How to properly install a plow on a single axle tractor

Single and double hull

Single-furrow plowshares are ideal only for soft ground, their design does not include more than one share. The advantage of such equipment is that it is easy to assemble, it has a low weight.

The two-furrow plow is suitable for working on any soil, as long as there are no stones. With the help of such attachments, you can create furrows, huddle plants, clean the area from weeds.

It is desirable that the uniaxial tractor on which the equipment is to be installed demonstrates up to 3-5 horsepower.

The width of capture can be adjustable or fixed on such equipment.

Types and their design features

When making a plow, a special metal is taken that is able to withstand the load during operation.

Dump and dump

Among the varieties of plows there are non-moldboard and moldboard plows. The latter are more popular as a means of cultivating a small plot of land.

They have their own classification:

- furrowed;

- without furrows;

- plowing smoothly.

Those products that do not leave furrows are used in situations when the land needs to be processed in a dump; for the opposite effect, a plow is used, after which furrows remain.

On the dump structure, the share is at a special angle of inclination, so the earth layer does not just turn over. the earth becomes loose.

Such a device is best used in areas where there is not a lot of precipitation, but there is erosion on the soil.

How to install and adjust?

It does not matter which plow is used with the equipment. this attachment must be attached using a special attachment.

It can be of two types:

- stationary;

- universal.

The first option is better considered in more detail, since it allows you to configure the device as needed.

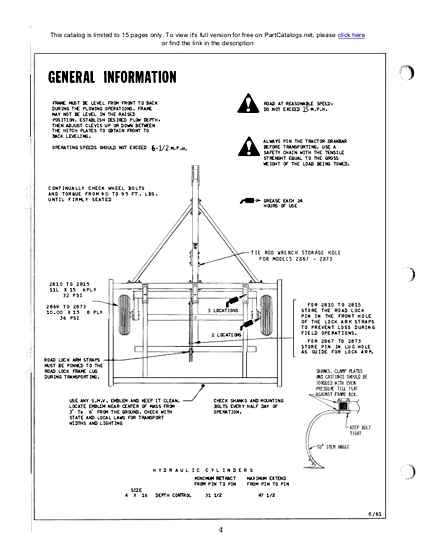

Hitch is carried out in accordance with the following sequence.

- First, you need to put the unit on a hill. it can be just bricks or logs.

- A hitch is applied to the towbar in such a way that the holes coincide completely.

- Using a bolt, the clutch is fixed, but it is not necessary to tighten the threads too much, since the increased rigidity will cause poorly performed work. If excessive resistance is created during the operation of the attachment, the plow begins to throw from side to side. This is why a small clearance is required.

Can be attached to the rear adapter if available.

Setting up Ford 8n 9n tractor with a two bottom plow

Even a beginner will not be difficult to fix the plow.

The adjustment process can also be divided into several stages:

- determining the required depth to which the plow will sink into the ground;

- adjustment of the angle of inclination of the field board;

- blade angle adjustment.

Not every operator knows how much the plow is best to sink into the ground. In fact, this value should be equal to the height of the metal part of the bayonet-shovel. If it is too small, then all roots and weeds will remain in the ground; will be too large. the infertile layer of earth will mix with the fertile.

Set up using three bolts that are located at the junction of the plow post and the lock. Raise the attachment or lower it. the operator decides.

A screw handle is used to adjust the incline level of the board. The technique is again raised on bricks or logs, the handles will need to be turned out so much that the field board is on the ground. The handle is turned in the opposite direction until the board is above the ground at a distance of three centimeters. If this indicator is made too large, then the plow will constantly cling to the ground, so the single-axle tractor starts to slip.

If you do not do it right and set the parameter to the minimum, then the technique will not be able to process the required layer.

When performing work on adjusting the blade angle, the equipment is placed on the edge of the area that needs to be processed. The first starting furrow is made to understand what depth is present and if it is suitable. The operator must walk straight; if there is no experience, then a stretched rope will help. The wheel is set in the track made, and the plow is set perpendicular to the ground surface. If you have a square at hand, you should definitely use it.

