How to properly cut a corner under 45 degrees

Guidelines for bending a metal angle

Sometimes you need to trim this or that part or product at a certain angle. As a rule, you should trim baguettes, moldings, platbands, baseboards and other similar interior elements at a 45 degree angle. Anyone can cope with this task. The main thing is not to hurry, not to be nervous, and everything will turn out well.

Buy ready-made corner elements

Of course, the easiest thing is not to torment with the trimming of this or that part, and buy a ready-made, not in need of processing and trimming. Such details and elements are sold today everywhere in large supermarkets or smaller stores.

For example, in the case of baguettes or fillets, special corner elements are sold that fit perfectly into the corner and do not need to be trimmed. They just need to be glued in place and pressed down well.

The method of connecting trim without trimming

Trims today often do not trim at an angle to dock with each other, and make the junction at right angles. This method of connecting trim panel does not require any special trimming, which is very convenient. In addition, this method looks more modern and attractive.

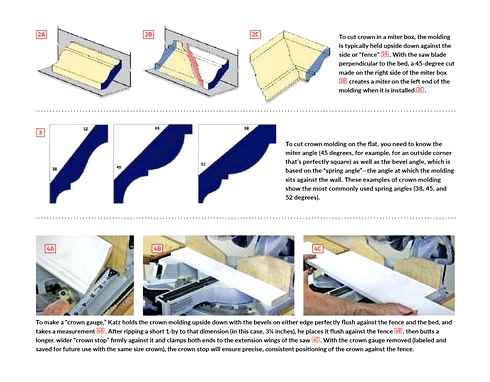

Trimming at an angle with a mitre saw

If you still need to undercut at an angle or another part, it is worth stocking the jigsaw. a simple device, in appearance resembling a small box. The chair has slots that are designed for a saw or a long sharp knife. Of course, these slots are made so that they form an even and accurate angle of 45 degrees.

In fact, the jigsaw can have many notches at once, at different angles. This is convenient, because with one device, you can cut any parts at different angles.

There are on sale adjustable jigsaws. The slots in this chisel are adjustable, allowing the craftsman to set exactly the angle required at any given moment. In particular, it is quite simple to translate slots of such a chair to a position in 45 degrees.

Now the workpiece can be trimmed elementary. In the chair put a baguette, platband or plinth, and then inserted into the slots saw and elementary cut off the excess. The resulting angle is a perfect 45 degrees.

What to do if you do not have a power saw? Very simple. It is necessary to make a template, by which it will not be difficult to transfer to the workpieces the necessary markings. You can choose thick cardboard or anything else that will be appropriate in this case as a template.

How to saw off at an angle of 45 degrees

From time to time it is necessary to cut a particular piece or item at a certain angle. Usually, it is necessary to cut baguettes, fillets, platbands, baseboards and other similar interior elements at a 45 degree angle. Everyone can cope with this task. The main thing is not to hurry, not to worry, and everything will work out. Buy pre-made corner elements

For example, as for the baguette or moldings, they are sold special corner elements that fit perfectly into the corner and do not have to be incised. It’s pretty easy to glue them in place and perfectly press them down.

How to make a correct joining

If, after gluing part of the baguette left some distance to the corner, you need to think about how not to make a mistake. a small margin does not hurt. First, it is better to cut off a piece with a good margin of about 10-15 cm. Then, having cut a corner by any convenient method, make its fitting on a dry surface. To do this, place the bar to the ceiling and mark the point where the boundary of the shortening will pass. Trim at a right angle.

Corner joining is just as important. Ready-made skirting boards are usually fixed at an angle smaller than 45 degrees, so there may be inconsistencies trimmed edges and the appearance of gaps. Here the initial trimming of corners is followed by the dry and possibly accurate joining of skirting boards on the ceiling itself. Problems usually arise with wood and plastic materials.

After completing the rough joints of the fillets, they should be glued or screwed, and then, if necessary, use putty and then. seal all the existing joints.

Using decorative corners

Special corner adapters are meant, which are usually supplied with polyurethane and polystyrene friezes. Decorative corners are glued to the very corner, and baguettes are attached to them on both sides. Fit in this case, or not required at all, or carried out with a simple office knife.

