How to Properly Assemble a Carburetor On a Stihl Trimmer

Carburetor assembly

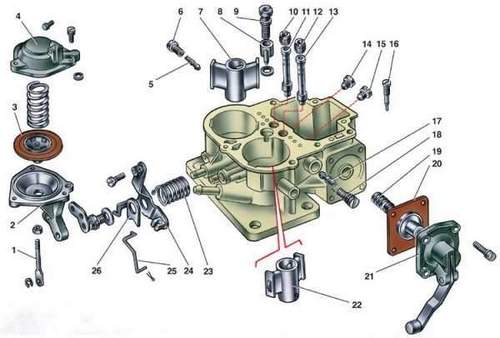

Assemble the carburetor, power systems of the car engine, sequentially, installing the removed early components and parts in their previous places. When assembling the carburetor, follow the tips and recommendations described below. Emulsion tubes, as well as air and fuel jets should be installed exclusively in their original places, and comply with their calibration data.

We want to draw your attention to the fact that the marking on the carburetor parts is made without a comma. For example, the marking of the main air jet is documented 1.70, on the jet-170. In addition, the jets of different carburetor systems visually differ from each other, it is possible to mix up the main fuel jets of the first and second chambers. The carburetor assembly must take place taking into account the data in the table below. The diameters of the holes of the main fuel jet:

In order not to damage the external thread on the nozzle and the internal thread in the bore hole, center the nozzle relative to the threaded hole so that it swirls smoothly without distortions.

And also we do not recommend applying physical force when twisting.

In order to establish the correct course of the diaphragms of the starting device and the accelerating pump, and thereby extend the service life, it is necessary to assemble the covers in place and do not tighten the fixing screws completely when assembling. Push the diaphragm stem of the starting device all the way by hand, tighten the fixing screws of the cover crosswise. Pull the lever of the accelerator pump drive to the limit, tighten the fixing screws, as in the previous case.

When installing the throttle and air damper, under no circumstances do not change the screws removed from the damper axes by any other. It is necessary to tighten the screws that secure the flaps, evenly, and then flare the end of the screws with a core. In order not to bend the axis of the dampers, it is necessary to rest the screw heads in a metal stand. The screws are expanded so that they do not loosen and do not fall into the combustion chamber, as this will lead to serious engine failure and not a small material cost. When tightening the lever fixing nuts on the throttle axles, the axles must not wedge. If the axes are wedged, slightly release the fixing screws of the dampers, in the air ducts, move the dampers so that they are not clamped, then tighten and lock the end of the screws.

In the image, the arrow shows the place where the solder is located, which is partially removed if the float exceeds a weight of 12.5 grams. If there is no heavy solder on the float, file with a file to the desired weight, the junction of the two parts of the float.

In no case do not change the washers and springs previously removed from the carburetor to others. Carburetor assembly should take place without the use of various kinds of sealing means. Adjust components and parts as recommended.

How to disassemble and assemble the carburetor?

I already noted that the carburetor is a rather complicated device. Therefore, it is not recommended to remove and disassemble it yourself, unless, of course, you are a car mechanic with many years of experience. However, some kind of malfunction can make itself felt at the most inopportune moment. For example, on a long journey, and it will be necessary to eliminate it on their own. That is why this subsection describes how to do this.

Remember that removing and replacing the carburetor, as well as tightening the fastening nuts, is only allowed with a cold engine and carburetor.

On most vehicles, you will first have to dismantle the air pump to remove the carburetor. After that, you need to disconnect the cable and the return spring from the throttle control sector. Then remove the draft of the air damper drive together with its shell, unscrew the fastening screw and remove the block intended for heating the carburetor. After that, it is necessary to disconnect the electric wires of the carburetor limit switch (some vehicles use a device called the economizer of forced idling). Next, unscrew the nuts that secure the carburetor, remove it and be sure to cover the inlet of the inlet pipe with a plug or sheet of paper so that dust, debris, etc. Do not get into it.

Installing the carburetor in its place is carried out in the reverse order.

Dismantling the carburetor is as follows. First, remove the screws holding the carburetor cover and remove it. When performing this operation, be extremely careful, otherwise you can disable the float, eco-bulb tubes, gaskets and other “delicate” parts. Keep in mind that if something happens to them. Most likely, you can’t eliminate the malfunction yourself.

If you need to disassemble the carburetor cover, the first thing to do is to carefully push the axis of the floats out of the racks with a mandrel and remove them. After that, remove the cover gasket, and unscrew the needle valve seat, fuel line, and then remove the fuel filter.

