How to properly adjust the Carver saw. How to adjust the carburetor on your chainsaw: settings and advice

Carver chain saw carburetor adjustment

Chainsaw. A useful, and sometimes just necessary, tool for the owner of a private home. It has a high degree of independence, can be used in the field, where there is no possibility of connecting to the power grid. For some craftsmen, the chainsaw is one of the main devices that performs large amounts of work almost every day. Such loads throw off the factory settings set for all important engine components.

The operating mode is often changed by the carburetor, which must be readjusted. Without an understanding of the design and principle of operation of this element, it is impossible to adjust it correctly. This question concerns many users who work closely with chainsaws, so it will be useful to consider it more thoroughly.

- Construction and principle of operation

- When you need a carburetor adjustment?

- Adjusting tools

- How to adjust the carburetor with your own hands?

- How to install a saw made in China?

Carver chainsaw carburetor setup

Most modern chainsaws (Carver is no exception) have either a completely single-type carburetor from one manufacturer (for example, by Walbro), or a very similar design. But even with the differences in appearance of the housing, the principle of operation of all carburetors is exactly the same.

But Carver carburetors differ from other chain saws in the adjustability. The adjusting screws on most other saw models are hidden under the housing and often have unique shaped notches. That’s why they can only be adjusted with special “brand-name” screwdrivers, which are sold in service centers. Carver carburetor is adjusted with an ordinary flat screwdriver. There are three holes in the housing for the adjusting screws. That’s why you can adjust the carburetor on your Carver chain saw without removing the cover.

The basic assemblies of Carver carburetors are

The carburetor of a chainsaw consists of the following main assemblies:

- The body is cast in light alloy;

- A diaphragm pump for manually pumping up the fuel before starting (suction);

- diffuser;

- Nozzles (strictly calibrated holes in the bronze sleeves for metered delivery of fuel);

- float chamber;

- atomizer.

Also in chainsaw carburetors there are fuel channels, throttle (gas) adjustable choke, air damper, filters and adjusting screws.

How the Carver carburetor works

After starting the chainsaw engine, the air flap opens and the purified air flows into the diffuser through it. The gasoline also flows in through the calibrated holes in the jets. The amount of air-fuel mixture that enters the combustion chamber from the carburetor is regulated by the position of the throttle, which is connected by a pull rod to the throttle grip.

A needle valve cuts off the gasoline supply to the carburettor when the carburettor is full. Gasoline passes through the filter before entering the nozzles, reducing the risk of clogging the calibrated orifices in the nozzles.

What the three carburetor screws L, H, and T adjust.

On older models of chainsaws, there are only two adjustment screws. One of them adjusts idling speed by simply lifting the throttle. When it is screwed in, the passage under the slide increases, the fuel flow into the combustion chamber increases, the engine speeds up. In essence, twisting it “adds throttle” without pushing the throttle knob.

In modern Carver chainsaw carburetors, the idle speed adjustment screw T regulates the amount of fuel flowing through the idle speed nozzle, not the throttle position.

The L screw has a sharp, needle-like tip inside, and regulates the main fuel flow through the calibrated orifice of the nozzle.

In modern models, there are two such screws. One. L. adjusts main fuel flow at low and medium rpm (not to be confused with idle). The second one, H, adjusts throttle at maximum rpm.

Inconsiderate adjustment of the “H” screw can lead to unpleasant consequences. For example, the engine of a Carver chainsaw designed for a maximum RPM of 12,000 rpm. one of them adjusts the RPM at full throttle to 15 thousand rpm. rpm and will fail. And, any adjustment only H leads to unbalanced fuel supply, and the engine can “sag” at certain revolutions.

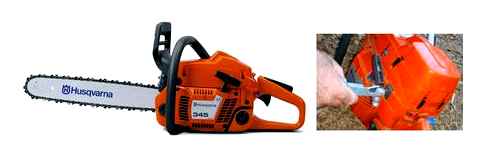

How To Adjust / Tune a Chainsaw Carburetor | Husqvarna Stihl BEST Way

How it works

The purpose of the carburetor is to prepare the working consistency for feeding it into the engine cylinders. This consistency is gasoline and air in the right proportions for engine operation. If this ratio is broken, then the engine will not work accurately. When the mixture has a lot of gasoline, then in layman’s terminology it is called saturated, and if, on the contrary, not enough, then poor. But in any case, a failure in the proportions of the working consistency will have a bad effect on the performance.

