How To Remake A 12 Volt Screwdriver Battery

How to repair a battery for a Makita screwdriver A step-by-step guide on how to restore a Makita screwdriver battery (12, 14.4 volts) with your own hands without damaging the power tool. Instructions from the online store of batteries, blocks and power adapters MegaBattery.Ru

How to restore the battery to a Makita screwdriver

If the battery has ceased to hold a charge, and it is difficult to quickly acquire a new one in the near future, the situation can be corrected if you know how to restore a battery to a Makita screwdriver on your own.

How to restore the battery of a 12 volt Makita screwdriver by applying high currents

A pulse current is supplied to the problem battery using the popular Imax B6 charger, or similar. Before starting work, you must:

- Clarify the electrolyte balance in batteries;

- Set mode to memory “nickel-cadmium”.

If the amount of electrolyte remaining in the banks is not large, the recovery cannot be started, because this will ruin the battery. The missing electrolyte volume is replaced with distilled water, and only then the reconstruction begins.

To fill in water, a hole is made with a thin drill on the side of the battery, as close as possible to the upper edge. Water is poured using a syringe with a needle until the can is completely filled. The procedure is repeated for all batteries, the filled elements are left to settle for a day.

After that, the bundle (“cassette”) batteries are connected to Imax B6 for charging with parameters: 12 volts in short-term pulses, resistance value. 40 ohms. When the batteries are charged to 100%, they are left again for a day. A multimeter is used to check the voltage on each element, finding out if it has dropped. If an undercharged battery is found, water is added to it again, charged and the voltage is checked again.

When each can is stable to hold the charge, the drilled holes are sealed with silicone glue.

General information

The battery housing of the screwdriver contains power elements (batteries, banks). They can be made from different components, which is reflected in their name:

- Nickel metal hydride;

- Lithium-ion;

- Nickel-cadmium.

Nickel and cadmium-containing batteries are widespread and highly recoverable due to their “memory effect”. This effect is a reversible loss of capacity that occurs if the battery charging mode is disrupted. For example, the battery for a Makita screwdriver was not completely discharged, but only up to 40%, but it was set to recharge. The battery remembers the 40% mark and in the future it will work only until the discharge of this value is reached. This inconvenience can be corrected in several ways.

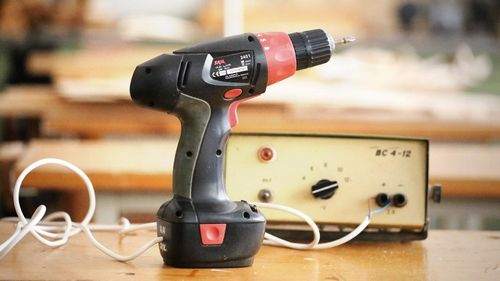

How to convert a cordless screwdriver to a network

The cordless screwdriver is absolutely indispensable in any household. However, during operation, its battery gradually loses its capacity, which leads to its complete failure. Many people solve the problem by purchasing a new battery. In some cases, this is not profitable, because the cost of some batteries is sometimes comparable to the price of a new screwdriver. The most optimal solution is to modify the instrument for mains power supply.

Since the operating voltage required to operate the screwdriver is between 12 and 24 volts, an appropriate power source is required. Best suited for this role are standard devices for charging screwdriver batteries, or power supplies from laptops or computers.

A standard battery charger is usually small in size, so craftsmen tend to place it inside a screwdriver. First, disconnect the battery from the tool, disassemble it and remove all power sources in it. Then, a charger is installed in the case. It is fixed with double-sided tape, or with a thermal gun.

Low voltage wires are soldered to the battery terminals. It is important to observe the polarity, otherwise the tool will immediately fail. As a rule, the body of the compact charger is equipped with a built-in plug, therefore, to connect it to the mains, you will need to make a connector. To do this, the housing and fastening elements are removed from a conventional electrical outlet, leaving only the contact part on a plastic base. A double-insulated flexible mains wire is connected to it and equipped with a plug. The wire is led out through a specially made cut in the housing.

To prevent the connector from disconnecting from the charger during operation, it is attached with rubber bands or electrical tape. At the end of the work, the battery case is assembled and installed in the screwdriver handle.

The power supply from an old laptop or computer has a large size that does not allow it to be placed inside the battery case. Because of this, it usually has to be installed on a workbench or other convenient location. In order not to hinder your movements and to simplify the work as much as possible, the low voltage wire coming from the current source must be extended to 2-4 meters. For this purpose, the connector is simply cut off from it and extended with another cord.

