How to saw chipboard without chipping with a jigsaw

How to saw a furniture board without chipping. Sawing Laminated Chipboard at Home. Choosing saw blades and blades

And also for sawing will need additional devices:

Cut Laminated chipboard in the following order:

- Marking out the material. A ruler and pencil will be needed to mark the workpieces, to draw dots on the sheet of material from the end. Then you need to connect the dots evenly into one trimmer line and glue the painter’s tape on top. A good way to saw laminated chipboard without splintering is by using tape, t. к. it helps reduce the number of sheet metal cracks that occur due to high temperature and high pressure. Sawing laminated chipboard.

- Sawing the laminated chipboard next. How to cut chipboard, and place the tool at the required angle to keep the edges of the saw blades straight. Sawing Laminated chipboard and chipboard should be done as gently and as smoothly as possible.

- Board processing. If the sawn particleboard at home is uneven on the ends that were cut, they are machined with a belt sander. In some cases it is better to immediately contact a company that provides services for the production of furniture parts to order according to the size of the customer and sawing laminated chipboard on special equipment. To be edged, a special edging strip is used for the processing.

Precision and quality

Formal cutting machines for cutting Laminated wood particle board and particle board have a high quality of cut, which reduces the subsequent cost of processing the cuts (sanding, removal of chips and burrs and so on). That is why such machines can be used for cutting of any complexity and configuration, which means almost endless possibilities in furniture production. Fancy children’s furniture, comfortable computer desk tops, carved curved decorations in the doors of kitchen fronts. all this is possible with machine tools.

There are two kinds of panel cutting machines:

- Vertical machines are solid vibration-resistant welded frames set vertically at 50° to the rear with guide rails at the top and bottom, on which the saw-bar slides. It is a bracket for the saw unit, which slides up and down along the beam and rotates 90°, allowing both vertical and horizontal cuts. Cutting accuracy is amazing. For sawing laminated chipboard, as well as hard, corrugated or porous boards, a special scoring unit is used. The saw blade rotates at up to 15,000 rpm;

- Horizontal saws consisting of a table for the board, a carriage for moving the saw along the saw mechanism and the saw mechanism itself consisting of one or two cutting units. The cutting units themselves are fitted with a main saw and a scoring saw. The principle is simple: the base saw cuts deep into the chipboard, while the scoring saw precisely and accurately cuts the bottom edge (veneer or laminate surface). The saw unit can also be tilted up to 45°.

Trimming saw is a home-made and highly reduced version of a horizontal machine. it cannot cut a wide sheet of particleboard or laminated chipboard, but it can handle small parts.

What you absolutely must not saw with Laminated chipboard

Before proceeding to the tools that can be used, it is necessary to note the one that is better not to use, especially it is only one. And this is an angle grinder, or, as it is also called, angle grinder.

For sawing it is not used, first, because in the process of use on the finished parts will definitely appear chips, no matter how hard you try. And secondly, because when working with an angle grinder it is easy to injure yourself. All the more reason to get furniture blanks from Laminated chipboard with much safer tools.

What tools can be used

Hacksaw

This tool is used for the good old-fashioned scraping method. I must say that a good quality cut with a hacksaw is difficult to achieve.

- First, we scratch or cut the line for the trimmer measure over the material with some stabbing-cutting tool (such as a knife) and scotch tape over it. It is necessary so as not to damage the laminate flooring.

- We guide the hacksaw towards material at an angle of 30 degrees and move it smoothly forward and backward. Chips from it in this case are sure to remain.

- If damage from the hacksaw remains, we go over it with a file (from the edge to the center).

- The final step is to process the cuts Laminated chipboard with sandpaper, so that no roughness remains.

The main advantage of the hacksaw is its accessibility and ease of handling, but it does not perform the necessary function to prevent chips, so we do not recommend its use.

Electric jigsaw

Electric jigsaw. this is the most popular solution at home, as the tool itself does not cost a fabulous amount of money, and therefore available to the average consumer.

