How to Replace Grinders on a Sander

How to choose the right grease for the angle grinder and which to use in the gearbox

Angle grinders (angle grinder), popularly called angle grinders, are widely used among tinkering enthusiasts. With their help, the home master can not only perform grinding work, but also cut metal, plastic, stone. Angle grinders are produced by various manufacturers, including domestic ones.

Angle grinder is a reliable tool that can work, with proper operation and timely replacement of grease and carbon brushes, for a long time.

The right lubricant for the angle grinder not only extends the life of the tool, but also improves performance.

Knowing the rules for choosing grease for an angle grinder or making it yourself, you can perform maintenance without contacting service.

Key lubricant characteristics for angle grinder

In angle grinders, the main unit subjected to the greatest loads during operation is a gearbox consisting of helical gears.

The rotational moment created by the rotor of the angle grinder is transmitted from the rotor to the working tool through a small helical gear to a large helical gear. Properly selected gear lubricant significantly reduces friction and heating temperature.

Bearings are used in the grinder, which also requires periodic lubrication. This is especially true for the spindle bearing of a large helical gear.

Such a grease is suitable that meets not only the listed requirements, but also environmentally friendly.

Lubricants for an angle grinder must have certain characteristics and must have the required consistency in properties.

Grease for gearbox angle grinder must have:

- Viscosity no more than 800 Pa · s;

- Dropping temperature not less than 120ºС;

- Tensile strength not less than 120 Pa.

Grease for an angle grinder should not have mechanical impurities, be resistant to corrosion, hold firmly on lubricated parts, do not melt at high temperatures, prevent the formation of scoring in the places of contact of parts and, of course, have water repellent properties.

In any angle grinder of any company, two types of sliding bearings are used: bearings for an electric motor and thrust bearings for a gearbox.

Grease selection for motor bearings is different from grease selection for gearbox bearings. It’s all about different working conditions.

Lubricants recommended by foreign tool manufacturers

Foreign manufacturers of tools, including an angle grinder, recommend specially developed ointments as lubricants for grinders.

One of the most common foreign lubricants is the lubricant labeled MoS2 NLGI 2 ISOL-XBCHB 2 DIN 51825-KPF 2 K-20.

- Mos2. Indicates filler material, in this case molybdenum;

- Nlgi2. Indicates a second viscosity class;

- Isol-XBCHB 2. Belonging to ISO standards;

- Din 51825-KPF 2 K-20. Grease manufactured according to German DIN standards;

- The numbers 51825 indicate that the grease is of type K.

Lubricants manufactured with these characteristics are quite expensive. On the Russian market there are imported, less expensive lubricants.

Each tool manufacturer, be it Bosch, Makita, Hitachi, DeWalt, Metabo, RedVerg, Interskol, E256, LEPSE, recommends its lubricants. This is a manufacturer policy. They insist that the lubricants specified in the instructions be used during maintenance. Over, non-compliance with these recommendations does not allow warranty repairs.

Gearbox grease Makita angle grinder is available in tubes. Its high cost is commensurate with high quality and long life.

Lubricants of domestic manufacturers for bearings and gears of grinders

With the growth of for foreign lubricants, lubricants of domestic producers became especially demanded.

Russian manufacturers of lubricants have learned to produce high-quality lubricants suitable for any tool.

Lubricants have been developed for reducers of grinders, rotary hammers, drills.

Nanotech Metal Plac Electra products are especially popular. The range of lubricants produced by this company allows you to choose the right lubricant for each unit

Bearing grease angle grinder

Three bearings are installed in the design of the angle grinder. Two bearings are mounted on the rotor of the tool, one bearing is mounted on the shaft of the driven helical gear of a larger diameter.

The angle grinder uses bearings already filled with grease. But from improper use, overheating of the tool grease leaks.

How to choose the right lubricant for bearings angle grinder?

Bearing grease must meet the following requirements:

- Increase glide;

- Reduce friction between component parts;

- Evenly distribute heat and act as a coolant;

- Prevent corrosion;

- Protect from contaminants and dust;

- Work in the required temperature range up to 150C;

The operating conditions of the bearings of the electric motor differ from the operating conditions of the bearing of the gearbox not only because of temperature requirements, but also because of operating modes, load conditions, frequency and speed of rotation.

The grease for motor bearings must have protective properties that prevent the ingress of dirt, dust and moisture onto the bearing parts.

A wide range of foreign lubricants for bearings operating under different conditions is presented on the Russian market. But their cost makes us look for cheaper, not inferior in quality, domestic lubricants.