Composition and characteristics of the material

To understand how to properly cut a baseboard, you should understand its composition. It helps to choose the right tool and cutting technique.

- Styrofoam. The cost and strength of this material is the lowest. But because we create a decorative ceiling decoration, the strength is not particularly required.

- Styrofoam skirting boards are more dense. than ordinary foam plastic. The most common knife is used to cut this kind of material.

READ How to Cut Skirting Boards to the Ceiling Corners

Tip: Sharpen perfectly the knife before implementation. This will eliminate the presence of jagged edges in the cut areas.

Advice: the flatter and more frequent the tooth of the saw, the more even the edges will be. You can even use a metal blade.

Using an ordinary hacksaw blade

Composition and characteristics of the material

To understand how to correctly cut a baseboard, you should understand its composition. This will help to choose the right tool and cutting technology.

- Styrofoam. The cost and strength of this material is the lowest. But because we are creating a decorative ceiling decoration, the strength is not particularly required.

- Styrofoam ceiling skirting is more dense. than ordinary Styrofoam. To cut such a material the most ordinary knife is used.

READ How to Cut Styrofoam Skirting on the Ceiling Corners

Advice: sharpen the blade well before installation. This will relieve the presence of jagged edges in the areas of the cut.

Tip: The shallower and more frequent the saw tooth, the smoother the edges will be. You can even use a sheet for metal.

Using an ordinary hacksaw blade

Record navigation

How to brew antiparasitic monastery tea

How to brew antiparasitic monastery tea High quality How to brew antiparasitic monastery tea at a bargain price Eco-friendly How to brew antiparasitic monastery tea

White tea how to brew properly

How to brew white tea correctly Assuming you manage to buy quality white tea. Suppose. because to buy it in our,

How to brew ground coffee correctly in a cup

How to brew coffee in a cup with a cup of well brewed coffee for breakfast increases vigor for the whole day. Everyone knows, of course, that coffee

Slicing without tools

How to cut the corner of the ceiling plinth without a jigsaw? It is possible to perform the calculation and cut manually.

It is enough to make a good marking on the ceiling, then evenly cut the right angle. A significant disadvantage of this option. in the inconvenience, when you have to hand hold all the strips in the process of measuring. In general, this method is no worse than helping to make the necessary measurements.

Applying the product to the place where it will be mounted, you can immediately take into account all the errors on the walls.

First cut two blanks at an angle of 90 degrees. Then one of the slats is attached, pointing it perpendicularly to the wall. Run the trimmer line along the ceiling, outlining the desired contour. Then remove the trim strip and apply a second trim strip to match the outline. The intersection of the straight lines will be the cut point. Then the place for the future cut is marked on the strips.

The best way to cut the ceiling plinths in the corners, experienced carpenters, joiners and builders know. Most people advise to make cuts on the side and try the slats on the ceiling, if necessary. trim in the direction of adjacency of parts to the surface.

Having made the rough joint, finally screw the finished boards to the wall. Seams are sealed. the installation of the skirting board is complete.

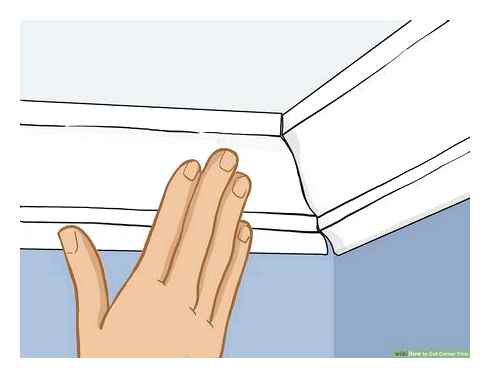

The skirting board for the ceiling is an excellent means of concealing the various irregularities that necessarily arise at the joints of the walls with the ceiling. The result is not only visually smooth corner, but also quite aesthetic completed interior.

An important point in fixing a ceiling plinth is to measure and cut it correctly.

So, let’s consider how you can cut a ceiling plinth.

First, let’s define what a ceiling plinth is, and what it can be made of.

For the manufacture of ceiling plinth strips use different material. It can be quite flexible polyurethane, wood, polystyrene foam, PVC.

