearbox, a power take-off shaft is installed on the hole from the chainsaw. It regulates the speed of the engine’s crankshaft without loss of power. This makes it possible to make the drill more efficient and reduce the amount of fuel consumed by the motor.

How to make an ice screw from a chainsaw with your own hands?

An ice screw or a motor drill is a useful household device designed for quickly making holes of a certain diameter in ice or soil. The simplicity of the design and principle of operation makes it possible to make an ice drill for everyone, using a household chainsaw for this.

Preparing for equipment assembly

To make a homemade ice screw from a chainsaw, you need to prepare all the materials and equipment required for work. It is best to do this in advance, so that during assembly you do not waste time looking for the missing part.

To work you will need:

- durable metal drill without damage and corrosion;

- household chainsaw engine;

- gearbox. needed to transfer torque from the internal combustion engine of the saw to the drill;

- several solid steel pipes, from which the body will be made in the future;

- welding machine;

- machine for grinding metal surfaces;

- screwdriver or drill with a set of attachments for working with metal.

The work may also require a stationary lathe. With its help, the owner of the chainsaw will be able to fit any used part to the dimensions required for assembly.

Before assembling equipment from a chainsaw, a diagram is also needed. It should describe in detail the dimensions of the parts used, as well as the method of their installation in the drill from the chainsaw.

After preparing the necessary equipment and studying the drawings, you can proceed directly to the assembly.

Self-made body

The ice drill attachment must be equipped with a sturdy housing. This element of the device will protect all internal parts of the equipment from mechanical damage, as well as the ingress of dust, debris and moisture into the structure. For the manufacture of the case, you need to use metal pipes on which there are no traces of rust or other defects. Pipes will need to be bent in the form of frames.

This is done in the following order:

- To begin with, you will need to measure a piece from the first pipe, the length of which should be equal to the perimeter of the planned frame. The optimal segment will be about 160 cm long;

- Then, on the surface of the prepared segment, it will be necessary to make cuts, the depth of which should not exceed 1/3 of the radius of the pipe used. These cuts should be located at the bends of the line. In order for the pipe to bend easily, in each place of its bend, 4–6 cuts must be made at a distance of 5 mm from each other. If, during bending of the pipe, it is not possible to obtain an even right angle, then the incisions made will need to be slightly ground off with an angle grinder;

- After bending the segment, all joints and corners will remain welded with a hand-held welding machine.

In the same order, you will need to make another frame, the perimeter of which should be about 40 cm.Then the two frames must be connected in such a way that the distance between their planes is about 35 cm.When assembling the frame, you need to make sure that the corners are installed pieces of metal pipes of approximately the same size.

The result should be a body with the shape of a quadrangular uniform truncated pyramid. Inside it, you will need to securely fix the engine from the chainsaw, as well as the gearbox and other elements of the drill.

Self-fastening drill

The working nozzle of a homemade drill must be securely fastened. This can be done in several ways. The first is to use a pipe on which the gearbox and the drill to be used are mounted. An important advantage of this method is that, if necessary, the damaged element can be quickly replaced.

The second method is more difficult to perform, but it will make it possible to drill not only in the vertical, but also in the horizontal direction. This requires a frame made from a metal tube. In the future, you will need to weld another segment of the vertical pipe to the frame. Several metal rings must also be welded to the finished case. There should be no gaps inside the rings. When installing the drill, the rings must be put on the vertical pipe. After that, you can start operating a drill from a chainsaw.

There are two drawbacks to this method. The first of them is the increase in the weight of the equipment, and the second is the difficulties during operation due to the vertical pipe.

Preparing for equipment assembly

To make a homemade ice screw from a chainsaw, you need to prepare all the materials and equipment required for work. It is best to do this in advance, so that during assembly you do not waste time looking for the missing part.

To work you will need:

- durable metal drill without damage and corrosion;

- household chainsaw engine;

- gearbox. needed to transfer torque from the internal combustion engine of the saw to the drill;

- several solid steel pipes, from which the body will be made in the future;

- welding machine;

- machine for grinding metal surfaces;

- screwdriver or drill with a set of attachments for working with metal.

The work may also require a stationary lathe. With its help, the owner of the chainsaw will be able to fit any used part to the dimensions required for assembly.

Before assembling equipment from a chainsaw, a diagram is also needed. It should describe in detail the dimensions of the parts used, as well as the method of their installation in the drill from the chainsaw.

After preparing the necessary equipment and studying the drawings, you can proceed directly to the assembly.

How to make an ice screw from a chainsaw with your own hands?

A chainsaw drill is assembled in several stages. Each of them must be treated carefully. Otherwise, there will be a risk of rapid breakdown of one of the important elements of the device.

How to make an ice screw from a chainsaw with your own hands?

An ice screw or a motor drill is a useful household device designed for quickly making holes of a certain diameter in ice or soil. The simplicity of the design and principle of operation makes it possible to make an ice drill for everyone, using a household chainsaw for this.

