How To Properly Install The Cover On An Angle Grinder

Selection and replacement of discs for an angle grinder What are the types of discs for an angle grinder, their typical sizes. How to change the attachment to an angle grinder correctly. What to do if the disc is stuck and the nut won’t loosen?

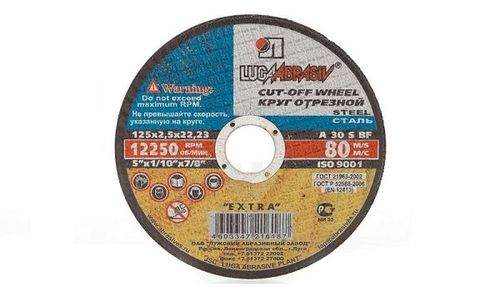

Cutting discs

The most common task performed with an angle grinder is cutting various materials. The choice of tool material also depends on what material needs to be cut.

- Metal cutting. The metal cutting disc is made from crystalline alumina corundum, as well as from a synthetic corundum called fused alumina. The main color of wheels for cutting metals is blue.

- Cutting stone and concrete. For cutting stone, you should choose a disc made of another abrasive material. Silicon carbide. This abrasive cuts white brick (silicate) and slate with ease. But to cut red brick, some types of concrete or ceramic tiles, this circle material will not work. Stone discs are available in green.

- Cutting ceramic tiles, red brick, porcelain stoneware and concrete. For these purposes, a diamond disc is already used.

This nozzle is made of metal, an abrasive mass with diamond chips is applied to the cutting edge. The picture above shows a segmented saw blade designed for dry cutting of material. All-metal discs require water cooling during operation.

- Wood cutting. Although there are saw blades on the market for wood that are no different from circular saw blades, it is best not to use them for safety reasons. When working with such a tool, the user often receives serious injuries due to jamming, bouncing, accidental slipping of the tool, etc.

Therefore, if you are still going to use a saw blade for wood, then you should adhere to safety measures. The angle grinder must be fitted with a protective cover and handle, and the user must wear a face shield or goggles. In addition, you must not use this tool to cut materials that are not intended for it.

Sharpening

To sharpen the tool, grinding machines (sharpeners) are usually used. But if you do not have the latter, but have an angle grinder, then you can purchase a sharpening (grinding) wheel for it, with which you can easily sharpen almost any cutting tool.

Unscrewing methods if the disc is jammed

What to do if the pressure flange is stuck? This nuisance, when the nut is bitten, often occurs if, while working with thick and durable materials, the tool is jammed in the workpiece. In this case, the abrasive wheel often breaks, and the spindle continuing to rotate tightly tightens the pressure flange. There are several ways to spin an angle grinder if the disc is jammed.

How to place the disc on the angle grinder correctly?

In order to correctly place the disc on the angle grinder, it should first be noted that the disc is installed on the spindle of the angle grinder using a special clamping flange with M14 thread. Let’s take a closer look at how to remove a disc from an angle grinder. In order to unscrew the disc from the angle grinder, the flange must first be removed. Especially for such purposes, manufacturers complete the angle grinder with a special open-end wrench. It has a specific shape. The pins located on the arms of this key are inserted into specially provided holes on the flange.

To unscrew the flange, we fix the spindle. To do this, we clamp the latch, which is usually a button on the top of the case. When pressed, the cotter pin is placed in the hole of the driven disc of the gearbox, and this in turn prevents it from rotating. Next, we insert the pins of the key into the specially provided holes on the flange, pressing the retainer, you must simultaneously turn it counterclockwise and move the flange from its place. If the manipulations were successful and the flange succumbed, you can unscrew it by hand and put it aside.

Now let’s dismantle the disk. Often, in the process of intensive work with the tool, a kind of plaque from small particles of metal and abrasive material forms on the inside of the protective casing. For optimal, stable and durable operation of the angle grinder, remove the bottom of the flange and clean the casing with a steel brush.

To install a new disk, after cleaning the casing, you must perform the following actions:

- Install the bottom flange in its place;

- We put a special gasket on top of it (if gaskets are not provided, you can cut them out yourself. The optimal material will be cardboard or tin).

- Install the disk;

- We put the second gasket;

- Install the top flange on top;

- We wrap the upper flange by hand in the opposite direction from the rotation of the angle grinder wheel, while holding the disk itself;

- Next, press the release button again and scroll the flange with your hand until you feel resistance;

- At the final stage, we make the final fixation using the same open-end wrench. To do this, insert the key into the holes and scroll a little more.

After all the actions taken, you can safely continue to perform the work.

One of the most frequently asked questions about mounting / dismounting accessories of an angle grinder is: “Which side should I put the disc on the angle grinder?”

Usually, inexperienced masters ask such a question. Is it possible to set the circle on the wrong side. Yes. Firstly, if the disc is not flat, but, for example, a petal disc, then you will not be able to install it incorrectly, if the petals are located incorrectly, you just need to twist the casing and the handle on the angle grinder. That is, the question disappears by itself.

If the circle is still flat, then you should focus on its label, the so-called “shirt”.

If the angle grinder rotates towards itself, the disc should be installed with the “jacket” outward, if the disc rotates away from itself, then, accordingly, it must be installed with the “jacket” inward.

If you do not adhere to this algorithm, there is a high probability that the disk will fail very quickly or immediately deform.

Method # 1 remove the disc from the angle grinder

First, figure out which way to unscrew the nut.

The flange must always be turned in the direction in which the disc rotates.

For this kind of work, you will need either two gas keys or two clamps.

Here’s what you need to do: destroy the remains of the disc, fix the washer located behind the disc with one key, unscrew the flange with the second.

Discs for an angle grinder differ in the following main features:

- Outside diameter;

- Disc thickness;

- The material from which the disc itself is made;

- The characteristic of the maximum rotation speed;

- And, of course, the area of the proposed work.

For the best understanding, let’s take a look at the main types of angle grinder discs and define their application:

- Cut-off wheels. It is the most widely used consumable for angle grinder. Their main purpose is to work with metal, stone and wood. A variety of cutting discs for an angle grinder are diamond discs. This is a heavy-duty tooling for processing high-strength materials such as reinforced concrete, tiles, porcelain stoneware, marble.

- Grinding and roughing wheels. As the name implies, this type of disc is used for grinding various materials, for example, polishing products made of stone, or for removing (roughing) the top layer, for example, removing a layer of rust or old paint coating.

How to place the disc on the angle grinder correctly?

In order to correctly place the disc on the angle grinder, it should first be noted that the disc is installed on the spindle of the angle grinder using a special clamping flange with M14 thread. Let’s take a closer look at how to remove a disc from an angle grinder. In order to unscrew the disc from the angle grinder, the flange must first be removed. Especially for such purposes, manufacturers complete the angle grinder with a special open-end wrench. It has a specific shape. The pins located on the arms of this key are inserted into specially provided holes on the flange.

To unscrew the flange, we fix the spindle. To do this, we clamp the latch, which is usually a button on the top of the case. When pressed, the cotter pin is placed in the hole of the driven disc of the gearbox, and this in turn prevents it from rotating. Next, we insert the pins of the key into the specially provided holes on the flange, pressing the latch, you must simultaneously turn it counterclockwise and move the flange from its place. If the manipulations were successful and the flange succumbed, you can unscrew it by hand and put it aside.

Now let’s dismantle the disk. Often, in the process of intensive work with the tool, a kind of plaque from small particles of metal and abrasive material forms on the inside of the protective casing. For optimal, stable and durable operation of the angle grinder, remove the bottom of the flange and clean the casing with a steel brush.

Cut-off wheels for an angle grinder, in turn, have their own subspecies, such as:

- Cutting wheels for metal work;

- Abrasive wheels for working with stone;

- Wheels for woodwork;

- Diamond discs (mentioned above).

The purpose of each type of disc usually corresponds to its name.

Among the grinding discs, there are four main subtypes. Flap, wire, diamond and bakelite-based grinding discs (straight, T41 profile and disc-shaped, T27 profile).

- The flap disc is made from sandpaper. Its main purpose. This is the elimination of existing coatings such as old paint, primer or paint coat. Also, with disks of this type, wood products are polished.

- Wire discs are used by artisans to remove rust. They can also remove other types of stubborn dirt.

- Diamond discs are used for stone polishing work.

- Disc discs are made of plastic or rubber and are used to polish metal surfaces.

How to properly install the guard on an angle grinder

For correct and safe work with an angle grinder, you should determine the basic rules for yourself when performing the necessary actions.

Having fully understood the peculiarities of working with this tool, you can ensure high-quality performance of tasks, as well as avoid injury. For this, it is necessary not only to know the technology of work, but also to comply with safety rules.

Preparing the tool for work

Advice on the correct use of an angle grinder would be incomplete without talking about the preparation step. First of all, you should tune in to the workflow and be prepared.

It is dangerous to handle this tool without observing safety rules, in case of health problems, as well as in case of a high degree of fatigue, or while intoxicated. Carelessness in handling this instrument can cost your health and possibly your life.

- First of all, you should prepare personal protective equipment to protect the worker from possible injury. It is imperative to install a protective cover, and use protective goggles.

The reason can be small fragments, sparks of hot metal, scale, in any case, appearing when using this tool. Severe injury is guaranteed in case of eye contact.

- The mask or goggles used must be of a closed type, since the flight of sparks and fragments occurs along a non-constant trajectory, and when using an open type of protective equipment, they can fly over them. The best option for a mask is a product with a safety net, since an unreinforced mask can break at the most inopportune moment;

- Installation of a protective cover.It acts as a barrier between the rotating cutting disc and the operator. In the process of work, there are often cases of breakage of circles. Anyone who often has to work with this kind of tools has had such cases. The most common cause of breakage is the wheel jamming in the slot. The protective circle is placed in such a way as to protect the operator from the flight of fragments and sparks. In the event of a sudden destruction of the circle during operation, the casing will become an obstacle between the fragments and a person who will be protected from injury.

The casing is fastened in such a way as to exclude its spontaneous rotation. Working with the installed protection is not always convenient, but it is strictly forbidden to remove it, as this can have dire consequences for the employee’s health.

Using quality consumables and serviceable tools, working with an angle grinder will be fast and safe.