How To Remove The Coil From The Np Gt500 Trimmer

Coil. Brake solenoid

The brake solenoid coil, powered by a rectifier, is activated by relay contacts. When the power source is disconnected, the relay contacts break the electromagnet circuit. This eliminates the possibility of a short circuit of the electromagnet coil with a rectifier and reduces the falling time of the brake electromagnet armature. [1]

Coils of brake electromagnets are switched on with the help of magnetic starters KZ and K. The resistors Rl, R2 and the third contacts of the magnetic starters in the circuit of the electromagnets are designed to reduce the falling time of the anchors of the electromagnets. [2]

Coils of brake electromagnets are relatively easy to repair by drying, partially rewinding a damaged one or winding a new winding. Damaged springs, as a rule, are replaced by new ones from the number of springs included in the set of spare parts supplied by the manufacturer of brake electromagnets. [4]

Coils of a brake electromagnet: overheating over 60, which is caused by a poor-quality factory supply, as well as an overload of the electromagnet due to excessive opening of the pads, incorrect position of the rods and the buzz of the electromagnet. [5]

Coils of brake electromagnets TM, TT, TP (bridge, trolley and hoist) are switched on via the block contacts of the corresponding contacts. [6]

Install the coil of the brake electromagnet in place and lead the coil wires through the holes in the housing to the outside. Connect the bolts connecting the rectifier to the output wires of the coil of the brake electromagnet by bolting and isolate the terminal connections with an insulating tape; The insulation tape must be laid in at least 3 layers. [7]

The motor and brake coil of the electromagnet are de-energized, a mechanical brake is applied and the cab stops. [8]

The RD in the circuit of the coil of the brake electromagnet eliminates the possibility of moving the cab by direct voltage supply or the electric motor using contactors. With the TafcoM method of voltage supply to the stator winding, the z-contact RD does not close, the brake electromagnet does not turn on. The brake cannot be removed and the cab does not move. [9]

C and decreases on the coil of the brake electromagnet. At the end of the transition process, the brake electromagnet is activated, part of the voltage (less than rated) is installed on the coil of the brake electromagnet, and part on the additional resistance. The voltage distribution depends on the ratio of the active resistances of the coil and the additional resistance. [10]

The winch drive electric motor Ml and the coil of the brake solenoid E MT become hardened. A mechanical brake is applied and the cab stops. [eleven]

The winch drive motor Ml and the EMT brake solenoid coil are de-energized. [12]

From the side of the positive pole L1, the coil of the brake electromagnet MM of the bridge motor is switched on by the contacts of the contactor 1L, the coil of the brake electromagnet TT of the trolley motor. Contacts of the contactor 2L, and the coil of the electromagnet TP of the lift motor. Contacts of the contactor ZL. Negative pole. L2 to all three coils is fed by the contacts of the linear contactor OL. [thirteen]

At the same time as the engine is turned on, voltage is applied to the coils of the brake electromagnet T, which releases the clamped pads of the brake device. [14]

Resistors connected in parallel to the diodes in the power supply circuit of the brake solenoid coil serve to uniformly distribute the reverse voltage across the diodes, since the characteristics of these diodes are not the same. [fifteen]

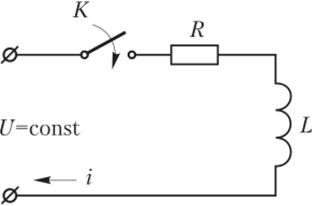

At time t = 0 contactor TO closes (Fig. 6.2), and the coil with inductance L and active resistance R is under constant voltage U.

Find the law of change in current in the circuit over time.

Before the contactor closes, the current in the circuit is zero:

After an infinitely long time, the transient in the circuit will stop and a constant (forced) current will be established for which the inductance resistance is zero:

Thus, during the transient, the current in the circuit n and

Increases from 0 to.

Based on the second law of Kirchhoff

Where andto = iR. Voltage drop across active resistance, d /

Research institutes; and, = Lvoltage drop in inductance.