How to choose a gearbox?

First you need to choose a gearbox for a chainsaw for a drill. When buying an item, you should consider such important factors as the power of the chainsaw engine and the size of the drill. It must be remembered that the motors of most gasoline tools are powerful. If, during operation, the motor-drill from the chainsaw rotates at too high a speed, then it will be impossible to work with it. At the same time, if the gearbox transfers too low a rotational force to the used output shaft, then there will be very little benefit from using a gasoline tool. For these reasons, it is necessary to make accurate calculations of the gearbox parameters.

In most cases, in addition to the gearbox, a power take-off shaft is installed on the hole from the chainsaw. It regulates the speed of the engine’s crankshaft without loss of power. This makes it possible to make the drill more efficient and reduce the amount of fuel consumed by the motor.

Drill motor installation methods

The result of the previous actions was the previously removed engine from the chainsaw. as well as a reliable housing, inside which the gearbox is located. The existing elements will need to be connected together. To do this, you need to think over the method of connecting them.

If the motor in the future will be used exclusively for drilling holes, then a drill from a chainsaw for earth or ice can be made in the form of a solid structure. In this case, the used motor will not be removed, and its fastening will be more reliable.

If the motor is sometimes removed to mount it back on the chainsaw, then its mount will need to be made removable. This option is more practical to use, however, the motor mount in this case will be less reliable.

To make a removable mount, a large hole must be made in the manufactured housing to fix the motor. Its diameter must be the same as the internal combustion engine used. Next, you need to carefully consider the mount of the engine. It should be as reliable as possible and cost-effective in terms of time. It is best to use a few bolts and nuts to secure the motor. In this case, the owner of the drill will only need to unscrew the bolts, lift the housing cover and carefully remove the motor.

When planning the engine mount, provide free access to the fuel and engine oil filling containers. Also, the owner of the drill must have access to the valve, which is needed to regulate the pressure in the engine cylinder.

It is best to equip a fishing drill with an engine from an old chainsaw. This motor can be installed permanently, and not be removed during the entire service life of the drill. You will need a frame to mount the old engine. It should be at the top of the equipment. When installing the motor on the frame, you will need to remove the fuel and oil filler neck. An emergency switch must be installed in the same part of the device. This element is very important in cases where the drill will be used not only for ice, but also for land. The emergency switch will make it possible to turn off the equipment when the soil is too hard.

Most often, motors from Ural chainsaws are used to make a drill. These ICEs require minimal modifications. The only drawback is that only people of medium and tall stature will be able to work with these engines.

Self-made body

The ice drill attachment must be equipped with a sturdy housing. This element of the device will protect all internal parts of the equipment from mechanical damage, as well as the ingress of dust, debris and moisture into the structure. For the manufacture of the case, you need to use metal pipes on which there are no traces of rust or other defects. Pipes will need to be bent in the form of frames.

This is done in the following order:

- To begin with, you will need to measure a piece from the first pipe, the length of which should be equal to the perimeter of the planned frame. The optimal segment will be about 160 cm long;

- Then, on the surface of the prepared segment, it will be necessary to make cuts, the depth of which should not exceed 1/3 of the radius of the pipe used. These cuts should be located at the bends of the line. In order for the pipe to bend easily, in each place of its bend, 4–6 cuts must be made at a distance of 5 mm from each other. If, during bending of the pipe, it is not possible to obtain an even right angle, then the incisions made will need to be slightly ground off with an angle grinder;

- After bending the segment, all joints and corners will remain welded with a hand-held welding machine.

In the same order, you will need to make another frame, the perimeter of which should be about 40 cm.Then the two frames must be connected in such a way that the distance between their planes is about 35 cm.When assembling the frame, you need to make sure that the corners are installed pieces of metal pipes of approximately the same size.

The result should be a body with the shape of a quadrangular uniform truncated pyramid. Inside it, you will need to securely fix the engine from the chainsaw, as well as the gearbox and other elements of the drill.

Self-fastening drill

The working nozzle of a homemade drill must be securely fastened. This can be done in several ways. The first is to use a pipe on which the gearbox and the drill to be used are mounted. An important advantage of this method is that, if necessary, the damaged element can be quickly replaced.

The second method is more difficult to perform, but it will make it possible to drill not only in the vertical, but also in the horizontal direction. This requires a frame made from a metal tube. In the future, you will need to weld another segment of the vertical pipe to the frame. Several metal rings must also be welded to the finished case. There should be no gaps inside the rings. When installing the drill, the rings must be put on the vertical pipe. After that, you can start operating a drill from a chainsaw.

There are two drawbacks to this method. The first of them is the increase in the weight of the equipment, and the second is the difficulties during operation due to the vertical pipe.

From the saw blade

If you have an old saw blade of a suitable diameter, you have found an almost perfect option. They use hardened steel, and it is elastic and strong. But such a disc cannot be bent, therefore it is cut in half and these halves are bred at the required angle.

