How to put the coil on the trimmer

Thick line

It is stored at the top of the trimmer body.

In addition to the standard lawn line, my trimmer also has a thick line for cutting rough weeds. It has the shape of a pigtail, i.e. three lines are tightly intertwined. This line has its own spool.

Storage space for spare coil

It is very simple to install such a fishing line into the reel. according to the internal scheme inside the reel. We insert the center of the line with a metal mount in the upper part of the reel, and draw the ends of the line along the grooves and bring it out.

Trimming the line into the trimmer.

I want to devote today’s article to the sore subject of summer residents and gardeners of the entire post-Soviet space “How to fill the line in the trimmer.” Not many trimmer manufacturers answer this question in their instruction manuals. Therefore, it is also difficult for simple gardeners to figure out how to do it correctly.

I want to start with a brief description of the technical characteristics of the trimmers.

So, trimmers are electric and gasoline. The cutting element for trimmers can be a line and a knife. The fishing line is ordinary, four. pentahedral and intertwined (in the form of a pigtail). Knives come in 2, 3 and 4 bladed knives. Knives also come in plastic and metal.

The line feed system from the trimmer is manual, semi-automatic and automatic.

Development engineers who create new models of trimmers accurately calculate the diameter (thickness) of the line and the number of knife blades, according to the power of the trimmers. Otherwise, the engine is overloaded, resulting in damage to the engine. And these are additional and significant costs.

Trimmers on the market today:

With one nozzle. only a line.

With two nozzles. a fishing line and a three-four-blade knife.

With one attachment. only three to four blades.

Our Kulibins have long ago learned to improve any mechanisms. So, for example, some gardeners make successful, in their opinion, replacement of fishing line with a metal cable, or fishing line. But at the same time, they do not think about the safety of their own and their loved ones, because, like a cable with the power of a working trimmer, it can easily break out and not only injure the mower and others, but leave him crippled for life. The use of a fishing line can and gives a better effect, I have never personally tried it than a trimmer line, but this work has a number of inconveniences: when it comes into contact with hard objects, it loosens or it can simply be pulled out of the reel indefinitely.

So, what is called closer to the topic. Here is an example of how to thread the line into the trimmer (Trimmer BOSCH Art 30). Everything is very simple. Started.

After you have chosen the line for refueling, you need to cut off the required amount of line, because all the line in a skein will not wind up in a reel.

Cut off and start reeling.

Remove the coil and the protective cover from the coil.

They took it off. We fix one end of the line in the gap and carefully and evenly wind the line.

The amount of line should be such that the protective cover of the reel closes and the line on the reel unwinds a little.

We put the other end of the line into the hole on the protective casing.

Next, we take the coil and the protective cover of the coil. We squirt the end of the line from the reel into the metal hole on the protective cover of the reel. Tighten the line a little.

We put it all on the trimmer. Turn the coil clockwise until it clicks.

They fixed it. Now we connect the trimmer to the network. We put the trimmer in the starting position for work. We turn on the trimmer. Excess line length will be cut on the trimming blade.

Coil in trimmer

That’s all we start working.

Heavy-duty line in a reel

Such a reel is attached to the trimmer in the same way as a reel with an ordinary line.

How to thread the line into the trimmer spool and which one is better to use for this?

Very often, those people who personally own dachas and vegetable gardens are faced with the need to care for the lawn on the site. In such cases, you simply cannot do without the usual manual braid or trimmer. The first is slowly fading into the background, and the number of people who use it is getting smaller and smaller. The trimmer works automatically and does not require a lot of effort. over, you do not need to have a special skill to use it.

How the trimmer works?

The principle of operation of such a device is that the grass is cut by a special fishing line installed on a fast-rotating head. The number of revolutions per minute can reach 8000. In a short time, the line becomes unusable, more precisely, it is erased. Then summer residents have a question: “How to fill the line in the trimmer coil”?

Types of trimmer lines

First of all, in order not to resort to frequent replacements, it is better to use a denser line. The number of its types and manufacturing firms is simply amazing. The main parameter of the trimmer line is its diameter. It varies from 1.6 to 3.2 mm. The most common type is 2mm line. However, its selection must be made depending on the type of trimmer you have.

There are several options for the section of the line. So, it can be round, square, in the form of an asterisk with sharp edges. The last option is the most effective. However, it should be used only on powerful braids and at the same time you need to know how to thread the line into the trimmer spool. Therefore, we can conclude that the more powerful your brushcutter, the thicker the line should be.

A process such as winding a fishing line on a trimmer is not difficult, but it has its own characteristics. First, you need to choose the right fishing line, the diameter of which is prescribed in the device’s passport.

First, unscrew the spool cap. Be careful, as the thread can be left or right. The left-hand thread is necessary so that the head of the scythe does not unwind during operation.

Threading the line into the trimmer

Before threading the line into the trimmer spool, measure 5 m from the skein (this is the average amount of line installed on trimmers). Then fold it in half to find the middle. The resulting center must be inserted into a special slot located on the spool. After that, wind the line in the direction of the arrow on the head.

From the above it follows that the process of replacing the fishing line itself is not difficult. Having carried out such a manipulation as winding a fishing line on a trimmer reel several times, you will bring this process to automaticity. The only thing is that you need to constantly monitor the condition of the fishing line in order to avoid breaking it at the time of work on the site, when a spare coil may not be at hand.

Now you know how to thread the line into the trimmer spool, and you can do it yourself without much effort.!

How to tuck line into the trimmer: a few simple tips

Thanks to modern power tools, a person is given a lot of opportunities to reduce manual labor. These innovations include the trimmer, which greatly facilitates the process of mowing and lawn care. This device reduces the time for gardening work, turning difficult physical work into entertainment. The trimmer uses a fishing line as a cutting tool. It stretches strongly and thus mows grass of almost any height. It is quite easy to operate a power tool, but the problem arises when the cutting material runs out. Not everyone will immediately figure out how to tuck the line into the trimmer. Although this is a simple operation, it is not always clear to a person who is faced with this task for the first time how to properly wind it on a reel. over, the instructions do not contain information on how to choose and replace the trimmer line.

