How to properly use a tile cutter. Design of electric tile cutters

How to cut tiles with an electric tile cutter: advantages, technical features and video

Home repair can become a real disaster if you do it yourself, not having enough knowledge and experience. This applies to every stage of repair, and tile laying is no exception. It’s one thing to put a whole tile on a flat surface. It is quite another thing. to fit it to size, to cut the necessary holes. Then there is a logical question: how to cut tiles with an electric tile cutter qualitatively and quickly?

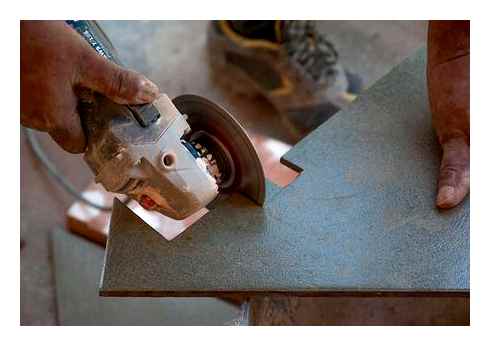

Before understanding how to cut ceramic tiles with an electric tile cutter, it is a good idea to figure out what this tool is. A modern electric tile cutter cuts the tile with a diamond disc, cooling the surface with water. This tool may resemble a circular saw or mitre saw. They have the same arrangement of motor, cutting disc, support platform and bed with a swiveling head. The special feature of the tile cutter is the diamond spraying on the disc in use, the ability to supply water into the work area. The system of gripping and positioning of the workpieces is also characterized by a certain complexity.

Electric tile cutter through the use of diamond successfully copes with cutting not only glazed tiles, but also stone (natural and artificial), brick, concrete, ceramic, faora, glass and many other building materials. For this purpose it is enough to choose the right disc and feed speed.

water-supply aids in cooling of surfaces of parts and tools itself, as well as in “binding” the dust to such an extent that it is practically absent during the operation. fed water ensures quick and clean cuts, even edges of tiles, no chips and no serious damage to the glaze.

To achieve accuracy in electric tile cutters there is a cantilever plunge mechanism, a system of stops (parallel and angular), line pointers, and more.

A modern electric tile cutter has a number of advantages:

- Even cut lines on the tiles,

- the possibility to minimize the number and size of chips,

- angled cutting ability,

- a minimum of dust during work,

- high safety and good performance,

- The ability to make grooves in the tiles, to cut diagonally and from the middle,

- It is even possible to cut a few millimeters off the edge.

However, like any other tool, the electric tile cutter is not without some disadvantages:

- no possibility to make the cut on a curved line,

- High enough cost, which is justified by the quality and functionality.

laser cutter || laser cutting machine price || manual tiles cutter machine full details in hindi

About the tool

A tile cutter is a generalized name for a tool designed to make straight and curved cuts in ceramic tile. Several modifications are produced:

- Manual tool. pliers (cutters) equipped with a cutting roller.

- Mechanized with manual control.

- Power operated tile cutter.

The power of a fixture is measured by the application of a single human force (hand-held tool) up to several kilowatts for an electric drive. The last option is the professional series.

How to properly use an electric tile cutter

The use of a more technologically advanced device. an electric tile cutter allows you to get a very accurate cut with somewhat rounded and smooth edges. There are no sharp edges that are obtained when working with a manual tile cutter, when cutting ceramic tiles with an electrically powered device. It also allows you to cut pieces of tile less than 5 millimeters wide.

The technology of cutting tiles on an electric tile cutter looks like this:

How to Use a Manual Tile Cutter Beginners Guide

- Before you use the tile cutter, you must mark the tiles.

- Place the tile on the tile cutter table along the guide rail that has been set up.

- Turn the diamond disc on and feed water to it.

- Gently move the tile to the disk with both hands. When the tile is brought under the disc, the pressure on it must be kept to a minimum. After plunge-cutting, it can be increased somewhat. If you press on the tiles too hard when plunging, you may experience strong vibrations and the tile may crack. When the diamond wheel exits during the cut, the pressure must also be reduced to prevent chips and irregularities.

- Make a clean cut and set the tile aside.

- Turn off the disc rotation and the water supply.

When working with an electric tile cutter, it is worth taking into account the recommendations of experts. It is important that the tile is accurately and evenly pressed against the tile cutter table when performing the operation, otherwise vibration will occur. Also uneven positioning of tiles on the table can cause the blade to jam in the central area of the tile or to catch the tile with the disc, resulting in an inaccurate cut not directed along the marked line. To move the tile accurately, you must use the guides, as well as press the tile with two hands, if you press it with one hand, you may also get an uneven cut.

Do not forget to periodically change the water in the tank, as it gets all the products of cutting. dust and larger particles of tiles. They can cause contamination of the diamond disc and subsequent seizure, which in the worst case can lead to disc or tile breakage. A disc breakage when the tile cutter drive is on is dangerous in terms of injury to the worker. If you see that the disc is excessively dirty or worn, you should replace it with a new one. In that case, you can make a clean, smooth cut.

