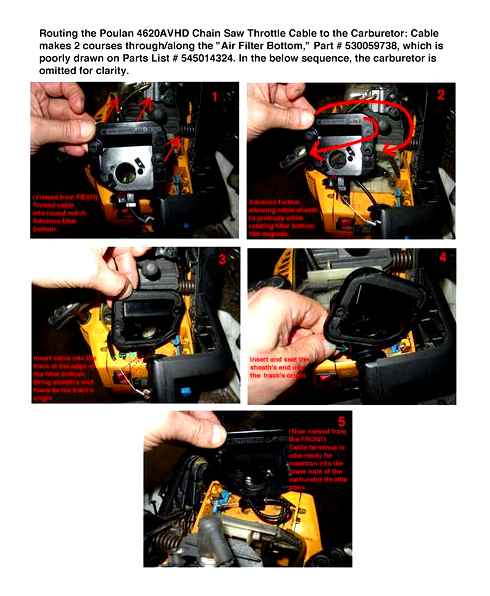

How to put the throttle cable on a chainsaw

Chainsaw starter repair: instructions for each part (photos and video)

A relatively simple and extremely important device that allows you to perform manual engine starting with minimal effort. The classic chainsaw starter consists of several components whose intricate interaction forms an effective mechanism. Despite the quality and operating conditions, precise and miniature elements of parts, sooner or later break down, bringing the entire system into disrepair. Fortunately, most defects can be repaired on their own, without the excessive cost of purchasing a new, one-piece mechanism.

Diagnose or repair the tool, much easier and more effective, if you understand how it works. To facilitate and speed up the process of restoring the starter, it is recommended to know what it consists of and how it works. The general picture, in an extremely clear and concise statement is presented below. Let’s start with the main components of the mechanism:

- The starter cover. the basis for securing the parts and protecting them. Needed for recirculating air blown internally by the flywheel rotation to cool the motor.

- Handle is the outer element with the attached end of the rope that winds up on the drum and unwinds it as it is pulled out of the housing.

- Ribbon spring. returns the reel to its original position by winding the rope back.

- Spring housing. provides insulation of the strap spring and fixes its end to prevent twisting under tension.

- The starter reel is the central element of the mechanism that interacts with all the parts. Has a locking hole and rope winding slot.

- Ratchet spring. performs an auxiliary role, adding a few turns after the cable is fully pulled. Not found on all chainsaw models and can be band or screw shaped.

- The ratchet is the outer part of the drum, with catching protrusions that rest against the handwheel dogs when the lever is pulled.

- The doggies are spring-loaded stops that transfer rotation from the drum to the flywheel and crankshaft. Precise shape and positioning ensure that the teeth of the ratchet engage firmly when pulling out the wire, and move freely in the opposite direction when winding up.

Having considered the main components and their functional purpose, we can shed light on a more pressing topic and understand the principle of operation of the chainsaw starter by the chain of mechanism parts interaction. Start-up sequence begins by pulling the crank, which pulls the cable and unwinds the ratchet drum. ratchet teeth rest on the handwheel and transfer the rotation to the crankshaft.

In one second pull of the crank, the flywheel and crankshaft make about 4 revolutions, driving the entire saw system. In this instant, a fuel-air mixture is fed into the combustion chamber, and the spark formed in the coil ignites it, pushing back the piston, which begins to rotate the crankshaft from inside the engine. In most cases, a well-maintained, cold saw starts with 3 to 4 strokes, and with a light starter even faster.

Having clarified the mechanics of manual start and understanding the overall concept of the device, let’s move on to practical things and see how to repair the starter on the chainsaw. For each malfunction, there is a separate instruction.

Repair Procedure

The peculiarities of starter operation mean a sharp and rough impact, which sooner or later will result in a breakdown. Fortunately, there is nothing much to break in this mechanism, and the following instructions address all possible causes of failure. From how to rebuild or how to insert the spring into a chainsaw starter, to installing the dogs with the removal of the flywheel. Step-by-step guides, step-by-step, for each problem.

Repairing the spring

The most popular fault is the breaking of the main spring attachment that is used to wind up the line. Looking for and buying a new part is not necessary, as the procedure requires a minimum of time and tools. You need only two things: source of fire (gas burner or stove) and pliers.

Carefully remove the spring from the housing. You can pick it up with a slotted screwdriver.