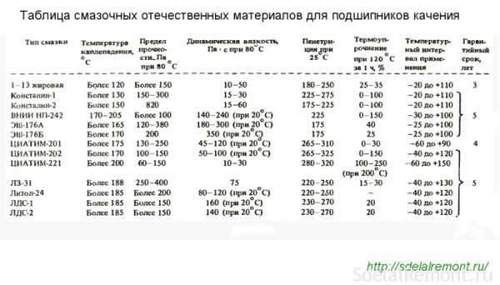

From domestic lubricants, we recommend paying attention to the lubricants Tsiatim-221, VNIINP-246 (GOST 18852-73), VNIINP-235.

Well proven lithium grease.

Possessing high water-repellent properties, they have a wide temperature range. The role of the thickener in them is played by organic and inorganic substances. For sealed bearings, it is best to use TsIATIM-203, VNIINP-242 lubricants.

Of the pigment lubricants for electric motor bearings, the blue grease VNIIMP-246 and the dark-purple ointment VNIINP-235 were widely used. Due to the high price, the first grease is less common than the second.

In today’s Russian market, domestic manufacturers of lubricants are represented in a wide range of products.

Gear Lubrication Angle Grinder

Grease for gearbox angle grinder differs from grease for bearings the main feature. Increased adhesion. It should firmly adhere to the teeth of the gearbox with a large rotation.

In general, the process of lubricating the gearbox in angle grinders occurs due to the fine spraying of the lubricant and its suspensions. The gearbox works as if in oil mist. Therefore, the lubrication requirements for gearboxes are slightly different.

In addition to increased adhesion, lubricant for gearboxes must have high heat resistance and not melt at elevated temperatures.

DIY grease for gearbox

Given domestic lubricants, although affordable, they are not always at hand.

Is it possible to make grease for the gearbox of a angle grinder with your own hands

And there is an affirmative answer to this question.

Since the main technical characteristics of the lubricants for the angle grinder gearboxes are presented above, they can be taken as the basis for making the lubricants of the desired characteristics with your own hands.

The basis of homemade grease for gearboxes should be a grease with high adhesion. It should hold firmly on contacting parts.

Grease for CV joints has increased adhesion. Shrus is a hinge in a front-wheel drive car operating in conditions of increased pollution, shock loads, temperature fluctuations and humidity.

Taking the lubricant for SHRUS as a basis, it is necessary to add a liquid lubricant (MS-20) to give the mass the desired consistency. Ms-20 oil must be served dropwise, thoroughly mixing the mass with a home-made mixer.

Good results are obtained with a mixture of a mixture of lubricant Tsiatim-221 and TAD-17, where the basis is Tsiatim.

The correct lubricant filling process in angle grinders

Stuffing grease in the nodes of the angle grinder has its own rules. You need to know not only the order of its application, but also how much and where to put it.

When to change grease in an angle grinder

The lubrication of the angle grinder changes according to the maintenance plan of the tool when replacing failed gear parts or rotor bearings.

Old grease has a dirty dark color. This is due to the ingress of foreign particles of metal or dust.

How to remove old grease in an angle grinder

Old grease is always removed completely regardless of its color. The parts should not have traces of old grease, but in the cavities of the particle housing of the destroyed parts.

To remove old grease, you can use various flushing fluids used by motorists to wash the motor and its parts. At home, it is recommended to use kerosene or a solution of kerosene and gasoline.

All parts and their cavities must be thoroughly washed and dried.

Lubrication procedure for gearbox angle grinder

The new grease is thoroughly mixed before application and applied with a thin layer. The bearings are lubricated by packing. If the grease is in a plastic tube, then the neck of the tube is attached to the side bearing cage and squeezed out before it flows out of the back side.

How much grease should be used when replacing the angle grinder in the gearbox

If the amount of grease in the bearings is controlled by leaking it from the back, then a certain amount of grease is packed into the gear of the angle grinder. Excess grease will leak during operation. And its small number will not ensure high-quality operation of the gearbox.

Leave as much lubricant in the gearbox as needed to cover the gear teeth.

For reference, apply so much grease so that it occupies a little less than half the volume of the cavity of the gearbox.

Checking the correct application of lubricant to the gearbox angle grinder

The control of the volume of grease stuffed into the gearbox is carried out by trial inclusion of the assembled angle grinder for a short time at idle.

