How to remove the mode switch of a Makita 2450 rotary hammer drill

Schematic diagram of a drill with a speed regulator and reverse

Many users of electric drills can sooner or later become interested in the question of how to connect the drill button to the tool’s wiring. Such a question usually arises when there is a malfunction in the old button, which requires you to connect a new one. In this article I will tell you how to connect it. what plugs in.

I will not describe here how to disassemble the case of an electric drill to get to the insides, because I assume that once you ask the question of replacement, it is not difficult to disassemble the case for you. I think that someone who does not know how to disassemble the body, will not even think about replacing something in the tool itself.

So, to begin with you need to buy a new button. It should match the old one in size and power rating, so when you go shopping, take it with you for a sample and write down the exact model of your tool.

The procedure for determining electrical faults

Determining the electrical continuity of your Makita torch. In order to repair a Makita 2450 or Makita 2470 peorator with your own hands, you need to arm yourself with instruments and tools. Any tester, screwdriver set, wrenches, hammer, wooden trivet will do. It is a good idea to have a screwdriver with a built-in phase indicator.

Take a tester, connect it to the ends of the plug of your torch and press the switch on the torch. If the tester shows any resistance, then the torch power circuit is intact.

The back cover (usually black) of the peorator is easy to remove, you just need to unscrew the three screws with an electric screwdriver or a screwdriver.

Remove the cover and use a screwdriver to disconnect the wire ends from the electric brushes. With the help of a tester or a home-made device, called “arcashka”, determine the integrity of the supply wires and the proper operation of the switch.

A few words about a simple test device called “arcashka”. This device consists of a LED or a light bulb from a lamp, a thumbtack battery and two pieces of wire. The whole circuit of the control device is a series of connected parts. Connect the battery to one end of the LED or light bulb, connect the wire to the free ends of the LED and the battery. You have a universal device for checking the integrity of electrical circuits.

Characteristic malfunctions of the Makita 2450 and 2470 Peorator Frequent malfunctions in the electrical parts of the Makita 2450 and Makita 2470 Peorator:

- fracture of the supply cable at the point of entry into the peorator;

- Failure of the breaker button TG813TLB-1, P/N.650508-0, item.68.;

- electric carbon brushes CB-419, item.191962-4, item.65;

- contact wear on reversing switch;

- Rotor bearing wear: bearing 609LLU, item 59.210060-6, item.51; bearing, item 607LLU, art.211021-9, item.56;

- 220-240V rotor short circuit, item 68.515668-8, item.54;

- stator winding failure 220-240 V for HR2450, item.633488-5, pos.59.

Switch TG813TLB-1, part no. 1 is used as the starting button.650508-0; item. 68.

Brushes must be replaced if they are worn or have poor contact. This fault is detected by intense heating of the points of electric brushes mounting locations.

Rotor failure can be caused by frayed contacts on the reversing switch. The troubleshooting is very simple.

Repair of reverse switch on a Makita torch

To repair the reversing switch it is necessary to disconnect the rear cover. Carefully disconnect the wires from the button. Carefully inspect the switch.

To disassemble the machine further remove the brush holder and free the brushes. By removing the brush holder you will reach the reversing switch contacts. Determine its condition, replace contacts if necessary.

Another common electrical problem, poor contact between the stator and the lower contacts of the reversing switch.

Repair the contact between the stator and the reversing switch

To remove the stator, disconnect the gear housing (black) from the stator housing (green).

Remember! On the mechanical side of the rotor, the bearing is held in place by a special ring. Be careful not to lose it when disassembling.

The green housing contains the stator. Looking in the middle you will see two 4×60 self tapping screws, Art. 266334-3, pos.57 securing the stator to the housing. Unscrew them, remove the plastic stator guard for HR2450, Art.419201-3, pos.58., release the stator. When you remove the stator you will see the contacts on the stator and the reversing switch panel.

Assembly of the electric part is done in reverse order.

The most popular tools among professional builders in Russia are the Bosch torches, and the most popular among hobbyists are the household models Bosch 2-20, 2-24, 2-26.

On the background of general boom of plastic window constructions wooden double-glazed windows are still popular and in demand. But even the most.

Specifications

The Makita 2450 has a certain set of qualities. Characteristics, presented by the manufacturer in the manual, are as follows.