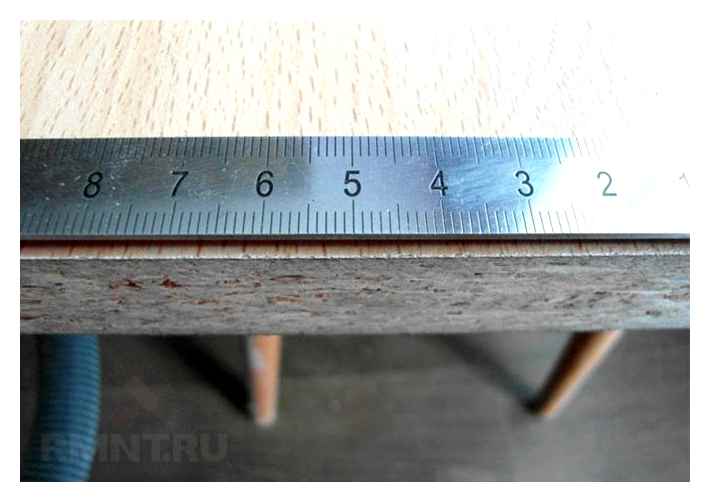

Saw blades for sawing worktops with a jigsaw should be of small length (not more than 75 cm) with teeth grades A or B, suitable especially for Laminated chipboard.

When sawing with a jigsaw, you should make smooth movements with the tool without pressure at a speed slightly higher than average. It is on the opposite side of the board from that into which the jigsaw teeth enter that the chips are most likely to appear.

Chips appear on the backside of the board in the process and spoil the appearance of the part. They can only be removed by the cutter, which is an additional amount of work and overconsumption of material. Consequently, this tool is not suitable for us either.

Circular saw

Circular (or circular) saw is another tool that can be used for furniture production.

For sawing you need to mark out the guide lines on the boards and fix the saw on the board, but it is not guaranteed that the edges of the parts will be straight. the chips appear on the opposite side of the board. And they can only be trimmed using plastic profiles with clips at the ends Particleboard. But a circular saw is not the cheapest option, and even with it, you can’t avoid chips, so in this case, there is no point in overpaying.

Milling tool

Another option for sawing laminated chipboard is an electric tool for manual woodworking. It is used together with a jigsaw. The process looks like this: first saw laminated chipboard with a jigsaw, a little deviation from the markings, and then a cutter with a bearing, which deepens the cut to the desired level.

The main disadvantages of this tool is that it is not as common as, for example, an angle grinder, and will not find everyone in the house. Well, its use. it is a rather labor-intensive process, with which only qualified specialists can cope, and beginners should not even approach it.

Slicing and trimming machine

Only one tool can provide the most correct cut and guarantee the absence of chips. the panel saw, which belongs to the professional equipment. Since the machine is very expensive and is used mainly in production, hobbyists usually can not afford it. The only optimal solution in this case is to turn to professionals. Companies that specialize in sawing parts for furniture, usually use these machines in their work.

Formatting and cutting machines have the following settings, which are set depending on the length and width of the plate to be sawn:

The machines themselves are divided into the following varieties:

Constituents of the formatting and cutting machine, which allow to ensure the accuracy and absence of chips in the production of parts:

- The bed is the stationary base of the machine, to which all other mechanisms are attached. The heavier it is, the better for sawing, because this eliminates vibrations and oscillations that can interfere with the process;

- The scoring unit. an element that pre-sawns the workpiece blank and serves to ensure that there are no splinters at the bottom;

- the main saw serves for the final sawing of the board and is responsible for a clean cut without splinters on top;

- Working tables. there are three of them. The first is stationary and serves as a base for the undercutting assembly, the second is movable and it feeds the plate on the disk, the third serves to support parts that are sawn off the plate;

- The carriage is the part of the machine that allows the format table to move;

- Stops and rulers. components whose main function is to hold the board in position.

The construction of the panel cutting machines allows them to ensure such precision in cutting Laminated chipboard for furniture parts that no other tool can guarantee. It is also the only way to avoid chipping completely.

Ways to minimize chipping

An additional cause of splintering can be a tooth separation of the file. That’s why first of all it is necessary to take care of getting a tool with straight cut (they are often Bosh saws). However, it should be taken into account that when working for a long time, such saws overheat and may even bend in the process of cutting. That is why it is necessary to make breaks in work for cooling down the cutting tool.

However one saw blade replacement is not enough and in order to cut laminated woodchip board (laminate) with an electric jigsaw without splintering it is necessary to do some fine-tuning of the electric tool. Namely, to make sure that when the saw moves against the slant of the tooth, the material does not tear out. For which it is sufficient to make a thrust pad. This is the conclusion that can be drawn from trying to cut two sheets of laminated chipboard at the same time. So there will be almost no splintering on the lower element.

In order to make a stop for the electric jigsaw it is enough to saw a rectangle of any dense material (for example, laminate) with dimensions identical to those of the base of the electric tool.

Then along the larger axial line, a notch should be made and the resulting tooling should be fixed to the sole of the electric jigsaw with insulation tape or double-sided adhesive tape. All completion is ready and you can perform finishing work in compliance with certain recommendations.

Recommendations for a splinter-free cut

Firstly, as already mentioned above, you should use a jigsaw file with a straight cut.