Characteristics

A plow for a walk-behind tractor is an irreplaceable device, in the design of which there are three planes. One is dump and is located in front, the second is horizontal and the third is vertical. If you remove it and put it on the table, leaning one part against the wall, then the horizontal will coincide with the surface of the table, and the vertical will coincide with the walls.

It is very important to take into account the dimensions of the lower incisal edge, which is 10–20 millimeters from the horizontal plane. On a good product, the cutting edge on the left is on the same line with the same edge of the blade.

Fabricate/Install Plow for Compact Tractor

The projection distance of both is 1 cm from the end of the vertical surface. There should be no gap between the share and the blade, and they themselves should sparkle from polishing.

When the work on using the plow is completed, it must be cleaned. Remove the soil and lubricate with oil. This is the only way to protect the metal surface from corrosion. Special attention should be paid to the height of the plow rack and, in general, the dimensions, since the quality of the work done depends on them. The back side of the share must be absolutely flat, and an angle of 20 degrees is observed between it and the installation surface.

Popular models

When the user chooses the type of plow that he is going to use, he should take into account not only the type of soil, but also take into account the peculiarities of the task that has to be solved. The power of the walk-behind tractor and its dimensions also matter. The model, named in Honor of the underground animal, “The Mole”, refers to the single-body version of the plow. The total weight of the structure is 8.5 kg, the depth of soil processing is 200 millimeters.

Such attachments can be used with the following types of walk-behind tractors:

- “Neva”;

- “Agate”;

- “Cascade”;

- “LANDER”;

- “MB-2”;

- “Oka” and so on.

On average, the one-hull “P1–20 / 2” can sink into the ground to the same depth. The weight of the structure is the same, but more. Suitable for most of those motoblocks that are listed in the list above.

“P1-20 / 3” reaches the price of 1,500 rubles. Its weight is more than that of previous models and is 13 kg, the maximum immersion depth in the soil is 250 mm.

Best used with “Belarus”, “Agros” walk-behind tractors.

The single-body plow “Salyut” has a very small weight, for such a product it is 8 kg, it can penetrate into the ground by 200 mm, but despite this, its cost is on average 1.5 thousand rubles.

Zykov’s plow weighs a little more, per kilogram as a whole, it has an indicator of immersion in the ground up to 25 cm. It is used on the Salute, Oka and similar techniques.

The weight of the reversible plow for the GS 81, 101 motoblocks is 12-18 kilograms, while the maximum that it can penetrate into the ground is 25 cm, it will cost more to the consumer a two-turn plow: it is estimated by manufacturers from 4 thousand rubles, with a weight of 15 kilograms and a plowing depth of 20 cm.

The heaviest and most expensive is the rotary plow. It is quite difficult to lift and install it for one person, since its weight is 40 kg, but these inconveniences are compensated by the increased immersion depth, which is 300 mm. The cost of such a product is from 70 thousand rubles.

All the described plows are made of metal, the horse plow can be partially wooden, it has only a metal plowshare. It is used no less often, sometimes it is hung on a single-axle swing-over tractor or with a skimmer.

Reversible

Reversible plows are used on soil that is difficult to cultivate. The required power of the walk-behind tractor is taken into account when choosing a share of greater or lesser weight. It is rather difficult to make such equipment on your own, since the pen is bent at an exact angle.

This design helps to turn the soil as soon as the plow lifts it.

How to set up a plow on a walk-behind tractor correctly? We work simply, quickly and easily.

Having become the happy owner of a walk-behind tractor of a particular brand, we are faced with the problem of choosing a plow and related elements for plowing our plots of gardens and fields. Spring is a hot season for all people who are not indifferent to the land, the topic of environmentally friendly food, summer residents and gardeners. How to make work easier, more enjoyable and more useful? This article will focus on the correct setting of the plow, the choice of the hitch, and work on your mistakes. Everything in order:

Having installed this attachment on a uniaxial tractor, I rushed off with wrenches in my hands for adjustments. For the first time in our life we plow the land. an experimental ride. Of course, I consulted with neighbors and acquaintances. Tips in the style: “put the uniaxial tractor on a brick, two fingers under the heel, angle of attack. “All these tips seemed simple, and it was frightening. I had to watch the work of walk-behind tractors when plowing. everyone was sweating, roofing felts were pushing a single-axle tractor, then they were running after it. without strength, arms and legs. At first, it seemed to me that this is exactly what plowing on a walk-behind tractor looks like. But it was all the result of a wrong plow setting.