If the gearbox began to heat up, traces of leakage of grease appear from the seals and gaskets, then the conclusion is clear. You shifted the grease. Open gear housing and remove excess grease. All excess grease will be placed on the gearbox housing covers. The insufficient amount of lubricant in the gearbox is determined by the increased noise of the gearbox.

During prolonged operation, the angle grinder lubricates the gearbox on the walls of the housing and loses its properties from external influences.

Having opened the gearbox cover, carefully inspect the condition of the lubricant, gear tooth profile. If you can, check the contact patch of the gears.

The presence of particles of dry or dried grease in the area of the gearbox or on the housing indicates that the time for changing the grease has come.

How to Replace Grinders on a Sander

repair angle grinder

Video: Repairing the Sparky 125 angle grinder / Repair the SPARKY 850 / jammed angle grinder \ maintenance of the power tool

How to grease the gear angle grinder

I welcome you in the next article on the site! Today we will talk about how to lubricate the reducer angle grinder (angle grinder), as well as how and when it is done.

When using this tool, any user sooner or later faces this issue. There are, of course, irresponsible people who don’t follow their equipment at all. And she eventually crashes before they should.

To avoid this, it is necessary to do certain simple procedures. For an angle grinder, the main maintenance action is to change the lubricant in the gearbox. Yes, it is a replacement, not a simple addition. Below I will explain why.

When you need to change the grease in the gearbox angle grinder

So, you disconnected the gearbox and looked inside. What do you have to see there to understand that it is time to make a replacement?

During operation, the lubricant scatters along the walls of the gear case. As a result, over time, it begins to dry out, forming lumps. If you notice this, then it means it’s time to change it.

It should also be borne in mind that the grease can overheat during operation, due to which it becomes liquid, as a result of which it follows corny. For this reason, it becomes small and this is also noticeable. If it does not lie on the gears with a rather thick layer, then it is not enough.

So, we conclude. We carry out the replacement in the presence of dried grease or with a small amount.

What type of grease to use for a gear reducer angle grinder

The best option would be to use special lubricants for gearboxes that come under the same brand as the tool itself. For example, if the angle grinder is called AEG, then the lubricant should be taken under the same name.

Using such products, you will maximize the life of the angle grinder, as each manufacturer produces lubricants, taking into account all the features of their equipment.

However, the price of such branded things can be quite high, which is why many do not want to shell out for it. In addition, a large number of people use an inexpensive Chinese tool, the manufacturers of which did not bother with the issue of having their own lubricating products. Nevertheless, even such equipment should be serviced. And what to do in these cases?

The most unfavorable options will be solid oil and lithol, since they are not designed for operation at high temperatures and excessive friction. Although some use them, dooming their machine to a quick failure. Trying to get immediate benefits, these users ultimately spend much more money.

How to lubricate a reducer angle grinder

Now, knowing what and when to lubricate, you need to find out how to do it. Here, the main rules imply that the lubricant should be enough to exclude excessive friction, but not too much so that it does not leak.

However, first you need to get rid of the old grease. To do this, you can use kerosene or a mixture of the latter with gasoline. Any liquids used to flush the engine of the car are also suitable. Thoroughly rinse all parts of the gearbox to make them completely clean. Only then can you start a new lubrication.

The required amount of new grease can be determined by eye. It should be slightly less than half of the internal space of the gearbox. When squeezing the right amount, smear it on all the rubbing parts. After this, you need to assemble the angle grinder, turn it on and let it run for a short time at idle.

If the grease flows out of the slots, then there is too much of it. We’ll have to disassemble everything and remove the excess.

If there is little lubrication, then the gearbox emits some rattling. In this case, be sure to make an addition.

That’s all! These are the rules for selecting and applying grease to the angle grinder gearbox. I hope you find this text helpful. See you soon!

What grease is needed for the gearbox angle grinder

Angle grinders (angle grinder) or angle grinder in modern versions allow you to perform complex tasks of processing solid materials. This is achieved by increasing the power of the tool and the use of high-strength elemental base. An increase in the number of revolutions also causes an increase in the loads on the electric motor. The gearbox is considered the weakest point in the power plant of such a tool. It is often replaced and repaired even when operating in an average operating mode. High-quality grease for the gearbox angle grinder allows you to extend the working life of the technical filling, but only if the right choice.