Secondly, in order to better control the process of cutting, it is justified to apply the marking line for the trimmer on both sides Laminated woodchip board and check the accuracy of machining from the top and bottom.

And thirdly, you have to take constant breaks to cool the cutting equipment.

Sometimes the solution in this matter can be a simple cutting through the laminated layer of material with a mounting knife, and the subsequent work with a jigsaw will no longer cause major defects in the form of splinters. However, this work requires from the performer a certain experience and accuracy.

If you liked the material I would be grateful if you recommend it to your friends, or leave a helpful comment.

Ways of working with a jigsaw without chipping on different materials

The jigsaw is suitable for a large number of workpieces (wood, metal, tin, plastic surfaces). There are specific methods and settings for each type of tool: specific stroke frequency, pressure force, smoothness of movement of the fixture.

Wood blade

When selecting the jigsaw, remember that wood must be sawed with standard jigsaws (with the teeth facing upwards). Tooth size is medium, and the pitch interval is from two and a half to four millimeters. The length of the jigsaw depends on the thickness of the sawn surface.

Set the stroke frequency to the maximum value. Reduce it if the material has a tendency to overheat, or if you feel discomfort while working. To increase the cutting speed it is necessary to use the pendulum function. The quality of the cut is lower, but this option decreases the amount of work if you do not have a lot of time.

In the process it is necessary to perform all operations on the back side of the blade to avoid damage. The marking should be done in advance. When sawing starts, it is necessary to press the jigsaw against the blade and slowly control the direction of its movement. It is not necessary to push the tool, as it will move on its own on the blade.

Laminate and chipboard

When choosing a saw it is necessary to choose such a variety as a back-cutting saw. Even with this type of vibration the quality level of the result is not compromised. It is necessary to work on the back side of the blade with an ordinary saw.

As in the previous point, the stroke frequency should be as high as possible. It is necessary to switch off the pendulum mechanism in order to prevent the formation of chips. In the process of the electric jigsaw should be firmly pressed and gradually lead on the blade (strong pressure on the tool at the same time is not necessary).

Chips occur on the side facing the tool. In connection with this, when using an ordinary saw, it is necessary to determine the front side in advance and make a cut on the back side. It is also possible to buy a special anti-slip insert. a small element with a kerf, which is inserted into the appropriate guides in the sole. The best version of a dome is one with a kerf that exactly matches the thickness of the kerf.

Metal

When selecting a metal saw blade, preference should be given to saws with fine teeth, whose pitch should be in the range of one to two millimeters. The stroke frequency should be set as low as possible, and should be switched off.

The tool should not be pressed down when in use, but should be moved smoothly. The blade itself should be secured, with its saw trimmer line placed as close to the support as possible. It is necessary to take short breaks and use a cooling system to prevent the tool from overheating.

If it is necessary to make a curved cut on thin sheet metal and place the cutting line tightly against the support, place the metal between the two sheets of wood. It is necessary to mark exactly the upper fiberboard layer, as it prevents the formation of burrs.

Plastic

It is worth choosing a saw with a small tooth, as it will increase the quality of the work. Adjust the jigsaw depending on the type of plastic. The evenness of the kerf will ensure a minimum or no pendulum motion. And the stroke frequency should not be more than 40% of the maximum value.

Tile

A saw blade without teeth must be prepared and an abrasive must be applied. The pendulum motion must be turned off and the speed must be reduced to a minimum. In this case, the electric jigsaw is one of the effective devices for sawing curvilinear elements on the tiles.

Tinplate

For easy cutting of the tin material you need to attach it tightly. The blade should be placed at the edge of the workbench or placed on a backing board. At the same time, the cutting line for the trimmer should be at the smallest distance from the intended support. The material has to be pressed down with the bar so that nothing impedes the freedom of movement of the jigsaw.

“Swing” should be set to “o” or “1”. The jigsaw you use should be designed exclusively for metal. If the processed blade is more than two millimeters thick, then it is better to lubricate the place of the cut with oil (for machines). For best results the tinplate blade should be placed between thin plywood boards. This makes it possible to work far from the support line, which is important in curvilinear sawing.

How fast should I saw Particleboard, Laminated Particleboard with a jigsaw?

To evenly cut the chipboard with the jigsaw, you need to work with an electric or hand-held tool at low speed, pressing the blade firmly against the workpiece. If you move quickly the cut is not very accurate, there is a higher risk of splintering.

Users say that in a minute the jigsaw goes about 50 cm with the tip straight and at low speed. If you increase the intensity of movement and set the maximum angle, you can cut up to 2 m in the same amount of time. But the cut will be rough, with big chips.