The disc is sawn in half

Such a homemade drill for earthworks shows a fairly high productivity. Even used discs have a well-sharpened edge. And to make drilling even easier, they also sharpen the drill on the sides with their own hands.

Materials (edit)

As already mentioned, the rod is most often made from a round or square pipe. Diameter. from 3/4 ‘to 1.5’, profiled pipe can be taken from 2020 mm to 3535 mm.

Blade knives can be made from:

- sheet steel with a thickness of 4 mm;

- saw blade for angle grinder of suitable diameter.

Earth auger with blades made of saw blade for angle grinder

It is easier to make blades from a saw blade. In this case, the cutting edges are already prepared. It will be possible to additionally sharpen the side edges so that the soil is cut easier.

The pico drill is made of different materials. there are a lot of its designs. They just make a sharpened rod. Then you need a piece of a large diameter bar. The second option is to make something like a drill from a strip of steel. And yet. a combination of these two.

And finally, about the pen. It is more convenient if it is made of a round pipe. Its diameter can be selected according to the girth of the palms. The main requirement is that you should be comfortable.

Shovel drill

For planting plants, it makes no sense to make a serious structure. In this case, you can make a garden drill from a shovel. They choose a high-quality shovel made of good steel, apply the markings, as shown in the drawing. According to the markings, you will need to cut out two small fragments, cut the lower part in the middle to a depth of 30 cm (pictured).

Further, the edges are bent one forward, the other back, the petals formed in the lower part are bent to them. The resulting seams are welded outside and inside.

Drill for soft soils

If the ground is soft, conventional construction does not work very well. For such cases, there is a special drill with an extended cutting part. It is a kind of glass with slots on the sides. The cuts are provided with cutting edges. They are best made from well-hardened steel.

Drill for soft soils

This drawing shows an interesting design of the handle. it can be rearranged as the length of the rod increases.

Drill for piles TISE

In the author’s version, the TISE drill is a blade with a soil receiver and a wider folding knife, which forms an extension in the lower part of the pile. But working with such a projectile is inconvenient. a folding knife interferes greatly. Therefore, in some structures it is made removable, but in general, it is recommended to drill the pits themselves with an ordinary garden drill, and to expand it, make a separate folding knife with a land receiver. This makes work easier and faster.

A do-it-yourself drill for TISE piles is one of the options

A cut-off shovel acts as a knife here, and the land receiver is made from a herring can. The knife is fixed movably, when it is lowered into the pit, it is pulled up by a nylon cable tied to the end. Having reached the bottom, the cable is weakened, the blade begins to cut the sides of the pit, forming the necessary expansion.

The photo below shows the second version of a homemade drill for TISE piles. The design is more complex, but also more efficient. The plow-blade is made from a piece of spring, sharpened and welded to the folding structure on bolted connections.

complex design

Dredger. from an old propane tank. The earth is collected from the bottom, because the receiver is made with a rounded bottom. It has two holes, their edges are sharpened.

This projectile works well even on dense clay. True, to reduce friction, the well must be constantly wetted with water.

Making a garden drill

A garden drill is the simplest but most effective design. It consists of:

-

Cutting part. It usually consists of two steel semicircles with sharpened edges. The diameter of the blades is selected depending on the diameter of the holes to be drilled. For convenience, the blades can be made removable. bolted.

Pole drill can be with an assembly rod

This is a basic design, and there are many improvements to it. But first, let’s talk about what a ground drill can be made of.

How to make a homemade earth drill (yamobur, earth drill)

Auger drill

The auger drill, due to the large number of turns, creates significant resistance, that is, it is much more difficult to work with it than a garden drill. But the augers are used mainly in the presence of a mechanized drive. when they make a drill for wells of great depth. for water, devices of underground probes for a heat pump, etc.

This is what a screw auger looks like

To make a homemade auger drill, you will need several metal discs. The number of disks is equal to the number of turns. The discs are cut out the same, in them, in the center, a hole for the rod is cut out, as well as the same sector. so that you can weld them.

A sector is marked in the rings, cut out

The disks are welded on one side, then, slightly stretching the resulting accordion, the seam is welded on the other side. Rings are welded on the outer discs. The welded discs are put on the rod, the lower edge is welded.

It turns out such a big spring

Next, you need a winch. The workpiece for the auger is fixed, the winch hook clings to the ring and stretches to the desired length, after which the auger is boiled.

2 How to prepare a homemade drill?

After the drilling rig has been successfully made with your own hands, you can proceed directly to the process of drilling wells. In general, using a gas drill, all work is done in a specific sequence:

- We develop a small preparation pit or pit.

- We collect and assemble all the tools.

- We carry out the development of a trial hole.

- We continue drilling until we reach the aquifers.

- We pump the well, install the casing, prepare it for further use.

Homemade auger for a gas drill, with the correct angles of rotation of the discs

A pit is dug with a size of 1.51.51.5 meters. It is imperative that all the walls of the pit be equipped with ordinary wooden boards or plates made of reliable metal in order to avoid possible destruction.