How to quickly and correctly tuck the line into the trimmer?

Once you figure out how to change the cutting material, the further use and maintenance of the electric trimmer will be greatly simplified. To wind the trimmer line, several operations should be performed, namely:

- Unscrew the nozzle by rotating the drum to the right. You will have a head in your hands with the remnants of an old thread. Open it with a screwdriver, or wring out the latch and turn the cover in the direction of the arrow. This operation should be carried out carefully, since there is a spring inside, which, straightening, can throw out all the internal parts of the drum. To change the line in the trimmer, you need to take out the spool and remove the rest of the material.

- Take 5 meters of new thread and fold it in half. There is a hole in the middle of the spool where you need to insert the material. There is also an arrow indicating the direction to reel in the trimmer line. It is important to consider some points. If the spool has two holes, then half of the trimmer line should be tucked in one direction and the other in the opposite direction. When finishing inserting the material, it is better to leave 15-20 cm free.

- Assemble the drum, reinstall the spring and washers. Then, while holding the spool, thread the ends of the line into the holes on the sides of the nozzle. Then put the head back in place, tightening the cutting material.

How to choose a fishing line. length, diameter, restrictions

IMPORTANT TO REMEMBER! Do not use fishing line or metal cables for the trimmer. This replacement is ineffective and dangerous. The rope can injure not only the mower himself, but also those around him.

As for the length, you should rely on the estimated frequency of use of the trimmer. The more often, the more it costs to stock up expenses.

Information about the possible line diameter can be found on the body trimmer spools. Most likely, the range will be indicated there. The thickness varies from 1.2 to 4 mm. Choose the appropriate option, taking into account the characteristics of the cultivated area. The larger the diameter, the easier it is to mow tough grass.

How to Wrap the Line on a Trimmer Spool Correctly. Step-by-Step Guide VIDEO

How to wind the line onto the trimmer spool

Preparation. remove and disassemble the spool

On most electric and petrol trims, you will need to remove the spool to replace the line. The FUBAG tool lets you skip this step. To make the instruction universal, we will still consider it in detail:

Secure the shaft. Insert the locking element into the corresponding hole. It can be a thin screwdriver or a metal rod.

Unscrew the bobbin case. In our example. strictly in the clockwise direction.

Unscrew the cover according to the direction indicated on the body.

Remove the coil for winding.

The preparatory stage has been passed. You can proceed to winding the fishing line.

Winding Algorithm

Insert the resulting loop into the groove.

Lay the line in the direction indicated on the element body.

Insert the short end into the slot on the side of the spool.

Secure the long end in the opposite groove.

Place the spool of coiled line into the spool body.

Pull the line out of the locking grooves.

Put on the cover and fix.

Trim the ends of the line, leaving 10 to 15 centimeters.

The replacement of the line is completed and now it remains only to screw the bobbin onto the trimmer and you can work.

ATTENTION! Typical line problems

No wonder they say: “Forewarned is forearmed“. Knowing about possible problems and the causes of their occurrence, you can prevent them in time. We recommend to remember or leave a memo.

| Problem | Cause | Decision |

| Line break | Stones, branches and solid objects in the grass | Avoid collision |

| Poor cord quality | Replace with a quality analogue | |

| Head outlet wear | Complete replacement of part required | |

| The line is unwound | The spring in the coil is weakened | Check spring and replace if damaged |

| The line is sticking | Poor line quality, due to which it can melt under the influence of temperature from the heating head | Reel in less line or replace with a better line |

For a better understanding of the mechanism of the process of changing the line in the spool with a video guide prepared by FUBAG specialists:

How to quickly and easily remove the coil with your own hands

Before replacing the old line with a new one in the detachable trimmer spool, you must remove the head.

The process is completely simple, even beginners can do the job:

- Remove the upper fixing cover.

- Take out the removable spool.

- Get the spring out, if any.

- Unscrew the bolt with a screwdriver.

- Remove the housing from the shaft.

What are the trimmers and features of their use

The trimmer is useful for mowing small or difficult areas, such as near hedges, between beds and along paths. Today, manufacturers produce a wide variety of gasoline, electric and battery models, which can be selected for any owner’s request.

A fishing line is used as a cutting element of the trimmer. In the process of work, sooner or later its length will end, and then the question will arise before the owner of how to properly replace and fix the thread tucked into a removable spool.

How to properly wind the line on the trimmer: step-by-step guide and video instructions

A beautiful lawn will only look truly well-groomed if you regularly mow the grass. A trimmer is best for tackling difficult areas. Any owner of the unit will sooner or later face a solution to the problem of how to wind the line on a reel, because wrong actions can not only worsen the quality of the mowing, but also disable the equipment. Today in the Homius review we will tell you about all the methods and nuances of replacing the fishing line and the features of choosing consumables.

How to wind the line around the reel of the double barb trimmer

You can watch the video before work, and also take into account the following recommendations.

- If there is only one track, both threads are wound parallel.

- If there are two tracks, each section is wound in a separate groove.

- Wind the threads in the opposite direction to the rotation of the head.

- The length of the free ends should not exceed fifteen centimeters.

- Thread the ends into the outlet holes.

- Assemble the head and check the trimmer performance.

Advice! If the loose antennae are of different lengths, do not worry. During operation, excess ends will be cut off.

Auto feed trimmer: how to wind the line into the removable spool

In some models of trimmers, a reel is installed, in which the line is refueled automatically. It is enough for the owner to fix the ends in the head, after turning on the equipment, the mechanism will perform all the winding manipulations on its own.

You should know this! The strengths of the automatic trimmer head include the ease of winding. The disadvantages of such equipment are frequent breakdowns of a complex mechanism and high cost.

How to wind the line correctly on the spool of a single-barbed trimmer

Most often, a thread up to five meters long is used. The procedure consists of the following steps:

- Bend the cord with a loop and insert into the groove of the head.

- Wind the thread in the opposite direction to the marks on the body. They indicate the direction of movement of the head.

- Leave the end of the thread up to fifteen centimeters free to increase centrifugal force.

- Thread the free end through the spool outlet.

- Assemble the trimmer head.

