How to properly charge the interskol screwdriver battery

Well, a little about recovery:

Rating: 4.0 / 5 (3 Votes)

Screwdriver battery. How to charge correctly, 4.0 out of 5 based on 3 ratings

How to Properly Charge the Interskol Screwdriver Battery

Working with Ni Cd Screwdriver Batteries.

The diary entry was created by the user Andrey-AA, 11/07/14.

Screwdriver battery charger

How to charge a screwdriver without a charger | Tools

Screwdriver Battery. How to Charge Properly

It would seem that charging a battery for a screwdriver is a simple process. Just insert the battery into the standard device and wait for the green LED to turn on instead of the red one. Then we take out the battery, and you can work. And in the work of the screwdriver there are no problems. it still works, and everything also successfully tightens and unscrews self-tapping screws, screws, screws. But let’s take a closer look at how the screwdriver battery works. How do I charge the battery correctly? You just need to understand what its principle of operation is based on.

Interskol screwdriver charger

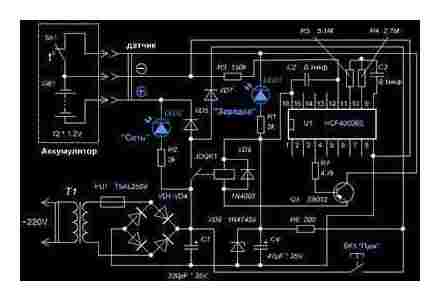

The power section of the screwdriver charger is a power transformer type GS-1415 designed for a power of 25 watts.

A reduced alternating voltage of 18V is removed from the secondary winding of the transformer, it follows to a diode bridge of 4 diodes VD1-VD4 of type 1N5408, through a fuse. Diode bridge. Each 1N5408 semiconductor element is rated for forward currents up to three amperes. The electrolytic capacitance C1 smooths out the ripple appearing in the circuit after the diode bridge.

The control is implemented on the HCF4060BE microassembly. which combines a 14-bit counter with oscillator components. It drives a bipolar transistor type S9012. It is loaded on a relay type S3-12A. Thus, a timer is schematically implemented, which turns on the relay for a time of charging the battery for about an hour. When the charger is turned on and the battery is connected, the relay contacts are in the normally open position. HCF4060BE receives power through a 12 volt zener diode 1N4742A, because about 24 volts goes from the rectifier output.

When the Start button is closed, the voltage from the rectifier begins to follow to the zener diode through the resistance R6, then the stabilized voltage goes to pin 16 of U1. The S9012 transistor, which is controlled by the HCF4060BE, turns on. The voltage across the open junctions of the S9012 transistor follows the relay coil. The contacts of the latter are closed, and the battery begins to charge. The protective diode VD8 (1N4007) bypasses the relay and protects VT from a reverse voltage surge that occurs when the relay winding is de-energized. VD5 prevents the battery from discharging when the mains voltage is disconnected. With the opening of the contacts of the Start button, nothing will happen, because the power goes through the VD7 diode (1N4007), the VD6 zener diode and the quenching resistor R6. Therefore, the microcircuit will receive power even after the button is released.

A replaceable typical battery from a power tool is assembled from separate series-connected nickel-cadmium Ni-Cd batteries, each of 1.2 volts, so there are 12 of them. The total voltage of such a battery will be about 14.4 volts. In addition, a temperature sensor has been added to the battery pack. SA1 it is glued to one of the Ni-Cd batteries and adheres tightly to it. One of the terminals of the thermostat is connected to the minus of the storage battery. The second pin is connected to a separate, third connector.

When the Start button is pressed, the relay closes its contacts and the battery charging process begins. The red LED lights up. An hour later, the relay with its contacts breaks the battery charge circuit of the screwdriver. The green LED lights up and the red one goes out.

A thermal contact monitors the battery temperature and breaks the charging circuit if the temperature is above 45. If this happens before the timer circuit works, this indicates the presence of a memory effect.

Indicators on screwdriver chargers

What does the green LED indicate? In most cases, it shows that some electric charge current is still passing through the battery. When the potential difference of the battery equals the voltage of the charger, the current stops and the green light comes on. When the charging current is still flowing through the battery, the red light is on. complex models of chargers have a special electronic control system that monitors not only the charging current, but also the potential difference of each element, and the magnitude of the charging current.

How to charge lithium screwdriver batteries

A lithium battery screwdriver is almost always an upgrade. Whereas Ni-Cd cells had the same charging requirements, they are now the opposite. First of all, you need to purchase or assemble a charger, specifically for the power-hungry lithium batteries of a screwdriver with a 18650 form factor. The charging scheme is used in two stages CC / CV.

Charging the lithium battery of the screwdriver is optimal when 20-50% of the capacity remains. one stick on the indicator. The more often you charge, the more stable the voltage at the terminals and the longer the life of the energy source. The more even the voltage at the terminals, the more cycles the lithium battery of the screwdriver will withstand.

| Discharge depth,% | Number of charge cycles |

| one hundred | 500 |

| fifty | 1500 |

| 25 | 2500 |

| ten | 4,700 |

If there are 2 batteries in the screwdriver, remove one, charge to 50-60% and keep in reserve. But always charge the second one at the end of work, even by 10%. The best temperature for charging is 15-25 0 C. At minus, the battery of the screwdriver will not charge, but it can work up to 10 0.