Tool weight is only 2.4 kg. Drill bits are fastened with SDS system. Peorator is designed for crushing, drilling and percussive drilling. It has three operating modes. The number of idle speeds is 1100 per minute, and the maximum number of strokes is 4500 per minute. The maximum propulsive force is 2.7 Joules. Maximum drilling diameter:

The Makita 2450 has additional functions as well. Features highlight safety clutch, reversing, power button lock, and electronic speed control.

Mains power is 780 watts. Cable length of 4 meters.

Makita HR2450 disassembly video

Depending on the number of functions they perform, they are divided into three groups:

- Single mode drill with a hammer, for example, Makita HR 2010.

- Dual-mode. drilling and drilling with impact, or drilling with impact and chiselling. The most popular poeorator is. the Makita HR 5001 C can drill with a blow or chisel.

- Three-mode. switchable to any operating mode. For example a Makita HR 2450.

- One-, two- and three-mode SDS Plus chucks are available up to 5 kg. Characteristics: power up to 850 W, impact force up to 5, 3 J, concrete drill diameter 18. 30 mm.

- Two- and three-mode models are available with SDS max chuck from 5, 9 kg. Features: power 1100-1500W, impact force 8, 3-17, 5J, the maximum diameter of the drill 40-50mm, bits 105-160mm. Advantages: high power and low vibration level.

Makita Shop. “Is an official dealer of the Japanese company and offers a wide range of torches Makita with the guarantee of the manufacturer and delivery. The professional managers who passed training courses will help you to choose the best model!

We offer Makita torches all over Russia: Moscow, St. Petersburg, Yekaterinburg, Chelyabinsk, Nizhny Novgorod and many other cities with delivery and warranty, please call! To get detailed information about delivery conditions and cost you can ask our managers.

Breakage Causes

Even very good quality machines with long use fail, wear out, need replacement of various spare parts. Before you start the repair, you need to conduct a complete inspection of the device, and understand the causes of the breakdown.

Here are a few variants of common problems:

- Filling with dirt, dust, moisture;

- The lubricant inside the machine hardens with long use, and therefore it no longer works as intended;

- after a while, the tool begins to make excessive noise, indicating that repairs are needed;

- heavy loads, long use in construction needs, overheating, an unpleasant smell comes from inside;

- Frequent switching of modes with time causes breakage of the switch button.

Design and function of the starter button for drills

The reversing unit, in most cases a separate unit that is included with the starter button. It is fixed to the housing via plastic pins. There are two most common types of switches: “snap action” and “slide action”. The device allows you to change the sequence of connection of carbon brushes and stator, thereby changing the polarity of the motor power, which leads to a change in the direction of rotation Technically it is implemented by “jumper”, which mechanically closes the correct pairs of contacts of the switch.

The start button is located in a separate plastic housing. Inside a textolite board with microfilm technology for compact dimensions, encapsulated in an insulating component (boards are maintenance-free).

For stepless adjustment of the rotational speed by pressing the button (trigger) implemented through a triac. Triac regulator provides high-frequency closing and opening of the circuit (by inducing current through the load), than allows to change voltage to supply motor. Fully pressed button does not change voltage, allowing the tool to work at nominal performance, while partially pressed button short-circuits the circuit by high frequency pulses, and the longer the button is pressed, the longer the circuit is closed during one pulse.

Mechanical presetting of the maximum key stroke, to limit the maximum speed. The function is realized through a pin, the length of which is regulated by a plastic disc in the end of the key. For convenience during long working hours, the buttons are equipped with a side button that locks the pressed position. Lateral button, mechanically holds back the return action of the button through a slot in the guide.

Design and function of the drill starter buttons

The reversing unit, in most cases a separate unit that is included with the start button. It is fixed to the housing via plastic pins. There are two most common types of switch: “checkbox” and “slide”. The device allows to change the sequence of connection of carbon brushes and stator, thus changing the polarity of motor power supply, which leads to the change of rotation direction Technically it is realized by “jumper”, which mechanically closes the necessary pairs of contacts of the switch.

The start button is located in a separate plastic case. Inside is a textolite board with microfilm technology to achieve compact dimensions, filled with an insulating component (boards are maintenance-free).

For smooth adjustment of the speed by force of pressing the button (trigger), implemented through a triac. Triac regulator, provides high-frequency closing and opening of the circuit (by inducing current through the load), than allows to change the voltage to supply the motor. Fully pressed button does not change voltage, allowing the instrument to operate at its rated specifications, while partially pressed button short-circuits the circuit by high frequency pulses, and the longer the button is pressed, the longer the circuit is closed during one pulse.