A tripod is assembled either from 3 bars or from metal pipes. The length of the material, both in the first and in the second version, should be about 3-4 meters. With the help of a chainsaw, you can cut pipes or bars of the required parameters.

The bars or pipes are laid out in a triangular shape, after which holes are created so that a pipe can be inserted into them. A pipe is placed, but the reliability factor must be taken into account, because the structure must stand confidently and not disintegrate.

An earth hole for a well can be created using both a mechanical and an electric winch. In the case of an electric model, it is fixed in the upper part of the structure, and for a mechanical one, a special block is made for a cylindrical cable.

An earthen gas drill is fixed to the end of the cable, after which you can start drilling a well for water. A factory auger is used for drilling wells. If for the development of wells it is necessary to go too long distance or create a large hole in the ground, then use a double earthen auger with the ability to control together with a partner.

It should be remembered that if you make water intakes of shallow depth, then in order to extract the drill string, you will not need to use a tower at all. Drill rods are most often created by hand. For this purpose, ordinary metal pipes are used, which must be securely connected to each other.

A drill is mounted at the bottom of the rod. Now you need to start the process of making the edges, but it must be borne in mind that during the operation of the tool, they must effectively cut the soil, rotating clockwise.

to the menu

1.2 List of required materials

An example of using a gas drill for well development

Chain Saw HACK 6. Earth Auger

Consider the basic materials that are needed when creating manual hole drills. Without this equipment, you will not be able to assemble the structure, therefore, you should familiarize yourself thoroughly with the following list. These materials are:

- Emery wheel;

- Welding machine;

- A small piece of ordinary gas pipe, which is necessary in order to make a vertical stand;

- Clamp for welding;

- Gas key;

- Machine for various turning works;

- Electric drill model;

- Installation vise;

- Several drills designed for metal processing.

Having all of the above materials, as well as using a chainsaw in some works, you can make a hole drill quickly, and most importantly on your own.

to the menu

How to create a drill for wells with your own hands?

Today, many land owners are faced with the same problem. the lack of a central water supply. They do not need to supply it, so you need to organize the water supply yourself. This can be done both by attracting specialists and manually.

An example of a hand-held gas drill assembled from a chainsaw

It should be noted that the manual process of drilling a well is not as complicated as it might seem at first glance. Now we will discuss in more detail how to make a drilling rig with our own hands so that it is possible to supply water to the garden plot.

1 Description of design and principle of operation

Today, a person who needs to provide a garden plot with water can make a yamobur with his own hands. Yamobur in its simplest version has the form of a metal rod with a fairly sharp end. About 20 centimeters from this end, you need to weld 2 knives. Such knives must be the same and have a thickness of 2-3 millimeters.

They must be welded against each other to the same rod. At the same time, in order to get a high-quality hole auger for creating a well, you need to place the knives strictly at an angle of 20 degrees. Also, the lower parts of the knives must be sharpened.

During the rotation of such a peculiar chainsaw, the knives begin to cut into the ground, and after being pulled out, they raise the ground along with the structure. As wells are drilled, namely, penetration more and more deep into the ground, it is common for a hand-held chainsaw to constantly build up and strengthen the rod, which is located at the end of the device.

The hand drill can have both a threaded and a sleeve connection of such rods. A homemade drilling rig can be used not only for drilling wells in ordinary soil, but also in clay. Fine gravel, which can be encountered from time to time, will not pose serious problems.

to the menu

1.1 Stages of work

At the present time, you can create a gas drill, which is necessary in order to provide a garden plot with water, with your own hands. When a yamobur is made, its blade is produced first. For this, a sheet of steel is used, which serves as a material for round blanks.

They are created taking into account the fact that the diameter of the circle should be approximately half a centimeter larger than the size of the well itself, which is planned to be created. A typical yamobur has, as a rule, two or four discs, which form 2 blades.

Auger for a gas drill from two discs and a screw steel band

After that, in such round blanks, you need to drill central holes. With the aim in the future, it is most convenient to mount them on a rack, it is best to make a diameter that is approximately 2-3 mm larger than the diameter of the metal pipe, that is, the future rack.

The next step is to mark the points where the disks will actually be installed to the rack. Here you need to drill holes in the pipe, and in order to securely fix the discs in manual mode, special metal bushings are made. Such bushings will then be bolted to the rack.

Then, using a chainsaw, you need to cut from the edge to the central part of the small sector. With the help of gas keys and a vice, it is necessary to stretch the edges of the cuts in different directions, but everything must be done with the utmost accuracy.

Ultimately, each of these circles should take the shape of a spiral. In order to complete the stage of preparing the blades, it is necessary to sharpen those edges that are at the bottom at an angle of about 55-65 degrees.

Let’s move on to creating a rack. In order for the drill to be able to easily enter the ground, at the location of the auger, it is necessary to first cut off the metal drills using a chainsaw, and then weld them to the structure. The tip itself should be sharpened at an angle of approximately 25 degrees for maximum efficiency.

