How To Make A Table For A Hand-Held Circular Saw

Making a table for a circular saw with your own hands. Instructions and installation Learn more about how to make a table for a circular saw with your own hands without any extra effort! The accompanying step-by-step guide will help you!

How to choose a circular saw?

If you do not already have this tool, and you plan to purchase it, the following characteristics should be considered when choosing:

- Unit power. For a household tool, 800 W is enough, but if you are thinking about making a table for a circular saw, then the amount of work with lumber will be significant. You’d better opt for a 1200W or more model.

- Cutting depth. The maximum thickness of the processed material depends on this parameter. Professional or semi-professional hand saws usually have a cutting depth of 40 to 70 mm, which is sufficient for cutting boards and plywood. Please note that the standard depth will decrease by about 10 mm when the saw is placed on the table.

- Rotation frequency.The higher the speed, the cleaner the cut. This rule applies to cutting hard materials. However, too high speed is not suitable for plastic. Due to the heating of the disc, it will begin to melt. Therefore, choose a model with a speed of 3000-4000 rpm or with a smooth speed control.

- Location of controls.When installing the saw from the underside of the tabletop, the on / off button must be safely accessible. Otherwise, you will need to provide an external control circuit.

We make a table for a circular saw with our own hands. Instructions and installation

The circular saw is a convenient and productive tool for construction work, with high productivity and maneuverability. But when cutting large batches of lumber, working with a powerful circular saw is quite difficult. A do-it-yourself circular saw table can greatly facilitate this task.

An easy-to-manufacture table can be made of plywood and boards. In this case, the hand-held circular saw is installed from the bottom of the tabletop, and its toothed disk is located in the slot of the tabletop. After turning on the saw, the blade begins to rotate, and when the sawn timber is fed, it is cut. The maximum thickness of the cut lumber depends on the blade size and saw power. When choosing a tool, it is necessary to take into account the thickness of the tabletop to which the saw is attached from below.

Necessary materials

When making a do-it-yourself circular saw table, you will need woodworking skills and the following tool:

- Hand circular saw;

- Plywood sheet with a thickness of at least 20 mm;

- Board 50×100 mm;

- Bar 50×50 mm for legs;

- Drill, screwdriver, jigsaw, hand router;

- Wood glue, self-tapping screws;

- Wood varnish;

- Clamps;

- Ruler and pencil.

The dimensions of the table largely depend on the length of the materials being processed. The cut is much more accurate and even when the entire workpiece rests on the plane of the table. At the same time, the unnecessarily large size of the table clutters the workspace, so it is necessary to find a middle ground. It is better to choose the height of the table individually, depending on the height.

Necessary materials

When making a do-it-yourself circular saw table, you will need woodworking skills and the following tool:

- Hand circular saw;

- Plywood sheet with a thickness of at least 20 mm;

- Board 50×100 mm;

- Bar 50×50 mm for legs;

- Drill, screwdriver, jigsaw, hand router;

- Wood glue, self-tapping screws;

- Wood varnish;

- Clamps;

- Ruler and pencil.

The dimensions of the table largely depend on the length of the materials being processed. The cut is much more accurate and even when the entire workpiece rests on the plane of the table. At the same time, the unnecessarily large size of the table clutters the workspace, so it is necessary to find a middle ground. It is better to choose the height of the table individually, depending on the height.

We make a table for a circular saw with our own hands. Instructions and installation

The circular saw is a convenient and productive tool for construction work, with high productivity and maneuverability. But when cutting large batches of lumber, working with a powerful circular saw is quite difficult. A do-it-yourself circular saw table can greatly facilitate this task.

An easy-to-manufacture table can be made of plywood and boards. In this case, the hand-held circular saw is installed from the bottom of the tabletop, and its toothed disk is located in the slot of the tabletop. After turning on the saw, the blade begins to rotate, and when the sawn timber is fed, it is cut. The maximum thickness of the cut lumber depends on the blade size and saw power. When choosing a tool, it is necessary to take into account the thickness of the tabletop to which the saw is attached from below.

How to choose a circular saw?

If you do not already have this tool, and you plan to purchase it, the following characteristics should be considered when choosing:

- Unit power. For a household tool, 800 W is enough, but if you are thinking about making a table for a circular saw, then the amount of work with lumber will be significant. You’d better opt for a 1200W or more model.

- Cutting depth. The maximum thickness of the processed material depends on this parameter. Professional or semi-professional hand saws usually have a cutting depth of 40 to 70 mm, which is sufficient for cutting boards and plywood. Please note that the standard depth will decrease by about 10 mm when the saw is placed on the table.