How to charge the lithium battery of a screwdriver with a charger depends on the scheme for collecting the battery from the cans. In any case, the voltage on the charger should be equal to that declared for the device, and the current strength is 0.5 C at the first stage. On the second, the terminal voltage is stable, and the current falls, until the end of the process.

How to charge a 12 volt lithium battery

Each lithium battery is a sealed product of a cylindrical, prismatic shape, for Li-pol in a soft package. All of them have a voltage of 3.6-4.2 V and a different capacitance, measured in mA / h. If you collect 3 cans in series, you get a battery with a voltage at the terminals of 10.8. 12.6 V.The capacity during sequential charging is measured by the weakest lithium battery in the bundle.

How to properly charge a 12 volt lithium 18650 battery or Pol, you need to know. To return the container to the device, you must use a charger with a controller. It is important to have in the PCM assembly for each can, protection against under- and overcharging. Another scheme of unprotected lithium-ion batteries is the installation of a PCB. a control board, preferably with balancers, for uniform charging of the cans.

On the charger, you must set the voltage under which the battery operates, 12.6 V. On the dashboard, the number of cans and the charging current are set at 0.2-0.5 C.

How to charge, we suggest watching the video, charging method for 2, 3 lithium 18650 batteries connected in series. Using a budget charger.

Charging options for lithium-ion lithium polymer batteries:

- Charger purchased with the device.

- Use the USB connector from electronic equipment. computer. Here you can get a current of 0.5 A, charging will take a long time.

- From the cigarette lighter by purchasing an adapter with a set of ports. Choose the one that matches the parameters of the 12V battery.

- Universal charger “frog” with a dock for installing the gadget. How to charge? There is a charge indication panel.

Experts advise using a standard charger to charge lithium batteries, the rest. only in force majeure circumstances. However, how to charge a lithium battery without a standard charger, you need to know.

How charging parameters are monitored

Since lithium batteries operate in a narrow range of voltage variation at the terminals, they cannot be recharged above 4.2 V and discharged below 3 V. The charge controller is installed in the charger. But each battery or battery has its own breakers, PCB board or PCM protection modules. In the batteries, it is precisely the protection against one factor or another that is installed. In case of violation of the parameter, it must turn off the bank, break the circuit.

A controller is a device that must implement control functions. switch CC / CV modes, control the amount of energy in banks, turn off charging. At the same time, the assembly works, heats up.

Homemade charging circuits used for lithium batteries

- LM317 is a simple charger circuit with a charge indicator. Does not power from the USB port.

- MAX1555, MAX1551- special for Li Batteries, install in phone to USB power adapter. There is a pre-charge function.

- LP2951- stabilizer limits the current, forms a stable voltage of 4.08-4.26V.

- MCP73831. one of the simplest circuits, suitable for charging ionic and polymer devices.

If the battery consists of several cells, they are not always discharged evenly. When charging, you need a balancer that distributes the charge and ensures that all the cells in the battery are charged evenly. The balancer can be separate or built into the battery connection diagram. The battery protection device is called BMS. Knowing how to charge devices, understanding the circuits, you can do it yourself with a circuit of a protective device for a lithium battery.

How much to charge a lithium battery

The charging time of the batteries is determined by the process of restoring capacity. Distinguish between full and partial charge.

Capacity is measured in ampere-hours. This means, if you apply a charge numerically equal to the capacity, then in an hour the required voltage will be created at the terminals, and the energy reserve will be 70-80%. If the capacitance is measured in units of C, a 1C-2C current should be applied during fast charging. Fast charging time about an hour.

For a complete charging cycle of batteries from several cells connected in series, 2 stages are used. CC / CV. The CC phase lasts until voltage appears at the terminals. equal to the worker, in volts. The second stage: at a stable voltage, a current is supplied to the jar, but with an increase in capacity, it tends to zero. Charging time takes about 3 hours, regardless of capacity.

How to charge lithium batteries

Lithium batteries are a galvanic pair in which lithium salts serve as the cathode. Whether it’s a lithium-ion, lithium-polymer dry cell or a hybrid battery, the charger fits everyone. Products can be in the form of a cylinder, or a hermetically sealed soft package, the charging method for them is general, corresponding to the peculiarities of the electrochemical reaction. How to charge a Li-ion battery?

How to properly charge lithium batteries

There are several schemes for charging lithium batteries. The two-stage charging developed by SONY is more commonly used. Devices with the use of pulse charging and stepwise charging, as for acid batteries, are not used.

Charging any type of lithium ion or lithium polymer battery requires strict voltage compliance. One cell of a charged lithium battery should have no more than 4.2 V. The nominal voltage for them is 3.7 V.

Lithium batteries can be charged quickly, not fully? Yes. You can always recharge them. Battery operation by 40-80% capacity extends battery life.

Lithium battery two-stage charging circuit

CC / CV circuit principle. constant charging current / constant voltage. How to charge a lithium battery using this scheme?