Mechanical presetting of maximum key stroke to limit maximum rpm. The function is realized through a pin, the length of which is adjusted by a plastic disc in the end of the key. For convenience in case of long work, the buttons have a side button to fix the pressed position. The side button, mechanically holds the return action of the key through a slot in the guide.

How to repair a Makita 2450 with your own hands

You should assemble any machine after making thorough preparations. Prepare not only the parts, but also tools, place, lubricant.

The tools you need are pliers, screwdrivers, a hammer, a brush to apply the lubricant.

So what’s the assembly diagram for your Makita 2450 and 2470?

You can assemble a Makita handheld torch with your own hands only if you follow the supplied instructions.

The goal of the assembly process is to replace defective parts with serviceable parts and ensure interchangeability and serviceability of the tool.

Installing Electric Brushes

Remove dirt from the brush holder grooves and install the brushes by locking them in place.

Now it’s time to test the performance of your torch. Plug in the rotor to the power socket, switch on the rotor briefly in “drilling” mode. Once you are sure the tool is working properly, turn it off. Set the mode switch to the “kick” position. Do not insert the tool. Check the working condition of the torch in this position. At the same time you have checked that the mode switch works as well.

It remains to check the placement of the speed regulator button, make sure the contact connections are secure, and you can proceed to install the cover plate.

The cover is attached with three M×4 self-tapping screws of different lengths.

Connect the machine to the 220Β mains and check in all modes. Your Makita 2450 or 2470 is assembled and working properly!

Tips

Proper care and periodic cleaning of the tool will extend its service life considerably. To reduce the risk of malfunction, it is important that you observe a few rules of thrift.

- Check the condition of the tool before use.

- Clean any dirt from the machine when you have finished your work. An air blast, such as from a vacuum cleaner, may be used.

- If you need to transport the power tool during cold weather, let it warm up before using it (the grease should thaw).

- Strictly follow the operating instructions.

- Keep tool in a warm, dry place.

- Do not allow moisture as well as condensation from the air to enter.

- If the machine is not used for a long time, it is better to store it in polyethylene and a cardboard box.

See the following video on how to troubleshoot your Makita Peorator.

How to repair the chuck and hammer mechanism of a Makita 2470 Peorator

Due to the ingress of dust, dirt and moisture, the internal lubricant becomes hard over time and does not perform its purpose. Peorator begins to operate with an abnormal noise.

When you begin repairing the torch, be sure to read the included instructions for disassembly, lubrication, and reassembly of the Makita 2450, 2470 torch assemblies.

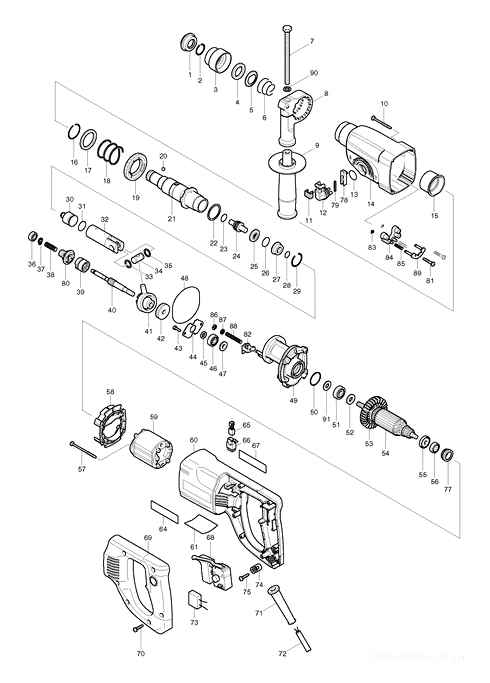

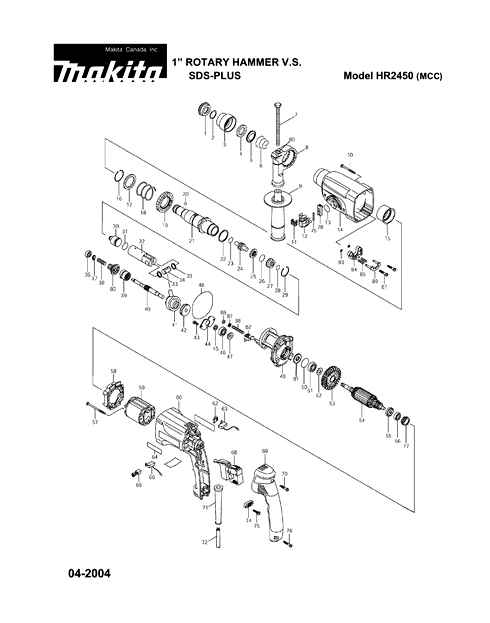

The diagram of the Makita 2450 and 2470 will help you correctly disassemble the defective parts and find the defective parts. We will also tell you how to disassemble the Makita 2450 Peorator.