Things to consider when choosing a fishing line

It is important to choose the right material before inserting and locking the line into the detachable trimmer spool.

Rating of the best models of gasoline trimmer. An overview of manufacturers and models, as well as useful tips from experts reviewed in this review, will help in a difficult choice among many device models.

How to wind the line correctly: replacement features depending on the type of removable trimmer coil

To figure out how to thread the line into the removable trimmer head, the following recommendations and video instructions will help.

How to make a coil yourself

The basis of a homemade reel is a disc made of durable material. It is best to use textolite about 5 mm thick for these purposes. It is strong and reliable enough. The size of the disc depends on the size of the trimmer and personal experience. how is it more convenient to work.

Next, a hole should be drilled in the center of the disc. The diameter of the hole must be equal to the diameter of the rod axis (the latter is attached to the rotating shaft of the motor). In this case, it is extremely important to determine exactly the center of the disc. After that, 4 holes should be drilled for the line. Their diameter will be equal to the diameter of the fishing line, and they will be located in pairs on opposite sides of the axis (2 on one side, 2 on the other from the axis of rotation). In this case, the design of the reel is greatly simplified: it is not required to wind a large amount of fishing line, but it is enough to fix (tie) a small section of it through the ready-made holes.

To give the structure the necessary strength and reliability, it is recommended to find a spring, the inner diameter of which will be equal to the diameter of the shaft, and install it on the shaft over the finished disc.

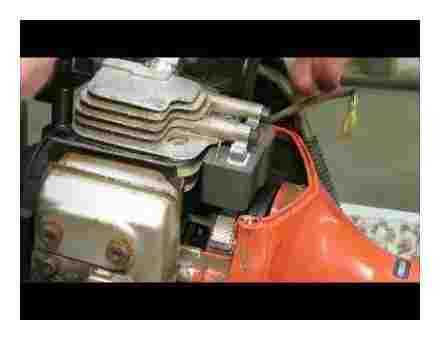

String Trimmer Ignition Coil Replacement #545046701

Once the line is tucked in and secured to the disc, you can start testing. The fishing line does not need to be fixed on the disc: even when threaded through the holes, it will not fall out, because the engine gives high revolutions to the shaft, and the centrifugal force is enough to hold the fishing line under load.

This design, instead of a purchased trimmer coil, has many advantages: you can install any line (both thin and thick) into it, the device itself is practically “indestructible”, and it will not take a very long time to acquire a new coil.

The disadvantages of this homemade product include the following:

- the need to cut a pair of pieces of fishing line of the same length;

- when installing without attaching the fishing line, it is necessary to make sure that equal lengths of fishing line hang from the reel.

Video about winding the line on the trimmer reel:

The body can be used from an old coil. it rarely breaks.

Coil specifics

In the modern world (both in the city and in the countryside) it is practically impossible to do without such a modern and useful tool as a trimmer. It is widely used by employees of municipal services in large cities, such devices are in demand in farms, they are used to improve summer cottages, vegetable gardens, orchards, etc.

Photo of the complete set of the coil of the garden trimmer.

However, it should be remembered that the main working element is the trimmer head. a spool with line. It is this element that most often fails and requires maintenance. The price of the reels has a wide range (from 10 to 150), which makes such a tool even more expensive. Any manufacturer (even a branded one) usually equips its product with an inexpensive and low-quality coil. However, it is possible to work for a long enough time with a primitive coil, provided that work is carried out on time to care for it.

string trimmer weed eater coil test & replace

Like any other mechanical element, the coil requires cleaning of accumulated grass, cooling in case of overheating and filling with lubricant. However, coils often fail for various reasons, and buying new ones or carrying broken ones for repair is quite expensive. In this case, almost all faults can be eliminated independently. It is not difficult to disassemble the coil, especially if you use the instructions.

The first part that often fails on the trimmer reel is the line. The line is a consumable for which the manufacturer is not responsible. At the same time, on many models of reels, changing the fishing line is a difficult procedure (and for some brands it is impossible). Attempting to replace the line with a material other than the parameters of the native line can lead to the destruction of the reel.

The reel itself (the part of the element on which the fishing line is wound) rarely fails, while the grooves through which the working part of the fishing line is threaded and which holds it can collapse (grind off), since they are almost always made of plastic.

Video about cable lubrication, shank replacement, installation of the guard and trimmer coil:

Despite the abundance of spare parts for trimmers on sale, not everyone can afford to buy them, in addition, there are often restrictions on available products. For example, manufacturers make “individual” mounts for the trimmer, a universal reel will not fit on such a mount. This often makes it impossible to obtain a suitable coil for the price. Some manufacturers make spools designed for thin line (up to 3 mm in diameter), which significantly limits the trimmer’s capabilities. Therefore, there is an option for self-manufacturing of the coil.

How to make a trimmer coil with your own hands

- 1 What is a trimmer

- 2 Why this tool is called differently

- 3 Specificity of the coil

- 4 How to make a coil yourself

- 5 Conclusion

The trimmer reel cuts the grass, but it will wear out and often need to be replaced. Recently, motorcycle or electric scythes have become widespread. The main working element of such a garden tool are spools with a fishing line tucked inside. Therefore, it is extremely important to choose a high-quality item so as not to waste your finances, because the device is quite expensive. To reduce the cost of servicing brushcutters, you can learn how to independently fill the trimmer coil with the forest.

Often, manufacturers of power tools do not complete their products with a number of devices that are necessary or useful for operation, offering to purchase them separately (as an additional option). With a reel for a brushcutter, the situation is different: since this is the main working element of a garden tool, all trimmers are supplied with it, however, the quality of the reel from the scythe kit leaves much to be desired.

The consumer has to purchase the coil separately. this is done to increase sales and generate additional profit for manufacturers.

Below are questions about what a trimmer is, what coils are and how to insert and fix the fishing line yourself.

What is a trimmer

A trimmer is understood as a brush or electric trimmer. In fact, it is a type of lawn mower (hand mower) that is designed for mowing grass. This is a modern braid. Initially they were developed for agricultural work, but the main application of trimmers was precisely lawn mowing.