The diagram before stage 1 of charging shows a pre-stage for restoring a deeply seated lithium battery, with a terminal voltage of at least 2.0 V. The first stage should restore 70-80% of the capacity. The charging current is chosen 0.2-0.5 C. It is possible to accelerate charging, with a current of 0.5-1.0 C. (C is the capacity of lithium batteries, digital value). What should be the charging voltage in the first stage? Stable, 5 V. When the voltage at the battery terminals 4.2 is reached, this is a signal to go to the second stage.

Now the charger maintains a stable voltage at the terminals, and the charging current decreases as the capacity rises. When its value decreases to 0.05-0.01 C, charging will end, the device will turn off, preventing overcharging. The total recovery time for a lithium battery does not exceed 3 hours.

If the lithium-ion battery is discharged deeper than 3.0V, a “jolt” is required. This consists in charging with a small current until the terminals are 3.1 V. Then the usual circuit is used.

Accumulators and batteries

Energy storage information website

We charge the battery of the Interskol screwdriver

The service life of the batteries of an electric tool is reduced from their improper use, but correct charging of the interskol screwdriver battery can even significantly increase this life.

Charging rules for Ni-Cd and Li-Ion batteries

In order for the batteries for the Interskol nickel-cadmium type screwdriver to last as long as declared by the manufacturer, and even more, it is necessary to charge them correctly for the first time.

- The battery is discharged until completely depleted, waiting for the spontaneous shutdown of the screwdriver.

- Connect the charger. The charging process should continue until the battery is 100% full.

- The screwdriver is used in work until it is discharged again before turning off, and then fully charged again.

This procedure must be repeated 1-2 more times. Subsequently, Ni-Cd batteries are always fully charged, and it is necessary to set them up for charging when the charge indicator drops to 10%.

Important! Nickel-cadmium batteries have the disadvantage of a “memory effect”. It manifests itself when an incompletely discharged battery begins to charge ahead of time. For example, the battery was depleted to 45%, and it was connected to the charger. After that, a fully charged battery will always work only until the charge decreases to those same 45%, that is, in fact, its capacity will almost halve. This circumstance must be taken into account and the timing of the start of recharging must be strictly observed.

For Lithium Ion Nutrients, Observe the Following Rules.

- The charger is connected when the battery is discharged to 20-10%, a stronger discharge harms it and reduces the service life.

- Overcharging has an extremely negative effect on lithium cells. As soon as the fullness mark reaches 100%, the procedure must be stopped immediately.

- Calibration should be performed periodically (about three times a year). The battery is completely discharged and charged, repeated 1-2 times.

How to properly charge the interskol screwdriver battery: other information

The temperature environment during charging also affects the batteries. Its acceptable range: minus 10, plus 40 degrees, optimal: 10-35 degrees above zero.

After the end of the process, it is imperative to disconnect the charger from the network and remove the battery from it. The process of replenishing the charge itself lasts for a different amount of time, depending on the model of the device and can be from one to seven hours.

For storage, lithium nutrients are left in a slightly discharged form (about 70%), while they should be outside of any devices. Even at rest, the charge, albeit slowly, is lost, so if the downtime is delayed, the battery needs to be recharged when its fullness reaches 20%.

Nickel-cadmium batteries, on the contrary, are stored discharged, otherwise their efficiency is greatly reduced.

To find out how to charge the battery of a hitachi screwdriver, you need to determine what type of battery cells it is equipped with. It can be nickel-cadmium.

If the battery has ceased to hold a charge, and it is difficult to quickly acquire a new one in the near future, the situation can be corrected if you know how to restore the battery.

How to charge a screwdriver battery

Recently, screwdrivers have become indispensable devices for quickly repairing removable structures, screwing in, unscrewing screws, working with a drill, grinding with a carpenter’s attachment and other small repair activities.

Hydride batteries

Hydride batteries have little or no environmental impact, but have less ability to remain charged when idle. Their energy consumption can be significantly reduced in as little as 30 days.

In view of such technical characteristics, the masters advise to always put the device on charge before use, and if you are going to leave for work and take the device with you, then do not forget to take the charger. Metal hydride batteries won’t last long without a charger. Not only will you not be able to do the intended work, but you also run the risk of making it completely unusable.

The role of the individual characteristics of metals in the composition of the battery

The chemical composition of the battery is almost its main characteristic, which determines the type of charging. Basically, it depends on the metal used how to properly carry out the charge-discharge cycle so that the screwdriver will serve you faithfully for many years. Based on the properties of the ions of the substance used in the battery, several types of batteries are distinguished.

Nickel batteries

Nickel batteries with an admixture of cadmium (Ni Cd). excellently hold a charge, work for a long time, provided that consumers do not begin to uncontrollably charge the device at the slightest decrease in the energy level. The capacity of the battery will drop and the unit will run for less time if charged frequently. It is better to wait until the battery is completely discharged and only then connect the charger.

You don’t have to worry about how to charge the screwdriver for a long time if you buy a low-weight, energy-intensive Ni Cd battery. Many craftsmen prefer just such models of the instrument. Charge the device to the maximum maximum and work quietly until the energy mark drops to the minimum possible. In the case of nickel batteries, the principle of “two extremes” applies. Even after purchasing a screwdriver, it is recommended that you charge it completely and only then start using it. When the device will not be used for a long time, it is better to leave it in a half-charged state. In this case, after a long lull, you will first have to fully charge the battery and only then start to work.