Gear lubrication tasks

To understand why a particular angle grinder needs lubrication, you need to understand how the gearbox is designed. The most sensitive and at the same time critical mechanical part of the tool. The gearbox is formed by a whole complex of small elements and parts that are enclosed in a crankcase. In the process, the gears actively interact with each other in direct contact with the generation of excess heat. Accordingly, the grease for the gearbox angle grinder primarily protects the mechanism from wear, deformation and various kinds of damage. The basic protection effect for such devices is provided by antifriction agents. This function involves minimizing friction between parts, which increases their resource and generally strengthens the technical and physical qualities. In addition, the grease must provide heat dissipation. Some compounds create a cooling effect, but in most cases external thermal protection of the elements is assumed.

Mandatory lubrication

To perform the above functions, the lubricant must have an appropriate set of characteristics. Among the main parameters by which it is possible to evaluate the capabilities of gear lubricants, it is worth mentioning the strength, dropping point and viscosity. Strength characteristic is directly responsible for the antifriction function. That is, it will determine how much the formed film on the surface of the part can retain its integrity.

In the question of which grease to use for the gearbox, an angle grinder from the point of view of tensile strength, values of 120-150 Pa can be considered. There are compositions with a strength of more than 400 Pa, but there is no need for such high rates. Especially since the growth of this parameter inevitably minimizes other important characteristics.

As for the dropping point, it is possible to give preference to products designed for 150-180 ° C, although this figure most likely depends on the requirements of a particular gearbox. Also with viscosity. Much of the selection of the optimal indicator depends on the recommendations of a particular manufacturer, but most often they advise a viscosity of no higher than 800 Pass.

Gear Lubricant Manufacturers

Manufacturers of lubricants for power tools can be divided into two types. First of all, these are directly manufacturers of tools. They are also engaged in the development of lubricant formulations specifically for their products. Such tools include grease for the gearbox Makita angle grinder under the index 181490-7. This is a composition designed specifically for angle grinders of Japanese manufacture, but, of course, it can also be used for grinders of other brands.

The basis of the segment is the products of specialized manufacturers of lubricants. Customers highly value Castrol lubricant. A well-known company produces a special composition of green color for an electric tool, which can also be used for a bearing group. A similar lubricant for the gearbox angle grinder is presented in the Mobile line. This product is already blue XHP 222, which is supplied in cabinets with the shape of a syringe for oil supply. For budgeting, many praise and lubricant “Nanotech.” The composition is suitable as a periodic maintenance tool for an angle grinder used in homework.

Lubrication Technique

During operation, the angle grinder is important not to miss the moment when the tool requires a lubricant update. It is not always possible to determine it by external signs, so you should periodically disassemble the crankcase and directly inspect the condition of the gearbox. Lubrication will be required either in case of drying of the previous composition, or with insufficient quantity.

Next, you need to determine which lubricant is best for the gearbox angle grinder of a particular model? Again, if we are talking about manufacturers of the level of Makita, Bosch, AEG, then you can trust the lubricants of the same brands. But if the angle grinder is made by a little-known Chinese company, then it is better to contact specialized manufacturers.

For lubrication, you will need to disassemble the tool, remove the gearbox and perform cleaning. How to remove the old composition will be described separately. By the time of application, a lubrication tool should be ready. An oiler with a suitable nozzle in size or a syringe included in the kit. Apply exactly the amount that is enough to fully cover the working space without gaps.

Removing old grease

It will be nice if the old grease is dry and not difficult to remove. In extreme cases, it may be necessary to collect pieces of the composition that have scattered throughout the body, but if the product has maintained its state, then it will be necessary to prepare kerosene or a gasoline solution. After wetting a napkin or rags, carefully select the entire volume of old grease from the groove. Then repeat the procedure until the surface is completely clean. If an angle grinder with a reduced temperature endurance threshold was used to lubricate the gearbox, then a hot dryer can also be used. It will melt the lubricant to a fluid state. Then it remains only to rinse the gearbox and dry to apply a new composition.

Alternative lubricants

Refusal of special grease for the gearbox angle grinder can lead to negative consequences for the technical base of the tool, so alternative solutions should be resorted to only in extreme cases. Most warnings apply to materials such as lithol and solid oil. These tools can only externally simulate a full anti-friction mass, but in work they turn out to be of little use. And yet, what kind of grease to lubricate the reducer of the angle grinder, if there is no way to use a special compound at a particular moment? Experienced craftsmen advise you to always have on hand a universal lubricant for a ball bearing group. This is an inexpensive product, but according to its main characteristics, it can, although for a short time, make up for the lack of the required lubricant for the gearbox.