For the first time the idea to create a trimmer came to mind of the American entrepreneur J. Bollas. While driving his car through an automatic car wash, he noticed that the principle of rotating brushes could be used to mow crops.

Trimmer configuration diagram.

After that, he assembled a primitive trimmer from a tin can (as a spool) and a line threaded through the holes drilled in it. He installed the resulting structure on a pole, on which the engine from a moped was previously mounted. The device mowed not only wheat, but also grass. Realizing that he would earn a lot of money by selling the scythe, the entrepreneur improved his product and gave it the name “Weed killer”. A feature of the invention was the ability to mow the grass around the trees. the forest cut the grass perfectly, but did not injure the bark.

The main purpose of such a tool was to mow grass in small areas in places where classic wheeled vehicles cannot be used:

- in the presence of a large number of shrubs;

- in gardens with many trees;

- near fences and fences;

- if the site has uneven terrain.

All trimmers include a barbell. the main structural element. A gasoline or electric engine is attached to the rod from one end, and a reel with a fishing line is put on the other. the main working element. In this case, the type of transmission can be any. it is limited only by the capabilities of the manufacturer and commercial parameters.

Why this tool is called differently

Trimmer was originally understood as a hand-held lawnmower with an electric motor. At the same time, the mower was powered both from the mains and from the battery, which can be installed on a rod or carried in a special pouch.

The main cutting element is the fishing line, which creates some restrictions on the type of processed grass: you can only mow plants with a thin and soft stem. The mowing area is limited by the length of the cable or the capacity of the battery. However, recently, braids with gasoline engines have also been called trimmers. They give greater mobility to the worker, which can significantly increase the size of the site.

But electric and gasoline scythes were originally varieties of lawn mowers, however, with the advent of the trimmer, these designs have ceased to be in demand and are now rarely produced, and their names have passed to trimmers. most people are more accustomed to call this tool that way.

Such a self-made coil can significantly reduce the cost of operating the trimmer, which improves its operating parameters. The same trimmer can be used to cut small shrubs as well as soft and thin lawn grass.

DIY trimmer coil repair

The trimmer, whether petrol or electric, is the only solution for mowing grass in hard-to-reach places that a wheeled lawnmower cannot handle. As a cutting tool in trimmers, metal knives or special fishing line are used, which is tucked into the trimmer coil. But, unfortunately, trimmer heads become unusable over time during operation. Some malfunctions can be eliminated by hand, and some require a complete replacement of the mowing head.

How to remove the spool and replace the line

Trimmer owners, mostly beginners, find themselves in confusion, bordering on panic, when they need to change the cutting tool or line in the reel. Very often, when trying to unscrew the mowing head, users simply render it unusable, not suspecting that it is unscrewing in the opposite direction. To prevent this from happening, if you need to replace the tool, it is recommended that you read the step-by-step instructions below.

- Stop the brushcutter engine or power off the electric trimmer before threading the line into the spool to avoid injury from accidentally starting the cutting tool.

- Unscrew the attachment attached to the gearbox shaft. To do this, the shaft must be fixed by aligning the holes on the washer and on the axle, and inserting a metal rod or screwdriver into them.

- Unscrew the nozzle. You should be aware that the thread on the shaft is left-handed. Therefore, turn the trimmer coil to the right, that is, clockwise.

- Disassemble the mowing head. Most often, the head cover is attached to the clips. To remove it, you will need to sink these latches into the case, squeezing the edges of the cover. If your trimmer has a semi-automatic mowing head with a button on the bottom, then the disassembly of the attachment should be done carefully, since you can lose the spring, which sometimes flies out when the cover is removed.

- Cut off the required amount of line. Usually its length is 5 meters. Use a cord of the same diameter as indicated in the instructions for the tool. It is not recommended to exceed the maximum line diameter as this will result in increased engine load and higher gas mileage.

- Find the midpoint of the line by folding it in half. You will have a loop.

- Special grooves are cut inside the coil (there may be holes). Insert a loop of line into this groove.

- Wind the line around the spool by turning it counterclockwise. It is necessary to fill in the cord as evenly as possible, the turns should lie down without overlap and with good tension. When the winding is finished, leave free ends of the line about 20 cm long and fix them in the grooves on the sides of the reel.

- Assemble the mowing head. Be sure to insert the spring and washer (if equipped) before final assembly of the accessory. Place the spool in the body and thread the ends of the cord through the holes or lugs.

- Put on the cover and secure it with the latches.

- Screw the adapter back onto the gearbox shaft, also securing it with a screwdriver. You will need to twist the trimmer coil to the left (counter-clockwise).

The cord lengthens spontaneously

There are times when the trimmer user notices a very fast line flow. However, he never hit the ground with a button to lengthen the line. The reason for the fact that the line spontaneously lengthens, being cut on a special knife on the casing of the device, may be the absence of a spring in the mowing head. Often novice users of mowers, trying to load the line into the reel, forget to install the pressure spring in the head, or completely lose it when opening the lid, and in the future, do not even know about its existence.

Also, the line can be lengthened without using a button if the spring is loose. If checking the spring has confirmed this fact, then several washers must be placed under it in order to enhance its clamping properties.

Line does not lengthen automatically

If the line does not lengthen when you lightly hit the trimmer button on the ground, then the reasons for this may be the following.

Option 1. a bite has occurred, i.e. clamping the cord between turns. This problem usually occurs if the user has been winding the line on the reel unevenly, with intersecting turns, or winding it with insufficient tension. In the latter case, when the mowing head rotates at high speeds under the influence of centrifugal force, the cord begins to tighten, as a result of which inter-turn clamping of the fishing line is possible. To fix the problem, you will have to disassemble the coil on the trimmer and rewind the cord correctly, that is, in even turns with good tension.

Option 2. too short ends protrude from the head. The line may not come out when hitting the ground if the ends sticking out of the head are not long enough (short). In this case, the centrifugal force is not enough to stretch the line. Therefore, it is required to stop the unit (turn off the engine or disconnect the electric trimmer from the mains) and pull the line manually, after pressing the button.

Option 3. the line is brazed inside the mowing head. This causes the coil to lock and not spin when the button is pressed. Basically, this happens for several reasons: poor quality of the cord, overheating of the coil during prolonged operation of the unit, hitting the line against hard objects.