Disassembling the Makita 2470 starts with removing the mode switch handle.

How to disassemble the machine

Lay the machine on a clean surface.

When disassembling the mechanics of a Makita 2450 or Makita 2470 you must always remove the jog handle.

The handle is set to “Punch” mode (rightmost clockwise position) at the beginning of operation. Use a screwdriver to pry out and remove the latch on the handle. After removing the latch, the handle is moved to the leftmost position, in “Drilling” mode.

Finger gripped handle is pulled out of the housing slots.

Instructions for disassembling the handle of the Makita 2450 peorator mode switch

How to place / How to remove the mode switch on a Makita HR 2450

How to install the mode knob

To install the mode switch in the housing, you must perform some actions: to insert the switch in the “drilling” position into the seat until it clicks; to move the switch counterclockwise to the “impact” position; to move the switch with a click counterclockwise to the “drilling” position; to insert the spring and the red button; to insert the lug from above until it locks.

The second step is to disassemble the quick-release chuck and repair the chuck with your own hands. By the way, the chuck only requires disassembly on the Makita 2470. The design of the chuck is simple enough and any person with a little knowledge of locksmith skills will be able to cope with its repair.

Disassembling a Makita chuck

The repair of the peorator cartridge begins with placing the peorator vertically on the back cover of the housing. To correctly perform the disassembly will help the schematic diagram of the peorator.Does the Makita 2470 need a chuck replacement?? The answer can only be found after you have completely disassembled the chuck with your own hands.

Use a screwdriver or a puller to remove the dust cap, free the cartridge from the circlip, coupling guard, metal ring 20 pos.4. Next step is to carefully remove the ball pos.20, remove the guide washer pos.5 and conical spring pos.6 supporting it. Cartridge disassembled.

The following diagram shows the design of the chuck.

The main malfunctions of the Makita 2450 peorator that cause defects in the chuck are:

- Wear of protective rubber dust cap pos.1;

- loosening of locking ring pos.2 or its partial wear;

- ball wear pos.20;

- Loss of cone spring elasticity pos.6 or its elongation.

The repair of the chuck is a simple procedure and as a rule it is easily done by anyone who can hold a screwdriver in his hands.

If replacing the rubber dust cap, retaining ring, conical spring is not difficult, then replacing the new ball requires attention. New ball must have a diameter dimension of 7 mm ±1 µm.As a lubricant, it is recommended to use a special grease designed for the Makita beater.

Lubricant is indexed Makita P-08361, Makita 183477-5 SDS-PLUS 30g for the gear. Makita lubricant 196804-7 is recommended for drill shanks.

When assembling the chuck, mount the conical spring with its narrow side facing the chuck. Don’t forget, repairing the peorator chuck with your own hands requires care from the assembler.

Assemble the quick-release chuck

Assemble on a clean surface. Parts are prewashed, dried and coated with a thin film of recommended grease.

The gearbox shaft is lubricated with Makita 183477-5 SDS-PLUS grease. Assemble all the included chuck parts to the shaft in a specific sequence. Install the conical spring pos.6, slide the guide washer pos.5 and secure it with the ball pos.20 by inserting it into the groove of the gearbox shaft.

It is only necessary to put on the ring.4, coupling guard pos.3, fix the parts with a retaining ring pos.2. The last step is to insert the protective cap pos.1This completes the repair of the Makita 2450 geared motor chuck. It remains to check its quality by inserting the auger into the chuck. When properly assembled, the chuck keeps the auger from spontaneously falling out.

Disassembling the Geareducer

To get to the mechanics, it is necessary to remove the plastic case.

To disassemble the mechanics of the Makita torch, you must first remove the black protective plastic housing. The housing is removed after you have removed the four screws that hold the housing at the front. Press the end of the shaft and push the gearbox out of the housing.

After removing the plastic housing, we will need to separate the rotor from the gearbox. The gearbox is referred to as the overall mechanical part.Separating the rotor from the machine part (gearbox) is simple.Clamp the gearbox with the right hand and clamp the rotor with the left.oscillate and pull both parts in opposite directions. The rotor is retained in the gearbox by the friction of the helical gears.