How to properly charge the battery of a screwdriver

Proper charging differs from device to device and depends on specific factors:

- residual amount of energy (for some models it is recommended to wait until full discharge or, conversely, not to bring it to the limit);

- the chemical composition of the battery, that is, the characteristics of certain metals included in it (metal ions are extremely sensitive to the effects of heat, and prolonged, uncontrolled effects of energy can adversely affect the properties of conductors / semiconductors, which will lead to a rapid failure of the battery);

- charger type (impulse / conventional).

Lithium batteries

Lithium batteries also have good capacitive performance. Li batteries are more modern technology than nickel ones, because they can be charged without waiting for a full discharge. In addition, recharging does not take long and the working session lasts longer than the Ni Cd version.

Leading manufacturers of electrical appliances, including screwdrivers, are trying to implement the use of lithium ions in batteries, which allows them, in turn, to guarantee customers a long-term serviceability of the charger and the device itself.

Despite all their modernity, the Li models are not without flaws. They are more expensive in price and are very capricious at low ambient temperatures, which negatively affects their energy consumption, stability and duration of action until the next discharge (it noticeably decreases in cold weather). For long-term storage of these models without work, it is also better to have at least 50% charge and recharge the battery with energy once a month or one and a half.

Why the battery of the device quickly runs out?

Since the screwdriver is not a stationary device and needs to be moved from place to place, it cannot be connected to the mains at the time of operation and is charged mainly after use. In fact, it turns out that after each long-term use, the question arises: how to charge the screwdriver’s battery so that it does not fail in a matter of months, but lasts for many years. Correct fulfillment of the requirements for the duration of the charging-discharging cycles of the battery plays a paramount role in this.

How long does it take to charge the screwdriver

The indicator is individual. It varies from 30 minutes to 7 hours and depends on the capacity. Usually the time is written in the manuals for use.

Most chargers are equipped with an indication, so you can see how many percent are left until the end of the charge.

Car charger

It is not necessary to use this method all the time due to the mismatch of the parameters. A car charger is suitable if it is equipped with voltage and voltage regulation elements. You just need to set the indicators correctly: the current is set as 0.5-0.1 of the total capacity of the battery.

External sources of electricity

The option described above also belongs to the category of external devices for charging the battery. Alternatively, you can connect the instrument to a different power source, such as an old battery, to act as a power bank. The main thing is that it is working and has identical parameters. But here remarkable knowledge of electrical engineering is required: it is necessary to create a chain with the help of crocodile adapters. You will need a 10 amp fuse, and you will also need to use oversized wiring.

Tip: if you need a power tool to work for a long time, it is better to select a model among professional options. Their batteries are much more powerful than household models.

Tester

A device that allows you to diagnose a malfunction of elements on your own.

The main types of such devices:

- Control lamp (dial tone). equipped with two wires and makes it possible to determine the breaks in the wiring of the electrical appliance.

- Pointer. a device with a digital scale and an arrow. Such models are not very convenient to use. So that the numbers are clearly visible, the measurement scale should be half a page in size. In addition, such testers are often distinguished by confusing graduations and can only be operated in a horizontal position.

Tip: If you need an inexpensive multimeter, 94W101 will do.

- Digital. with LCD display. The scale only shows absolute values. The switch, as in the previous case, is manual. The tester is not suitable for AC.

- Automatic. as the name suggests, this type of testers does not require manual adjustments of the regulator position. It is enough to indicate the required value using a special button.

Universal charger

An option that will fit almost any battery. Usually this is a model with crocodile clips. Often the user has the ability to set the required values. The method will not harm the battery, since the charging process will proceed in the same way as with the complete charger.

Charging methods without using a dedicated charger

If for some reason the memory from the set is out of order, you can use a third-party device.

In this case, it is important to take into account the characteristics of the battery when selecting such a charger. Voltage and capacity must match. Otherwise, the battery could be damaged.

Upgrading dead Black and Decker Screwdriver to Li-ion – 282

Interesting: The DF457DWE impact screwdriver comes with 2 batteries. If one is discharged, you can simply insert the second and continue working.

If there is no charger at all, there are three alternative methods.

Nuances of charging various types of batteries

Most of the features that need to be taken into account are described in the first section. Here. about how long the power tool should be kept on charge.

How to discharge the battery

The battery of a screwdriver can be discharged naturally. Namely: just let it run idle or with a small load. Loss of power or torque already indicates a complete discharge of the battery. Further discharge can only harm the battery, and a complete discharge will significantly reduce its performance. In lithium-ion models, there is a simple circuitry that will not allow the battery to completely discharge or overheat.

How to properly charge the battery

You can find out the rules for charging the battery for each specific model of the screwdriver in the instruction manual. This must be done before using it. Let’s take a look at the advantages and disadvantages of different types of batteries. Each has its own characteristics of charging, discharging and storing for a long time.

In terms of composition, the most popular varieties are:

- Li-Ion lithium-ion

- Ni-Cd Nickel-Cadmium

- Ni-MH Nickel-metal hydride

The most common and affordable battery is nickel-cadmium (Ni-Cd). All manufacturers provide a wide range of models with just such batteries. Using their example, we will consider the basic rules of charging.