The last phase consists in making a lever handle, with which it will be possible to rotate the whole device. To do this, you need to securely fix the bushing on the rack, which was previously made on a conventional lathe.

It is best to make a removable version of such a handle, because during drilling to great depths, you will often have to use additional elbows for lengthening. Also, do not forget about the preparation of the knees. Homemade Well Drilling Rig is now considered crafted.

to the menu

2.1 Drilling process

A hole is dug for about 2 bayonets of a standard shovel, thanks to which it is possible to clearly determine the vector in which the yamobur will work. At first, one person can work, but the further the device goes deeper into the ground, the harder the whole process will seem, and therefore the help of other people will be needed.

Cased homemade well

Some in order to make the job a little easier, before using a gas drill, significantly moisten the ground. At the time when the handle of the tool begins to compare with the surface of the ground, it is necessary to mount another elbow.

When making a drill with your own hands for water wells and performing their direct development, you must make sure that the soil does not begin to sprinkle during operation in any case. For this purpose, so-called casing pipes are most often installed.

The garden hole should now enter the aquifer. To determine the effectiveness of such an entry, the degree of moisture is taken into account. That is, if it was possible to reach the aquifer, then you need to carefully move the gas drill to the same water-resistant layer. Thus, you can count on the maximum amount of drinking water in the well.

At the very end, you need to eliminate dirty water. Using a manual or submersible type of pump, it is first extracted in an amount of about 3. 4 buckets, but if clean water still does not appear, then you need to walk about 2 meters deep into the well.

In general, as you can see, it is possible to make a drill with your own hands, but you need to make some effort. With the help of a chainsaw, pump, shovel and other tools, having all the necessary materials, a person will certainly be able to provide his garden plot with water, although this of course will take more time than if you turned to professionals.

to the menu

Do-it-yourself ice screw. is it real?

What are ice axes

A drill for winter fishing is an irreplaceable thing. The speed of making holes will depend on its quality, size and drive. Most often, screw devices are used for these purposes. This is the most common type of borax. Both factory and self-made products use a brace as a drive. It is suitable for drilling holes with a diameter of 100-115 mm. It will be difficult to make a hole with dimensions of 130-150 mm, since much more effort will be required.

For such purposes, you can use an ice drill from a chainsaw. With this tool, you can quickly drill a hole of any diameter, with little or no effort. They are most often used on bodies of water with thick ice. Almost any fish will pass in a wormwood with a diameter of more than 130 mm.

For the manufacture of a type of motor-drill. a gas-drill. for winter fishing with your own hands, a saw with a gasoline engine or a drive from a lawn mower is suitable. The device will be mobile and efficient. Holes are drilled in a few seconds despite the thickness of the ice.

Self-made ice screw

Manufacturing from scratch

The easiest way to make a homemade ice screw for winter fishing is in the form of a garden drill. As knives, simultaneously performing the role of auger, use a blade from a circular saw of the required diameter. It is sawn in half and welded to the drill stem at an angle for the best cut.

The saw teeth have victorious surfacing, which protects the edges from breakage when drilling ice with inclusions of sand and at the border of the underwater part. The use of a screwdriver for an ice screw will help to increase productivity. The increased speed of rotation of the rod will make it possible to make holes even with not quite sharp knives.

What is an ice ax and what is it for

The purpose of the ice screw is to drill holes for ice fishing. The tool must have a solid base, sharp blades and a comfortable drive for drilling. Auger drills are especially widespread. They not only provide access to water, but also allow you to remove ice chips formed during the drilling process.

The cutting part of the device is a platform with installed steel blades, which is attached to the head of the auger. Knives are made from durable grades of steel. They are fastened with screws for the possibility of replacement in case of breakage or the need for sharpening. Knives can be of various shapes and have one or more cutting edges. The speed of drilling and the force applied at the same time depend on the angle of attack of the blade.

The auger of an ice ax is a rod with a reinforced screw band. The length of the auger part determines the depth of ice drilling. The auger in the drill can be solid-drawn or consist of welded elements. Domestic ice augers are made using this technology. All parts of the device are painted to prevent rusting.

A curved handle (brace) or 2 handles located at an angle of 90 ° to the drill pipe is used for the drive. In the rotors, the upper handle is located coaxially with the auger. Only one hand is involved in drilling. This significantly reduces the drilling speed. In a two-handed tool, both hands work, so holes are drilled faster with less effort.

Annular

Now this type of drill is unjustly forgotten and is almost never used. It is a ring with an outer diameter of 130 mm and an inner diameter of 80 mm. The cutting serrated edge picks the ice only by the shape of the ring, and the ice cylinder remains inside. The drill is centered with a triangular shoulder, which is located at the bottom of the working part. The eccentrically positioned handle distributes the force evenly to both hands. During operation, the characteristic noise is not heard, like with other ice drills.

The disadvantage of the annular drill is the lack of a device for removing ice chips.