- Rotation frequency.The higher the speed, the cleaner the cut. This rule applies to cutting hard materials. However, too high speed is not suitable for plastic. Due to the heating of the disc, it will begin to melt. Therefore, choose a model with a speed of 3000-4000 rpm or with a smooth speed control.

- Location of controls.When installing the saw from the underside of the tabletop, the on / off button must be safely accessible. Otherwise, you will need to provide an external control circuit.

How to make a simple do-it-yourself circular saw table to bookmarks 8

Many home craftsmen dream of self-cutting sawn timber. This is a simple matter, but without suitable equipment it is practically impossible. So why not adapt a hand-held circular saw for this and assemble a table with your own hands with the possibility of longitudinal and cross-cutting?

A hand-held circular saw can be used for this quite ordinary. The power and diameter of the disc directly depends on what and in what volume you are going to process. Remember also that the table attachment steals up to 20 mm from the maximum cutting depth, so single-handed saws with a 120 mm blade are of little use for such purposes. The presence of the circular functions for adjusting the depth and angle of the cut will give you more options for fine processing of parts and cutting box grooves.

Table materials and bases

It is recommended to use 9 or 11 mm laminated plywood for the countertop. The material really deserves to go looking for it: durable, does not bend, the surface is smooth and slippery. It is ideal if at the point of purchase you order a cut according to the desired table dimensions, so that the edges and cuts are strictly rectangular. In our case, the dimensions of the table top will be 800×800 mm.

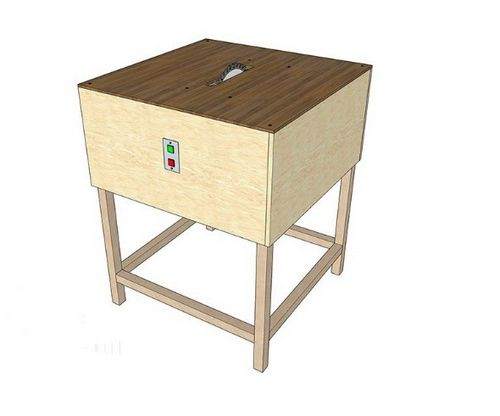

Almost any sheet material is suitable for the table body, for example, laminated chipboard with a thickness of 16 mm. You will need four strips without pasting the ends with dimensions of 400×784 mm. From them you need to assemble the walls of a rectangular box, fastening the strips with black self-tapping screws with preliminary reaming of the outer part by 5 mm. For strength and stability, bars of 40×40 mm are installed in the inner corners of the assembled box, it is better to fasten to them in the same way. The ends of the bars will be used to secure the table surface.

Such a fixture for permanent installation of the saw can be placed on top of any workbench of sufficient size. If you are planning a stand-alone installation, attach long pieces of wood in the corners of the box to act as legs. Do not forget that at the bottom they need to be fastened with crossbars and provide for the installation of additional oppression for greater stability.

Attaching the hand saw

Mark the longitudinal and transverse center axis on the wrong side of the plywood. Measure the width and length of your saw foot and transfer them to the table top markings. Determine the diameter and thickness of the lower guard and the distance it is from the edges of the support shoe. Mark out a rectangle according to the obtained dimensions on the plywood and cut a hole with an electric jigsaw.

Make one 10 mm hole in the four corners of the shoe. Drilling locations are arbitrary. Place the saw blade into the groove on the table top and align the shoe with the markings. Mark the centers of the holes made on the plywood and transfer them to the back side with a thin drill.

If there is not enough room in the support shoe to drill such large holes, use two steel plates with 6mm studs welded on, attached to the base of the saw with wing nuts lined with star washers. In this case, it will take five minutes to remove the saw for manual work and return it to its place without additional adjustment. The plates, in turn, have one large hole, for secure mounting and initial adjustment of the saw position.

To attach the saw to the tabletop, use M8 countersunk taper head plowshares. A hole of 8 mm is drilled under them from the front side and a countersink is made under the head, which, when not tightened, should protrude no more than 1 mm above the surface. On the reverse side, the bolts pass into the holes in the support shoe (or steel plates) and are tightened under a wide and spring washer, or with a nut with a plastic spring.

If the fitting was successful, the tabletop must be fixed to the box. In the four corners of the plywood board, you need to drill one of the same holes as for fixing the saw. The distance from the edges is half the side of the used bar plus the wall thickness of the box, in our case it is 30 mm. A 10 mm hole is drilled in the center of each bar, a steel foot M8x18 mm is screwed inside.