I will try to tell in simple language and share my experience on the correct setting of the hitch and plow, in which you can easily cope with any amount of plowing on a walk-behind tractor of any brand. Realization of this came after one season. there is no need to rush anywhere.

First: The plow plows in a position strictly perpendicular to the plane of the ground, we carry out this adjustment after the first and subsequent passes, since the wheel goes into the track. Everything is simple. as on

Thirdly: An error in which a single-axle tractor seeks to run away to the left. then to the right. If you look at a uniaxial tractor from the top point, then the hitch should be in a position strictly perpendicular to the axis of the walk-behind tractor. It’s easy to understand. imagine you are sailing on a boat. how do you steer? You guessed it. everything is on the same principle here. Outlined schematically with lines on

But all these adjustments are meaningless. if the hitch is of poor quality. And this is the biggest mistake! We choose a high-quality, reliable. strong hitch in order to quickly and easily make adjustments, while the reliability of the fasteners should not be questioned at the time of plowing.

In the photo, the hitch is black. it has proven itself. a decent thickness of the metal, does not walk in the attachment points, does not tear off threaded connections

In the photo, the hitch is red. of satisfactory quality. bends, walks, the thread on the adjusting pin gets confused.

Thank you my friends for reading to the end.

I hope that this material will be useful for beginner walk-behind tractors. plowing on car wheels. as an alternative to lugs in my next articles on the Positive Village channel

Rotary plow for a uniaxial tractor. manufacturing features

A rotary plow for a walk-behind tractor with a support wheel is the most complex type of attachment used today for plowing. When working on it, you need to be extremely careful, since the slightest mistake will lead to poor quality soil processing. The manufacturing procedure is as follows:

- A milling cutter acts as a working body, which can be made from a steel pipe and metal plates. The plates must be welded to the pipe in such a way that when they rotate, they grind the soil and throw it aside;

- Next, make a frame for the plow gearbox. It can have any shape, the main thing is that moisture and debris do not get inside the gearbox;

- The gearbox cannot be made. you need to purchase it. After that, the mechanism must be connected to the gearbox of the walk-behind tractor;

- Since the rotary plow is a rather large structure, separate wheels will be required for its use. They can be taken from an old moped or motorcycle.

A ready-made plow for a single-axle tractor will serve well for more than one year. The main thing is to change the oil for lubricating the gearbox on time.

Features of plow adjustment on a walk-behind tractor

Every owner of a vegetable garden, a garden plot, a small farm understands what it is like to manually plow the beds and pull out weeds. To simplify plowing, a plow is used. However, using a tractor or animal traction for a small plot of land is not cheap and stupid. For such tasks, motor vehicles MB 90, “Oka”, Brado Garden, “Neva” are used. In other words, it is a motor on wheels, on which a variety of attachments are mounted: from trailers to plows. Our article is devoted to the features of adjusting the plow on a walk-behind tractor.

Plow to walk-behind tractor

A plow for a walk-behind tractor is one of the most useful devices that allows you to plow any soil with high quality, saving a lot of time and effort. Let’s look at the features of installing a plow, as well as how to make a structure with your own hands.

Types of plows for motoblocks

The plows used for plowing are divided into several types. These include:

- single-body designs. these products are the easiest to use. They are lightweight and consist of fewer parts;

- reversible or reversible plows. the upper part of such structures is equipped with a curved blade designed to turn the soil directly in the process of plowing. The reversible plow is most effective when working on heavy soil;

- rotary plows. this type of attachment has the most complex design. On sale you can find a two-body plow, consisting of two, and a three-body plow, consisting of three plowshares;

- disc plows. structures of this type are used mainly for plowing wet soil. The depth of soil processing with such plows is slightly less than in attachments of previous types.