- In the first case, third-party cord can be made of low-quality and low-melting materials that cannot withstand mechanical and thermal stress. Therefore, you should give preference to “branded” lines.

- But, if you nevertheless purchased a fishing line of unknown quality, and it is often soldered during operation, then you can follow the example of some users who, after filling the cord into the reel, wet it with either silicone grease (from a can) or mineral oil. This procedure greatly reduces the likelihood of soldering the turns of the fishing line together.

- Also, the line can be soldered if it hits a hard object (stone, fence, dry branch, etc.) during mowing. As a result, it stretches slightly and is pulled back into the head at high speed. From friction, the cord heats up, and its turns stick together. The only thing that can be done to eliminate this malfunction is to open the trimmer spool and rewind the line.

Trimmer coil device

Trimmer mowing heads come in a variety of designs, both simple and complex. The figure below shows a disassembled semi-automatic trimmer head from a Husqvarna brushcutter.

This type of head is present in the complete set of most mowers and electric trimmers, such as Stihl (Calm), Patriot (Patriot), Champion (Champion), Bosch (Bosch), Huter (Hooter) and others. The device of the mowing head is quite simple. It includes the following details:

- mowing head base;

- button for semi-automatic cord feed;

- bobbin (spool) into which the line is tucked;

- spring;

- eyes. through them the line comes out;

- trimmer head cover;

- line (cord).

There are also simpler trim heads shown in the following photo.

All these attachments do not allow you to change the length of the line in a semi-automatic mode (after pressing a button). If the cord breaks, you have to stop the mower and change it manually.

Major coil malfunctions

Users of electric trimmers and petrol cutters often face a problem with a semi-automatic cutterhead. Coil malfunctions can be as follows:

- the line does not lengthen automatically;

- the cord spontaneously comes out of the reel.

Is it possible to make a coil for a trimmer with your own hands

- Take a piece of plywood or PCB and draw a circle about 14 cm in diameter on it.

- Cut the disc with a jigsaw or metal hacksaw.

- Drill a hole in the center of the disc that matches the diameter of the gearbox shaft. Do not forget to put a washer on it before installing the disc on the shaft.

- Small corners can be screwed on the edges of the disc or 1-2 holes can be made on opposite sides. They will serve for refueling the fishing line in them.

- Several screws can be screwed into the plywood to secure the line.

This homemade mowing head is secured to the shaft with a nut. It will not work to tighten or unscrew the nut without fixing the shaft. To replace the cord, it will be enough to loosen the screws, insert a piece of line of the required length and press it again.

Also, the mowing attachment for attaching the fishing line to it can be made of metal sheet. How to do this can be understood from the following video.

How to assemble a new mower starter?

To assemble the starter, do the following manipulations.

- Pass one end of the cord through the opening at the beginning of the spool and tie it in a knot. The knot must not pass through the hole. Otherwise, you will disassemble the starter again.

- Wind the cord onto the spool itself.

- Install the spring into the starter housing, hook one end of it in the groove and wind it. For convenient winding, twist the body counterclockwise.

- Place the ratchet on the spring.

- Hook the return spring to the ratchet itself, attach it to the spool.

- Install the main spring and housing with the assembled ratchet, connect the parts of the starter together and tighten everything with the main bolt.

After assembling the starter, pass the free end of the cord through the hole in the housing for the reel. Re-pass the same end through the hole in the handle that the cord is pulling on. Tie a strong knot on the handle. Check the operation of the starter parking brake.

Worst failure scenario

There are times when the starter is still operational, but a worn out cord can break, for example. The ratchet has not yet had time to work when the engine is started, and the remnants of the cord are immediately wound around the coil, the return spring loses its hooks, the grooves in the starter housing break. Bottom line. replacement of both springs and housings.

If a petrol cutter or trimmer model has long been discontinued, it will be difficult to find exactly the same parts, and the starter is changed entirely.

How does the starter for petrol cutters or trimmers work??

The starter is a generally single and universal mechanism for petrol cutters, trim tabs, gasoline and diesel generator sets. It is not a problem to equip them even a car, motorcycle or scooter, if your vehicle has free space for its installation. It was not for nothing that many Soviet cars and trucks were equipped with a starter tool that vaguely resembles a tire bent twice.

The modern “handbrake” starts exactly from the cord. it is tied to the mechanism, and it is impossible to lose it.

The starter assembly has the following parts:

- hook ignition spring;

- cord wound on a reel;

- return spring;

- ratchet drive and main spring;

- mechanism housing protecting the ratchet;

- locking bolt.

Starters for petrol cutters: device and installation features

- How does the starter for petrol cutters or trimmers work??

- Worst failure scenario

- How to replace or replace the starter spring?

- How tight is the spring cocking??

- Assembling the brushcutter starter

- How to assemble a new mower starter?

- How to change the starter cord?

The recoil starter for a petrol cutter or petrol trimmer is a mechanical unit that includes a pulley fitted to a ratchet. A rope is wound on the pulley in the initial position. At the start, it is pulled outward. The pulley is spring loaded. as soon as you let go of the end of the rope, it will reel back. A flat tape rolled into a ring is used as a spring. It resembles a spring in a large mechanical watch that is wound once a day. The starter itself is located more often at the rear than closer to the front end of the mower or trimmer. In order to correctly perform all the manipulations with the starter for petrol cutters, you need to know the features of the device and installation.

Assembling the brushcutter starter

When servicing and repairing the starter, it is important to assemble it correctly. as if the assembly was carried out by the manufacturer. Any part that is incorrectly installed will prevent you from fully using the trimmer or brushcutter.

- After winding the spring, turn the coil over and place it so that the second spring hook falls back into place. To control the correct installation of the spring, there are technological windows on the coil itself.

- Install the starter pulley and make sure that one of the spring hooks fits into the groove located on the starter cover.

- Insert the spring and washers on the sides to prevent the spring from rubbing off the plastic compartment in which it is located. If the spring is broken, but the other is not the same, an additional washer is placed in its place.

- Insert the cup with antennae into the slots of the coil.