Varieties and characteristics of motor-drills

For ice fishing, manual and motor-driven drills are used. Often they are made independently for their height and choosing the side of rotation. Making an ice screw with your own hands is difficult, but possible. This requires skills in welding, and also requires the help of a turner.

A self-made drill must meet the following characteristics:

- have little weight;

- be collapsible;

- be made of quality material;

- have a drive corresponding to the diameter of the auger.

When making an ice ax from a chainsaw with your own hands, the connection diagram of the engine and the auger is performed using a reduction gear. The most commonly used mechanical part of a low-speed electric drill.

Preparing for self-assembly of the drill

Before you start making your own equipment, it is important to study the detailed drawings. The finished circuit should tell the manufacturer exactly how to install the drill elements, in what sequence to do it, and what size all the components used should be.

Next, you need to start looking for parts.

The manufacturer should have at hand:

- a working body that can be taken from an old motor-drill. If it is not possible to find a ready-made tip, then it can be made from a round solid metal pipe;

- engine from a serviceable chainsaw;

- gearbox. its task is to convert and transfer the rotational force from the motor to the working body;

- metal pipe and ties. needed to assemble the protective case.

Of the tools, the operator will need a welding machine, a drill, a grinder and an angle grinder.

Assembling the case

To protect a homemade chainsaw motor-drill from dirt and moisture, it must be equipped with a protective case. It should be as resistant to vibration and resistance as possible, which is formed during making holes in solid soil.

The order of work looks like this:

- First, the operator must measure a piece from the metal pipe. As a result, it should be the length of the perimeter of the support frame. about 160 cm;

- Then, small cuts will need to be made on the pipe. They should be approximately 1.3 times the total pipe radius. According to the cuts left, the manufacturer will be able to navigate in what places the pipe will need to be bent in the future. To bend the frame tube more easily, you will need to make additional cuts. 4–6 pieces at a distance of 5 mm from each other. In order to obtain perfectly even right angles during the bending of the metal component, the prepared cuts will need to be carefully ground off with an angle grinder;

- At the end, all joints and corners will need to be welded.

Following the same principle, the operator must make another frame. Then both parts of the supporting structure must be fixedly connected to each other by welding. As a result, the final distance between the horizontal planes of the frames should be at least 1/3 meter. For greater reliability in the corners of the frames, you will need to install pieces of metal pipes and spacers.

The finished truncated 4-sided pyramid supporting structure must be coated with a primer and several coats of paint. It will protect the skeleton from rust and dirt. The gearbox must be fixed inside the frame.

Choosing a way to mount the engine from a chainsaw

The chainsaw earth drill initially works on the basis of the torque generated by the power unit. In the process of assembling a motor-drill, it is important to determine in advance how to attach the motor to the overall structure of the device.

Non-removable mounting means that the operator will not be able to use the motor to re-install it on the chain saw in the future. This option is suitable for those who have 2 or more chainsaws on the farm, and one of them can be “donated” to make a drill.

The second method is more popular. It consists in making a mount for removable mounting of the power unit. To do this, in the supporting frame of the fishing auger, you will need to make one large through hole, which will be required to install the motor. The dimensions of the hole must match the dimensions of the power unit.

In the future, the motor will be attached with 2–4 screws. They must be able to withstand strong vibration without weakening the motor.

Drill. purpose, types and features of operation

A motor-drill is a type of equipment designed for making holes in hard and clay soil, as well as in ice. Depending on their design features and purpose, drills are divided into:

- household. small-sized tools, distinguished by relatively low power and traction characteristics. Fixtures of this type are well suited for short and irregular use. They consume a minimum of fuel and do not require regular specialized maintenance;

- semi-professional. equipment of medium power, which in size does not differ much from household models. The main task of tools of this type is regular operation by making small and medium-sized holes in loose soil and ice with a layer thickness of up to 10 cm;

- professional. devices of this type have a solid power and traction reserve. They are good at making holes in hard soil and ice, up to 15-18 cm thick.

The most powerful drills on the market are considered to be industrial drills. These rigs are designed exclusively for oil and gas drilling operations. A team of several experienced employees is required to operate and maintain them.

In addition to specialized branded accessories, there are small-sized nozzles on the market that are distinguished by their ease of installation and maintenance. The most popular of these is the chainsaw attachment for drilling ice and soil. This device allows you to combine the working parts of the attachment and the power of the factory engine of the garden tool. Thus, the user gets the opportunity to drill holes without hindrance without the need to purchase specialized equipment.

The utility chainsaw drill attachment does not require any special skills from the operator. All that is needed is to install it instead of the saw cutting bodies, fill the tool and fix it with the working bodies downward. After that, you can start the saw motor and start making holes.

Chainsaw attachment for drilling ice and soil

Making holes manually in ice or preparing holes in the soil for laying a pile foundation can take a lot of time and effort. However, if you use gasoline technology for this, you can achieve a better result. Buying specialized equipment “one time” is not always the best option. In this case, you can use a drill made on the basis of a chainsaw available on the farm to make holes.