When charging a new battery or after a long period of inactivity, it may not be fully charged. This is a normal situation, although it may appear that there is some kind of defect. The battery will be fully charged after several full discharges. Such a battery has a so-called memory effect. That is, the ability to acquire a capacity that will be equal to the capacity of the first charge and discharge cycles.

To make the most of the battery capacity, it is recommended that the first five charge and discharge cycles be done completely. That is, fully charge after the device is completely discharged. It is recommended to charge the battery before first use, or when it does not provide the required supply voltage.

The battery may heat up slightly while charging. This is normal and does not indicate a problem. It must be charged in a heated room. The temperature can vary from 4 to 35 degrees. Store in a room with normal humidity at a temperature not lower than 5 degrees. The battery must be charged at least every 3 months.

Lithium-ion models are rapidly occupying their niche in the market. This is because they do not have a memory effect, and the charge rate is much higher than that of nickel-cadmium. You can recharge at any time without worrying about the battery capacity. The main disadvantage of lithium ion is the price. But for a professional tool, price is a priority indicator.

Nickel-metal hydride ones are found, but they are much inferior in popularity. The advantage of these models is that there is no “memory effect”. But there is a big drawback: high self-discharge. This is a phenomenon in which the battery itself discharges over time.

In terms of time, the charging speed of each individual device is individual for each individual screwdriver model. This information can be found in the instructions. For example, if it is an 18 V battery with a capacity of 1.5 A / h, then it takes 1 hour to charge. In this case, 14.4 V with a capacity of 2 A / h is charged for 3-5 hours. But do not keep the battery on charge for too long. On very long charges, the battery can become very hot and begin to lose its properties.

If you need to charge a screwdriver, but there is no charger (broken, lost, stolen. there may be different cases), then you can resort to using a universal charger. With this method of charging, you must strictly adhere to the instructions so as not to spoil anything.

It is important to understand that the charging time directly depends on the current strength (indicated on the charger). So, with a current of 400 mA, a 2 A / h battery will be charged for 5 hours. If the current is 2000 mA, the same battery will be charged in 1 hour. Weaker and more gradual charging increases the battery life. High charging current saves time, but the battery heats up more.

In some cases, you can charge the battery with a screwdriver using a car charger. Remember that car charging supplies 12 volts. Therefore, only 12-volt screwdrivers can be charged with it. In rare cases, 14.4 volts, but not more. And be sure to remember that the current strength should not exceed 1-2 A.

How to properly charge the battery of a screwdriver

One of the most versatile power tools in our time is the screwdriver. A variety of attachments, adapters and accessories makes it an indispensable assistant in any repair.

But the main advantage of the screwdriver is its mobility. Using a battery for a screwdriver allows you to work quickly and not worry about extension cords and sockets. On-site or just on the street. However, batteries have a limited lifespan. In order to extend the life of the battery, it must be properly charged.

If the battery overheats

Strong heating of the battery indicates either poor contact between the cells, or the failure of one storage cell. But you need to panic only if the temperature is very high (over 40 degrees), because charging the battery is always accompanied by the release of heat. Almost all devices are equipped with a temperature sensor, which does not allow overheating.

If the battery is heated over 40 degrees, this indicates a malfunction either in the temperature sensor, or in other elements of the battery. It is best to take the device for repair to diagnose and replace defective parts.

If your device is charging too quickly

Fast charging (like discharging) may indicate that the capacitive properties of the battery have already been reduced. This happens over time. On average, it is 2–4 years and depends on the intensity of the use of the instrument. The resource is measured in discharge-charge cycles. The battery appears to be outdated and needs a complete replacement.

- Ni-Cd Nickel-Cadmium is 2000 cycles

- Li-Ion lithium-ion. approx. 3000 cycles

- Ni-MH nickel-metal hydride. 1000 cycles

Decreased operating time may be due to mechanical damage.

I would like to note that when choosing a cordless screwdriver, it is very important to know the differences and features of the installed power source. There are professional and household tools. For household use, nickel-cadmium will be enough. But it is better to charge it once every 3 months when not in use. For permanent use, Li-Ion units are better suited. The price will be higher, but the convenience and reliability will be one level higher.

Should I charge before long-term storage??

Don’t use a screwdriver battery for a long time? Experts give the following recommendations.

- Nickel-cadmium batteries, before storing, must be discharged to the point where the screwdriver ceases to function at full strength. For long-term storage, it is necessary to carry out 3-5 full circles of charging / discharging.

- Nickel-metal hydride ones are provided with a higher self-discharge value, in contrast to the previous elements. Experts advise keeping them charged, and after a long break, put them on charge for a day. The capacity decreases after 200-300 charge-discharge cycles. Partial discharge allowed for this type.

- Lithium-ion devices are distinguished by the complete absence of the “memory effect”. The battery can be charged whenever you want. It is not recommended to completely discharge them, as a result, you can disable the protective circuit. Equipped with special controllers that switch off the element at high temperatures to prevent overload. You can keep the cell charged only 50%.