- Install the coil in its place, tighten the bolt as far as it will go, but without fanaticism.

If you do not protect the compartment with washers from the main spring, where it moves when winding and unwinding the starter cord, the coil often jams when you try to start the petrol trimmer or brushcutter. Loosening the coil bolt will result in its loss.

How to assemble a brushcutter trimmer starter, watch the video.

How to replace or replace the starter spring?

If everything is in order with the rope on the starter, suspicion falls on the reel itself. It is driven by a ribbon spring, coiled into a roll. To change the spring, certain steps must be taken.

- Remove the starter from the brushcutter.

- Remove the starter coil.

- Unscrew the main bolt holding the pulley to the housing.

- Pull out the gripping tendrils and spring, the ribbon spring is almost fully extended or coiled into larger diameter rings.

- Hold it in advance.

- Check if the spring is intact (rusty streaks, fractures, etc. may be present). If the hooks at its ends are torn off, it will not be possible to bend new ones. high-carbon steel breaks when you try to bend it. Loose hooks are suitable for slight bending.

- Make sure the auxiliary (regular) spring and washers are in place. These parts protect the coil body from being punctured by the ends of the main spring. If the washers and spring are broken, and new ones are not available, do not tighten the coil bolt tightly, but watch it. it can unscrew and get lost.

- If the main (flat) spring is damaged, insert the same new one. Place the hook on the end of the spring in its place and bend it, inserting coil after coil into the space where it should be.

The rewinding of the spring takes a minute. Dexterity in this action is acquired quickly.

How to replace or replace the starter spring, see the following video.

How tight is the spring cocking??

It is possible to give the spring the necessary potential force necessary for a clear and fast winding of the cord, by determining the length of the cord in turns. To prevent the cord handle from drooping, add 1-2 more turns to the number of turns. So, if the cord has a length of 5 turns of the coil, then when charging the spring, turn the coil 6-7 full turns.

How to change the starter cord?

It happens that it is not the spring that is to blame for the inability to start the starter, but the cord itself. It can seize or even break. Disassembly of a petrol cutter or trimmer starter is universal in its steps.

- Remove the starter block from the trimmer or brushcutter.

- Remove the main bolt holding the handbrake.

- Pull out the spool and rewind the remnants of the worn out cord from it.

- Untie the knot on the cord handle and pull the end out of it.

- Untie the knot at the other end (at the beginning of the spool) and remove the old cord. Knots that have become tight are untied with pliers or pliers.

- Tie a knot at one end of the new cord, pass it through the hole at the beginning of the spool (closer to its axis).

- Wind a few turns of the new cord onto the spool. If it is long, then cut off the excess.

- Load and charge the spring-loaded cord tensioner (if removed) and spring-loaded elements in the correct sequence.

- Replace the spool and thread the free end of the cord through the starter outlet and handle.

- Reinstall the starter block.

Twist the starter by the cord, start the engine of petrol cutters or trimmers. The larger and more powerful the engine, the more jerks of the cord will be required at startup, the norm is no more than 7 times. The result is a quick and smooth start of the motor, the readiness of the unit for operation.

Trimmer coils. types and features

The efficiency and performance of a household trimmer in an area largely depends on the quality of the line. It is located in the spool, or, as it is also called, the trimmer head. Manufacturers produce different types of coils. Each of them stands out for its design features and individual operating principle. Having studied them in detail, it will be easier for the gardener to choose exactly the head that is suitable for specific operating conditions.

Types and features of trimmer spools

The device of a household brushcutter begins with its working body, the role of which is most often played by a trimmer coil.

There are 3 types of heads on the market that differ from each other in the method of feeding the cutting line:

- automatic spools. in nozzles of this type, the cord is fed when the brushcutter’s engine speed rises. At the same time, the operator himself does not take part in lengthening the line. this happens in a fully automatic mode. Automatic heads are the most convenient to use and are most often used by gardeners caring for large areas. Among the disadvantages of these attachments, experienced users point out frequent breakdowns of the device and the highest cost among all types of trimmer coils;

- semi-automatic heads. attachments of this type work on a rather simple principle: to feed the cutting line, the reel must rest against the surface of the ground. By simultaneously pressing a special button, the built-in anchor mechanism is activated. as a result, centrifugal forces arise, under which the line is lengthened and the operator can continue to work on the site. A certain skill is required from the operator to operate these attachments;

- hand reels. in the design of these heads, the cutting line is mechanically lengthened. Accordingly, to feed the line, the operator must stop the brushcutter engine and pull the line manually. Despite the inconvenience during operation, it is this type of coil that is recognized as the most reliable and popular among gardeners.

In addition to the listed types of mowing heads, there are universal attachments on sale. They can be installed on any model of a household trimmer, regardless of its original equipment and purpose. The universal head stands out for its high reliability and does not require frequent repairs.

Head types by line threading method

In addition to the difference in the feeding algorithm, the trimmer spools are divided among themselves according to the method of threading the cutting line.

The following types of attachments are found on the market:

- “Fast”. these reels do not need to be removed from the trimmer. To thread the cutting line into the head, the operator needs to pull its end into a special hole in the side of the nozzle, and wrap the line several times around the central axis of the head. At the end, the opposite end of the cord will need to be cut and continue mowing;

- collapsible. to refill the line, the user needs to remove the reel from the trimmer and disassemble it. After that, it is necessary to wind the cutting line, assemble the attachment and install it back on the brushcutter.

Often on the market you can find semi-automatic reels, the factory device of which includes a body, a pair of built-in parts and a spool. The built-in parts are equipped with springs, and the spools themselves can be one- or two-piece. In single-section spools, the line is wound evenly on each side. In two-section, each of the ends of the cutting cord is wound from the corresponding side. This type of attachments is considered to be the most practical and convenient to use, since the cutting line inside them never gets confused.

The design of a single-section spool assumes the possibility of its own revision. To convert it into a two-section one, the user will need a strong metal plate on which to measure the diameter of the existing spool and cut the workpiece along the applied contour. To get the thickness, you need to measure the place where the cutting cord is wound. In this case, you must make sure that nothing interferes with the rotation of the circle. After that, you will not need to make a small incision and put it on the spool. It is better to choose Moment glue or special adhesive tape for fastening the ring. As a result, the manufacturer will have a homemade two-piece trimmer head. which can be installed on different brushcutter models.