In place of a broken off ear, you should make a new one, making an ordinary ribbon bend. To prevent the metal from breaking, before bending it should be heated to red hot and bent until it cools down (it is better to do this directly over the fire).

The shape and size of the bent part should be identical to the original, so that it fits snugly against the ledge of the limiter. How to tuck the spring into the chain saw starter and save your nerves, see below. Allow it to cool down completely before proceeding to install it.

How to install the chain saw starter spring

Basic skill and standard manual dexterity, coupled with uncomplicated technology, will reduce the time required, allowing the operation quickly and almost effortlessly. Installation of the return spring begins by locking the ear on the notch, counterclockwise (if looking at the inside of the spring housing).

Tape insertion is done gradually, layer by layer. The thumb of the right hand holds the already placed portion of the spring, while the finger of the left hand places the new portion. After inserting about 1/3 of a circle in the housing, the tape is pressed with the left thumb and the right hand is brought to it, and the cycle repeats. The entire installation process takes no more than a minute.

It is even easier to insert a new spring, purchased as a starter part. It may be in a fixing winding, which is gradually removed during installation. The already twisted element is simply inserted into the body. The easiest option is an off-the-shelf kit with a ribbon spring in the housing, which are put in place of the old elements in one motion.

Replacing the cord

The cases of handle cable breakage are quite common and characteristic for both Chinese models, and for brand-name manufacturers. Since this binding element is subjected to serious stress and periodically tears, the process of replacement is extremely simple. First of all, it should be decided what length should be the cord on the chainsaw. Depending on the size of the drum and the diameter of the rope, the value is around 120. 140 cm (always with a small margin). After preparing a suitable cut, you can use a Phillips screwdriver and proceed to replacement.

We remove the starter from the chainsaw and unscrew the central screw on the ratchet.

Remove the drum and remove the old cord.

Thread the new cord through the hole from inside the groove of the drum (for convenience, the ends can be melted with a lighter).

Pull the end out of the hole by about 10 cm and tie it into a knot to prevent the rope from coming off.

In a special recess under the drum, put the unit and the rest of the cable. To avoid resting against the body of the spring, it is advisable to leave about 1 cm.

Fit the reel in its place, aligning it with the spring ear, and tighten it with the screw and washer (do not coil the cord).

The opposite part of the cord is put through the body of the starter and the hole in the handle, and then make a fixing knot at the end.

The cord is wound by the spring. Simply pull the rope lightly from the hole in the reel to the edge of the reel, and while holding it at this point, rotate the reel clockwise. The spring is tensioned and when released winds the rope itself. Repeat the procedure until the handle is firmly pressed against the body.

The device chainsaw Partner 350

The Partner 350 stands out with its great selection of features and quality construction. The basis of the garden tool. a 2-stroke 1-cylinder engine, running on a mixture of gasoline AI-92 and engine oil. The piston group of the engine is forged and coated with a chrome alloy to prolong the life of the engine. The device of factory engine includes proprietary filter CCS, distinguished by the ability to trap the smallest foreign particles, preventing them from entering the fuel.

The Partner 350 chain saw differs from its peers in that it has easier starting, thanks to a redesigned starter motor with self-cleaning drum, a professional fuel pump, and long-lasting electronic ignition. To pre-charging the cylinder, the model is equipped with a primer.

For operator safety during chain saw operation, Partner equipped the garden tool with a quality inertia brake that triggers immediately if the saw chain hits a nail or other foreign object.

Partner Saw Engines. Metal bar and chain. Two wrenches to tighten the chains without having to remove the plastic cover.

One of the best things about the Partner 350 chain saw is the placement of the controls. The throttle lever, the combination switch and the factory starter rope are all located in the rear of the tool, making it easy to operate in tight spaces.

Partner 350 Chainsaw Oil. How to Choose?

To extend the life of the engine and other working mechanisms of the garden tool, it is necessary to use quality engine oil for the fuel mixture. When it burns in the cylinder it must produce as little ash as possible, which can deposit on the muffler and spark plug walls.

Used engine oil should quickly dissolve in gasoline and be thoroughly cleaned of harmful impurities that tend to settle in the narrow channels of your Partner carburetor.

In addition, Partner 350 chain saw oil should have good lubricating and anti-corrosive properties and be highly resistant to wear and tear.