How to evaluate the quality of lubricant use

To understand that the grease used is suitable for a particular model can be based on several criteria. Firstly, it holds its shape, does not spread and does not spill out. Drying is also not a positive factor, but high-quality compositions are not safe from this. Secondly, when deciding what kind of lubrication is needed for a gear reducer, an angle grinder, you should pay attention to the working process. The presence of vibrations, the appearance of new noises, the instability of rotation speed support. These phenomena can also indicate the wrong combination of lubricant and gearbox.

Conclusion

Like any power equipment, a power tool needs maintenance of the element base. If the angle grinder is operated in a regular mode, it is advisable to initially determine the complex lubrication scheme of the entire working parts of the tool and adhere to it in a constant mode. What type of grease in the gearbox can be used as universal and suitable for the bearing group? Such a composition can be determined by the averaged values of strength, viscosity and temperature resistance. For each parameter, there should not be ultra-high values, since they may be appropriate in one part of the application, but will not fit in another.

How to lubricate the gear angle grinder?

What does lubrication matter?

In order for the angle grinder to fully perform its functions and not cause any problems, its service must be approached with great responsibility. The effective operation of an angle grinder under heavy loads, the duration of successful use of equipment and environmental safety depend on the quality of the lubricant.

Before deciding what kind of lubricant to lubricate the gearbox, the angle grinder must be learned that this element is one of the main parts of the angle grinder. During the operation of the equipment, it heats up very much, so heat removal plays a huge role. To some extent, this is facilitated by the fact that its casing is made of metal, but proper lubrication is also of great importance. If the master bought a quality tool with high reliability, for example Makita, he is simply obliged to monitor it and pay due attention to it. Otherwise, the equipment will not be able to prove itself at full capacity and will not serve the entire term for which it is designed.

Is it a better lubricant to use in practice?

According to the vast majority of specialists, the necessary lubricant for an angle grinder should correspond to the manufacturer of the device used. That is, if the equipment is released under a certain brand, then the lubricant must be chosen the same. This option is optimal, since the development of such materials is carried out by specialists who take into account all the features of a particular device. In order for the unit to work with maximum efficiency and for a sufficiently long time it is better to use original lubricants. This approach will save the owner of the angle grinder from many unnecessary problems associated with the maintenance of the tool and its use.

If for some reason the master does not have the opportunity to use optimally suitable lubricants, then the second most preferred option will be a lubricant for CV joints. It also allows you to achieve good results and is used by many on an ongoing basis. Finding it for sale is quite simple.

The worst way to keep the gearbox in good condition is to use solid oil and lithol. It should be said right away that many do not disdain these materials, but you should not count on the full-fledged operation of the tool. Even if the difference is not visible for short periods, after some time the master will most likely run into problems.

If, however, the user has chosen the best way to care for his angle grinder, it is worth deciding which original grease is used to lubricate the gearboxes of Makita angle grinder? Or if a device from another manufacturer is used, then in accordance with it. This will create the most favorable conditions for the long and high-quality functioning of the equipment and in order to solve the corresponding problems with the highest possible results.

How to maintain the angle grinder under warranty?

If the angle grinder has not yet reached the warranty period, then there are no problems with lubrication at all. Regardless of which manufacturer the tool was released, the described works are best handled by the appropriate workshops.

What materials, for example, are used to lubricate the gears of Makita angle grinders?

Specialists, as a rule, know this much better than ordinary users and can do everything with the maximum efficiency that is possible in each case. In addition to using high quality materials, professionals have the most correct idea of the dosage with which to use them, which also significantly affects the final result. At home, even the most suitable lubricants can be applied incorrectly and thus cause some damage to the tool.

An important point is that a grease that is inappropriate for the equipment greatly violates the rules for using an angle grinder. In the future, this may well become the reason why services refuse to service the angle grinder. Workshop services can also be used when operating devices that are no longer under warranty. This is a pretty good approach, which allows you to maintain the equipment in the best condition. Most masters, as a rule, do not do this, since they are used to lubricating the gearbox on their own and believe that it makes no sense to spend time visiting services.

In conclusion, it is worth saying that it is strictly forbidden to leave the angle grinder without lubrication at all. At first, this will lead to some problems with the operation of the angle grinder, and then the gearbox will simply fail. Changing it is quite difficult and in many cases it will be preferable to purchase a new unit. Some inexperienced and irresponsible users have already managed to verify this in practice, but after buying a new tool they have radically changed their attitude to timely service.

As you can see, the lubrication of the gearbox during operation of the angle grinder is a fundamentally important issue that should not be neglected. Only a timely and correct solution to this problem allows you to maintain the equipment in a fully functional state.

Source: Makita on-line.Ru. The official dealer of Makita.