Each of the listed types of plows has found application when plowing a particular type of soil. Nevertheless, the reversible double-sided plow is considered to be the most versatile. it shows high efficiency in processing any type of soil.

First furrow and blade angle

After the previous steps have been made, it is time to make the final adjustment so that subsequent furrowing is easy. To do this, a uniaxial tractor is placed at the edge of the plot, the plow is driven into the ground and the first furrow is passed. It is important at this point to keep the line straight so that subsequent passes are also straight. A string stretched on pegs or some other landmark can help here.

At this stage, it is best to check how deeply the plow goes into the ground. place a ruler or tape measure in the furrow. Adjust the plowing depth if necessary.

Then, with one wheel, a single axle tractor is placed in the furrow and the plow is oriented so that it is perpendicular to the ground, to do this accurately, use a square. If you are uncomfortable doing this in the ground, place the single-axle tractor on a level surface with a support under one wheel that matches the furrow depth. After that, the plow setting is considered complete and you can proceed to the second, third furrow.

Installing the plow on a single axle tractor

In the design of any plow, regardless of its size and shape, there is a hitch, by means of which the device is attached to the walk-behind tractor. The hitch can be stationary or universal. The most optimal option is considered to be an element of the second type, since it gives more opportunities for adjusting the plow.

Regardless of the type of hitch, the installation of the structure on a single-axle tractor is always carried out in the same order. To attach the plow to the walk-behind tractor, you should act in the following sequence:

- First, place the single-axle tractor on stands. you can use bricks or logs for this;

- Attach the plow hitch to the hitch of the walk-behind tractor so that the holes on both elements coincide with each other;

- Secure the hitch to the towbar with the bolts.

Many beginners believe that the more reliable the attachment of the plow to the walk-behind tractor, the more efficient the work of the attachment will be. However, practice shows that too rigid a connection will only worsen the quality of plowing. The fact is that during the operation of the plow, forces act on it, leaving perpendicular to the plane of the blade. Because of this, resistance arises, which pushes the plow away from the walk-behind tractor. To eliminate this, when installing the plow, you need to leave a horizontal backlash of about 5 degrees.

How to make a plow for a uniaxial tractor with your own hands?

Before you start making a plow with your own hands, you will need to carefully study the drawings. They should tell you how to attach the structural parts to each other. The further procedure is as follows:

- First, make a ploughshare. To do this, take steel with a thickness of at least 5 mm and give it the desired shape. Beat off the cutting part of the steel workpiece on the anvil, then sharpen it. This is done in the same way as in the case of sharpening a hand scythe for grass;

- Next, you need to make a homemade blade. A steel pipe with a diameter of 50 cm and a wall thickness of no more than 5 mm is suitable for this. Cut the blank for the future blade with a cutter. To give the product the desired shape, beat it off on an anvil and grind it;

- Next, you need to assemble the parts of the plow into one structure. Take a sheet of steel, the dimensions of which should be 50 × 50 cm, and the thickness should be 3 mm. Leave a 4 cm margin around the edges of the sheet and align it so that you end up with a zero angle;

- Then, using wedges, attach a ploughshare to the sheet and make double-sided spot welding, observing an angle of 25 °;

- Connect the ploughshare and the blade together as tightly as possible. An angle of 8 ° should form between the top of the blade and the share blade;

- Then weld the side shield, the share and the rear of the blade together. The video will tell you more about the manufacture of a plow.

Then take accurate measurements of all angles again. Only after making sure that the connections are correct can you finally weld on the plow parts. Once the structure is completely cool, clean out any existing welds.

Preparing to use the walk-behind tractor

Plowing the soil begins with the preparation of the walk-behind tractor. Let’s figure out how to do this.

- Before plowing, motor vehicles must be uncompleted. A uniaxial tractor must be transported to the workplace without carts and other attachments. As a rule, the unit is transported to its destination by road. If the land that you intend to cultivate is located near your home, the motoblock must be mounted on a flat surface in any suitable place.