Battery types

In order for the battery to last a long time “like a clock”, you must first familiarize yourself with the instructions supplied with the device. It should be noted that screwdrivers differ not only in price, power, manufacturer, but are also divided into professional and semi-professional. Accordingly, batteries will also have different prices, quality and charge capacity. Professional types are equipped with more capacious power supplies, which will cost a level more, but will also last longer than normal ones. Manufacturers use various batteries in the manufacture of their devices, each of which is endowed with certain parameters and features that should be taken into account during recharging. Screwdriver batteries can be classified into the following types:

Lithium Li-Ion

They are considered the most powerful batteries. They charge quickly enough, and they also have a complete lack of memory effect. Recharging this type of battery is easy. There is no need to recharge it after a complete discharge, it is allowed to recharge as needed. The high cost and intolerance to low temperatures discourage many people from buying, so they are not too in demand. Charge batteries at temperatures between 10 ° C and 40 ° C. If the battery heats up during charging, it must be cooled to avoid further damage.

Nickel-cadmium Ni-Cd

Nickel-cadmium battery is endowed with compact dimensions and large capacity. By following the attached instructions, they can be recharged more than 1000 times. There is a memory effect, if you charge it before a full discharge occurs, this can reduce energy consumption. Before the first use, you need to charge and discharge the battery at least three times. In the future, it is also recommended to completely discharge and charge the device, this will make it possible to bring the capacity to the required operating state. The same rule applies when storing the instrument.

Nickel Metal Hydride Ni-MH

They belong to the newest generation of batteries, for this reason, the memory effect is somewhat weaker than the previous version, which is an undoubted advantage. The disadvantage of the NMGB is the highest self-discharge current. In order for the battery to function for a long time, it must be kept charged. In case of long-term non-use of the screwdriver (about a month), it must be completely recharged.

As you can see, each rechargeable battery is endowed with characteristic features, given which, it will be possible to properly charge the screwdriver.

Features of charging one type or another

The initial charging of the screwdriver is considered a very significant factor, since it depends on it whether the full capacity of the charge becomes active or not. Any type of battery has its own characteristic features of primary recharging. The process of recharging a nickel-cadmium battery is somewhat complicated. Initially, it needs to be recharged three times in a row, and so that the charge capacity remains full.

It is recommended that the nickel-metal hydride species be completely discharged the first time, and also fully charged. The circle of full charging / discharging is repeated 4-5 times, then you can safely charge and discharge the battery regardless of the full capacity.

There are no special rules for lithium-ion, the capacity remains unchanged for a long time.

Advice! Do not allow the power source to overheat over 50 degrees.

How to properly charge a screwdriver

The screwdriver is one of the most demanded tools used by professionals and amateurs. Using power screwdrivers is not always convenient, especially if you are away from 220 V. With a cordless tool, this problem is solved, you can move freely with it without dragging the cord along.

One of the main elements of any cordless tool is the battery, which ensures autonomous operation. But what is the correct way to charge the battery in order for it to last as long as possible? Further in detail in the article.

What is the optimal amount of time for charging?

The recharging period is usually indicated in the device manual. In most cases, the device has a special indicator that helps you understand how long it takes to charge. After charging is complete, disconnect it to avoid damaging the batteries. The average charge for a screwdriver is between 30 minutes and seven hours. Longest period for Ni-Cd 1.2 V, 250 mA feed approximately seven hours.

There are also two types of battery chargers: ordinary and impulse. Standard charging is most often completed with non-professional tools, the charge lasts about 3-7 hours. The impulse device is designed for professional models and is able to power the battery in a maximum of 1 hour.

Advice: The Interskol screwdriver is distinguished by its versatility, besides the main function, it can also be used as a drill.

What to do if the battery does not charge? (2 videos)

The reason may lie both in wear and tear and in the breakdown of the device. It often happens that the contacts between the terminals of the charger and the battery are broken. Then you can independently disassemble the “charging” and bend the terminals.

As you know, all contacts oxidize and get dirty over time; this is no exception for a screwdriver with a charger. This usually results in a significant reduction in charging time as well as in the duration of the power tool’s activity. To eliminate the oxide, you need to gently wipe the contacts with a special substance or, in extreme cases, with alcohol.

Very often nickel-cadmium batteries lose their capacity, especially when it comes to non-professional models. Experienced users prefer to overclock these batteries. First, the battery pack is disassembled and problem areas are found. Then they need to be recharged. It is better to immediately use a higher current than it should be, and then discharge it again. If the Ni-Cd still has electrolyte, the procedure can restart the power supply.

And some connoisseurs even use a car charger to recharge the battery.

How to properly charge a screwdriver

The screwdriver is one of the most demanded tools used by professionals and amateurs. Using power screwdrivers is not always convenient, especially if you are away from 220 V. With a cordless tool, this problem is solved, you can move freely with it without dragging the cord along.

One of the main elements of any cordless tool is the battery, which ensures autonomous operation. But what is the correct way to charge the battery in order for it to last as long as possible? Further in detail in the article.

Features of charging one type or another

The initial charging of the screwdriver is considered a very significant factor, since it depends on it whether the full capacity of the charge becomes active or not. Any type of battery has its own characteristic features of primary recharging. The process of recharging a nickel-cadmium battery is somewhat complicated. Initially, it needs to be recharged three times in a row, and so that the charge capacity remains full.

It is recommended that the nickel-metal hydride species be completely discharged the first time, and also fully charged. The circle of full charging / discharging is repeated 4-5 times, then you can safely charge and discharge the battery regardless of the full capacity.

There are no special rules for lithium-ion, the capacity remains unchanged for a long time.