How to make an ice screw from a chainsaw with your own hands?

The whole process of assembling drilling equipment consists of several stages. The operability of the device and its effectiveness during active operation on a site or lake directly depend on their sequence.

Selection and installation of the gearbox

A chainsaw drill will not be able to work normally without a gearbox. When choosing this node, you need to be as careful as possible, since there is a great risk of installing an unsuitable element. The fact is that the power unit of an economic chainsaw has a relatively large initial power. It runs continuously at high revs, including idling. Accordingly, if a homemade hole auger from a chainsaw rotates at a speed equivalent to the speed of rotation of the crankshaft, then it will be impossible to work with it. At the same time, if the gearbox is transferred to the output shaft of too low speed, the operation of the equipment will not bring any results at all.

The gearbox for a drill chainsaw must have a certain gear ratio. Most often, in the design of home-made drills from chainsaws, it is 16. These indicators are possessed by a gearbox from a drill. It is small and easy enough to install in the body of the chainsaw. A drill equipped with such a gearbox will rotate the working body at a speed of about 15-25 rpm.

How to attach a detachable motor?

To connect a gearbox with a motor and a drill, it is necessary to decide whether it will be stationary or removable for frequent dismantling. To make the motor multifunctional, it will be necessary to develop a mount that will securely fix the motor, and its removal was carried out with a minimum of time and effort. For this you will need:

- A hole is made on the construction of a motor-drill from a chainsaw, repeating the size of the engine.

- Creation of a reliable clamping frame, with a fixation sufficient to perform its functions.

The dimensions depend on which drill from the engine of which chainsaw you will create. It should be borne in mind that most of the unit housings are made of polymers, which complicates the fastening process.

Preparatory work

Before proceeding with the creation of a homemade motor-drill from a chainsaw for fishing and other activities, it is necessary to calculate the compatibility of the characteristics of the gearbox and the existing motor. This condition is the most significant for the effective operation of a self-made chainsaw hole auger. This is due to the fact that the engine performs a fairly large number of revolutions per minute. This speed may be too strong for the structure.

Chainsaw drill attachment. design features

The drill is used in construction work, installing vineyard supports, poles and fences, as well as in winter fishing and other events. It can be used to drill holes of various depths and diameters, on surfaces made of different materials. To make working with a thick layer of ice, frozen ground and other hard surfaces easier, use a drill attachment for a chainsaw, which you can create yourself. The homemade unit is suitable for earth, sand, ice and more. Chainsaw ice auger can function correctly under all kinds of climatic conditions and temperature conditions.

How to fix the drill?

The drill nozzle on the chainsaw should also be attached as securely as possible. The construction will require a pipe with which the drill and the gearbox shaft will be connected. Fixation along the entire perimeter is performed with pins and dowels. By creating such a configuration, you get the opportunity to change the drill bits for chainsaws of different diameters, which will increase the range of work performed.

New Drill Machine Hack Making Chain Saw

What materials will be needed to create a do-it-yourself chainsaw motor-drill?

To design an ice screw from a chainsaw with your own hands, you need a diagram and the following devices:

- Chainsaw motor.

- Chainsaw reducer for drill.

- Metal pipe.

- Boer.

- Angle Grinder.

- Drill.

- Welding machine.

How to assemble an ice screw from a chainsaw?

After preliminary calculations, you can start creating a homemade ice screw from a chainsaw:

- First, you need to design a body, for this a frame is made from a metal pipe. we measure a pipe segment corresponding to the length of the frame being created and make cuts across it.

- The notches on the chainsaw hole in depth will be one third more than the radius of the pipe. After that, the material easily lends itself to giving the required shape.

- After the structure acquires the necessary shape, the joints and corners are welded.

- A second smaller frame is created in the same way. Both products are connected, leaving a gap of about thirty centimeters.

- The result is a truncated pyramid, inside which the reducer will be fixed.

Security

Before starting operation, you need to check the strength of the product. The chainsaw attachment must not only be effective, but also safe for the operator. To ensure this condition, you will need:

- Weld to the finished structure at the top and bottom, two small diameter metal rings.

- A pipe must pass through them vertically.

- After the homemade chainsaw drill is put on the guide, you can start working.

Using this simple technique, you will not only provide a clear vertical direction of the motor-drill from the chainsaw, but also make drilling as convenient as possible.

Stands for motor-drill

With a large amount of work, the motor-drill is very inconvenient to hold in your hands. In this case, you can make a special bed to hang the made equipment. Experienced craftsmen implement different types of racks:

- Lifting mechanism: use a chain drive that is installed inside the center post. The mechanism can be raised and lowered using an electric motor or mechanically using a handle.

- Moving the bed on wheels: two wheels are attached to the lower support to change position by simply tilting.

The material for the manufacture of racks must be durable: usually a profile pipe, a section of a channel and metal corners are used.