Different chainsaw models may have different carburetor designs, but the principle of action they are all similar. The air moves through a special channel at a speed that can be adjusted by closing or opening the flap. Gasoline, in its turn, gets into the carburettor through the nozzles and mixed with the air there, creating a special mixture, which goes into the engine.

The pressure in the float compartment of the carburetor, where the gasoline is before mixing, is close to atmospheric pressure. When you open the valve air becomes more, so does gasoline, so the engine speed increases. In the air duct with all this creates a vacuum and gasoline is drawn into the air flow. This is the principle of the carburetor.

To make the chainsaw runs smoothly and perfectly, but with all this was not a huge expense of fuel, its carburetor should be configured as appropriate. Before such works it is necessary to check the air and gasoline filter beforehand. if you find dirt on them, they need to be replaced.

Chainsaw adjustment in most models is usually done with three screws. high and low speed and idle.

adjustment of the carburetor on the Chinese chainsaw

About the correct adjustment should testify to such signs:

Repair the carburetor of a chainsaw with their own hands should be carried out very carefully, because no matter what mistake made can lead to serious consequences, even to the complete destruction of the motor. If you do not have sufficient experience, it is better to ask for help from an expert.

Adjustment instructions

The scheme of adjustment of the carburetor and the recommended position of the adjusting screws are specified in the manual for each specific tool. When getting acquainted with a new saw it is recommended to tighten the screws to the limit, counting the number of revolutions, in order to be able to return to the factory settings later. The general principles of the adjustment are as follows:

- Before beginning with the adjustment the engine should be warmed up at idle for 10 minutes.

- Turning the L screw should achieve such a quality of mixture that at idle the engine runs evenly at 1500-2000 rpm. Acceleration should be fast but smooth when you step on the gas pedal. Dip in rpm indicates too lean mixture, turn the screw back until the phenomenon is gone.

- After adjusting the mixture for low revs, turn the screw T until the chain starts to rotate and then turn it back out to 1/2 turn. 1/3 turn. The important thing here is to keep an eye on the serviceability of the clutch mechanism.

- Screw H is not adjustable at home.

The danger of adjusting the H screw yourself is that a too lean mixture at high rpm, and especially under load, leads to rapid wear of the piston and ignition system malfunctions. Do not change the throttle trigger unless you fulfil three conditions:

- The chainsaw is obviously not giving the power it needs while sawing.

- The person performing the adjustment has a general knowledge of the structure of carburetor engines.

- A means of measuring engine speed is available.

The latter can be either a tachometer or a multimeter with integrated oscilloscope. To connect the multimeter, you need to wrap 3-4 coils of thin copper wire around the spark plug wire.

The main task of the H screw is to compensate for rpm overshoot or undershoot due to a change in fuel type, oil concentration or air composition. Also, insufficient precision in adjusting the low speed screw can throw off the “high” setting. The adjustment scheme is simple. the screw is tightened or unscrewed until the saw engine at maximum throttle will not give 14.5-15 thousand rpm or the value specified in the instruction manual.

If you use an oscilloscope, its reading (spark discharge frequency) should be around 230-250 Hz. Take into account the accuracy class of the gauges and the fact that under load the rpm drops by 10-15%. It is better, if the engine will work at low RPM than if it will work at high RPM, even just a little.

Features of the Carver RSG-246 chainsaw

All customer feedback has been incorporated into the design features of the Carver 246 chainsaw. Separate note can be made of the excellent balance, vibration damping design and low noise level. All of these features enable the operator to work comfortably for extended periods of time.

The Carver 246 chain saw has an easy-start system, and the chain is lubricated automatically during operation. Despite its weight of 6.9 kg, the saw feels compact and the handles are ergonomically positioned to facilitate the operator. Both the filter and fuel system are easily accessible. No problems with self-tensioning the chain and adjusting the chain drive mechanism.

Modern technical features are perfectly balanced with the saw’s classic design that focuses on user-friendliness.

Tools for adjustment

For the carburetor option is useful Philips or slotted screwdriver of different length or thickness; the size depends on the design of this unit and the peculiarities of the assembly of the motor. It should be emphasized that some manufacturers make carburetors, designed for the use of special tools.

Specifically, for the option of carburetors Husqvarna and other imported tools can be useful special screwdrivers. It is wise to check this question even when buying the chainsaw, so that you can buy the right accessories in advance.

Other than that you can wash and clean your device with refined gasoline or acetone. They are used to clean the outside of the carburetor. All internal passages are flushed with kerosene, diesel fuel or snow white spirit. Before washing, the carburetor is dismantled and all rubber or plastic parts that can suffer from contact with brutal chemical compounds are removed.

To disassemble the carburetor open-end wrenches or wrenches are used. The internal channels are flushed in specially provided trays, occasionally plastic syringes are used for this purpose.

Pros and cons of Chinese carburetors

Chinese carburetors can be low, medium and high quality. Low-quality products have the advantage of an extremely low price. The best option in terms of price-quality ratio is usually in the medium price segment.

STIHL original European-made carburetors or the purely Japanese Walbro are excellent quality. But their cost is sometimes equal to the price of the entire Chinese chainsaw. So it is better to navigate confidently in a variety of Chinese carburetors, which flooded our market, and make an appropriate choice.

Carver chainsaw engine carburetor is responsible for supplying a properly metered fuel-air mixture. Engine speed is increased by increasing the mixture when the accelerator pedal is depressed. Stable idle speed also depends on a properly working carburetor. This is an important chainsaw system and you need to have an idea of how it works, know the basics of diagnosis, as well as know how to adjust and repair.

Product Range

The range of Carver chain saws is quite extensive. Available Carver chain saws are divided into several main categories, have similar technical characteristics and are very popular, thanks to their affordability and ease of use.

The machine is notable for its high horsepower and torque. This extends the functionality of the saw and makes it suitable for all domestic, construction and felling tasks.

The device model consists of a gasoline 2-stroke motor, 62 cm3. The engine is started with a standard manual starter and cooled by the forced-air system.

- engine power. 3,2 litres. с.;

- Recommended length of the bar to use. 18-20 “;

- Number of chain links. 76;

- weight in ready-to-use condition. 7.6 kg.

This Carver chainsaw is equipped with a manual fuel pump, which facilitates starting the motor at low temperatures.

Repair your chainsaw with your own hands

The chain saw faults can be divided into two main groups: the engine faults with all its components and systems (ignition, fuel system, piston/cylinder group, exhaust system) and faults with other components (chain brake, lubrication system, clutch, guide bar, etc.).).

Engine trouble

- The engine will not start;

- starts up, but stops;

- works unsteadily;

- does not develop power, t.е. Works fine at idle rpm, but shuts down under load.

Carrying out the repair of a chainsaw with their own hands, it is necessary to act by the method of elimination. to check all the possible causes of failure, starting with those, checking and eliminating which takes less time (about the device and work of the two-stroke engine, see here).

Ignition System. Almost all of the engine problems listed above can be caused by ignition system malfunction. Therefore, when they occur, it makes sense to begin troubleshooting with the spark plug. It is all the more justified, the condition of the latter can give useful information about the work of the fuel system. So, if you have a problem, it is necessary to unscrew the spark plug and look at it.

The wire is disconnected and the spark plug is unscrewed with a special key.

If the spark plug is dry, the problem is probably not the ignition system, but the fuel mixture not flowing into the cylinder. You can screw the spark plug back in and take care of the fuel system. If the spark plug is heavily spattered with fuel mixture, it means that there is a fuel surplus. This can be caused by a carburetor malfunction or a breach of the rules of starting. Wipe and dry the spark plug, dry the cylinder by cutting off the fuel supply and running the starter. to ventilate the combustion chamber and remove excess fuel. After that put the spark plug back and restart.

The presence of a large amount of black sludge also indicates a malfunction in the fuel system.

The oil to gasoline ratio in the mixture may be abnormal, the carburetor not adjusted, or low-quality oil used. The spark plug is rinsed in petrol, cleaned from sludge with a needle or awl, electrodes are cleaned with a fine cloth and refitted.

In all these cases, it is worthwhile to check the gap between the electrodes. Depending on its brand, it should be in the range of 0.5-0.65 mm. It is necessary to check the spark plug gasket as well. If it is worn or damaged, the sealing of the combustion chamber can be compromised, resulting in reduced compression in the cylinder and engine performance problems.

Even if there is good reason to believe that the problem is in the fuel system, you need to check the spark plug. If only to be sure that there is nothing wrong with it. To do this:

- put the ignition cable on the spark plug;

- Using pliers with insulated handles, apply the thread or nut of the spark plug to the cylinder;

- pull the crank of the starter and see if there is a spark or not.

If there is no spark, you should simply replace the spark plug. If even a new spark plug has no spark, check the high-voltage wire for breaks and contact with the spark plug.

The reason for the lack of spark can also be a faulty ignition module or a gap between it and the flywheel magnet. It should be 0.2 mm. This gap is especially likely to be present if the saw has been disassembled and the flywheel and ignition module have been removed beforehand. The gap is adjusted with a 0.2 mm placed between the flywheel boss and the ignition module. The faulty ignition module needs to be replaced.

Having checked the ignition system in this way and not found any malfunction, you can move on to the fuel mixture supply system.

Fuel system. If an inspection of the spark plug revealed that fuel is not flowing into the cylinder, you should consider all possible reasons for this. It could be:

- no fuel coming out of the tank due to a clogged hole in its cover (breather plug), in which case a vacuum is created in the tank, preventing the flow of fuel;

- Contamination of the fuel filter installed in the tank;

- no or insufficient flow of fuel mixture from the carburetor to the cylinder.

To diagnose the first two causes, it is enough to disconnect the fuel hose from the carburetor and see if the fuel flows out of it or not. If it flows in a full stream, the breather plug and filter can not be checked, if it does not leak or leaks weakly, we can assume that the cause of failure is found. The breather plug is cleaned with a needle. The fuel filter is removed through the filler hole of the emptied fuel tank, with a wire hook, along with the suction hose, from which the filter is disconnected and cleaned or replaced with a new one. Chainsaw manufacturers recommend changing the fuel filter every 3 months.

Insufficient flow of fuel mixture from the carburetor to the cylinder or failure to maintain the correct ratio between fuel and air mixed in the carburetor may be due to several reasons: clogged air filter, unadjusted carburetor, clogged channels or filter screen.

As a rule, a chainsaw repair can’t do without cleaning the air filter, because it gets dirty pretty quickly. When this happens, the air flow to the carburetor is reduced and the fuel mixture at the outlet is too enriched, which prevents the engine from working properly. Remove the dirty filter for cleaning carefully, so that dirt from it does not get into the carburetor. You should clean or rinse the filter with water and some kind of detergent, dry it, and then put it back in.

The adjustment of the carburetor is corrected by adjusting it. This is usually done with three screws. maximum and minimum revolutions and the idle speed screw. Adjustment should be carried out in strict accordance with the instructions, non-compliance with which can lead to engine failure. Some saw manufacturers leave only one adjusting screw (idle speed) to prevent undesirable interference by inexperienced users with the carburetor. For an example of adjusting a chainsaw carburetor, see Working with a Chainsaw.

Adjusting the festool carvex for perfect cuts.

If adjusting the carburetor did not help, you need to clean its channels and filter grid, and at the same time check the integrity of the diaphragm. The carburetor. one of the most complex devices of a chainsaw, so proceed to its disassembly and cleaning should be fully aware of the responsibility of this operation. It consists of a variety of small parts, which have a feature of invisibly popping out of their places and irretrievably get lost, so that, having disassembled this capricious device, you may not reassemble it.