The most durable, stable and flexible are considered polyurethane baseboards. By the way, it is worth noting that this element of the decor has its own name. batten. Because it can be confused with moldings, which are attached to the flat surface of the walls or ceiling.

Types of corners in the rooms

When installing baseboards, it is necessary to decorate the corners in some way. By their appearance corners are external (which protrude forward) and internal (eg, the corners of the room). In rooms with normal geometry, corners are straight, ie.е. 90°. When joining two pieces of skirting board in a corner, they are cut so that each has a 45° angle.

To formalize the outer and inner corner, the baseboard must be cut

But how to make the angle on the baseboard to be exactly forty-five degrees? To do this, use a special carpentry tool. a plier.

Plastic, wood or wood-fiberboard. which to choose??

Convinced that the installation of corners is not just a whim, but a necessity, let’s study the construction market, in order to make the right choice. These products are divided into types, depending on the material from which they are made. So, the corner can be plastic, wood, bamboo, made of cork or fiberboard. Absolutely every type has its own advantages and disadvantages, consider them in more detail.

Plastic corners are made by hot bending a sheet of polyvinyl chloride. In general, they have the same width of the shelves. from 10 to 40 mm in increments of 5 mm. However, there are asymmetrical pieces, such as 10×25 mm, but regardless of this parameter, the angle between the sides is 90 degrees. If it is necessary to transform an arched opening, it is done by means of a special flexible profile. Their advantages are a relatively low cost, they do not need to be painted, in contrast to the same wood.

The next type. corners made of cork. Such decorative elements are quite often used for arched openings, but this does not mean that their use is limited to this area. They can also be used for the finishing of slopes of different shapes. Cork has a number of advantages, including durability, fire resistance, practicality and environmental friendliness. Basically, the material has practically no disadvantages, but if your pet wants to sharpen its claws on it, it will damage the surface.

What to cut slopes for windows. Installation of corners on the window or door jambs

Having understood what such products are made of, what their features are, and having decided on the choice, it is necessary to study how to install the corners on the slopes. Detailed instructions are given below.

What kind of glue to use

In addition to the corners themselves, we will also need and adhesive composition, with which we will attach the selected element. When choosing it is worth remembering that quite often, especially if you want to glue a narrow product, the glue leaks out from under it and, of course, gets on the walls. As a result, the latter may be damaged, which, accordingly, will have a negative impact on the appearance of the room as a whole. Therefore, you should choose an adhesive composition, the excess of which can be removed from the surface.

Basically, the corners are glued to new slopes, but nevertheless check that the surface is relatively flat, as large bumps will not be able to hide any decoration. It should be free of foreign objects like nails, self-tapping screws, etc. д. It is also necessary to degrease it, for this purpose white spirit is suitable.

How to cut correctly

Before discussing how to mount the corners on slopes, you should know how to cut them correctly. After all, this step is the most time-consuming of all, and perhaps even the most important, since it depends on how their edges will join, and this directly affects the aesthetic appearance of the room. It is best to perform trimming with a hacksaw with a fine tooth. First you need to measure the length of the opening, then we put a mark on the corner so that the cut corresponds to this parameter. Then the part that will be adjacent directly to the slope, cut strictly on the marks, and the part that will be to the wall. at an angle of 45 °.

To trim the angle you should use a hacksaw with fine toothing

How to glue

So, finally, we got to the main question, how to glue the corners on the slopes. However, before proceeding directly to the fixation, should carry out, so to speak, trying it on. Once you are satisfied that you have trimmed it correctly, you can go on. Apply to the inside of the corner, at the junction of the sides, adhesive mortar in increments of approximately 10 cm. At this stage, an indispensable helper will be an assembly gun. After that, quickly press the product to the surface and fix it in that position with masking tape. Begin with the horizontal slope, and then proceed to the sides. Remove excess sealant from the wall surface with a damp cloth, and let it dry well. You can remove the tape only after 24 hours.

Chisel for baseboards

The carpentry plier is a device for cutting at a certain angle. It is used with a hacksaw. In principle, you can make a crosscut saw yourself, collecting the guide from boards and making cuts in the walls. On sale there are different models costing from 15 to several hundred dollars. They differ in capabilities, materials, although they are all called a “chisel”. Professional models are made on the basis of a good hacksaw, have a scale that allows you to align the saw as desired. With such a tool, it is no problem to set any desired angle of cut to cut the skirting for a perfect junction.