The main faults in a Makita rotary tool are in the mechanical part of the tool.

The most common failure on the mechanical end is failure of the beater assembly.

Fitting the percussion unit The percussion unit consists of the gearbox shaft and the intermediate shaft and is assembled on the inner housing.The rotary motion is transmitted to the intermediate shaft through helical gears.

The gear shaft is a hollow shaft in which the cylinder moves freely.

Small spur gears mounted on the intermediate shaft transfer rotation to the large spur gear of the gearbox shaft where the percussion mechanism is installed. And the reciprocating motion on the percussion gear shaft is simultaneously transmitted from the roller bearing of the intermediate shaft to the cylinder that moves in the gear barrel.

Installing the electric brushes

Remove dirt from the brush holder grooves and re-install the brushes, securing them with latches.

Now is the time to test the function of the torch. Connect the plug of the torch to the socket, switch on the torch in the “drilling” mode for a short while. After making sure that the tool works, turn it off. Set the selector switch to the “kick” position. Do not insert the tool. Check that the horn works in this position. You have also checked that the mode switch works.

It remains to check that the speed regulator button is stowed correctly, check that the pins are securely fastened, and then proceed to install the cover plate.

Reinstall cover

The cover is fastened with three M×4 self-tapping screws of different lengths.

Connect the rotary table to the mains 220 ₂ and run it in all modes. Your Makita 2450 or 2470 is assembled and working properly!

Installing electric brushes

Remove dirt from the brush holder grooves and install the brushes by locking them in place.

Now is the time to test the performance of the torch. Plug the machine into the power outlet, switch on the machine briefly in “drilling” mode. After confirming that the tool is working, turn it off. Set the mode switch to the “kick” position. Do not insert a tool. Check the function of the torch in this position. At the same time you have checked that the mode switch works.

It remains to check the placement of the speed regulator button, make sure that the contact connections are secure and you can proceed to install the cover.

Installing the Cover

The cover is fastened with three self-tapping screws M×4 of different lengths.

Connect the unit to a 220° mains supply and check in all modes. The Makita 2450 or 2470 is assembled and working properly!

General Specifications

“The Makita 2450 is known among builders and repairmen as a fairly functional professional tool. It is simple and reliable in operation, lightweight and well-balanced. That makes the Makita 2450 durable for a long time. It has a good dust protection system, which makes the operation of the equipment durable.

Read also: Mechanical fuel transfer pump

Its popularity is due to the possibility of repairing the “Makita 2450” peorator at home. You do not need to spend a lot of money for its maintenance. However, before the process of assembling the “Makita 2450″ peorator, you should familiarize yourself with the technology of its disassembly and repair.

Makita hr2450 disassembly video

Depending on the number of functions performed, they are divided into three groups:

- Single-mode. they drill with a hammer, such as the Makita HR 2010.

- Dual-mode. drilling and drilling with a hammer, or drilling with a hammer and chiseling. The most popular peorator is. Makita HR 5001 C can drill with a blow or chisel.

- three-mode. switchable in any operating mode. For example, Makita HR 2450.

- With SDS Plus chuck produced one-, two-and three-mode peoratorov weighing up to 5 kg. Features: power up to 850 watts, impact force up to 5, 3 J, the diameter of drilling in concrete 18-30 mm.

- With a chuck SDS max is available in two-and three-mode models weighing from 5, 9 kg. Characteristics: power 1100-1500W, impact force 8, 3-17, 5J, the maximum diameter of the drill 40-50mm, core bits 105-160mm. The advantages: high power and low vibration.

Makita Shop. “Is an official dealer of the Japanese company and offers a wide range of Makita torches with the guarantee of the manufacturer and delivery. Professional managers, who passed training courses will help to choose the best model!

We offer Makita mowers all over Russia: Moscow, St. Petersburg, Yekaterinburg, Chelyabinsk, Nizhny Novgorod and many other cities with delivery and warranty, call! Detailed information about delivery conditions and cost you can ask our managers.

Technical Specifications

The Makita 2450 has a certain set of features. The specifications provided by the manufacturer in the manual are as follows.

tool weighs only 2.4 kg. Drill bits are fastened by SDS system. Designed for crushing, drilling and impact drilling. It has three operating modes. The idle speed is 1100 rpm, and the maximum impact speed is 4500 rpm. Maximal translational force of 2.7 J. Maximum drilling diameter:

The Makita 2450 has additional features as well. Features include the safety clutch, reverse, locking the trigger, and electronic speed control.