It is best to use STIHL and Husqvarna 2-stroke engine oils for the fuel mixture. They are a good lubricant for your Partner hedge trimmer and do not produce a large amount of ash when burned.

How to Change the Cord on a Chainsaw

STIHL 180 chain saw repair: troubleshooting and solutions

The STIHL MS 180 chain saw is one of the most rugged machines in its class. But machinery is machinery. and things do occasionally go wrong and you might need a STIHL ms 180 service to fix them.

IMPORTANT.Experienced electrician leaked the secret of how to pay half as much for electricity, the legal way. Read more

Read more about repairing components in this article.

How to change chain saw starter cord

The starter motor in a Champion chain saw. STIHL chainsaw repair with your own hands.

Replacing the starter cord on the STIHL MS 180 chain saw

Read more on our website: Follow our channel! Let’s be friends on social networks.

If the gear is in normal condition, disassembly of the saw continues, for this purpose the corkscrews are removed from the shock absorbers, the rear handle is unscrewed and the throttle control rod is disconnected, after which the handle assembly is removed from the shock absorbers with a strong slotted screwdriver.

It is necessary to remove the handles to provide access to the bottom at the place of the oil pump installation.

In the next step the oil hose coming from the oil tank is removed from its seat on the housing and the line is checked for blockage by blowing air through the oil hose into the oil tank housing. If you find a clog it must be cleaned, if it is not realistic defective hose must be replaced.

How to repair the chain saw starter with your own hands

Presented with chainsaw starter repair after a broken starter cord. Without a starter cord, the chainsaw becomes completely inoperable, there is no other way to start the tool. Repair is examined using a chainsaw Partner P350S, clever reliable start this saw requires a minimum of 4-5 times to pull the starter cord to make the saw worked, so I guess the first fault was a clogged cord. The cord does not break right away, first the protective cord sheath breaks and prevents the saw from starting. It’s better not to wait for all threads to break and fix the cord in advance. It is not necessary to invent anything, the repair should not cause difficulties, but the exact observance of the conditions of assembly is obligatory. The step by step instruction with a scheme of actions with photos and video is given below.

Remove the three screws that secure the starter cover. The included spark plug wrench with a straight screwdriver is good for this process, but to speed up the work it is better to use a normal tool.

Remove the starter. The chainsaw is equipped with a soft starter mechanism, it is located above the spool with cord.

Unscrew the screw fixing the soft starter mechanism and starter coil. Be careful not to lose the washer!

Starter removed Unscrew the screw Screw unscrewed

Soft starter Soft starter coil removed

Prepare a cord that suits the diameter and is 1.2-1.3 meters long. For the repair we used a kapron clothesline :).

Melt the ends of the rope in the fire so it does not unravel.

Tie a complex knot at one end. The knot should be large in diameter, but it should not stick out when inserted on the spool.

Insert the cord through the hole in the spool. Do not wind the cord!

Reinstall the spool. There may be an assembly error here. The spool has two slits, one of which must engage the catch of the coil spring. Position the spool so that it is securely in place and the hook engages the slot. Check by turning the spool clockwise to see if any return force is generated.

The knot on the cord The cord is fixed Spring out

Install the soft starter. The shoulder of the mechanism should fit into the groove in the coil.

Screw in the set screw and washer.

Tuck the other end of the cord into the outlet.

The screw is screwed on. The cord is coming out of the spool

Tuck the cord into the starter grip. Tying a big knot at the end of the rope. With a small knot there is a chance the cord will slip and the whole cord will get tangled in the starter bar and you will have to take it off again. Check the safety of the knot. See photo.

Cord in trigger knob Locking knot on cord

The most important moment! Let the cord loop go inside the starter and start turning the starter mechanism clockwise without winding the cord! For this saw it is necessary to make at least five revolutions. Secure the spool by hand. Tie the loop by the handle outward. Hold the cord and the mechanism and let it wind onto the spool. Watch video.

Install the starter in place and screw it with three screws. Repair done.

Repairing a broken or damaged cord using the step-by-step instructions will take 15 minutes, which is much faster and cheaper than going to a service center.

If the instructions helped you, tell us about it in the Комментарии и мнения владельцев.

Partner 350: Features

The Partner chain saw achieves the highest performance in the garden thanks to excellent factory specifications.