TOP-4 reels for brushcutters

Among experienced gardeners, the following trimmer head models are the most popular:

- Bosch K103 is a universal trimmer reel. weighing 300 g and a height of 6.7 mm. Most often it is installed on the Makita and Hyundai brands of brushcutters. Inside the nozzle, a cutting cord of increased strength is provided, which easily cuts weeds up to 5 mm thick. Among the advantages of this mowing head, users highlight the relatively low cord consumption. The extension of the line in this attachment is done automatically. The coil is designed with a reliable steel core, so it rarely fails. The body of the nozzle is made of shock-resistant plastic;

- standard trimmer head Efco 3060. this mowing reel stands out for its availability and good factory quality. The extension of the line in its basic device is carried out in a semi-automatic mode. The standard fixing diameter of the nozzle is 6.6 mm. The coil design is equipped with a threaded adapter. Inside the head there is a strong cutting line that successfully tackles weeds up to 3 mm thick. Most often this reel is installed on trimmers of the brands Efco, Hyundai and Intertool;

- Flymo 15. This mowing head is recognized by many gardeners as the best in the class of universal accessories. The scope of delivery of the reel includes an adapter that allows it to be installed on many brushcutter models. The extension of the cutting line in this attachment is carried out in a semi-automatic mode. Head body height is 7.4 cm.

The Efco 8100 reel is no less popular on the market. All parts of this attachment are made of steel, and the body is made of durable shock-resistant plastic. Inside the head there is a fishing line with a diameter of 1.3 mm. This allows the reel to be used for cutting weeds up to 5mm thick.

How does the head with a fishing line work on a brushcutter why you need to know the principle of operation

Depending on the manufacturer, the heads differ structurally not only externally, but also internally. Most drums have a pressure spring inside (semi-automatic and automatic). Above is an instruction on how to disassemble the trimmer head without a spring, i.e. on the head of the manual type. The principle of dismantling a semi-automatic head with a spring inside is almost identical to the instructions described above.

The principle of operation of the semi-automatic trimmer coil is as follows:

- Inside the head there is a coil, which is fitted on the slots, which prevent its free movement.

- A spring acts on the coil, which presses it against the splines in the cover structure

- A fishing line is wound on the tip, the length of which depends on the tool itself. Typically this length is between 1 and 4 meters.

- During the performance of work, if it is necessary to increase the length of the line, the protruding part of the drum is pressed, whereby it disengages from the splines. In this case, the line is unwound from the drum, increasing in length

- After releasing the required amount of fishing line, release the pressure and continue cutting the grass

The advantage of a tool with a line is that this consumable does not require sharpening, compared to metal discs. In addition, if a stone or a tree comes across on the way, the line simply breaks off, without negatively affecting the gearbox and engine of the tool, as is the case with metal cutting discs.

Knowing the design and device of the types of mowing or trimmer heads, it is necessary to go on to consider the process of threading the line into the trimmer spool. After all, it is this very moment that causes difficulties for most owners of special tools.

What you need to know about trimmer line

A fishing line is a consumable that is made of nylon and serves as a cutting device. By means of this equipment, the grass is cut, which is ensured by rotating the tool head at a high frequency. This material has a different thickness, which depends on its use on the corresponding tools, electric low-power (from 1 to 1.6 mm), electric from 500 W (2-2.4 mm) and gasoline trimmers with brushcutters (from 2.4 to 3. 2 mm).

The more powerful the tool, the correspondingly thicker the cutting equipment should be. This affects not only the quality of the grass cut, but also the service life of the material. If you are wondering how to wind the trimmer coil, then it is time to change and recharge the tool. With the onset of spring, this question is becoming more and more popular, so it’s time to figure out the step-by-step instructions for replacing the line in the trimmer reel.

How to remove the spool from the trimmer and remove the line

Initially, remove the line from the trimmer spool before inserting it into the trimmer spool. A reel or aiming device is a device that sits inside the mowing head, bobbin or drum. There are different types of heads (depending on the manufacturer), but the principle of replacing the line on the reel is the same for everyone. First of all, we will figure out how to remove the head from the tool, as well as how to get the drum and fishing line out of it.

The instruction on how to unscrew the manual head on the trimmer is as follows:

- Turn the tool upside down and, if necessary, clean it from dirt. With two fingers of one hand, grip the cover latches (on the mowing head), which are symmetrically positioned to each other. After lightly pressing them inward, remove the protective cover from the drum

- Next, remove the line spool from the drum shaft. It is mounted on a shaft without fasteners, therefore it can be dismantled with one hand

- The main part of the drum is fixed with a screw, which must be unscrewed with a screwdriver with an appropriate tip or bit

- To unscrew, hold the drum base with one hand, and unscrew it counterclockwise with a screwdriver with the other.

- After that, you can start dismantling. To do this, you do not need to pull it with all your strength, but slightly shaking it to the sides, slowly disengage it from the metal shaft on which the drum is seated.

- When reinstalling, fit the head into the square slots

- Periodic removal of the head is recommended to prevent corrosion of the threaded connection. If you never unscrew the screw, then if necessary, it will be difficult and even impossible to do this.

- If the screw has a four-sided bore of the head, then for unscrewing it is necessary to select a screwdriver or bits of a suitable size in order to exclude the licking of the edges on the head

- When assembling the unit, treat the threaded seat with lubricants, for example, grease or machine oil.

- If the edges on the screw are licked, then special clamping pliers can be used to unscrew it.

- There are drums that do not require preliminary disassembly. To dismantle them, grab it and rotate in the opposite direction to the clockwise direction

Knowing how to disassemble the drum, you should continue to figure out how to replace the trimmer line. The video below shows a detailed process on how to open the trimmer coil and disassemble it.

Learning to properly wind the line on the trimmer reel and petrol cutters installation instructions

Owners of private houses know how necessary this type of tool is, such as a trimmer. It can be gasoline and electric, but they differ in the design of power units. For cutting grass in areas where there are stones, trees and other obstructing objects, a fishing line is used as a cutting device. This consumable wears out during use, so how to wind the trimmer coil, we will consider in detail in the material.