Advice! Do not allow the power source to overheat over 50 degrees.

Battery types

In order for the battery to last a long time “like a clock”, you must first familiarize yourself with the instructions supplied with the device. It should be noted that screwdrivers differ not only in price, power, manufacturer, but are also divided into professional and semi-professional. Accordingly, batteries will also have different prices, quality and charge capacity. Professional types are equipped with more capacious power supplies, which will cost a level more, but will also last longer than normal ones. Manufacturers use various batteries in the manufacture of their devices, each of which is endowed with certain parameters and features that should be taken into account during recharging. Screwdriver batteries can be classified into the following types:

Lithium Li-Ion

They are considered the most powerful batteries. They charge quickly enough, and they also have a complete lack of memory effect. Recharging this type of battery is easy. There is no need to recharge it after a complete discharge, it is allowed to recharge it as needed. The high cost and intolerance to low temperatures discourage many people from buying, so they are not too in demand. Charge batteries at temperatures between 10 ° C and 40 ° C. If the battery heats up during charging, it must be cooled to avoid further damage.

Nickel-cadmium Ni-Cd

Nickel-cadmium battery is endowed with compact dimensions and large capacity. By following the attached instructions, they can be recharged more than 1000 times. There is a memory effect, if you charge it before a full discharge occurs, this can lower energy consumption. Before the first use, you need to charge and discharge the battery at least three times. In the future, it is also recommended to completely discharge and charge the device, this will make it possible to bring the capacity to the required operating state. The same rule applies when storing the instrument.

Nickel Metal Hydride Ni-MH

They belong to the newest generation of batteries, for this reason, the memory effect is somewhat weaker than the previous version, which is an undoubted advantage. The disadvantage of the NMGB is the highest self-discharge current. In order for the battery to function for a long time, it must be kept charged. In case of long-term non-use of the screwdriver (about a month), it must be completely recharged.

As you can see, each rechargeable battery is endowed with characteristic features, given which, it will be possible to properly charge the screwdriver.

Should I charge before long-term storage??

Don’t use a screwdriver battery for a long time? Experts give the following recommendations.

- Nickel-cadmium batteries, before storing, must be discharged to the point where the screwdriver ceases to function at full strength. For long-term storage, it is necessary to carry out 3-5 full circles of charging / discharging.

- Nickel-metal hydride ones are provided with a higher self-discharge value, in contrast to the previous elements. Experts advise keeping them charged, and after a long break, put them on charge for a day. The capacity decreases after 200-300 charge-discharge cycles. Partial discharge allowed for this type.

- Lithium-ion devices are distinguished by the complete absence of the “memory effect”. The battery can be charged whenever you want. It is not recommended to completely discharge them, as a result, you can disable the protective circuit. Equipped with special controllers that switch off the element at high temperatures to prevent overload. You can keep the cell charged only 50%.

What is the optimal amount of time for charging?

The recharging period is usually indicated in the device manual. In most cases, the device has a special indicator that helps you understand how long it takes to charge. After charging is complete, disconnect it to avoid damaging the batteries. The average charge for a screwdriver is between 30 minutes and seven hours. Longest period for Ni-Cd 1.2 V, 250 mA feed approximately seven hours.

There are also two types of battery chargers: ordinary and impulse. Standard charging is most often completed with non-professional tools, the charge lasts about 3-7 hours. The impulse device is designed for professional models and is able to power the battery in a maximum of 1 hour.

Advice: The Interskol screwdriver is distinguished by its versatility, besides the main function, it can also be used as a drill.

What to do if the battery does not charge? (2 videos)

The reason may lie both in wear and tear and in the breakdown of the device. It often happens that the contacts between the terminals of the charger and the battery are broken. Then you can independently disassemble the “charging” and bend the terminals.

As you know, all contacts oxidize and get dirty over time; this is no exception for a screwdriver with a charger. This usually results in a significant reduction in charging time as well as in the duration of the power tool’s activity. To eliminate the oxide, you need to gently wipe the contacts with a special substance or, in extreme cases, with alcohol.

Very often nickel-cadmium batteries lose their capacity, especially when it comes to non-professional models. Experienced users prefer to overclock these batteries. First, the battery pack is disassembled and problem areas are found. Then they need to be recharged. It is better to immediately use a higher current than it should be, and then discharge it again. If the Ni-Cd still has electrolyte, the procedure can restart the power supply.

And some connoisseurs even use a car charger to recharge the battery.

The main types of screwdriver batteries

Screwdriver batteries: lithium Li-Ion, nickel-cadmium Ni-Cd, nickel-metal hydride Ni-MH.

In professional models, which are more expensive, as a rule, batteries with a larger capacity are installed, so they can work without recharging for a much longer period of time. Most professional builders have a spare, pre-charged battery for uninterrupted work, but if the screwdriver is designed for simple housework, it is not necessary to have a second battery, although in some cases an additional screwdriver battery is included with the unit. There are 3 main types of batteries that are most often used in screwdrivers:

- lithium-ion;

- nickel-cadmium;

- nickel metal hydride.

Screwdriver battery connection diagram.