Technical features of the garden tool include:

- power of industrial engine. 1.8 liters. с./1.3 kW;

- Standard forged cylinder capacity. 36 cm3;

- Idle speed is 4,000 rpm;

- Fuel tank capacity of 400 ml;

- oil reservoir capacity. 200 ml;

- the recommended length of the tire. 40 cm;

- Saw chain pitch. 3/8″;

- weight. 4.7 kg.

Partner chain saw makes little noise and vibration during operation. Sound pressure to the operator at maximum engine speed: 108 dB.

Partner 350 chain saw starts and stops

There may be several reasons for this malfunction. Most times the engine starts and stops right away because of a clogged industrial breather that prevents an adequate amount of fuel from getting into the cylinder. To fix the problem, the breather plug has to be removed and cleaned. If it’s damaged, it needs to be replaced.

Another cause is a spark plug loose contact with the electronic wiring cap. This can be caused by a mechanical shock or engine oil buildup on the spark plug. To repair your Partner 350 chain saw the spark plug must be removed and cleaned. In some cases, it may help to replace the spark plug.

The 3rd cause is a badly clogged chainsaw muffler. Over time, soot builds up on the walls of the cylinder and this prevents the exhaust from coming out of the engine. As a result, gases accumulate inside the engine and prevent it from working properly. To remove the damage, you need to remove the muffler to clean it with compressed air. It is also necessary to disassemble the engine and blow out the cylinder.

Do-it-yourself repair

Not all chain saw malfunctions are due to a broken carburetor or improper carburetor adjustment. In this case it will have to perform the repair of chainsaws Partner with their own hands, which is easy to do if you have the tools. This work is done in several steps depending on the condition and the nature of the failure:

- Tasks with the fuel system. In most cases it is caused by a dirty fuel filter or breather. In the first case, you need to remove the fuel hose and clean it. It should be washed and thoroughly dried before re-installation. As a preventive measure, it is recommended to change the fuel filter every three months. Additionally it may be necessary to clean breather plug, so a needle or narrow wire is good for it. Similarly, the air damper is cleaned and.

- Repair of the carburetor chainsaw Partner. Not always the adjustment leads to the desired result. A clogged duct may be a cause. Compressed air can be used to clear blockages. It is necessary to keep in mind that the reverse assembly allowed to carry out only if unstained and dry parts.

- Muffler cleaning. If it is necessary to repair the chainsaw in this case, when the tool begins to stall at high speeds, it will be necessary to disassemble and clean the muffler. To do this you need to remove the part, unscrew all the bolts and disassemble. After that, using conventional detergents remove the soot from all surfaces, and then thoroughly dry, you can use a hair dryer. Under no circumstances can remove sludge by dry method, as it contains unsafe for health substances that can not be inhaled.

Even more complicated problems are possible, for example the wear of the piston and crank mechanism that can not be removed without the help of others. Therefore, from time to time it will be necessary to turn to professionals for help.

Repair with your own hands

Not all chain saw malfunctions are due to a broken carburetor or improper carburetor adjustment. In this case, you will have to perform the repair of the chainsaw Partner with your own hands, which is easy to do if you have a tool. This job is done in several steps, depending on the condition and the nature of the failure:

- Tasks with the fuel system. In most cases it is caused by a clogged fuel filter or breather. In the first case, you need to remove the fuel hose and clean it. It must be washed and painstakingly dried before reinstalling. Replace the fuel filter every three months as a preventive measure. In addition, you may need to clean the breather, why it is comfortable to use a needle or a narrow wire. The air damper is cleaned in the same way.

- Repairing the Partner chain saw carburetor. Not always the adjustment leads to the desired result. The cause may be a clogged ducts. You can use compressed air to clear the blockage. It is necessary to keep in mind that the reverse assembly is allowed only if the parts are unstained and dry.

- Muffler cleaning. If it is necessary to repair the chainsaw in this case, when the tool begins to stall at high speeds, it will be necessary to disassemble and clean the muffler. This requires removing the part, unscrewing all the bolts and disassembling. After that with the usual detergents remove the soot from all surfaces, and then thoroughly dry, you can blow dry. Under no circumstances can not remove sludge dry method, because it contains unsafe for health substances, which can not be inhaled.

Probably more complicated problems, such as piston and crank wear, which can not be removed without assistance of others. Therefore, from time to time it will be necessary to turn to the experts for help.