Further, everything unnecessary is removed from the battery case and its contacts are soldered to the wire terminals. At the same time, we must not forget about the observance of polarity, which is easy to check with a conventional tester. The tool is now ready for use.

The benefits of rework

The home craftsman rarely uses fitting and assembly tools. The cordless screwdriver lies idle for a long time. And during this period, an arbitrary discharge occurs in the power supply, which leads to changes in the internal structure.

Having remade a 220 Volt screwdriver, the home craftsman gets the following advantages:

- No time-consuming charging required;

- Storage does not entail violations in the design of the tool;

- Mains supply provides constant torque.

The minus of the converted screwdriver is one: binding to the mains.

What is needed for rework

In the process of work, you will need:

- Charger included with the cordless screwdriver;

- Electric cable (multicore);

- A worn out battery.

In addition to the above, you must prepare an insulating tape, a screwdriver, a soldering iron, solder and phosphoric acid for soldering.

How to remake a 220 volt screwdriver correctly

When the batteries fail, you have to think about how to remake a 220-volt screwdriver. Replacing an energy source is sometimes too costly and troublesome. Some types of batteries are almost impossible to find on the market.

- The benefits of rework

- What is needed for rework

- Step-by-step instruction

- Power supply recovery

Converting the battery of a screwdriver to lithium cells

Many screwdriver owners want to convert their batteries to lithium battery cells. Many articles have been written on this topic and in this material I would like to summarize information on this issue. First of all, we will consider the arguments in favor of converting a screwdriver to lithium batteries and against it. And also we will consider certain moments of the process of replacing batteries itself.

The cons

- Lithium battery cells cannot be charged above 4.2 volts and discharged below 2.7 volts. In real conditions, this interval is even narrower. If you go beyond these limits, the battery can be damaged. Therefore, in addition to the lithium cans themselves, you will need to connect and install a charge-discharge controller in the screwdriver;

- The voltage of one Li─Ion cell is 3.6─3.7 volts, and for Ni─Cd and Ni─MH this value is 1.2 volts. That is, there are problems with assembling a battery for screwdrivers with a voltage rating of 12 volts. From three lithium cans connected in series, you can assemble a battery with a nominal value of 11.1 volts. Out of four ─ 14.8, out of five ─ 18.5 volts, and so on. Naturally, the voltage limits during charge-discharge will also be different. That is, there may be problems with the compatibility of the converted battery with a screwdriver;

- In most cases, 18650 standard cans are used in the role of lithium cells for conversion. They differ in size from Ni─Cd and Ni─MH cans. In addition, you will need space for a charge-discharge controller and wires. All this will need to fit in a standard battery case of a screwdriver. Otherwise, it will be extremely inconvenient for them to work;

- A cadmium battery charger may not be suitable for recharging a battery after a redesign. You may need to revise the charger or use universal chargers;

- Lithium batteries lose their performance at low temperatures. This is critical for those who use a screwdriver outdoors;

- The price of lithium batteries is higher than cadmium batteries.

Conversion of a screwdriver from battery to mains supply

- Battery Disadvantages

- There is a way out. Reworking the screwdriver in the network

- External power supply

- Battery case power supply

- DIY screwdriver alteration

- Using a power supply from a personal computer

- Using a car battery charger

- Making a homemade power supply

- Ac adapter for screwdriver in battery housing

- We build in a ready-made power supply

- Homemade power scheme

Those who have used a cordless screwdriver have appreciated its convenience. At any time, without getting tangled in the wires, you can crawl into hard-to-reach niches. Until the battery runs out.

Battery case power supply

Mobility remains, you are limited only by the length of the network cable. The only problem is how to squeeze a sufficiently powerful transformer into a small case.

We recall Ohm’s law again, and understand that a powerful 220 volt electric motor can be compact.

We build in a ready-made power supply

To do this, you need to purchase a ready-made block with suitable characteristics and dimensions. There is enough of such stuff on the radio markets.

Take the body with you and go to the fitting. When the required power source is purchased, we carefully separate it from the case.

We place the screwdriver in the battery box. All components must be securely fastened.

If necessary, extend the wires between the control board and the transformer. If the circuit touches the metal parts of the transformer during operation, a short circuit will occur.

Since the space in the case allows. Separate the board and the transformer for better cooling. Whichever quality power supply you choose, the load will be high and overheating is possible.

It will not be superfluous to fix additional radiators on the power control microcircuits. Operate the screwdriver for a long time, disconnect it from the mains and touch the radio components on the control board.

You yourself will understand which elements need heat dissipation. Holes for air circulation can be made in the housing.

Redesigning the power supply unit with your own hands will not take much time, and the cost of the purchased module is incomparable with restoring the battery’s performance.