With the table top secured, turn the table on its side so you have access to the blade and saw attachments at the same time. After removing the protective cover for a while, align the saw blade along the longitudinal axis of the table using a rail and a square. After adjusting the disc, tighten the retaining nuts well. Using a ruler or level attached to the disc, mark the edges of the table and draw the line of the cutting plane along them. Run an awl along the mowing line several times, leaving a shallow furrow, such markings will definitely not be erased after long use.

Start button and electrician

The standard power button must be shunted, and if this is not possible, clamp it with a clothespin or a tourniquet. Instead of a button on the handle, a small electrical grid will be used, laid inside the box.

On the outer front side of the box, install a double “Start / Stop” button with latching. Its normally open contact is connected to the break in the power cable. The ends of the wire are connected to a plug socket which is screwed on the inside.

After the saw is connected and checked in operation, it is necessary to pull the three times folded nylon stocking onto the air intake grill.

It is convenient to trim parts if there is a thrust beam that moves along the guides along the cut line. This can be made from ordinary 9 mm plywood.

You only need a few tablets:

- 150×250 mm 2 pcs.

- 100х820 mm 2 pcs.

- 150х820 mm 1 pc.

- 142х300 mm 1 pc.

As before, it is preferable to cut plywood with precision equipment. Three long boards must be assembled in the form of a channel 150 mm wide and shelves 100 mm. Since the caps of the self-tapping screws will be facing the tabletop, under them you must first drill out the plywood and sink the fasteners, and then process the traces with emery cloth. It is safer to use confirmations instead of self-tapping screws.

Boards 150×250 mm are screwed on like channel bar plugs, the free ends are directed downward. The remaining bar is screwed between the shelves exactly in the center. If this beam is placed on a table, the side boards will drop down the sides of the box with a gap of about 10 mm on each side.

Use ball bearing full extension furniture rails. First, attach them to the beam, and then try on and screw to the body. The holes for the fasteners are oblong, use them to adjust the beam: it should slide over the tabletop with very little clearance and at right angles to the cutting plane. Slide the beam once with the saw on to make a cut at the bottom. For quick removal and installation of the beam, it is recommended to snap off the plastic clips on the rails in advance.

Adjustable rip fence

It is much easier to dissolve the wood with a longitudinal stop. It can be made from a conventional aluminum curtain rod or other lightweight profile with a perfectly flat edge and stiffening ribs. You will need a section along the length of the table, that is, 800 mm.

At 150 cm from the edges, make two holes of 8 mm and insert them along the M8 bolt, orienting the thread down. Screw on the nut without washer and tighten firmly. Run two mowing lines the same distance from the edges of the table. At the intersection with the centerline of the tabletop, drill 12 mm holes. One more hole is drilled on the same fishing line with an indent of 30 cm.Using a router or jigsaw, make two thin slots, it is advisable to make an undercut as evenly as possible.

The stop profile is bolted into these slots; after adjustment, it can be tightened with thumbs with a wide washer on the inside. If the cutting width needs to be changed frequently, fit the table body with door hinges for easy opening. To quickly adjust the stop, attach tape from a tape measure to the ends of the trimming table.

DIY circular saw table

How to make a table for circular from chipboard? To make such a table for a circular, you need:

- A sheet of laminated plywood with a thickness of 9–11 mm (800×800 mm);

- 4 sheets of laminated chipboard 16 mm thick (400×784 mm);

- Several bars 40×40 mm;

- Several bolts and screws;

- Aluminum cornice.

Any hand-held circular saw with a large blade can be mounted on such a table. Drawings of this type of circular table can be easily found on the Internet.

Such a saw is made in several stages:

- A drawer of the future table is made from laminated chipboard sheets. It does not have a bottom, and the walls are fastened with bars, which, in turn, must be secured with bolts and screws.

- A cover is made of plywood with a hole into which you will need to insert a saw. The marking for the hole is carried out along the support shoe and the lower protective casing of the circular saw. The hole is cut with a jigsaw.

- The saw is attached to the plywood with ploughshare bolts with a countersunk cone head. The plywood cover is fastened to the laminated chipboard body with an 18 mm steel case.

- Wiring is laid along the side of the table top and a start button is installed.

Circular saw guides are made from timber or aluminum curtain rod.

DIY circular saw table

A circular saw is used to cut wood along the solid wood. Its cutting base is a disc-shaped plane with a serrated outer edge. Such saws are not only hand-held, but fixed on the table. How to make a universal circular table so that this cutting tool can be installed on it? Below are several ways to make a do-it-yourself circular saw table.

The second version of the circular table. Photo of manufacturing technology

A do-it-yourself saw-table is made of boards, as the most affordable material, quite often. To make this table you will need:

- Plywood sheet (thickness 20 mm and more);

- Boards 50 by 100 mm;

- Bars 50 by 50 mm;

- Several self-tapping screws;

- Wood glue;

- One of the types of wood varnish.

A workpiece with a hole is cut from a plywood sheet with a jigsaw. A tabletop in which the saw will be placed. When marking the holes, they are guided by the dimensions of the saw sole. Stiffening ribs are made of the boards, which will be attached to the tabletop with self-tapping screws. In the process of fastening, the boards are pulled together using clamps. A start button is later installed on the front stiffener. For the manufacture of legs, boards about a meter long are used. They are bolted to the outside of the stiffeners.

DIY circular saw table

A circular saw is used for cutting wood, plastic. Its cutting base is a flat metal disc with a serrated outer edge. Choosing such a tool, everyone decides for himself what kind he needs: desktop, manual, stationary. Many people prefer the manual option. However, in some situations it is necessary to secure the saw. In this case, you can make a table for a circular saw with your own hands, having the opportunity to fix the tool if necessary.

Preparation of tools and materials

Having decided to make a table for a hand-held circular saw yourself, you need to take care of the availability of all the materials necessary for work:

- Film faced plywood (9 or 11 mm), size 800 mm by 800 mm;

- Chipboard 16 mm or other sheet material suitable for the manufacture of the case, sheet size 400 by 784 mm. 4 pieces;

- Bars 40 x 40 mm (length depends on the installation method);

- Self-tapping screws;

- Bolts.

Any hand-held circular saw is suitable for such a table. It should be remembered that when attached to the table, the cutting depth decreases by 10–20 mm. So saws with small discs are not suitable for such a table.

Step-by-step instructions for assembling a circular saw table

1. Manufacturing of the case. The sheet material for the body is cut to size: 400 mm by 800 mm. Parts are fastened using self-tapping screws and bars. It is better to carry out the assembly by pre-drilling the outer parts of the box. The result is a rectangular box without a bottom and a lid. The top of the blocks is then used to secure the plywood sheet.

2. Prepare and fix the plywood top. Slot holes. First, a piece of 800 mm by 80 mm is cut from a sheet of plywood. Next, measurements are taken of the support shoe of the saw that will be mounted on the tabletop. On the back of the plywood, markings are made. You will need 2 center axes. Without them, you cannot perform accurate markup. Then marks are applied to the plywood, corresponding to the dimensions of the support shoe. Then they make such measurements that the circular has: the diameter of the lower protective casing, its thickness, the maximum distance from the edges of the support shoe. In accordance with the obtained dimensions, they put marks and cut out a rectangular hole with a jigsaw.

3. Fixing the saw to the plywood table top. First, 4 holes are made in the shoe. Diameter. 10 mm. Then the tool is installed so that the working part goes into the cut hole. When the saw is aligned, mark the location of the holes. Marks are made in the central part. In order for the tool to stand securely, plow bolts with a countersunk cone head (M8) will be needed for fastening. To install them, you will have to take care of a high-quality deepening of the cap, it can protrude a maximum of 1 mm in an untightened state.

Plywood is drilled from the outside, the diameter of the holes obtained should be 8 mm, and then a countersink should be made under the head. When the holes are ready, the saw itself is installed on the sawing table for the circular saw, the bolts are tightened from the inside using nuts with plastic grovers or spring washers.

4. Fastening the table top to the body. Start button. First, at a distance of 30 mm, holes are made in the corners of the plywood tabletop. Then a hole is drilled in the central part of the bars. The parts are connected using a steel foot M8 by 18 mm. On the side part, the usual “Start. Start” button is installed. An electrical network is laid inside the body, and the button on the instrument itself is clamped.

5. Manufacturing of a thrust beam. A simple circular saw table will become much more convenient if you equip it with a persistent bar. The drawings contain all the dimensions you need. The beam can be made of plywood and secured with full extension furniture rails. The resulting beam should slide over the surface at a 90 ° angle to the cut plane with little clearance.

6. Stop for rip cuts. It is made from an aluminum curtain rod. At 150 mm from the edges, holes are first drilled for the bolts, and then 2 lines are drawn from the bolt attachment point to the axial mowing line. At the intersection and further towards the bolts, 12 mm holes are made at a distance of 30 mm. Tighten the bolts from below with nuts. And according to the drawn lines, they make cuts for the tonic, their width can be seen in the photo.

Information on how to make a table for a circular saw can be viewed at This will help you quickly and easily improve the equipment of your workshop.