Start installing baseboards in one of the corners. If this is the first experience for you, choose the part of the room in which there will be something to stand. Not always, of course, the first pancake, but still better to be on the safe side. To make the corner on the baseboard neatly, work without haste. One sawed off, checked, adjusted. Move on to the next one. Fix it better after the two adjacent corners are assembled. But don’t put off assembly too much either.

Trimming the baseboard in the corners requires some skill. But having made a few joints yourself, you can beautifully decorate complex corners

How to use a plank to cut the baseboards? Place the device in front of you, preferably on a table, but you can also do it on the floor. It doesn’t matter which way you turn it, it’s symmetrical. You insert the bar into the profile, turn it as it will stand against the wall. When sawing a skirting board in the jigsaw, the “wall” is the wall that is further away from you. Once again: press the skirting board firmly against the back wall in the position in which it will be installed. Insert the hacksaw into the necessary slots. You can start sawing.

The first joint in the room

The first baseboard plank should be cut as close to the edge as possible. Carpenters have their own lingo and they say “cut” the corner. No matter what you call it, the important thing is that we put the plank in the jigsaw so as to make a cut at the very beginning. Using the cutting trimmer fishing line, pull out the skirting board by a small distance, you can start by 1-2 cm. It’s harder to cut a smaller piece, so save it for later, when you have some skill.

Position the skirting board in the jig at the far wall so that it’s facing in that direction. This makes it easier to check if you are cutting/sawing correctly

Further to do a corner on a skirting board is necessary so:

- Place the baseboard in the jig, press it against the opposite wall from us. We expose it in an assembly position. as it will stand at a wall.

- Insert the hacksaw into the required slots (see the picture below).

- Move the bar so that it is slightly out of line for the cut trimmer.

- Cut off.

- We take the second piece of the skirting board, repeat the same operations, but the position of the saw on the jig is reversed. Insert the strip from the other side. Be careful here, otherwise you’ll have to redo it several times, because the connection will not work.

How to cut a skirting board in a jig is correct: for external and internal joints

We have two pieces cut to fit into the inner corner. To make a perfect joint, try on the parts in place. There are likely to be some imperfections. We take sandpaper with a medium grain, remove everything that prevents the docking. Then using fine grain we achieve a tight joint without gaps and clearances.

When connecting baseboards in the corner, use a transparent silicone sealant. Before you install the fasteners, a layer of silicone is applied to the cut. Immediately after the skirting board is fixed, remove the excess that has appeared on the outside. Remove until the surface is completely clean. This method of connecting the baseboards in the corners looks more accurate, it does not clog dirt and dust.

How to file the corner of the baseboard at the right distance

The second and all other corners of the skirting boards must be done at a certain distance. If the following corner again internal and distance to it is less, than length of a plank, we use the same fragment on which already there is a notch. We measure with a tape measure. strictly from corner to corner. Then this distance is set aside on the plank using the same tape measure. We align the beginning of the tape measure with a ledge, measure the required distance, make a mark with a pencil. This will be the starting point for the cut.

It is necessary to know at what distance to cut

The skirting board with a mark is laid in a plane, select the desired direction of sawing. The dash can be aligned with the hacksaw blade or with the slot in the jigsaw. Whichever is convenient. Cut off. This piece should be “tried on” in place. If both corners are against opposite walls or the gap is only 1 mm, it’s ok. You can cut a second slat from the new piece to make the joint. And again we remove the imperfections with sandpaper.

If the length of the wall is longer than the baseboard trim, cut a new trim. The second corner we will cut on it. It’s important not to make a mistake which way to cut. Having established both slats along the wall, on one of them to mark the place of connection, to make a straight cut. There are also slots in the jigsaw for making a straight cut. So there won’t be any problems.

Inserting and installing the hinges for the door frame

I want to draw your attention right away that you are unlikely to get a good quality mortise hinges without professional tools and experience. Insertion is made with a manual milling machine, not with a chisel and hammer, as many people think, and are mistaken.