Design of the Partner 350 chain saw

The company’s model Partner in the 350th set stands out for a good selection of devices and high quality build. The basis of garden tools. 2-stroke 1-cylinder engine that runs on a consistency of gasoline AI-92 and engine oil. Engine piston group is forged and plated in bright alloy to prolong engine life. As a part of the industrial engine includes proprietary filter CCS, characterized by the ability to trap the smallest foreign particles, not allowing them in the fuel.

Chainsaw Partner 350 differs from the analogues lightweight starting, which has been achieved by redesigned starter with a self-cleaning drum, profound fuel pump and a long-lasting electric ignition. For the preparatory pumping of fuel used in the cylinder model is armed with a primer.

For the safety of the operator during the operation of running chainsaws Partner company has equipped garden tools high-quality inertia brake, triggered single-step in case of a saw chain on a nail or any other foreign object.

Husqvarna 445 nuances of throttle cable replacement

The Partner saw‘s tools are an iron bar and chain. Their tensioning is made with 2 wrenches, without the need to remove the protective cover of the plastic housing.

One of the biggest advantages of the Partner 350 chain saw is the successful layout of the controls. The throttle lever, recoil switch, and pull rope industrial starter are located on the rear of the tool, making it easy to operate in tight spaces.

How to disassemble a chainsaw: step-by-step process with photos and video

Full coverage of the construction of a multi-faceted mechanism based on a two-stroke internal combustion engine. From the air filter cover, to the crankcase oil seals. Here’s an example of a complete, step-by-step breakdown of a chainsaw system. For informativeness and compression, the purpose of each part is described in a nutshell. The following photo and video instructions, will show the principle of fixing each part, with the nuances of different models.

The technical complexity of any mechanism can be measured relatively accurately by the number of parts that interact in it. Efficiency of repair and maintenance of tools, depends on understanding of the task of each element, but for following the step-by-step instruction, the knowledge of individual terms is quite enough. The following list, supplemented with a picture, popularly demonstrates what a chainsaw consists of, with a description of the purpose of the main parts in one short phrase (where necessary).

- Fuel tank housing. the basis for mounting the mechanism and control elements.

- Shock absorber plug.

- Special screw. shock absorber retainer.

- Rubber buffer. 1 of 4 installed.

- The throttle trigger is the throttle control element of the carburetor.

- Gas pull. the curved bar that connects the carburetor to the trigger.

- Air valve. supplies air to the tank when the fuel volume decreases.

- Fuel filter.

- Fuel hose. conveys fuel from the tank to the carburetor.

- Air filter cover.

- Air filter. protects carburetor from dirt.

- cylinder head.

- Lever. adjusts carburetor air damper position.

- carburetor. a device for metered delivery of air-fuel mixture into the combustion chamber.

- Insulator. effective seal between carburetor and engine.

- Carburetor elbow. connecting component.

- Spark plug. supplies the spark into the combustion chamber.

- Cylinder. main part of the engine casing.

- Silencer. reduces noise, dampens sparks and directs exhaust away from the operator.

- Ignition coil (magneto). generates an electrical impulse transmitted to the spark plug.

- Ignition switch. closes and opens contacts on the coil.

- Knob.

- Flywheel. balances the clutch, pre-clears the air, and generates the charge in the coil.

- Bearing. secures crankshaft to crankcase.

- Crankcase housing left. part of the base for fixing the engine and moving elements of the mechanism.

- Piston.

- Piston shaft. which connects the piston to the crankshaft.

- Crankshaft. converts reciprocating motion of the piston into rotation.

- Oil suction hose. which connects the oil reservoir to the pump.

- Right crankcase case.

- Oil pump. pumps oil from the reservoir to the chain as the sprocket rotates.

- Clutch drum. first element of chain contact.

- Clutch. transmits rotation to drum when revs are increased.

- Chain brake handle.

- Tire cover. hides clutch and oil pump (includes tensioning mechanism).

- Chain catcher. winds or engages the chain if it breaks.

- Starter. mechanism for manually turning the crankshaft, to create a spark and start the engine.

The components shown above, form a complete picture of the device standard gasoline saw. Most parts, consists of several smaller parts, but disassemble them individually only when repairing a specific node. To get to the engine, elements can be removed in groups without disassembling the bar cover or the starter by screws. If you want to get a better understanding of the chain saw’s components, or to learn about all the parts that make up a particular part, with the full list.

