How to screw in a screw without a screwdriver.

Tested methods that will help to screw a self-tapping screw into a loose hole

Receive one of the most read articles in your inbox once a day. Join us on

Very often during repairs, craftsmen encounter such an unpleasant phenomenon as a loose screw hole. The main problem is that it is practically impossible to screw metalware into such a hole again. Finding yourself in this situation, you have to go to all sorts of tricks that could help solve the problem. Here are some of the most simple, affordable and yet popular ways.

Matches

The easiest, most affordable and most obvious way to solve the problem of screwing a screw into a loose hole. However, this method is also the least effective. All you have to do is put one, two or more matches in the hole before the screw is screwed in. This method can help only in the most unstarted versions, when the deformation of the hole is not yet too large.

Chopik

The method is generally similar to the method with inserting matches, but it has its own nuances. In most cases it is recommended to screw the screw not next to the wooden element, but into it. And this in turn means that it is highly desirable to pick up such a wedge to work, which will completely (or at least almost completely) overlap all the screw hole.

Wire

A great way to solve a loose screw hole that works backwards. In this case, it is not the hole itself that is sealed, but the hardware that will be screwed into it. All you need to do is choose a suitable flexible wire and wrap it around the screw all the way from the cap to the end. Depending on the nature of the wood damage, the wire may be wound either more tightly or more loose. The method is recommended for use when the hole is not too badly damaged.

And also: glue and sawdust

The best, tried-and-true, and most effective method of restoring loose screw holes. Perfect for work with the most different materials, whether it is a sawdust-chip composite or usual wood. The essence of the method is very simple: we mix sawdust, wood chips and wood dust with PVA glue, so that at the end we have a porridge with the consistency of thick sour cream. The mixture is thoroughly mixed, infused for a couple of minutes, after which it is firmly placed in the damaged hole. There thoroughly pressed and dried. Once the adhesive dries, you can securely screw in the screw.

If you want to know even more interesting, it is worth to read about 5 effective ways. that help get rid of scratches on laminate.

Scotch tape or duct tape

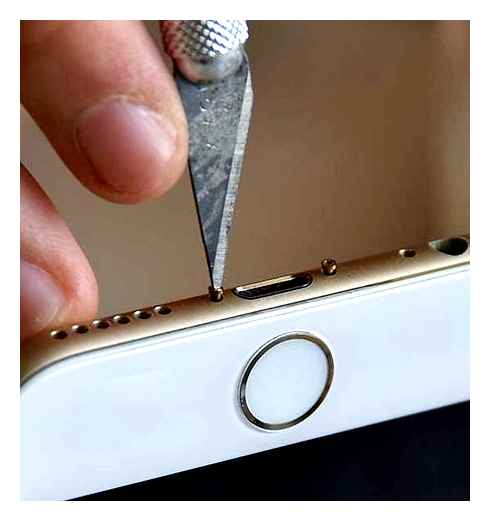

Bit is a special bit that is installed in a chuck of a drill or an electric screwdriver. Thanks to its use, the user can quickly screw in a variety of fasteners, such as screws, bolts, or self-tapping screws. According to their classification bits can be:

There are also special bits for nuts, as well as similar devices that are made in the form of a star. To ensure that, during construction or repair work, the bit does not constantly fall and does not slip off the screw, it can be glued with ordinary duct tape. To do this, you need to take a small strip of duct tape, attach it to the bit of the self-drilling screw and tape it on the outer circle of the head. It is worth noting that you do not need to apply a large amount of duct tape, as it will still have to be removed after the work.

If you do not have at hand an ordinary Scotch tape or the so-called masking tape can be used. To do this, you need to cut a small strip of duct tape and make a hole in the center of it. Then you need to insert a self-tapping screw into the hole and place it on the bit of the electric screwdriver. After that, the tape is carefully glued together with the self-tapping screw.

Effective method, how to properly screw in long screws, so they do not bend

Receive one of the most read articles in your inbox once a day. Join us on and

Self-tapping screws. one of the most universal fasteners, which are used in many construction and repair works. There is a wide range of products from 11 to 200 mm in length. But the biggest problem occurs with larger screws. Why this happens and how to screw in long products correctly tell us in our article.

The main reason

In order to screw in a self-tapping screw, you need to apply a certain force. A low-quality product can bend or break at the most inopportune moment. To avoid trouble, choose proven products. If you can not decide, ask for advice from a consultant or acquaintances. Yes, better self-tapping screws do cost more, but the result is much better.

What Problems Can Occur?

Screwing long self-tapping screws, you may encounter a number of problems. Among them:

When using an electric screwdriver, sometimes the following happens: the tool’s bit licks the edges on the self-tapping screws. It is a rather unpleasant situation, which slows down the speed of work and complicates the process of unscrewing screws in the future.

Screwing a self-tapping screw into a wood construction causes the bit to skip in the cross, followed by a breakage. Such a problem can be solved with a new fastener and workpiece. However, this entails additional financial costs.