How to screw the handle to the interior door

That’s why I recommend to buy the superimposed hinges like on the photo. They do not need to be mortised and can be mounted quickly and easily. A hinge consists of two parts that fit together to form one plane. The smaller inside part is fixed to the door leaf and the bigger one to the frame pillar.

Mark up 20 cm on the edge of the door leaf. from each edge. Examine the leaf carefully and decide in which direction the door will open. It is important not to make any mistakes here and to position the hinges correctly. The hinge pivots must face the opening side of the door.

Place the hinge on the end of the hinge to the hinge stop. Do not press the hinge too hard against the edge of the leaf. The hinge must rotate freely on the hinges without crossing the leaf. If you notice when you open the hinge that the hinge scrapes the leaf, leave a small gap of 1mm.

Make a mark in one of the holes in the hinge and drill a hole, slightly thinner than the self-drilling screw that came with the hinges. It is not necessary to drill all four holes at once. You could make a mistake in the marking and the loop will drift to the side. Screw in one screw, make sure the hinge is straight, drill the rest of the holes, and fasten it. Do the same with the second hinge.

Now let’s screw the counter part of the hinge to the box post. For convenience, it is better to put the door leaf on the floor and place the frame pillar next to it. To evenly place the hinges on the box, the door should be slightly lifted by adjusting the height with shims. Leaning box post to the end face, make sure it is slightly protruding above the leaf along the length that, after assembling the necessary gap of 3 mm will be formed. After that drill holes to fix the hinge. There is no need to screw the hinges completely yet, because you still need to assemble the box, and it is more convenient to do without the leaf.

Template 45 degrees. The template of a corner of 45 degrees

Often a home handyman needs to make an urgent measurement or marking at a certain angle, and there is no square or protractor at hand. In this case he will be rescued by some simple rules.

If you need to urgently build a right angle, and do not have a square, you can use any printout. The angle of a piece of paper is a very precise right angle ( 90 deg.). The cutting (punching) machines in printing houses are set up very precisely. Otherwise the original roll of paper will begin to cut crookedly and tangentially. So you can be sure that this angle is exactly a right angle.

And if you do not even have a printed edition or need to build an angle on the ground, such as when marking a foundation or a sheet of plywood with uneven edges? The rule of the golden (or Egyptian) triangle will help us in this case.

A golden (or Egyptian or Pythagorean) triangle is a triangle with sides that relate to each other as 5:4:3. According to Pythagoras’ theorem, the square of a right triangle is equal to the sum of the squares of its cathetuses. Т.е. 5×5 = 4×4 3×3. 25 = 169 and it is undeniable.

Therefore, to build a right angle, it is sufficient to draw a straight line on the workpiece for the trimmer with a length of 5 (10,15,20, etc.).д. multiple of 5 cm). And then, from the edges of this line begin to measure off on one side 4 (8,12,16 and t.e is a multiple of 4 cm), and on the other side 3 (6,9,12,15, etc.д. multiple of 3 cm) distances. You should get arcs with a radius of 4 and 3 cm. Where these arcs intersect each other will be a right angle (90 degrees).

Such angles are commonly used in the construction of rectangular frames. The material from which the frame (baguette) is made is sawn at an angle of 45 degrees and joined. If you do not have a plane or protractor handy, you can get a template angle of 45 degrees as follows. It is necessary to take a sheet of writing paper or any printed matter and bend it so that the line for the bending trimmer passed exactly through a corner, and the edges of the bent sheet coincide. The resulting angle and will be equal to 45 degrees.

House lamp made of wood with his own hands

A 60-degree angle is required to construct equilateral triangles. For example, you need to saw these triangles for decorative work or to accurately set a power swath. The 30 degree angle is rarely used in its pure form. However, it (and the 90-degree angle) is used to construct a 120-degree angle. And this is the angle needed to build equilateral hexagons, a figure very popular with carpenters.

To construct a very precise template of these angles at any time, we need to remember the constant (number) 173. They derive from the ratio of the sines and cosines of these angles.

Take a sheet of paper from any publication. Its angle is exactly 90 degrees. From the angle on one side measure 100 mm (10 cm).), and the other is 173 mm (17.3 cm). Connect these points. This is how we obtained the pattern, which has one angle of 90 degrees, one of 30 degrees, and one of 60 degrees. You can check on the protractor. everything is exact!