The most widely used today are nickel-cadmium batteries for screwdrivers. This type is distinguished by its rather compact size, relatively low cost and large charge capacity. The main drawback of these batteries is the same “memory effect”, but with proper use and recharging, batteries of this type can be recharged more than 1000 times, although it should be noted that even with proper use, the charge capacity will gradually decrease until it reaches a minimum. Among other things, it should be noted that such a battery contains highly toxic substances, therefore their production significantly harms the environment, which became the reason for their ban in many countries.

Nickel-metal hydride batteries are in second place in terms of frequency of use. Batteries of this type belong to a new generation, as they are completely safe for the environment. This type has a lot of advantages, the main of which is the absence of a “memory effect”. However, it is worth noting that they have a high self-charging current, and these batteries should be stored exclusively in a charged state, and if the screwdriver is not used for a month, it is necessary to discharge the device and recharge it.

Lithium-ion batteries are a relatively new product in the market for these products. They do not have a “memory effect”, therefore, they do not require adherence to recharge cycles to restore the charge capacity. It takes a very small amount of time to fully recharge these batteries, and the capacity of these funds is quite high. However, these batteries also have disadvantages, including reduced performance in cold weather and a rather high cost.

How and how much to charge the screwdriver battery?

Screwdrivers have long been invariably popular not only among professional builders, but also among ordinary people, because these units are indispensable when you need to screw something or, conversely, untwist it. The versatility of screwdrivers is the main reason for the popularity of these units, both in everyday life and in large construction, but all users of these units have a lot of difficulties when it comes to recharging the batteries, which are equipped with most models of screwdrivers.

Diagram of the structure of the screwdriver.

The thing is that with incorrect charging, the so-called “memory effect” appears, that is, under certain conditions, the charge capacity may decrease, and in the future the unit will be discharged less completely. As a rule, this effect occurs when a person tries to recharge an incompletely discharged screwdriver battery. Proper charging of screwdriver batteries has a lot of subtleties, so it is very important to consider all aspects of this matter so that the screwdriver retains its functionality and performance for a long time.

Features of charging screwdriver batteries

Charger circuit for a screwdriver.

A very important point is the first charging of the screwdriver, since it depends on it whether the full charge capacity will be activated. Each type of battery has its own characteristics of primary charging. The biggest challenge is charging nickel-cadmium options. Their first recharging should be three times so that the entire charge capacity is filled. Thus, after the purchase, the unit must be fully charged, then turned on and left to work until it is completely discharged, then you need to put it back on to recharge and discharge again, and so on 3 times.

For the first time, the nickel-metal hydride version should be completely discharged immediately, because, as a rule, when you buy such a battery has a small charge, after that you need to leave it to fully charge. Recharge this type of battery only after it has been completely discharged. The full charge-discharge cycle should be considered the first 4-5 times, after which you can additionally recharge the batteries, even if they are not completely discharged.

Screwdriver specification table.

Lithium-ion batteries are more modern, so there are no special requirements for their recharging, since in any case their capacity does not decrease.

During the first and subsequent recharging, it must be borne in mind that the most optimal recharging effect can be achieved only if this process takes place at a temperature of 10 to 30 ° C. Among other things, it should be noted that when charging, some types of batteries may begin to heat up, which can extremely negatively affect the entire battery. Do not allow the entire battery to overheat above 50 ° C. After work, it is best to store the battery separately from the screwdriver, although this is not necessary.

How long does it take to charge screwdrivers?

Battery composition.

Important issues regarding charging screwdriver batteries include the time it takes to fully charge the battery. Many people think that charging a screwdriver battery is worth until it heats up, but in fact this is a sure way to reduce the charge capacity and performance of the entire unit. It should be said right away that at present there are hundreds of types of screwdrivers and no less number of batteries, so it is very important to familiarize yourself with the instructions that come with a specific unit, because in one case 30 minutes will be enough for charging, while in the other for a full charging will take more than 2 hours.

Many types of batteries have an indication system, that is, there are 2 LEDs on the upper instrument panel, usually red and green. These LEDs let you know exactly when charging is complete. However, even if the indicator is present, it is necessary to disconnect the batteries from the mains in time, since a long stay in the connected state after recharging may damage the battery.

In addition, considering the duration of charging, you need to immediately notice that there are 2 main types of chargers, and it depends on which type is attached in the kit with a screwdriver, how long the charging process will take.

Chargers are divided into impulse and conventional.

As a rule, cheaper semi-professional devices are equipped with conventional chargers. Pulse chargers are more expensive, but at the same time, they allow you to charge the device in less than 1 hour, which is especially important for professional devices.

Not charged screwdriver ENERGOPROM YES-10/14 L2

Additional tips for charging screwdrivers

If the tool is not planned to be used in the near future, the question immediately arises: is it necessary to recharge it before moving it to storage? In this case, a lot depends on the type of battery. Common nickel-cadmium batteries need to be recharged first. It should be noted right away that if the tool will not be used for a long time, then before starting to use it, it will be necessary to perform at least 3 discharge-recharge cycles of the battery in order to restore its charge capacity.

Nickel-metal hydride units should also be recharged before sending the tool for storage, and if the period of non-use of the tool exceeds 1 month, it is worth putting the unit to recharge for about a day before using it. This will restore the charge capacity. Lithium-ion batteries are considered the most convenient in this regard, as they do not need to be charged before storage.