From trimmer

For the manufacture of a mechanism for drilling the earth, you can take the engine from the trimmer. To reduce the rotational speed, it is recommended to use several gears combined in a single housing with the required gear ratio. The speed can be reduced if the input shaft gear is smaller and the gear that is attached to the output shaft is larger.

To create a stable motor-drill from a trimmer, you will need a strong frame to which a motor and a gearbox are attached. Handles are attached to the same frame to hold the tool. The auger is made of hardened steel, and the drill is made with a pointed tip.

Reducer

Choosing a gearbox for a homemade drill is a critical stage in the assembly process of this tool, since this element is one of the main components of the mechanism. By the type of output speed, gearboxes can be increased and decreased. In order to be able to regulate the speed, the second type is chosen for the motor-drill.

The direction of rotation of the gearbox should be reversible, so that the tool can be easily unscrewed from the hole when it is jammed in hard ground. The gearbox device includes several elements:

- Output and worm shaft

- Two gears (bevel type)

- Bearings

- Housing.

The gearbox must have holes for filling lubricants.

From a chainsaw

You can make a drill with your own hands from a chainsaw. For this, the old model is suitable, which is no longer suitable for performing its functions. The best option would be an old saw “Friendship”, “Stihl” or “Partner”. The engine from the chainsaw is fixed on a structure made of frames, while the fuel supply system and emergency stop of the unit are brought out to the upper one.

To secure the drill, it is connected to the gearbox using a pipe. If necessary, it can be replaced in the future. You can make a motor drill from a chainsaw with your own hands with the possibility of vertical drilling. This is achieved by welding metal rings to the frame, which are put on a vertical metal pipe. This design is put on a pipe with a drill, after which you can work.

Principle of operation

A motor-drill, or drills, is used for earthwork to drill holes for the installation of fence posts, lanterns, for planting trees, and even for the construction of a foundation. It is used not only for drilling soil, but also for ice more than one meter thick during winter fishing.

A motor-drill consists of an engine (electric, gasoline or hydraulic), transmission, auger, as well as a frame and an extension. The function of the transmission is to adjust the power of the motor for comfortable operation of the drill. It is she who creates the torque of the motor-drill. The mechanical type hand-driven tool is equipped with a helical or worm gear to reduce the speed. To transmit rotation to the drill, a centrifugal clutch is used, which is located between the shaft of the gearbox and the motor. A mechanical drilling tool contains many parts that fail over time. this is the main disadvantage of a hand-held motor drill.

The device can be equipped with a hydraulic pump and a hydraulic motor. The principle of operation of this type of equipment is that pressure is created on the oil, which promotes the rotation of the hydraulic motor, respectively, and the drill itself. Such a motor drill works longer, since there are no strong loads on the parts. This is facilitated by the action of the fuse, which relieves the tool from overload.

Electric motor drills are less powerful and efficient than gasoline drills. In addition, the first type is dependent on the availability of electricity and does not have the same mobility as gasoline. The efficiency of the equipment depends on the presence of oil in the transmission.

The main part of an electric or gas drill is a drill with auger. Its length is from 50 to 70 cm, it loosens the soil. The cutter, which is located above the drill head, cuts the soil, which is ejected by the auger from the cavity. The shape of the hole is given by the auger, and depends on its diameter. To drill a hole more than a meter deep, use an extension cord.

Self-production

Many craftsmen ask themselves the question: how to make a motor-drill so that it is not inferior to industrial designs? With some skills and the necessary tools, the creation of a drill is quite feasible. Before making the equipment, you need to consider the criteria that a good motor-drill must meet:

- If you plan to make a compact, lightweight model, the power can be 3 hp. If you need a more powerful motor drill, you should choose an engine up to 6 hp.

- The larger the engine displacement, the more efficient the unit. Considering the type of soil, you should choose one or another engine size.

- You should also take into account the diameter of the auger, the possibility of replacing it if necessary.

In order to build a tool, some skills are a must. If there are none, you should enlist the support of a locksmith.

Making a motor-drill with your own hands

Owners of personal plots know firsthand what an urgent need sometimes arises for this or that tool. There is always a lot of work on the site, but sometimes it is impractical to purchase expensive equipment. For example, a tool such as a drill is useful when performing specific work, but purchasing for a one-time event can be too expensive. But it makes sense to make a motor-drill with your own hands and save money.

How to make a motor drill with your own hands

Before starting the process of manufacturing a motor-drill, it is recommended to listen to the recommendations:

- Before manufacturing, it is better to make a drawing of the installation in order to visually represent the location of all units of the unit.

- It is necessary to calculate the power and dimensions of the tool: in the manufacture of a powerful device, a strong bed should be provided, possibly a trolley for moving.

- When choosing a gearbox, you should pay attention to its coincidence with the required number of revolutions. If the number of revolutions is too high, it will be difficult to work with a motor drill.

When working with the equipment, you must observe safety measures, protect your face and hands from stones, rock debris, dust.