Instructions with a step-by-step description of how to wind the trimmer coil and petrol cutters

In order not to be mistaken with the choice of a suitable fishing line for your tool, you should first disassemble the head and look at the side wall of the reel. This information is usually presented on a tip, which will not allow you to make mistakes with the use of the appropriate equipment.

If there is information on the reel about the diameter of the line you can fill in, then this information can be clarified in the instructions. Having decided on the thickness or diameter of the rig, it remains to figure out how to charge it. There are two ways to do this, but not all of them are applicable. We will consider both methods in detail, and depending on which models of brushcutters and trimmers you use, you decide on your own which option is suitable.

Method 1. how to properly wind the line or put it on a reel and choose the required length

To implement this method, you will need to first prepare a fishing line of the required length (usually up to 4 meters). It all depends on the thickness of the equipment used, as well as the design of the coil. There is an easy way to find out the amount of line you need to refuel to charge the reel. To do this, wind the rig inside the coil until it is aligned with the side protrusions. In this case, the rigging should not go beyond these extreme protrusions.

The thicker the equipment used, the shorter its length will be needed and vice versa, the thinner, the longer the segment will be needed.

The instruction on how to properly tuck the equipment into the trimmer or brushcutter is as follows:

- To begin with, a piece of fishing line that was prepared to be installed in a reel must be folded in half. In this case, one edge should protrude more than the second by 10-15 cm

- After that, take the second end from the other side, and fold it in half. Move to it so that the measured protrusion of 15 cm is preserved

- There is a slot in the inner baffle of the coil, into which the resulting loop should be inserted. The cut in the wall is shown in the photo below.

- Next, we find out the direction of winding the line. If you wind the rig in the wrong direction, then it will not function correctly, and you will need to redo the work. To insert the line and wind it in the correct direction, inspect the surface of the spool. The direction of winding should be indicated on it (in 99% of cases, this direction is indicated). What the direction indicator on the coil looks like is shown in the photo below.

- This arrow-shaped pointer can also have the designation, as in the example above “WIND LINE”, which means the direction of winding. If the pointer is missing on the reel, then you need to look at the head. There is a direction of its rotation on the head, and in order to properly wind the line, wind it on the drum in the opposite direction to the indication of the arrow indicator. So, if the arrow is on the tip, then you need to wind in the indicated direction, and if it is not there, then you should wind against the direction of the arrow on the surface of the head

- Having decided on the direction of rotation, you should start winding. Each end should be guided in its own groove. If there is no separator, then the equipment must be laid in the appropriate distribution order.

- When almost all the fishing line is wound on a reel, you will need to do the following. place a short part in the hole of the side wall of the pickup, the protrusion of which should be up to 10-15 cm, and then do the same procedure with the other end, placing it in the hole on the parallel side

- We insert the coil into the head, first passing the ends of the fishing line into the holes of the drum

- We put the drum in place and, by pulling the ends of the line, we disengage them from the temporary clamps in the wall of the reel. After that, you can put on the cover until the latch engages.

- This completes the process of how to replace the fishing line on the trimmer, and if necessary, you can only trim the ends (if their length does not suit), and install the assembled drum on the tool

With how to put the drum in place, no difficulties arise. There is a second way, how to charge the mowing equipment in the brushcutter. What is the difference, and how is the second method of threading the line on the reel of the brushcutter carried out, we will find out in detail.

Method 2. how to properly put the line on the reel of the brushcutter with photo description and video

The second method differs from the first in that it is not a single piece of equipment that is charged into the coil, but segments from two parts. This method is used by manufacturers, and it is also suitable for those who have leftover material. The principle of how to insert two lengths of line into the brushcutter is the same as with the first method, and to make sure of this, below are detailed instructions:

- There are two equal length pieces of material that you can use.

- One piece is taken, and the edge is bent in the form of a clamping bracket or hook, with which the fishing line will be fixed

- Inside the coil there are holes in the form of a bracket for fixing, which are there for a reason. If they are not there, then the second option will not work. The appearance of these brackets is shown in the photo below. Each bracket is in its own half

- The brace of the fishing line should be hooked on the bracket, and wind it in observing the direction of the arrow

- The rig is wound until a 10-15 cm segment remains, which is fixed in the corresponding hole on the side of the guide

- Manipulations with the second end of the fishing line are carried out in the same way.

- The protrusions are inserted into the holes of the head, and then, removing the equipment from the temporary fasteners in the reel, a cover with latches is installed

The above instructions on how to install a fishing line in a brushcutter will help not only correctly, but also quickly make the replacement procedure. Assembling the trimmer coil, as mentioned above, can be done without removing the head, but in this case, you will need to conveniently fix the tool. Video instruction is presented below.

Tips and tricks on how to wind the line and what you need to know

There are some useful tips and tricks that will be useful to learn not only for beginners, but also for experienced mowers. These tips will help prevent negative consequences in the form of injury and improper functioning of the mechanism. These guidelines read as follows:

- It is necessary to install the cover until it clicks. over, this is 2 or more clicks, which depends on the number of latches. If one of the latch does not snap into place, the drum may jump out when starting the tool and injure a person.

- Do not reel in the line with a strong pull, or more than you can insert it into place. It is better not to wind up the rig than there will be more of it, as this will lead to negative consequences in the form of the impossibility of unwinding it if necessary

- If you own a tool not with two line leads, but with one (usually these are low-power units), then the winding process is carried out in the same sequence as described above, only with the difference in the absence of a middle edge between the extreme bases of the coil

- After replacing the material, it is necessary to first check the operability of the tool, and after that start mowing the grass. If you do not make a preliminary check, then the scaffolding can unwind and injure a person

The result of the work done is as follows. after the replacement of the new material, the usual one is enough for an area of up to 600 square meters, but taking into account the presence of a reinforcing layer on the fishing line. Conventional nylon materials last less, which is important to consider when working. Do not try to cut thick-stemmed grass with fishing line, as there are special metal discs or knives for this.