Tip! If you have to saw the material carefully, it is worth turning off the pendulum motion in the tool.

How smoothly the jigsaw will cut chipboard also depends on the sharpness of the blade. The new blades allow you to cut the material cleanly in the line you have planned and at a constant speed. But after about 3 m of work, the tooling begins to blunt, which slows down the progress and makes the cut rougher.

Why a jigsaw might cut crookedly

Not everyone knows how to cut a workpiece evenly with an electric jigsaw. The tool is light and without enough skill, the entire cut could be crooked.

- Lack of experience with the tool.

- The saw blade is defective.

- Backlash in the guide roller. There are 2 possible causes: Wear on the inside and damaged seating holes.

- Wear on the piston rod. This fault results in a large backlash.

These are the most basic faults. There can be others, so you have to consider all points.

Different methods are used to obtain a precise cut

Correction of the chips that appeared

Any craftsman should know not only how to saw with an electric jigsaw without chips, but also how to fix them if they do appear, because it is almost impossible to avoid them.

There is a way out. The tool cuts the workpiece with an allowance of about 2 mm, then the allowance is ground with a band grinder or milled. The edge is much cleaner with the latter than with a sander. Milling mainly on a self-made bar. Spiral cutters increase the quality, they should be prepared in 2 pieces. If you need to get a clean one face side, use an ordinary 2-pass cutter, both sides. a 4-pass cutter with 2 main branches, which have left direction, and 2 undercutting with right direction. In this case, when cutting the workpiece, the lower branches pull the material up, the upper branches press it down. No chipping on edges as a result.

Specialists advise using a work area light to increase control over the direction of the cut. Saw metal boards, wooden kitchen countertops and other products with a device with a well-sharpened saw blade.

Correct sawing Laminated chipboard: sawing Chipless chipboard, machine with your own hands

Particle board (Chipboard), and nowadays mostly laminated (Laminated Chipboard), is one of the main materials for making affordable furniture in the home workshop. This board is made of coniferous and deciduous wood materials, so it has qualities such as strength and ease of processing. But if not sawed properly, chipping of this material is possible. Therefore, before making furniture, it is necessary to find out how to saw correctly Laminated chipboard.

For this purpose you can even assemble yourself industrial equipment. a cutting machine.

Rules of sawing

First you need to choose the method of sawing.

Be sure to make the following preparations (cutting):

- To protect the laminated coating of the board from damage during the work, it is necessary to prepare paint tape or tape;

- for marking blanks. a ruler and a pencil;

- Mark the future cutting points on the ends of the board with a pencil;

- In order to avoid chipping, you need to put masking tape or scotch tape on the place of sawing;

- after taping, connect the pre-marking points with a pencil;

- Prepare sandpaper for the final cut lines.

The following rule concerns not the preparation, but the actions after sawing, but it is common for any method: if you find roughness on the edges they need to be processed with a file or rasp. Cover the sawed edges with veneer with a veneer pattern similar to the laminated veneer.

What not to saw

Laminated chipboard cannot be sawn with an angle grinder, also known as an angle grinder. There is a high risk of injury, especially with large-diameter blades. You can also get injured when the tool guard is removed.

Rating of the best jigsaws for the wood jigsaw

For sawing wood, you can choose high-quality, but inexpensive blades. They are especially good at cutting soft materials, but they can also cut hard materials successfully.

Practice 035-837

Electric jigsaw blades made of rugged carbon steel are highly resistant to damage. Suitable for wood and plywood for a quick cut.

You can buy the Practice 035-837 set from 190 Pros

GMT JT234X-5

Italian-made products are made of high-strength alloy according to international standards. Brand-name coating for longer service life. Working length is 90 cm. blades of this size are sufficient for most tasks.

Attention! GMT jigsaws are only suitable for clean and precise cuts.

Pros of

VIRA T111C552025

Budget jigsaw blades have a length of 75 mm and are suitable for sawing medium thickness workpieces. Can be used for cutting plywood, wood and plastic. Saws are DIM certified in Germany and meet Russian GOST requirements. Made of high-carbon steel that resists kinking.

Saw blades for VIRA jigsaws are available from 60

How to saw a tabletop with a circular saw

When working with a tool called a circular saw, a fine-toothed finishing saw blade is required. A circular saw is more convenient than a jigsaw for making long, straight cuts. However, chipping at such work is formed much more, as the side with teeth plunges into the material and breaks off pieces.

But even working with a finishing disc on one side of the countertop, many chips are formed, which must be subjected to long processing afterwards. And it is not a fact that after processing, there will not be millimeter chipping or microcracks, which in the future will lead to failure of the material or a strong moisture penetration.