The solution of the resulting differential equation can be represented as the sum of the particular solution of this equation and the general solution of the equation without the right side:

A particular solution to the equation is steady-state or forced current, satisfying the equation for t = = oo, when the rate of change of current is zero:

General solution of the equation without the right side

We will search in the form

Substituting this solution into the truncated equation, we obtain

Continuous integration AND we find from the initial conditions. Since the current in the coil cannot change abruptly, then at

Substituting these values in the last expression, we find

The current graph is shown in Fig. 6.3. This curve is called the exponent.

The quantity m =., having

Dimension of time, accepted

Call time constant

Considered electric circuit:

In theory The transition process lasts an infinitely long time. However, the transition process is considered to have almost ended after a lapse of time. T

4t, since the current reaches approximately 98% of the steady-state value.

Thus, the current reaches a practically steady-state value the faster, the less m, and, conversely, the transient process dies the slower the more m.

For inductors L = 0.01 H and an active resistance of 10 Ohms

Consequently, the practically transient process in such a coil decays after 0.004 s.

Card No. 6.3 (343)

Dc coil inductance

R ,-Prrs? / “10 V;

U K L = 10 ohms;

O- °. L. 0.1 GN

Determine the value of the current in the circuit at t = 0 (for t = 0 closes the contactor TO).

Coils electromagnetic to electromagnets

- Coils for MIS electromagnets

- Coils for EM, EMIS

- Coils for electromagnets MO

- Coils for MT

- Coil to electromagnet EML

Coils electromagnetic to contactors

- Coils for CT contactors

- Contactor coil CT 6053

- Coil CT 6023

- Coils for KTPV contactors

- Coils for KTP contactors

- Coils for brakes crane TKP

- Electromagnet Coils ED

News on the market of electromagnets and electric coils, magnetic coils, electromagnetic coils:

1. Resumed production of an electromagnet EM 44-372. Resumed production of an electromagnet KMTD-1023. Resumed production of the KMT electromagnet4. Launched coil on frame EM 44-375. Launched coil (cast version) ПМА 4000 380В

The interaction of electric and magnetic fields is called induction. It is this phenomenon that underlies the action of electromagnetic coils or otherwise inductors. They are different in their characteristics and appearance, but they definitely have a winding of insulated wire.

By changing the materials of which the coil is made, adding or removing the core, you can change the ability of the coil to more strongly display the desired properties. Either magnetic or electrical. Therefore, conventionally induction coils can be divided into electric and magnetic.

Electric coil allows you to store electrical energy in a magnetic field and convert it to other types of energy, in particular thermal. Magnetic coil able to store magnetic energy.

Electromagnetic coils are used in generators, receiving antennas, transformers, stabilizers, electromagnets, electric motors, electrical meters, and electrical devices for rectifying, smoothing, or frequency selection. And even in particle accelerators.

Make AN APPLICATION AND WE WILL DELIVER ANY ELECTROMAGNETIC COIL OF RUSSIAN PRODUCTION!

During operation, the electromagnetic coils of various electrical devices are damaged: wire breaks, the appearance of windings, carbonization of insulation are observed.

Breakage of a thin (0.07. 0.1 mm) winding wire, most often occurring at the place of soldering the wires, can occur due to inaccurate stripping of the enamel of the wire with a knife, scissors or other sharp objects (incision of the wire), the use of various ointments for soldering the wire , compounds subsequently corroding the copper conductor (wire corrosion), etc.

Coil circuits in the coils occur due to the destruction of the enamel coating, which occurs due to a factory defect in the conductor or when the coil temperature exceeds the permissible one (for example, if the coil is incorrectly calculated or if it is turned on incorrectly for increased voltage).

Circuit short circuits that occur during operation often lead to the destruction of not only the entire winding, but also to the destruction of the frame.

Various mechanical damage to the insulation during assembly and disassembly of the magnetic cores can also disable the coil.

If damage to the coil is detected (open circuit, short-circuited turns, etc.), it is removed from the magnetic circuit and repaired. Repairing coils takes a lot of time, here you can buy coils for electrical appliances quickly and inexpensively.