And to consolidate you can watch a video on how to use the electric tile cutter by the example of Kalibr PLE-200 900.

How to properly cut tiles with a tile cutter

Working with a manual tile cutter is not too difficult. If possible, you can practice on a piece of unusable tile. Learn how to use the handheld tile cutter below.

- To begin, the tool must be placed on a level and solid surface. Not only the end result depends on it, but also your safety.

- The trimmer line for the required cut is outlined on the face of the tile.

- Once the lines of cuts are outlined, you should position the material on the working base of the tool.

- The tile should be set against the far side of the tool, and then use the ruler to correct the trimmer line of the cut.

- The handle that connects to the torch should be moved toward you.

- Start the cutting process. To do this, we slightly press the handle, and then spend it along the entire length of the material. One such movement from yourself to the outermost edge of the material is enough to make a groove.

- After that the handle should be pressed slightly, so that the tile breaks in the place of the groove formed.

When working with tiles, it is important to remember that all movements should be smooth, because the slightest wrong or uncertain movement will lead to the fact that the tile will break in the wrong place. a diamond tipped cutter produces a precise enough groove to break the material accurately and easily.

Important to know! Roughness can be expected at the point of fracture. You can grind it with a hand file.

The video below shows how to properly cut ceramic tiles quickly and easily.

Edge refinement

It is unlikely to get a near-perfect cut without professional equipment, but if we are talking about 2-3 elements, then the average quality can be acceptable. All the more so that unsatisfactory results can be corrected with a grinder or fine abrasive. Even a regular emery board will hide obvious defects and chips on the cut edges. With electric grinders and polishers you will get a better processing, but for this it is recommended to practice on the waste beforehand. In any case, in order to minimize the number of defects, you should initially adhere to a number of rules. How to use a handheld tile cutter to ensure even and smooth edges? To do this, you need to make do with one pass without creating duplicate marks. Therefore, the pressure should be sufficiently strong, but with full control and endurance of the cutting line. Also, be extremely careful when breaking, just follow the marked line.

Safety precautions when working with a tile cutter

Manual tools are less dangerous, but it is worth remembering the safety rules with them as well. The user must wear safety glasses and goggles to prevent slivers and dust particles from getting into the eyes.

Conversely, the use of gloves is not recommended for the hands. the clamping mechanism in case of gripping the matter can also lead to injury.

The question of how to use a handheld tile cutter is also important from a safety standpoint if you have a large amount of work to do. In-line operations leave a lot of fine dust. Even careful periodic cleaning will not eliminate fine particles. That’s why you must wear a respirator or a mask that protects the respiratory system.

Cutting tile and porcelain tile with a mechanical tile cutter

To properly cut tile with the tile cutter, it is recommended to hold it in water for a while beforehand. this makes it easier to cut.

Using a mechanical stationary tool, cut the tile material in the following way:

- On the surface of the tile is applied marking line for the trimmer;

- Lay tiles on the bed so that the marking coincides with the path along which the cutting wheel (carriage) moves;

To make the edges of the final pieces neat, the trimmer line of the cut should be at least a centimeter from the tile edge.

The pressure on the carriage should be so strong that the wheel will cut through the tile enamel, and the tile will not squeeze through. Do not grind several times, because the edges of the fragments will be uneven. When the bevel is uneven and chipped, it will need additional sanding. Cutting porcelain tiles with a stationary cutter is possible only if the thickness of tiles is up to 15 mm. The algorithm of the process is completely similar to the above.

Manual roller cutters work the same way as stationary devices. Only very thick tiles are suitable: such tools are not designed for professional use. Some beginners quite often have a question about whether it is possible to cut glass with a tile cutter. It can be done, but only with normal material. To cut hardened varieties, you will need a special power tool.

Work with tile cutters as follows:

- bring the tool to the edge of the tile, placing its wide part on the front surface of the ceramic, and the central part of the pliers is placed along the line of the bend just above the groove;

- Then carefully break off the pieces of material.

You can make round holes with the wire cutters, but you need the right skills and care to do the job well.

Advantages and disadvantages of handheld tile cutters

Like any other tool, the handheld tile cutter has positive and negative qualities that must be taken into account when choosing a device for cutting tiles.

Among the advantages are the following characteristics:

- Independence from the electric grid;

- The ability to use at any temperature and humidity;

- compactness;

- low weight;

- low cost.

The main points in a nutshell

Manual tile cutter is represented by a platform, guide and carriage, which has a handle, a foot for breaking tiles and a cutting element in the form of a roller.

The tool is characterized by mobility, low weight, ease of use and low cost.

The disadvantages of tile cutters are low productivity and relatively poor cutting quality against the results of electric counterparts.

During the work it is important to accurately position the tile and form a groove on the surface along the entire length with equal depth.

For best results, the tool must be properly cared for and checked for proper operation and any deficiencies must be corrected in a timely manner.