This is why it is better not to use this option for sawing worktops. Better leave the usage of a circular saw to other work. If this is the only option for you, you will have to work hard to finish the sawed material.

A table made of bars and chipboard

A more complex design involves making the table from wooden planks. In this case the table is assembled from square timber (the legs are made of 80×80 mm timber and crosspieces of 40×80 mm timber) with a tongue and groove joint.

To strengthen the construction you need to use glue, dowels and screws. The distance between the legs is 60-70 cm. The legs are secured with collets. In the places of junction of beams and nails are drilled and dowels are fastened. Height of table is set by the manufacturer based on the convenience of machine operation.

The tabletop is made of laminated plywood of 18-20 mm in the size of 90×90 cm. For convenient saw blade changing the table top is made in a lifting version. To do this, it is fastened to one of the pins of the table with hinges. It is more convenient to remove the jigsaw if there is a kerf from the hole to the edge of the tabletop. It is recommended to make such a kerf.

The jigsaw mounting system should be complicated to ensure its removal. The jigsaw blade is pressed to the table top with two wooden slats, on which a profile is made by selecting a quarter-bar. The base of the jigsaw fits into this profile, like on rails. To fix it, holes are drilled in the bar and clamping screws with a wingnut are installed.

Diagram of the table top for the jigsaw.

Making this table requires some carpentry skills, because the joints between the legs and the feet are made in tongue and groove. However, you can use dowels, joinery glue and self-tapping screws instead. The lid of the machine will be liftable to provide easier access to the tool during disassembly.

The distance between the legs can be from 600 to 700 mm. The timbers for the side members and footstep boards are obtained by sawing 80 x 80 bars longitudinally. You can choose the height of the feet yourself, based on how comfortable it will be to work on the machine. On each end of the back posts and footstops, 2 holes are drilled for dowels.

Corresponding holes are made on the sides of the legs. The rods are smeared with glue half-lengthwise and inserted into the ends. The frame is then assembled in place. After correcting any imperfections it is finally tightened. All contact surfaces are lubricated with glue before assembly. Additional strength of the construction will give the self-tapping screws, which are screwed through the holes prepared in advance for them.

Hand-operated wood jigsaw: description, photos and prices

The lid is attached to one of the tiers on the hinges, for this purpose a slit is made in it to facilitate the installation and removal of the jigsaw. To the back of the table top are screwed 2 slats with the selected quarter, which will enter the bottom of the power tool. Holes are made in the slats, in which the clamping screws or bolts will be installed.

A jigsaw mounted underneath the worktop will be able to cut thicker workpieces if it has a recess in the lid for the sole. The easiest way to make one is with a milling machine. The table is quite spacious, so that a thick plywood or laminated chipboard can provide sufficient strength to its cover. Use 20 mm and thicker boards.

How to decipher saw blade marking

Determining the purpose of a saw solely by its appearance is by no means an easy task; it requires experience. For those who have not such experience, we recommend to be guided in the first place by the marking on the blade, which contains all the necessary information. There is no single standard for saw blade markings, but most manufacturers try to stick to the Bosch classification.

#1. On the tail part of each file there is a set of numbers and letters.

The first letter indicates the type of shank, for example T- or U-shank. It is followed by a number, the size of which can be used to judge the length of the blade:

The second and third digits indicate the intended use of the saw blade. We will not bother to decipher them, because this information is duplicated on the files in other, more understandable and memorable forms.

After the numbers, the letter again. it indicates the size of the teeth:

Finally, the last letter will help provide additional information about the saw:

- F. bimetal blade (considered the strongest and most durable),

- O. narrow blade (for shape cutting),

- P. thick blade (allows you to saw strictly perpendicular to the surface),

- R. reverse toothed,

- X. with variable tooth size (universal blade suitable for cutting any material).

#2. You can determine the purpose of the saw by the color of the shank:

- grey. for wood,

- blue. for metal,

- white. for wood and metal,

- Red. for plastic,

- black. other materials.

#3. The use of a saw blade is determined primarily by the steel grade from which it is made. The letter designation of the steel grade can be found on the neck of the saw, t. е. on the edge of the shank and blade:

- CV. chrome vanadium steel (for wood and wood-based panels),

- HCS. high-carbon steel (for wood and wood-based panels as well as plastic),

- HSS. high speed steel (for ferrous and non-ferrous metals),

- HM. tungsten carbide-based carbide (for ceramics, fiberglass, etc.)

BM (or BIM or Bi-Metal) is a highly flexible combination of HSS and HCS (professional saws for wood and metal).