Disassembling a Chinese chainsaw

Here is a detailed photo guide to how to fully and consistently disconnect all the parts of the mechanism. On the example of Chinese chainsaw, the principle of interaction of all structural elements is shown. disassembly is performed on a clean drive, without a bar, chain, gasoline and oil.

To facilitate the manipulation of the object and easy access to the parts, first of all let’s remove the handle, unscrewing the busbar cover in advance.

Having cleared the maneuvering space, you can move on to the main components. Remove the top cover, air filter and spark plug.

Loosen fastening screws and remove cylinder head.

We remove the carburetor for what disconnect the lever of the air valve, unscrew 2 fixing screws and take out the base of the air filter. Disconnect throttle trigger and pipe connections.

Remove the throttle lever so it does not interfere with further disassembly. To do this we remove the top cover of the handle, disconnect the rod from the trigger and pull it out through the hole.

Remove the starter cover by removing the 4 screws.

Begin separating the crankcase from the crankcase by removing the chain catcher and shock absorbers.

Start disassembling the engine by removing the carburetor elbow ring, gasket and insulator. For convenience, it is better to use the narrow pliers.

Unscrew the fixing nuts / screws and remove the silencer. Remove the gasket and studs.

Now, the removal of the engine cylinder is reduced to a simple unscrewing of 4 screws. You will need a screwdriver or a bit with a long rod.

To disconnect the piston from the crankshaft, remove the retaining ring and remove the axle.

The ignition module is fixed with a couple of screws and can be removed with a few rotations of a screwdriver.

The clutch is unscrewed clockwise and rotates with the crankshaft, which should be secured by placing the axle in the handle of the pliers. You can use a wrench from an angle grinder, or a hammer with a chisel, but it is better to use a special puller.

Actually, it is more convenient to unscrew the clutch and flywheel before you remove the cylinder and piston, which is easier to fix by putting a piece of thick rope or cable into the spark plug hole.

After the clutch remove the drum with the sprocket, needle bearing and worm gear.

Unscrew the side plate of the crankcase and the oil pump cover and remove the oil pump.

Pull out the pipe that connects the pump with the oil reservoir.

Fix the crankshaft and unscrew the flywheel (counterclockwise).

Unscrew the cover and unscrew the oil seal.

It remains to unscrew all the screws fixing the crankcase and separate the halves (you will need the force).

Remove the bearings from the crankcase, you can usually knock out. To install it back into place, use a construction hair dryer to warm it up.

Reassembling the STIHL MS180

In this video we’ll show you how to change the piston on a STIHL chain saw

Once the piston in the cylinder is locked, you can unscrew the flywheel nut. The threads in the nut are common, so twist to the left side. After loosening the nut, you do not need to remove it completely, just unscrew it until its top edge is flush with the tip of the shaft, and then set the soft metal mallet on the nut and make a sharp blow on it. So the flywheel pops right off the shaft and can be easily removed without any tools.

How to adjust the carburetor on a Chinese tool

Let’s find out how to correctly adjust the carburetor on different makes of Chinese chainsaws. The principle of adjustment is similar to the one described in the material above. The first thing to do is to inspect the tool and find out if there are any adjusting screws. Normally the T screw is on top and the L and H screws are below. To access these screws it is not always necessary to remove the protective cover or guard.

If the Chinese chainsaw has a different number of screws, then based on their number, you need to make the appropriate adjustments. The design and operation of all brands and makes of chainsaws are about the same, so you shouldn’t have any problems with adjustment.

It is always easy to do any job, even a new one, if you have the instructions, so don’t be afraid to take on the adjustment. Even if you do something wrong, if you contact an expert, he will definitely point out your mistakes. If you have difficulties with the adjustment of the chainsaw carburetor, then describe them in the Комментарии и мнения владельцев. Professionals, craftsmen and hobbyists together with the founder of the portal will help you to understand this question.

Parts of a chainsaw fuel system

After a cursory introduction to the system and its construction, let’s take a closer look at each component with all the nuances. How varied are the shapes of the same parts in different chainsaw models, and how they can be installed. See the following for more information and photos of the fuel system components.