- Removal of transport wheels. After the single-axle tractor has been delivered to the area to be plowed, it is required to dismantle the transport wheels in order to exchange them for specialized lugs (iron wheels). To facilitate this work, tragus can be placed under the hitch located at the rear of the unit. Lugs are necessary for a more solid grip on the soil. They are irreplaceable equipment for plowing, planting beets, carrots, potatoes.

- Rotation of the hubs. At the next stage of the preparation of the unit before plowing, it is necessary to change the hubs on which the transport wheels stood for longer ones. This is necessary to increase the distance between the lugs. Such a solution will significantly improve the stability of the unit during operation.

- Installation of lugs. Moving on to the installation of iron wheels. It is essential that these elements are correctly mounted. Correct fit is determined by the directionality of the tread pattern. Narrowing the pattern shows the direction of forward movement.

Varieties

In order to choose the right plow for motor vehicles of a suitable design, it is necessary to find out what types of such devices generally exist. Depending on the direction of agricultural work, the following are practiced:

- monohull,

- 2 case;

- swivel;

- rotary;

- dump;

- moldboard devices.

You can make a multifunctional plow for a walk-behind tractor on your own, which is suitable for many types of soils. The most successful solution for plowing a summer cottage and for use by people who do not have the proper skills is a lightweight single-body device.

How to properly adjust?

The plowing depth is the distance the plow plunges into the soil while working. It is necessary to adjust it as far as the bayonet of the shovel takes. Otherwise, the following problems may occur.

- With insufficient depth, a considerable proportion of the roots of weeds will remain under the ground, which will require new strength to eliminate them.

- If the depth turns out to be deeper than required, the fertile soil layer will mix with what is located under it, and the vegetation will not have adequate nutrition. In this regard, you need to keep the golden mean.

LEMKEN Plough Adjustment | 01. Tractor Preparation | EN

The required depth is adjusted by means of bolts that mate with each other the lock and the bearing part of the plow. Therefore, when the plow is moved up and down, this debugging occurs. Inspect your plow design: if there is only one bolt connection and therefore a single hole, adjustment on this modification is not feasible.

Features of plow adjustment on a walk-behind tractor

Every owner of a vegetable garden, a garden plot, a small farm understands what it is like to manually plow the beds and pull out weeds. To simplify plowing, a plow is used. However, using a tractor or animal traction for a small plot of land is not cheap and stupid. For such tasks, motor vehicles MB 90, “Oka”, Brado Garden, “Neva” are used. In other words, it is a motor on wheels, on which a variety of attachments are mounted: from trailers to plows. Our article is devoted to the features of adjusting the plow on a walk-behind tractor.

Attack angle

For those who already have the practical skill of plowing the soil with motor vehicles, there is no need to explain what and how to perform at this stage. Further information is given for informational purposes to the one who encounters this case for the first time. The slope of the angle of attack, or, as it is also called, the slope of the angle of the field board, is the slope that indicates the height of the plowing plane in relation to a flat plane. Adjustment is carried out using a screw knob.

- put the unit with the plow on the supports, which were already mentioned earlier;

- turn the adjustment knob to the limit so that the field board is completely laid down on the ground, without gaps;

- start rotating the handle in the opposite direction until the back of the board rises 2-3 cm above the ground.

If you make a miscalculation, then the following unpleasant consequences will appear:

- at a large angle of the field board, the plow will become an anchor. the unit will begin to slip regularly and move forward with an effort;

- at a small angle. the required layer of soil will not be removed.

- check if everything is correct, only the plowing stage is possible. the unit should not resist or move excessively freely.

Regulation on heavy implements

Above, the technology for adjusting light motor vehicles was described, which is mainly used in summer cottages. But there are also heavy modifications. Their main difference is that the heavy ones are several times more powerful and massive than the rest of the models. In addition, they are equipped with diesel engines. This choice is explained by the fact that with an equal number of revolutions, a diesel engine has a higher torque than a carburetor one. Installation and adjustment of the plow for this type of equipment does not differ at all from those presented above. The only thing that needs to be indicated is that it is advisable to carry out the adjustment by the 2nd worker due to the fact that the mass of heavy units sometimes exceeds 200 kilograms.

Installation

The tragus can now be removed and the plow can be assembled. It consists in mounting a coupling mechanism on the plow, which is called a coupling. The coupling mechanism is whereby the plow is fixed to the towing hitch (tow hitch, hitch) of the unit. It can be of 2 types: universal and stationary. One hitch makes it possible to use a variety of objects (harrows, diggers, plows, etc.), and the other is needed to mate the adapter and the device.

To make the installation of a plowing tool more comfortable, install motor vehicles on supports, the function of which can be played by stones, bricks or boards. Fixing the plow is very simple. the hitch for the unit has its own place on the drawbar and is secured with a single kingpin. Many people believe that by fixing the plow firmly on the machine, things will go easier and faster. In practice, everything is exactly the opposite. Because in the process of plowing, the force is acting on the tool, concentrated vertically to the blade blade, there is a counteraction, which is trying to drag the entire single-axle tractor sideways.

In case of “dead” fixation, the worker must apply force, literally crushing the machine into the soil. this is one of the most common mistakes. Therefore, it is required to leave a clearance in the horizontal plane of approximately 5 degrees.

How the adjustment is done

The exact adjustment of the plow for the walk-behind tractor is built according to three parameters:

- width;

- depth of entry;

- tilt angle.

For self-adjustment of the plow, the width is set along its edges. For better crushing and easy cuts in the soil, its edge should be fastened at the same height with the ground hook, focusing on the inner side.

Read here what is better to use a single-axle tractor or cultivator in the country.

The depth is built up after the single axle tractor is placed on the stands. Set up firmly, without shifting towards the plow.

The height of the stands should be adjusted depending on how deep you plan to plow the soil. If this is plowing before the winter season, then the depth is chosen to be approximately 25 cm.In the spring, the depth is up to 20 cm.

After setting and choosing the depth, the plow attachment is adjusted. The option is considered ideal when it is adjacent to the soil.

If this is the first experience in plowing the ground with a walk-behind tractor, then use a tension rope for a guide, since the first row should be straight, so that you can push off further from it.

You can also use the wheel for support, it is located to the left of the plow, and walks on uncultivated ground, thereby preventing penetration too deep and regulates the depth.

After installation, a single-axle tractor is adjusted with special bolts in such a way that the rear of the plow is parallel to the soil.

The last step in the adjustment is to remove the walk-behind tractor from the stand, set the steering wheel to the height of your lower back. This is done to reduce the stress on the arms during prolonged work.

Plow on a walk-behind tractor: adjustment parameters and step-by-step instructions

In the article we will cover such topics as preparing the walk-behind tractor for work, the correct installation of the mounted plow on it. Also, how to properly adjust it, and finally advice on plowing the land.

a single–axle tractor is an excellent assistant for the gardener in preparing the land for further work. One attachment can replace many tools for plowing, loosening and other work.

Preparation for use

The first stage when using a walk-behind tractor is its preparation, which consists in the following steps:

- Removing it on a flat surface.

- Preparing the hook for soil and variable axes.

- Removing wheels and replacing them with soil hooks.

After preparation, you should proceed with the installation of the mounted plow.

Installing the plow attachment

There is nothing difficult to install. To do this, you will need:

- fix the plow to the coupling device without overtightening the nuts. This is done so that in the future it would be possible to adjust the parameters of the plow;

- the hitch should be fixed together with the plow to the shackle with two fixing pins.

This completes the installation and you should proceed to the next stage. adjustment.

Adjustment is a very important step, since the quality of plowing and the amount of effort expended depend on it. If the adjustment is incorrect, a single-axle tractor will not be able to cope with its work efficiently and a lot of time will be spent on simple tasks.

Recommendations for high-quality plowing of the land

- Change the plowing direction each time to prevent soil displacement.

- To simplify the work, turn the steering wheel of the walk-behind tractor to the left, then you will go on unplowed soil.

- With petrified soil, you should work the ground twice: the first time with a small grip depth, the second time. with the required.

For high-quality operation of the walk-behind tractor, it is important to correctly install the plow and adjust it. These tips will help you with this. Also adhere to all recommendations for plowing the land.

From this video you can visually familiarize yourself with the adjustment of the plow on the walk-behind tractor: