How to properly sharpen a chainsaw chain. Chainsaw sharpening machines with “manual drive

Chainsaw chain sharpening. Necessary materials, video reviews, reviews

The performance of an electric or chain saw depends on the model and power of the tool, as well as on the proper care and maintenance. Correct chain sharpening is especially important. A correct chain not only increases machine performance but also protects the engine and bar from overheating and increases durability. In addition, using a tool with a dull chain can greatly increase your gas and oil consumption.

Sharpening can be done in a sharpening shop or in your own garage. Most chainsaw owners prefer to sharpen their chainsaws themselves, without the help of specialists. In today’s review we will consider in detail the main methods that are used by chain saw owners, we will introduce the devices and tools, without which neither a novice chain saw owner, nor an experienced mechanic can do without.

How to sharpen a chainsaw chain

Chainsaw chain sharpening is a procedure regularly encountered by gardeners and professional woodcutters. In this article, a master plumber will tell you how to restore the damaged teeth of the saw chain and quickly return it to its previous working condition.

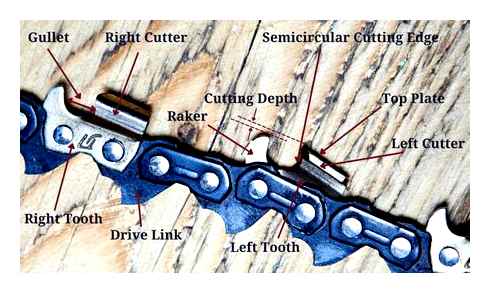

To understand how to properly sharpen a chain, you need to understand the basic principles of chain design and operation. You cannot just sharpen a chain by eye, you need to know the basic characteristics of the chain and its components.

A chainsaw chain consists of three types of links made of high-alloy steel:

How to sharpen a chainsaw

- Cutting. basic chain elements. A distinction is made between right-handed and left-handed, which are arranged alternately, with their cutting edges above the plane of the bar. The tooth design includes a depth-of-cut limiter.

- Drives (shanks). serve to transmit torque from the gasoline motor to the chain through the drive sprocket. This feature extends sprocket life and makes the chain more stable on the bar.

- Connecting. connect the shanks and cutting teeth of the chain.

One of the main elements of the chain is the cutting tooth, which plunges into the wood and removes shavings. Tooth depth limiter determines thickness of wood chip and limits depth of penetration into wood.

Recommended settings relative to the limiter are 0.025″ (0.65 mm) or 0.030″ (0.75 mm), depending on the chain.

The long service life of any chainsaw depends on proper care and use, including the use of the chain head. The good performance of the latter influences the performance of the device and the parameters of productivity. Incorrect sharpening can cause some problems with the saw itself. The most common are:

- Curved cuts;

- High loads on the saw, resulting in increased wear of parts of the device, and therefore a reduction in the service life of the entire device;

- Increased fuel consumption.

If the saw produces fine, dusty chips and the saw plunges into the cut with great force, it means that the target is blunt.

There are other signs of a dull chain:

- Speed of the tool is reduced;

- This results in an uneven and sharp sawdust;

- force is needed to cut through the wood;

- The chain is stretched or has become slack.

The chainsaw chain can quickly become blunt for the following reasons:

- Working too often with the saw;

- When the operator presses hard on the saw while sawing;

- If the chain is made of low-quality metal, or the steel has undergone an improper heat treatment;

- If you frequently cut wet or resinous wood;

- When sawing trees with hard wood, such as: oak, birch Karelian, cherry, acacia, elm, ash and others;

- If the chain encounters an obstacle in the form of sand or stones;

- If the chain is not properly sharpened or has insufficient tension during operation.

The device of all chain saws is similar, so the chain removal algorithm will be the same:

- First, you should wear protective cotton gloves to avoid cuts from the cutting teeth.

- Remove the protective cover from the chain saw and put it on its side on a flat surface.

- Unscrew the fastening nuts that hold the body and the guide bar with a socket wrench of the desired diameter, remove the top cover of the body.

- Now slide the guide bar all the way down to the sprocket, thus loosening the chain, and remove the working parts from the fastening bolts.

- Detach the chain from the bar.

How to know if your chainsaw chain is blunt and it is time to sharpen it: SIGNS

The long life of any chainsaw depends on proper care and use, including that of the chainsaw. The chainsaw’s good performance can affect how the machine performs and what it can do. Untimely sharpening can cause some problems with the performance of the saw itself. Most often these are:

- Curved cuts;

- High loads on the saw, resulting in increased wear and tear on the parts of the device, and thus a reduction in the life of the entire device;

- Increased fuel consumption.

If the saw produces fine, dusty chips and the saw plunges into the cut with more force, it means that the saw has blunted its aim.

There are other signs of a dull chain:

- the speed of the tool has decreased;

- Uneven and sharp sawdust is formed;

- You need to use more force to cut through the wood;

- The chain has been stretched or has become slack.

How to tell if a chain is blunt?

There are several indications that a chain is not working properly at this time:

- physical effort is needed for the same action.

- Chain stretching.

- Vibration sensation when working with the tool.

- Unevenness of the sawdust, which, in addition, becomes more like dust.

There are also several reasons why a chain can become blunt:

- Improper handling.

- Contact with too hard objects, such as rocks.

- Excessive and time-consuming work.

How to know when it’s time to sharpen your chainsaw?

There are several ways to know when it’s time to sharpen your chainsaw’s main element, as follows:

- You put more effort into your saw;

- The chain is sagging;

- Vibration is present when you are sawing;

- The cut is jagged.

If during any activities with the tool you see at least one of these causes, it is necessary to give a chain saw for sharpening, or to sharpen the chain on your own hands. Those who felling or working with wood often need to sharpen their chain saws. In some cases, the saw needs to be sharpened several times during the day.

How to sharpen a chain saw with a file

To sharpen a chainsaw chain manually you will need a whole set of special tools.

A flat file is needed to mill the depth stop.

Circular file. used for sharpening the cutting edge, for the work you need a suitable thickness of tool.

Holder. has guide lines along which the file slides while you sharpen the teeth.

HOW TO SHARPEN A CHAINSAW CHAIN.

Template. needed for sharpening along lines and correcting jobs.

Hook. needed to remove filings from the chain.

Special tools for sharpening the chain can be purchased as a set or individually. Some chain saw models come with this kit.

Position the template on the chain so that it fits into the kerf below. Place the round file on its rollers under the cutting edge of the tooth. The sharpening tool will move in a straight line parallel to the sides of the template.To grind the depth stop to the proper height, apply a template that fits inside the hole in the depth stop.

The limiter is machined on the basis of the type of wood you will be sawing. For soft wood you need to set the stop next to the word “SOFT”, for dense wood. “HARD”. A flat file is used for the job. Move the tool smoothly and evenly, strictly away from yourself.

Tips and recommendations for sharpening at home

“I noticed that the chain boxes have different sharpening angles on them, for different chains are different. The factory angle, for example, is more than 25 degrees, everyone writes that not less than 35 degrees, but in order to saw pine well, I put the angle of 40 or 45 degrees. Some machines don’t move the chain forward and backward, so it’s not even close to the factory sharpening! Individually select the thickness of the grinding wheel, and constantly monitor the form of its edge”.

“My opinion as a craftsman is that file sharpening is the best in the world. Machines are certainly good, but still listen to the advice of an expert, I’ve been working with chains for ten years no less. The machine will give you only 30 degrees horizontally and 45 degrees vertically sharpening, and a file up to 10 degrees horizontally. Verticality of the file is the same in degrees, but the shape of the cutting edge does not change and the working blade becomes wider. No other attachment will do that! Second: the machine always overheats, which is bad for steel, but the file is not. Third: the file is gentle on the teeth, if used, the chain will last about six sharpenings, two longer than after the machine.

The main disadvantage of working with a file, you need to train! Practice and only practice”.

First things first

You will saw with a dull chain saw, you will get three negative factors:

- Reduce the efficiency of your process. For example, instead of two cubes, saw one (in the same time);

- Exposing the mechanism to intensive wear, with the risk of destroying the drive sprocket and the tire;

- You get increased fuel consumption;

There is a fourth, perhaps not so important, factor: the “torn” cut of the cut.

And of course, you will be more tired, you will (probably) angry with yourself, such as “what to me the fool, not to sharpen beforehand, now torment”

Here is a test question (picture on the right). Guess which shavings “came out” from under the sharp and dull chain? (the answer is given below).

How to find out if the chain is blunt

- Increased physical effort;

- Sagging (stretching) of the chain;

- Vibration and “slowing down” of the cut;

- Inaccuracy of cutting and change of sawdust look (it becomes uneven with sharp “needle-like” edges, fine and dusty). This is the answer to the test.

“According to experts and me too: well sharpened teeth, more important than the power of the engine.”

Why the bluntness? The reasons are generally known, but I will name the main ones:

- Intense or volume work;

- Accidental contact with rocks, earth, hard knots, etc.п.;

- Improper handling (broad term).

Mechanized sharpening on a machine

Sharpening on a sharpening machine is much more convenient and doesn’t require a highly skilled sharpening machine. Such machines are electrically powered, and are equipped with special sharpening wheels.

For a domestic workshop, it is worth buying compact units that do not take up much space during storage, and are suitable for quick and high-quality sharpening of chainsaws chains from different manufacturers. Such units must operate from a 220 V fixed power supply, have low power consumption (up to 100 W) and be easy to install on the chain.

Choosing a machine, you should pay attention to the following technological characteristics:

- Possibility to process teeth with different thickness of the top edge and different chain pitch;

- The possibility of adjusting the angle of sharpening, within the limits specified above;

- Interchangeable sanding discs;

- Constant cutting width.

The design of the machine is simple and includes a driving motor, a shaft with a seating place for the sharpening disk, a handle with controls, a device for securing the machine to the chain. Adjustment of pressing force on the element to be sharpened is secured by a spring clip. The modern models of the sharpening machines are equipped with a differentiated clamping device, which makes the product self-aligning on the machine. A measuring scale on the body of the clamp is available for easier handling.

Optionally the machine can also be equipped with a miniature electric light which illuminates the working area, as well as with a hydraulic power unit which facilitates sharpening.

Safe working is ensured by the folding safety guard.