How to properly assemble a jackhammer. Design and principle of operation

Electric Demolition Hammer. Principles of a Demolition Hammer

Some people think that it was the pneumatic jackhammer that was the first step in the development of chisel tools, but the electric jackhammers were the real first to be invented. However, it was quite dangerous to use them in the most topical area at the time. mining. due to the high risk of ignition from sparks inside the machine. Therefore, when pneumatic hammers arose, they long supplanted all competitors aside. Today the situation takes a different turn.

Most users value mobility and convenience much more, but work with hammers indoors, far from the risks of ignition, or even outdoors. Builders are not communal services began to actively master the electric demolition hammer, because Such chisel tool works on impulses of the electric motor that drives the striker. Dependence on power supply in the premises, where the repair is made, is usually almost imperceptible, that is why electric models are most popular among repairers, because they do not cost relatively cheap, but they cope with their assigned tasks on fire.

Petrol-powered bumpers over electric non-pneumatic tools has a weighty advantage that the game slots have. it is not tied to a power source. But in its arsenal of course other disadvantages. it is not the noise level, not a lot of fuel consumption, not toxic exhaust. Therefore, the room with such will not necessarily be able to work, or it is wonderfully ventilated. The pneumatic chisel tool is the most reliable not the safest among. It does not spark, is not afraid of moisture, does not need fuel (if you do not consider air as fuel), does not pollute the air with exhaust.

The only downside is that it is tied to a compressor, which pressurizes air. For repairmen to buy such a tool makes sense only when the compressor is already there.

Instructions for use of a pneumatic hammer IP-4613MO and its modifications

Preparation of the pneumatic hammer for work

- To prepare the air hammer for work:

- unscrew the end-spring;

- remove the plug 28 from the barrel;

- wipe the shank of the working tool and insert it into the end-spring and then into the barrel

- screw the end spring onto the barrel;

- Screw the coupling nut on the fitting as far as it will go;

- remove the plug 22 from the nipple and fill it with 30 g. kerosene, pre-pressing the handle;

- Choose a hose with the right diameter, blow on it, put it on the nipple and fasten it;

- connect the air supply hose to the line;

- open the valve and put the hammer into operation by pressing the handle for 1-2 minutes;

- turn off the air supply from the line with the valve and disconnect the hose from the hammer by unscrewing the union nut from the socket;

- pour grease into the nipple according to table 3; 2.3;

- Connect the hose to the hammer by screwing the coupling nut all the way around.

- Place the hammer with the working tool on the object to be worked on and let it go to work.

- If the working tool is jammed in the material to be broken up, do not apply any force to the hammer which causes expansion of the end spring. If the spring is tensioned for this reason, the hammer is not accepted for warranty repair.

How to properly assemble a jackhammer

in turn trigger consist (2):1. the handle is made of nylon or silumin;2. anti-vibration washer;3. spring;4. washer;5. spool starter;6. plug;10. cup;18. nipple. for compressed air supply (working pressure 0,4.0,5 MPa );

air distribution mechanism consists of:7. valve box;8. ring valve;9. valve seat;11. The protective apron that covers the exhaust ports;

percussion mechanism consists of:12. piston. striker;13. barrel. the main and the most expensive part of the hammer, is made of alloy steel with polished inner bore and drilling of longitudinal holes for the compressed air supply into the barrel;14. damper;15. bar;16. peak. actuator, has a length of 350. 450 mm and is made of carbon steel U7. У8;17. retaining spring to keep the pike from falling out when the hammer is moved and at the same time the pike can be moved along the hammer axis.

The operating principle of the pneumatic hammer is based on the reciprocating. progressive movement of the piston. of the firing pin. stroke. of the striker when striking the peak is called the working stroke, the reverse stroke. idle.

Working principle of starting mechanism. On pressing the handle 1 the spool 5 moves and compressed air flows through the nozzle 18, channels cup 10 to the valve body 7 of the air distributing mechanism.

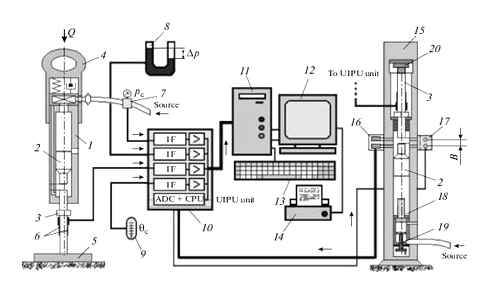

The principle of operation of the air distribution mechanism is shown in figure 2.3.Idle stroke. When reaching the valve box 7 compressed air reaches the ring valve 8. Through channels 19 in barrel 13 compressed air flows to the striker piston (3 a). Pressure under the piston.by the striker increases and above it decreases, because the compressed air will escape through the exhaust ports 20. Due to difference of pressure the ring valve overflows, opens an inlet port 21 and closes aperture 22 of the valve seat 9.