Next, you need to get the idle system actuator and its fuel jet. Then you need to remove the liquid chamber, having previously unscrewed the corresponding bolt, remove the bimetallic spring housing clamp, and also the spring with the shield. After that, remove the cover and the body of the semi-automatic starting device, diaphragm, throttle lever pull rod, adjusting screw, plunger stop.

The accelerator pump sprayer comes with the valve. The nebulizers of both chambers must be carefully removed from the diffusers. Then, unscrew the nut of the throttle axis of the first carburetor chamber, remove the pump drive cam and washer. Next, unscrew the fixing screw, remove it and take out the electric wire that goes to the idle mixture adjustment screw.

Then take a screw and use it to remove the plastic plug, then unscrew the screw that regulates the composition of the working mixture for the engine to idle.

After that, remove the actuator of the main dosing system, as well as the nozzle, then the return spring from the diaphragm together with the o-ring.

Unscrew the main air jets and main fuel jets.

Assemble the carburetor in the reverse order of disassembly. Please note the following:

The needle valve must move freely in the socket, smoothly and without jamming. Otherwise the engine will work unstably;

Assemble the accelerator pump as follows: first, fasten the mounting screws, then press the drive lever all the way, then tighten the screws and release the lever;

The float must be free and not touch the walls of the chambers;

Do not confuse jets (this is one of the most common mistakes that motorists make when disassembling and assembling a carburetor on their own), for this, carefully monitor their markings and take into account the calibration data of your carburetor.

Remember: disassembling and assembling the carburetor does not accept any trifles. Everything must be done clearly and correctly. Otherwise, the “appetite” of your “four-wheeled horse” can increase quite significantly.

Flushing the carburetor without removing it from the engine and disassembling

- We leave for the nearest gas station.

- Turn off the fuel tank cap.

- Open a can of washing liquid (opens like a beer can).

- Using a watering can, pour the product into the tank.

- Pour gasoline into the tank (to full);

- We drive a car until the fuel runs out.

According to the manufacturer, the Hi-Gear HG 3205 additive not only promotes self-cleaning of the fuel system, but also helps:

- Facilitate starting a cold motor;

- Reduce exhaust toxicity;

- Save fuel (up to 7%).

Maybe, of course, everything is not so colorful, but after driving 300-400 km on this additive, you will definitely notice positive changes in the engine. To maintain the fuel system and carburetor in particular, it is recommended to repeat the described procedure every 3000 km.

Partially disassembled flushing

We will consider the carburetor washing process with its partial disassembly using the Solex carburetor and the Jet 100 Ultra as an example. You don’t have to buy it much. One can of 200 ml is enough. The cost of this tool is 450-500 rubles. In addition to special fluids, you will also need:

- Set of wrenches;

- Phillips and slotted screwdrivers;

- Pliers;

- A tank with a wide “neck” of 2-3 liters (for soaking the carburetor cover);

- A container with a wide “neck” of 0.2–0.5 liters (for soaking small parts);

- Kerosene (refined gasoline, acetone);

- Tire pump or taper compressor;

- Toothpicks

- Old toothbrush;

- Clean, dry, lint-free cloth (preferably coarse);

- A small wooden spatula (like an ice cream stick).

Dismantling the carburetor 2108, 21081, 21083 Solex. Carburetor how to assemble

Carburetor in the car. Essential device. For what it is needed, read the article What does a carburetor do? There are situations when, for one reason or another, you have to deal independently with the issue of assembling a carburetor. How to assemble the carburetor to fix the malfunction?

If you disassemble the carburetor, then assemble it in exactly the reverse order. It is important that you do not have one extra bolt left. Remember that the engine and carburetor must be cold during assembly.

Assembly CARBURETTOR. How to assemble a classic Lada carburetor

How to assemble a carburetor

Assemble the carburetor, power systems of the car engine, sequentially, installing the removed early components and parts in their previous places. When assembling the carburetor, follow the tips and recommendations described below. Emulsion tubes, as well as air and fuel jets should be installed exclusively in their original places, and comply with their calibration data.

We want to draw your attention to the fact that the marking on the carburetor parts is made without a comma. For example, the marking of the main air jet is documented 1.70, on the jet-170. In addition, the jets of different carburetor systems visually differ from each other, it is possible to mix up the main fuel jets of the first and second chambers. The carburetor assembly must take place taking into account the data in the table below. The diameters of the holes of the main fuel jet: