How to properly adjust the carburetor of a Chinese chainsaw

Why a chainsaw shoots into the carburetor?

If during the start and operation of the tool, its owner hears sounds reminiscent of gunshots, then it indicates a malfunction of the node, in which the fuel is mixed. This is most likely caused by such malfunctions of the chainsaw carburetor:

- overtightened ignition. in this case, the fuel does not burn through, which leads to specific sharp shots;

- feeding into the carburetor a mixture with a low concentration of gasoline. to fix the problem, you will need to adjust the jets.

If the popping noise comes from the muffler side the problem is in oversaturation of the fuel mixture with petrol. If there is too little air in the fuel, it will burn not only in the chamber but also in the silencer. This is evidenced by a large amount of soot on the inner walls of the muffler.

How the chainsaw carburetor works. principle of operation

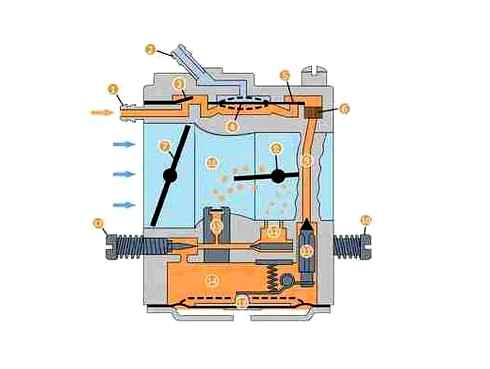

The operation of the unit in question, despite its complex design, is simple and understandable even for beginners. Principle of operation is based on the following actions:

- As soon as the internal combustion engine is started the air damper is opened

- In the area of narrowing of the diffuser 16 the incoming air stream is accelerated and mixed with petrol-oil mixture

- The petrol-oil mixture is fed through nozzles number 15 and 12, and the air, before passing through the valve 7, passes through the filter placed before the inlet

- The damper 8 is located behind the diffuser, and serves to regulate the amount of mixture in the combustion chamber

- Screws 17 and 10 adjust the volume of gasoline, which passes through the jets. On the carburetor control panel, these screws are labeled L and H

- The needle valve 11 controls the volume of the fuel mixture in the float chamber 14. In order to adjust the position of the needle valve there is a diaphragm in the mechanism 13

- Another diaphragm 4 is responsible for the fuel supply to the combustion chamber of the cylinder. Position of this diaphragm depends on engine rpm

- Fine filter for cleaning the oil-petrol mixture

The simple principle of the carburetor ensures trouble-free working of the engine. The quality of tuning determines how the power tool behaves when idling and in operation. The mechanism in question has a direct effect on the performance of the entire tool. Adjustment quality affects tool life.

Adjusting and troubleshooting chainsaw carburetor

Internal combustion engine of a chainsaw is based on burning a fuel-air-oil mixture. To mix the gasoline-oil mixture with air, and then batch feed it into the combustion chamber, the engines are equipped with a rather complicated by design carburetor device. When you buy a new chainsaw, the carburetor is already factory-set, but over time it becomes confused and the device that controls the flow of fuel needs to be adjusted again. If you don’t know how a carburetor works and don’t understand how the module works, it is very difficult to set it up correctly.

STIHL and partner chainsaws

In STIHL 250 and 361 chain saws, as well as in Partner 351 and 350 carburettor adjustment is done with the help of screws H and L by adjusting the proportions of gasoline and air. If they are loosened, it is possible to add a large quantity of fuel and therefore the RPM will be high, otherwise the opposite will be true.

Partner chain saws adjust idle speed with a screw marked T, and Stihl is usually marked LA. A typical chainsaw adjustment is the final test. In general, after such adjustments the percentage of fuel in the working mixture is more than air, which does not correspond to the optimal parameters. But it is important to keep them in during the first hours of operation during the break-in period. After that you may adjust the saw yourself, but it will work fine even with the factory settings.

But if you decide to adjust it yourself, you should do it in this sequence:

- adjusting the L screw;

- then adjust the H nozzle;

- then go on to the idle speed adjustment with the T screw (if the STIHL chain saw is LA).

First turn the L screw in both directions to find the maximum engine speed. If that point is found, turn the same screw ¼, thus slightly reducing the rpm. If the chain continues to idle, turn the T (LA) screw immediately until the chain comes to a complete stop.

After adjusting the maximum rpm with the screw H, check the frequency with the tachometer. In the event that it does not correspond to those specified in the service book, the adjustment must be repeated. If at maximum revs there is a lot of smoke coming out of the exhaust pipe, the mixture is too rich in fuel, if noises are heard and the engine is getting warm, it is too lean. Then you need to adjust the idle RPM. When properly adjusted, you should see a smooth sound of the engine at low RPM, and the chain should not move.

Main adjusting screws

There are only three adjustment knobs for the carburetor, they are spring-loaded screws for the flathead screwdriver. There are a pair of screws on the bottom, L on the left and H on the right. A little higher is the T (or S) screw. So, that’s what they’re for:

Chainsaw Carburetor Adjustment | How to Tune ‘Correctly’. by Craig Kirkman

- Screw L is the valve that adjusts fuel channel cross-section when working at low RPM.

- Screw H, similar to the previous one, is the channel flow regulator for high rpm.

- Screw T is the throttle control. It determines its position when the gas pedal lever is completely released.

The structure of the first two adjusting screws is very simple: on their ends there are needles inserted into spools with variable cross-section (cones). All have right threads, so tightening the screw clockwise, you drive the needle deeper and reduce the flow. Turning it counterclockwise does the exact opposite.

This is how the quality of the mixture is regulated in the different modes of operation. If the fuel increases, the gasoline does not have enough time to burn completely and the engine speed is low. When the mixture is lean, the rpm increases and the engine temperature rises as well. It is worth noting that even if the screws are tightened all the way, the flow of both channels is not completely blocked, unless there is a blockage.

The structure of the carburetor

In this short review we will not be able to describe in detail all the details of the carburetor and thoroughly familiarize with all the nuances of its work, but we will dwell only on the main points.

A carburetor consists of these components:

- Tube with air damper. A small aerodynamic tube, which is designed to regulate the air flow. A transverse flap, depending on its position, reduces or increases the amount of air, thinning or enriching the fuel mixture;

- Diffuser. Made in the shape of a narrowing at the end of the aerodynamic tube. The main task is to increase the pressure and velocity of the air when mixing it with fuel;

- Nozzle, or atomizer. Designed to supply fuel and mix it with oxygen.

- Float chamber. A special reservoir that ensures a stable level of gasoline, at the inlet to the air duct.

Poor and rich mixture

A little more detail about lean and rich mixtures.

rich mixture

A rich mixture is a fuel mixture in which the amount of fuel fed to the carburetor. In this case, the fuel does not have time to burn completely and less energy is produced than at the optimal fuel/air ratio. Partially empty fuel ends up in the muffler, and the chainsaw emits heavy smoke.

Poor mixture

In a lean mixture there is an excess of air, which is also not good, because it has its own disadvantages. Namely: insufficient energy during the flash (and thus a loss of power as a result), excessive heating of the cylinder due to insufficient lubrication and high speeds, which leads to scuffing, and there is not far and to seizure of the engine.

How the carburetor works?

All processes in the engine are not cyclical, but constant.

Cleaning a chainsaw carburetor and how to do it correctly

One of the most important mechanisms of a chainsaw is the carburetor. It is designed to dose the fuel-air mixture into the engine cylinder. Without it, an internal combustion engine would not work, and it is often the cause of instability in the engine. To correct the situation, you will need to clean the chainsaw carburetor, which you can do yourself.