The striker piston moves upwards, passes the outlet holes 20 (fig. 2.3 b) the pressure below it decreases and above it increases. The ring valve is overloaded. The piston begins to move. of the striker (Figure 2).3 в).

Working stroke. Under the action of compressed air, the piston striker rushes downwards, passes the outlet openings 20 and strikes the peak 16. Compressed air above the percussion piston exits into the exhaust ports of. The pressure above the striker piston drops sharply and the ring valve is overloaded (Fig. 2).3 г). Pressure rises below the striker piston. Piston idling begins. of the striker. Thus, the valve changeover is due to the difference in pressure in the valve box above and below the valve when the exhaust ports are opened by the piston. by the striker.

Maintenance of demolition hammersThe demolition hammers received at the site should be disassembled, cleaned of grease and dust, washed in kerosene (diesel fuel), assembled, lubricated, and tried out. As a lubricant recommended industrial oil I20A with the addition of 25. 40% kerosene (diesel fuel).The hammer is lubricated during operation by means of an automatic grease gun. If there is no automatic grease gun, lubricate the hammer by pouring 30. 40 г. lubricating fluid in the nozzle;. lubricating oil in the nozzle. Lubricate with grease at least every 2 hours of operation.Prophylactic inspection and repair of hammers shall be carried out in the mine workshops at least every 150. 200 hour operation.

Safety rules for the operation of demolition hammers

Before you start work you should check:. condition of tunnel face and make sure that the face is reliably fastened;. serviceability of hammers;. fastening of spade and absence of its bending;. looseness of spade in the shaft box. Radial clearance between the spade shank and the axle box must not exceed 0.25 mm;- air supply hose fastening;- oil presence in the oil seal. It is forbidden: – work with chipping hammer without retaining spring or cap;- switch on hammer if there is no contact of chisel with bottomhole (idle work);- switch on hammer with impact.

2.1.2. GEORATORSPeerators refer to mining machines percussively. rotary action and are designed for drilling boreholes and bores with a diameter of 20. 150 mm in rocks of any strength.

Peorators are classified by the following main features:

According to the type of energy consumed:- electric. pneumatic torches, which are the most widely used due to their large dimensions and weight. pneumatic submersible pumps are the most widely used because of their complicated design. pneumatic torches, which are the most widely used. 2. By design:- Mobile (PP) work together with pneumatic pads;- Column (PC) are produced as a set with feeders;- Telescopic (PT) for drilling of rising boreholes and holes.3. By the way of drill bit rotation:- with dependent rotation;- with independent rotation.4. By design of air distributing mechanism:- with spool valve;- with valveless distribution.5. By frequency of blows:- Normal (1800 beats/min);- Rapid blows (2300 and more).6. By way of cleaning the borehole from drilling fines:- with washing;- with blowing;- with dust exhauster.

The marking of the gator contains information about its classification. Refer to Figure 2 for the marking of the peorator with respect to classification.4

For example, for the PP35VB peorator, where:P. peorator;P. portable;35. impact energy, J. rinsing;B. lateral method of water supply for cleaning of borehole from drill fines.

The following characteristics are characteristic of pneumatic peorators:– Rated pressure of compressed air. 0.5 MPa.- Air flow rate for:. portable 2,8. 3.5 m 3 /min;. telescopic 3,3. 4,5 m 3 /min;. column hammer 9.0. 13 m 3 /min.

Design and principle of operation of the pneumatic torchThe design of the torch is shown in Figure 2.5. The torch consists of the housing 1, control mechanism 2, vibration-damping device 3, noise suppressor 4, a device for cleaning of borehole from drill fines and dust suppressor 5.

SAFETY MEASURES

3.1. Do not operate the hammer as a crowbar if it is not turned off.

3.2. It is not allowed to point the hammer with the spade at yourself or other workers when trying it out or working.

3.3. Do not try the hammer “on hands” without the end spring.

3.4. During the work, check the tightness of the threaded joints of the pipe fitting with the pipe fitting, the cap nut with the pipe fitting.

3.5. The exhaust air from the exhaust openings must not come into contact with the operator’s hands.

3.6. The air inlet hose should be secured to the nipple with a special hose clamp to prevent the hose from coming loose.

3.7. Since the hammer is source of harmful factors of production, namely noise, vibration and dust, it is recommended when working with them to use personal protective equipment, namely:

- To protect the hearing should be applied personal protective equipment in accordance with GOST 12.4.051-78 “SSBT. Personal hearing protection equipment. See “General Specifications”;

- e.g., anti-noise earmuffs or ear muffs;

- Vibration damping springs of a handle are provided in hammers design. Additionally antivibration gloves may be used for hand protection from vibration in accordance with GOST 12.4.002-74 “SSBT. Personal hand protection from vibration. General Technical Requirements;

- To protect respiratory system in conditions of considerable dustiness it is necessary to use respirators such as ShB-1 “Lepestok”, “Astra-2”, “Kama-200” or similar.

The permissible total time of work with the hammer, taking into account noise and vibration levels, is 6 hours.

In this case the mode of operation should be as follows. 1 hour of work, 20 minutes break.

The principle of operation of the tool

The main feature of the respirator is that it makes a great impact during the working process. Impact energy is an important characteristic of this type of tool. When calculating it the number of blows carried per minute of operation time is taken into account, as well as the energy output during the same time interval.

Modern demolition breakers have a rather simple design. The striker located inside the housing performs oscillatory movements, thanks to its drive. The mechanical impulses during its work are fed to the working body of the tool, the pick, which performs a rapid reciprocating motion, due to which the material is broken.

The tool produces rather rough energy, which causes the operator to feel the strong vibrations and noise. To minimize these vibrations, the striker should be started up with the necessary protective measures.

The electric version of the bumper works a little differently. Here, too, the striker has a rotor-driven striker, which is rotated by an electric motor. The mechanical movements of the striker are transferred to the pick. Although this tool is one of the most sought-after not only by professional builders, but also by home craftsmen, it has a number of significant drawbacks. During operation of the electric motor can produce sparks, so it is prohibited to work with an electric bumpers in areas with high fire safety. Another disadvantage is the need for power supply.

Top 5 medium class electric demolition hammers

Which chipping hammer would you recommend to other users??

#5 “Zubr ZM-1500EK”

The fifth place of the rating is given to the model with the Russian-speaking name and quite democratic price. Behind the name, however, still hides a Chinese company, but it is believed that it conducts the assembly of domestic developments. I don’t know if this is true, but it turned out to be a really good model, a “good worker”.

The main characteristics are shown in the table

| Feature Name | Figures |

| Tool weight, kg | 10.04.2019 |

| Drive power, W | 1500 |

| Unit impact force, J | 25 |

| Shock frequency, times per minute | from 900 to 1800 |

| Type of tooling chuck | SDS-Max |

| Vibration level, m/s² | 19.95 |

| Noise level, dB | 84 |

| Dimensions (without spade), mm | 160×390×660 |

#4 “AEG MH7E”

The fourth place in our rating is also very honorable. And proof of this is an excellent model of the German “World Electric Company”. demolition hammer “AEG MH7E. It handles all tasks typical of the medium class with ease.

An excellent model with many advantages. “AEG MH7E”

The main characteristics of a jackhammer:

| Feature name | Indicators |

| Tool weight, kg | 7 |

| Drive power, W | 1500 |

| Power of single blow, J | 10.5 |

| Frequency of blows, times per minute | up to 2700 |

| Chuck type for tools | SDS-Max |

| Dimensions (without chisel), mm | 185×465×590 |

#3 “Hitachi H60ME”

Without such “authorities” as “Bosch” and “Makita” this model could pretend for the first place. It has everything necessary for this. excellent ergonomics, considerably high impact force, electronic frequency regulation, etc.п. In a word, a full-fledged high-quality Japanese development.

Pneumatic Hammer Internals

An excellent choice would be a demolition hammer “Hitachi H60ME”

| Features name | Figures |

| Tool weight, kg | 11.6 |

| Drive power, W | 1500 |

| Force of a single blow, J | 26.5 |

| Impact frequency, times per minute | 1500 to 2100 |

| Chuck type for tools | SDS-Max |

| Noise level, dB | 99 |

-excellent “destructive abilities”-high impact energy along with considerable frequency;

#2 “Bosch GSH 5 CE PROFESSIONAL

an interesting picture: in terms of its size and weight, this demolition hammer is closer to the initial, lightweight category. But by its performance capabilities this tool can compete with many representatives of the middle class. This model showed good results and at removal of old coatings, and at cutting walls, and removing the old screed, and even at cutting apertures in the ferro-concrete parts of the house construction.

“The Bosch GSH 5 CE PROFESSIONAL is a compact demolition hammer with a lot of power

| Feature name | Dimensions |

| Tool mass, kg | 6.2 |

| Drive power, W | 1150 |

| Force of a single blow, J | 8.3 |

| Impact frequency, times per minute | up to 2900 |

| Type of chuck for tools | SDS-Max |

| Noise level, dB | 86 |

| Dimensions (without spade), mm | 105×235×480 |

Hammer breaker Bosch GSH 5 CE PROFESSIONAL

#1 “Makita HM1203C”

Getting to know the “champ”. High power and maximum convenience in work. all this makes this model extremely popular among professional builders and finishers. Let’s add real Japanese quality and the picture becomes clear. And that’s with practically no negative feedback and minimum complaints in the service center.

PREPARATION AND WORKING PROCEDURE

8.1. The hammers received from a factory or from warehouse after a long period of storage should be disassembled, details should be cleaned from grease and carefully washed in kerosene, and assembled again.

8.2. Check for free movement of the firing pin in the barrel by turning the hammer vertically.

8.3. Make sure the intermediate link is screwed tight and secured with a stopper.

REMEMBER that if this link is loose and there are gaps in the air distribution unit, the hammer performance will be severely impaired.

Makita HM0810TA jackhammer Hindi nagha hammer?

8.4. Check that the handle can move freely.

8.5. Connect the hose from the hammer to the filter and nozzle lubricator in the compressed air supply before beginning work. If there is no grease nozzle, inject grease through the nipple. Lubricate the hammer periodically as you use it to ensure consistent lubrication of the moving parts. Lubricate a new hammer 3 to 4 times per shift during the first two weeks of operation. Lubricate a worn hammer at least twice per shift.

8.6. Clean the shank of the spade of dirt, put the rubber bushing on the spade, insert the spade into the hammer and secure it with the end spring by screwing it onto the barrel until it stops, so that the lock hits the corresponding groove of the barrel.

8.7. Blow through the hose with compressed air and make sure it is clean and dirty before attaching it to the hammer nipple. Make sure the sleeve is securely fastened and that the operating air pressure is at least 0.4. 0,55 MPa.

8.8. Hold the hammer down while operating the spade.

8.9. When not in use, keep the hammer away from dust, water, etc.п.

HAMMER COMPOSITION

A list of the main parts and assemblies included in the hammer is shown in Table 1.

| № | Name | Quantity | № | Name | Qty |

| 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. | Intermediate link Barrel Handle Valve box Seat Cover Pin Belleville Spring Valve Spring | 1 1 1 1 1 1 2 1 1 1 | 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. | Retaining ring Striker Lokewell Lokewell washer End spring Nipple Sleeve nut Locking pin Sleeve Silencer | 1 1 1 1 1 1 1 1 1 1 |

How it Works?

Compressed compressor air flows through a hose into the device, including the mechanism in the handle. Valve spring provides resistance to pressure. The valve is ajar along with the air distribution system openings. The strikers are set in motion by the air mixture hitting the upper and lower sections of the cylinder alternately. This results in fast, strong up and down movements of the tip. The effective work of the air hammer depends on the force and speed of movement.

The device starts to work under the effect of the air mixture.

Operational properties

The table shows technical characteristics of some kinds of hammers made in Russia. Note to the table: MOP. pneumatic hammer; BC. concrete breaker:

| Name | Energy of one blow, J | Number of strokes per second | Pressure, Atm | Power, W | Weight, kg |

| MOP. 2 | 39 | 22,5 | 3-5 | 875 | 7,4 |

| MOS 3 | 44 | 20,5 | 3-5 | 905 | 7,8 |

| MOS. 4 | 55 | 17 | 3-5 | 945 | 8,5 |

| BK-1 | 65 | 19 | 3-6 | 1235 | 11,5 |

| BK-2 | 75 | 15,5 | 3-6 | 1240 | 12,6 |

| BK. 3 | 95 | 13 | 3-6 | 1300 | 13,3 |

According to the way the mechanism is activated there is a difference between volumetric and turbine air tools. the first ones are activated by a sharp expansion of the air in the chamber; the second ones are activated by the rotation of the turbine. The heavier the weight of the device, the heavier the concrete it will break. There are 5 to 15 kg of equipment. Tools and attachments should be used for their intended purpose in each case.

Devices differ in weight, which determines what material they can work with.