Screwdriver warping that prevents it from turning.

There is a problem with the ratchet of an electric screwdriver, which makes it impossible to tighten the screw completely.

Breakage of the fastener at the base of the head during the final screwing process. In that case you need to replace both the screw and the workpiece.

How to screw in long self-tapping screws correctly

If you want to avoid these troublesome situations when working with fasteners, use our tips.

The easiest variant. Pre-drill the socket for the self-drilling screw. Another way. choose the right bits that can hold the screwdriver in the right position without getting magnetized. It is worth noting that such solutions do not always help, because there may not be a drill of the right diameter and length or a suitable bit at hand. Then a little handy trick comes in handy.

An effective technique that will help screw a long fastener, even without drilling. It is enough to rub the threads with soap or dip them in a thick soap solution. The disadvantage of this solution. Difficult to remove. If you want to take it out years later, it might be a problem.

The most effective and easy way to easily and safely screw long screws into a wooden surface. First of all, you need to treat the threads with paraffin. Even regular candles are suitable, and even for cake. During screwing the wood and the screwdriver get hot because of the friction force. Paraffin melts and soaks the wooden surface around the fastener. Using this trick, you can screw the screw in easily and protect the thread and the wood from damage. There is no difficulty in unscrewing the self-tapping screw if necessary.

Another common method, but one that is the least effective. In addition, it is better to use lithol or solidol. It is necessary to wipe the thread and start screwing the screw. Over time, however, the wood around the fastener will darken and the grease will begin to seep in. As a result, the paint on the place of the screw may change color and the oil may come out. A risky option, because it can entail new repair work.

So make sure you buy quality fasteners first. When working with self-tapping screws, it is best to use paraffin, which will simplify the screwing process. And how to keep the self-tapping screw on the bit, so that it does not fall off at the slightest movement, learn from our article.

Into metal

As for screwing a self-tapping screw into metal, then only metal fasteners are used. The method of screwing depends on the thickness of the workpiece. If it is thin sheet metal, it can often be screwed together without much effort with an electric screwdriver or screwdriver. over, there are different types of self-drilling screws. Some have a small drill bit with sharpened teeth at the tip, as shown in the picture.

Self-drilling screw with sharpened teeth

But as practice shows, not all such self-tapping screws can be screwed into the metal, it is explained by the weak sharpening of the drill bit. So, an electric screwdriver is used to screw them in. Do not drive too fast, otherwise the screw could overheat and become dull quickly. Such fasteners can be used for metal up to 7mm thick.

If the metal is too thick, then the best option is to pre-drill the hole with a drill/drill, and then screw the fastener into it. This method is not associated with any problems.

When making the hole keep in mind that the diameter needs to be smaller than the screw. When the hole is ready, it can be lubricated with machine oil. This allows the screwdriver to be driven in without much difficulty.

The self-tapping screw used for metal should be made of hard steel, which is harder than the product.

Glue and sawdust

With silicate or polyvinyl chloride adhesive, you can try to fully restore the structure of the wood in the former hole location. The main thing is to thoroughly mix the glue with a handful of small wood shavings. Because of the structure of particleboard or MDF panels, this will help maximize the bond between the glued piece and the rest of the solid wood.

So, it is best to take PVA glue, Moment glue, or, in the most ideal case, joinery glue (not recommended, as it takes a long time to prepare, and the minimum volume will be much larger than the total volume of any group of holes).

Superglue is also not recommended, as cyanoacrylate will begin to cure in the air faster than you can place the glue emulsion in the hole.

Accurately crush a piece of wood (for example, part of a pencil), stir it into a sour creamy mush with the chosen glue, and gently fill the hole, pushing the mortar with an ordinary match.

We wait for complete drying, and that’s all, the landing place under the screw is ready! So you can perfectly restore to paint any door of furniture, cabinets, bookshelves, even if they are made of natural wood. By the way, leave a small piece of liquid slurry just in case, what if after drying you find that the first attempt gave shrinkage.

Tools for screwing screws

Fasteners can have different sized flats and different shaped and sized recesses in them. Therefore, before you screw in a screw, make sure that your arsenal is present screwdriver or screwdriver with a suitable nozzle. And in general, it is better to have, as they say, a maximum of nozzles for the relevant tools. Plus, they should be replaced regularly, because wear and tear during operation cannot be avoided.

Pay attention! The best nozzles are those made of tool steel with hardening additives. Do not stop your choice for the first available set, otherwise after a couple of days of intensive work you will have to go for a new.

If you plan to screw one or two self-tapping screws into an unstable surface, you can work with a screwdriver. If it is more. you can’t do without an electric screwdriver. Screwing with a screwdriver is not as easy as it may seem at first sight, and requires a certain skill. And an electric screwdriver does it all quickly and efficiently.