Remember this number. 173, and you can always build angles of 30 and 60 degrees.

When marking up the workpieces or drawings on the details, besides the corners themselves, the correlation between them is very important. This is especially important when making rectangular parts or for example when marking foundations, cutting large sheets of material. Incorrect marking or marking brings a lot of unnecessary work or a lot of waste.

Unfortunately, even very precise marking tools, even professional ones, always have a certain accuracy.

Meanwhile, there is a very simple method of determining the rectangularity of a part or construction. The diagonals of a rectangle are exactly equal! So, after the construction it is necessary to measure the lengths of the diagonals of a rectangle. If they are equal, all is well, it really is a rectangle. And if not, you have built a parallelogram or rhombus. In this case it is necessary to “play” a little with the adjacent sides to achieve exact (for this case) equality of the diagonals of the marked rectangle.

Ending at a 45 degree angle. How to saw at a 45 degree angle

During home repair work you may need to saw materials at a 45 degree angle. Usually this is done for joining two parts “in the whisker”, that is 90 degree angle (frames, skirting boards, door trims, etc.). It is important to fit the adjacent parts of the workpieces absolutely precisely to ensure that you are happy with the result of the work. Make it without a special device. a jig. is extremely difficult, especially for the novice craftsman.

Prepare an angled template that will help you easily make a precise cut of the workpiece of wood at an angle of 45 degrees. This device is an inverted U-shaped profile with gaps on each side for the hacksaw. Usually they are 45, 60 and 90 degrees. The more complex power saws are additionally equipped with freely selectable fixed slots, or have a pivoting design. this allows you to set the saw in the optimum position.

Buy a ready-made joiner’s tool at a hardware store with a wooden, metal, or plastic tray. For the beginner craftsman this is the best option. If you want, you can make a simple crosscut with your own hands from three boards or plywood strips (thickness. about 1.5-2 cm).

Drill a few holes in the walls of the future of the cutter, apply joinery glue to the ends, and assemble the box (tray) of the cutter. Fix the corner template with screws. The walls of the tool should lie strictly parallel one to the other; the bottom and each side make clear perpendiculars.

Mark a 45 degree angle with a pencil, add additional groove lines if necessary. In order not to make a mistake in your calculations, use a protractor.

The most responsible thing is the slots. It is recommended to make them with the same hacksaw that will later be used to cut the finished jigsaw. Start cutting without exerting too much pressure on the power tool and hold the blade. Saw one sidewall first, then the opposite sidewall.

Proceed to finish the lumber. Secure the baseboard on a workbench or work bench with a screw clamp (clamps to secure parts) or screws. Then make a mark for the future sawing on the lath (plank, baseboard) and put the workpiece into the box. Press it firmly against one of the side walls of the template, aligning the marks with the 45 degree angle cutout.

Insert the hacksaw into the grooves of the jigsaw and saw the workpiece. The saw will be limited to a fixed kerf, and you will make an even and precise cut.

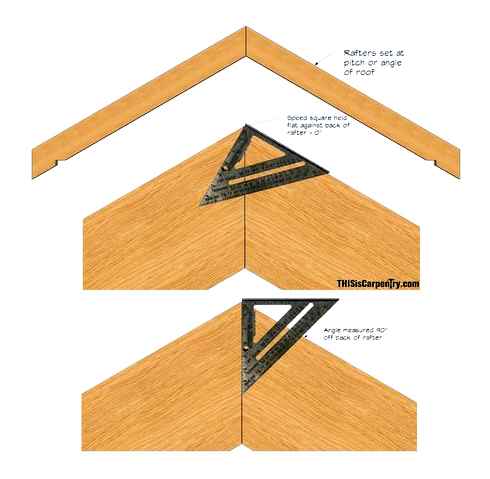

When sawing the skirting boards, make sure the corners of the room are actually right. If the walls are very uneven, the angle of the kerf on the workpieces should be corrected. Measure with an angle meter the joints of the interior walls and divide the result in half (the joint of the baseboards “in the whisker”). To make an accurate cut, it is recommended to make grooves with a given angle in a homemade jigsaw. Another option. a store rotary tool, which allows you to change the angle from 0 to 180 degrees in increments of about 15 degrees.