How to Rivet a Chainsaw Chain Video

Often during operation of the chainsaw, the saw chain stretches, which makes it impossible to further use the tool. Today, there are specialized workshops that provide services for shortening chains of chainsaws, but there is an opportunity to shorten the chain of chainsaws with your own hands at home or right at the workplace.

Reasons for chain stretching

The chainsaw chain, regardless of the manufacturer, can be stretched for several reasons:

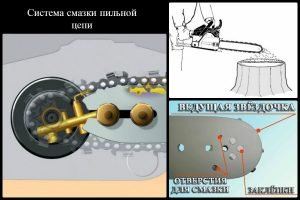

- Incorrect operation of the oil pump. Inadequate supply of oil leads to overheating of the chain and its rapid stretching.

- Natural wear. Occurs as a result of continuous tool operation.

- Use of poor-quality grease.

- Violation of the rules for operating a chainsaw.

Important: If a malfunction of the oil pump is detected, it is necessary to eliminate the malfunctions and ensure normal lubrication of the saw blade. Failure to do so may result in failure of the drive sprocket. You should also pay attention to the quality of the oil. The presence in the oil of various kinds of abrasive microparticles is not allowed.

Tools you need to shorten

Properly shorten the chain of the chainsaw with your own hands using special devices.

Rivet remover

For dismantling, a specialized machine is used. A punch. The machine is made in the form of a small mechanical press. In its lower part, a removable anvil is installed having grooves of different sizes. The working rod of the device also has nozzles of different diameters. This makes it possible to use the machine for chains of various manufacturers. The rivet is removed by squeezing it out of the seat.

Attention: the diameter of the removable tip of the working rod must not exceed the diameter of the hole in the side plates.

Rivet machine

After disassembling and removing the circuit element, it is necessary to reconnect the working links. For this purpose, a rivet-rolling machine is used. The assembly process takes place using a special working roller, which is driven by an electric motor.

The rivet is clamped between the stationary anvil and the work roll. The operator independently sets the pressure of the working roller using the adjusting screw. During the rotation of the roller, the edge of the rivet is gradually crushed, which makes it impossible to disconnect the links from each other.

Reference: the use of machines in order to shorten the chain of the chainsaw allows you to maximize the quality of the assembly to the factory model. However, these devices have a fairly high cost, and their purchase for use at home is unprofitable. In addition, it is not always possible to use specialized devices directly at the workplace. In this regard, you can perform shortening with improvised tools.

Rivet removal methods without the use of specialized devices

There are several ways to remove rivets without using specialized tools:

- Grind off the emery tabs. When using this method, it is necessary to control the degree of pressing on the rivet in order to avoid damage to the working parts.

- Cut off with a cutting wheel of an angle grinder. It is worth considering that in this case the metal heats up, which will affect its properties.

- File heads with a file or file. With this method, the risk of link damage is minimized.

- Cut down using a chisel. Before starting work, you will need to securely fasten the chain in a vise.

After the outer protrusions are completely cut off, you will need to knock out the rivet from the seat. To do this, you need to choose a punch, the diameter of which will correspond to the diameter of the hole. The punch must be put on a rivet and knocked out with a sharp hammer blow. After completing these steps, the circuit will be disconnected.

Attention: To avoid damage to the links you need to securely fasten them. In addition, the punch should be installed strictly perpendicular to the rivet cut.

How to rivet a chainsaw chain

To assemble the chain, you will need to install a repair link on it. It must be borne in mind that its dimensions must strictly correspond to the dimensions of the working links. Installing a spare part with a different pitch or profile can cause damage to the drive sprocket and the saw blade of the chainsaw.

The repair link is sold with rivets that you just need to fasten. To do this, lay the chain of the chainsaw on the anvil. After that, point the punch onto a new rivet and flatten the head with a sharp hammer blow. Riveting is necessary until the resulting thickening overlaps the hole in the outer plate.

When flattening, the degree of clamping of the side plates should be controlled. After assembly, the installed link should move freely along the axis. A chain with a jammed link on a chainsaw is not allowed. Neglect of this rule may lead to more serious damage to the device.

Some people use electric arc welding machines for assembly. In this case, the rivet edges are welded to the outer plates of the link. The use of electric welding involves heating the metal to a high temperature. As a result of overheating, the properties of the metal change, it becomes less wear-resistant.

Recommendation: After assembling and installing the part on a chainsaw, you need to check its performance with a minimum load. Only in case of normal operation can the load be increased.

From the above information it follows that chain stretching on a chainsaw is a fairly common occurrence. It is quite possible to shorten the chain at home, you just need to enlist the traditional tools that are available to almost every owner.