Chainsaw tank

On most models the fuel tank is integrated into the chassis and is in one piece with the handle. Replacement of such a tank in case of burning or mechanical damage, requires complete reconnection of the gas lever and air damper (in addition to the hoses). There are systems that at first glance look separable (STIHL MS 440 for example), but even there the fuel tank is permanently attached to the housing and is not sold separately from the handle.

The fuel tank may be in the crankcase in addition to the chainsaw body (for example, Partner 351). In this case, the replacement process, if damaged, is longer and more laborious, because it requires disconnecting almost all units of the tool, including the engine. Fortunately, such designs are not always monolithic, and there are tools where the fuel and oil tanks can be removed (STIHL MS 180), making repairs much easier.

Fuel filter

An important accessory that protects the carburettor and engine from dirt and premature failure. There are two main types of filters: a plastic housing and a metal housing. Nylon (in plastic Chinese elements), felt (in all types of bodies), cortex (in plastic) and polymer foam (in metal) can be used as a cleaning material.

Regardless of the material, each chainsaw fuel filter has a weighting piece that guides it to the lowest part of the tank when the saw is tilted.

The highest degree of protection against small particles is provided by polymer foam and cortex. Felt is not less reliable, but it clogs up quickly enough. Nylon nets are categorically unsuitable for such purposes, so if you bought a Chinese saw with such equipment, it is better to immediately change it for one of the above. The replacement must have an identical diameter of connector, which can be 3.5, 4.5 и 5.5 mm.

Fuel hose

The most flexible part of the system that transfers fuel from the tank to the carburetor and primer (if any). In budget versions, made of silicone, and completed with a seal in the form of a sleeve, or does not have it at all and just fits tightly into the hole in the tank. Better quality hoses are made of dense gasoline-resistant rubber, and as a sealing contact, have special tabs, pressed to the tank on both sides.

Of course, in terms of service life, a special rubber fuel hose for a chainsaw will last longer before it starts to dry out and crack.

In a classic chainsaw system, there is only one fuel line connected to the carburetor inlet connection. In the presence of a hand pump (primer), the number of hoses increases to 3, where the first performs the main role, the second connects the carburetor and primer, and the third removes excess fuel from the primer back into the tank.

Chain saw check valve (breather)

Devices of small size, but of great importance for the entire fuel system. Located on top of the tank and ensures the normalization of pressure, when the volume of fuel decreases. Of the most common, we can distinguish 2 types of breathers: simple (cone-shaped) and collapsible (float). Both variants are widely used, both in amateur and in professional tools.

In addition to the standard valves, some models of saws are equipped with completely unique elements. For example, to replace the breather on the Makita EA3203S and STIHL MS 660, you will need to pick up a completely identical part.

If the valve’s passageway is clogged, air will stop flowing into the tank, which is necessary to normalize the pressure against the fuel being pumped out. Because the tank is airtight, a vacuum will begin to form in it. With each new “eaten” portion of fuel, the carburetor will have more and more difficulty pumping. At this rate, the operation continues for several tens of seconds until the diaphragm pump is. If the tool stalls due to a clogged breather, unscrewing the petrol tank plug sharply sucks air into it, normalizing the pressure.

Carburetor

The main distribution mechanism and the intermediate link between the gas tank and the combustion chamber. Includes a diaphragm-type pump, which operates by air supplied from the engine crankcase through an impulse channel. A fuel hose is connected to the second fitting, conveying the mixture from the tank. If your chainsaw is equipped with a primer, a modified carburetor model is installed with an additional (third) nozzle.

How to Check a Gasoline Filter on a Chainsaw

Decrease of flow capacity of main fuel feed channel has undesirable consequences: power reduction or complete stopping of the tool at high revolutions. These very same problems can be a strong indicator that the fuel filter is dirty. The more pronounced such malfunctions are, the more clogged the channel is.

It is not always possible to determine the need for replacement by visual inspection. The filter may look clean but its interior is clogged with small particles and particles. To determine the cause of the problem for sure, you can experiment by removing the filter and running the tool without it. If operation is normal, it means that a new element should be installed.

At companies that use a chain saw regularly, 5 days a week, the filter should be changed about every 3 months. If the tool burns ≈ 5 liters of fuel in 1 day, then in 60 days you get 300. For household saws, this figure can be divided by 2, because they are equipped with less reliable filters. As a result, in home/hobby use, replacement should be done every 150 liters or once a year.