How To Make A Mini ScrewDriver Which Opens Small Screws/Life hack

How to screw a screw into a loose hole

Very often during the repair craftsmen are faced with such an unpleasant phenomenon, as a loose screw hole. The main problem is that it is almost impossible to screw metalware into such a hole again. Being in such a situation, we have to go to all sorts of tricks that could help solve the problem. In this article, a master plumber will tell you how to screw a screw into a loose hole.

The easiest, most affordable and obvious way to solve the problem with screwing in a loose hole. However, this method is also the least effective. All you have to do is put one, two or more matches in the hole before the screw is screwed in.

After pressing it against the wall, the match fills in the kerfed area, and the fixing reliability increases. This method is suitable for products that are not exposed to high loads and intensive use. Such fasteners will not last long on actively used joints.

how to remove laptop screw without a Screwdriver at home

An excellent way to solve the problem with a loose screw hole, which works from the opposite direction. In this case, it is not the hole itself that is sealed, but the hardware that will be screwed into it.

All you have to do is choose the right flexible wire and wrap it around the screw all the way from head to end. Depending on the nature of the damage to the wood, the wire can be wound either more tightly or more loosely.

The method is recommended for use when the hole is not too severely damaged.

The method is generally similar to the method with the insertion of matches, but it has its own nuances.

- Take a drill on wood, put it on the limiter on the thickness of the chipboard (for example, if the thickness of 9 mm limiter put at 7 mm);. Giving it flatness from the inside and removing chips;

- Cut a riser out of any wooden lath with a penknife;

- Make a “fitting”, if necessary, trim the edges, bringing the size of the chopik to the right (it must fit tightly into the funnel);

- Pour some PVA glue inside the hole, coat the riser with glue too and put it in its proper place;

- Wait until the glue dries completely;

- Cut the chock flush with the surface of the product with a hacksaw or sharp knife;

- Screw in the screw, it is recommended that the screw is not driven next to the wooden element, but into it.

How to use a screwdriver correctly

Standard screwdrivers perform many functions:

There is a technique that should be followed to avoid making mistakes with each of these jobs, as well as setting up the instrument before you start doing them. It includes the basic items:

- proper preparation;

- changing attachments;

- setting the torque speed;

- how to screw in and screw out fasteners correctly

- chuck rotation direction.

Let’s consider each of them in more detail.

Preparing for work

Before you start using your helper for its intended purpose, you need to understand its kit. In different models they may be different, but the basic set, as a rule, is similar:

- the case in which everything is stored;

- Device for charging the battery;

- Removable battery;

- a set of nozzles (depending on the price category, their number may vary).

Once you have chosen the purpose for which you will be using the device at the moment, you should:

- adjust it, depending on the thickness of the wall (or other surface),

- set its power,

- pick up the appropriate drill bit/self-tapping bit,

- load the tool.

Before contact with the surface it is recommended to make a few turns in idle, paying attention to the compliance of its speed and direction of rotation of the nozzle to the thread of the fastener.

Changing bits

It is necessary to understand the constructive feature of the device. The element in which the bits are inserted is called the chuck. It can be inserted (depending on the purpose):

- drill bit (to make holes);

- bits (there can be several, depending on the different shapes of the edge) in which, in turn, are set:

- screwdrivers,

- self-tapping screws.

- straight edge. They are designed to perform work with a slot (a fastener that has a single slot in it). On its length, depth depends on the choice of such a bit);

- cross-shaped. The width of the fastener’s slot and the size of its head are what determine the shape of the bit.

In order to avoid the possibility of the fastener slipping, it should be set carefully so that the edge fits snugly into the slot.

To change the bit, it is necessary to use a simple method to reinforce the chuck in the bit. The way to do this is to:

Torque setting

The torque control makes it possible to set the rotational speed of the screwdriver. Accordingly, the bigger it is, the stronger the power will be and it will make it possible to drive the screwdriver or drill bit into the desired surface faster and deeper.

The adjusting ring is near the chuck and is marked with numbers corresponding to each speed. They should be set on the basis of the density of the material in which the hole will be made. You can switch speeds during operation, and their strength will depend on the pressure on the starter button.

You have to choose your power for a certain material, for example:

- When drilling plasterboard, you can set the value from 2 to 4;

- when working with hard wood it is advisable to use the highest possible number of revolutions.

Screwing in and screwing out screws

The setting should be carried out in a simple sequence.

- Insert the bit into the slot (screw, self-drilling screw);

- the electric screwdriver is switched on with the trigger;

- the screwdriver switches off automatically when the bit is twisted.

- The control lever on the device is set to reverse direction;

- the bit is inserted in the slot;

- pulling on the trigger causes unscrewing.

Chuck rotation direction

All wrenches have a trigger mechanism that reverses the direction of rotation, because it can work both screwing in and unscrewing fasteners. On the switch there is a corresponding value (forward or backward).

It is not possible to make the change-over switch during the actual operation. If it is necessary to change direction, you have to stop working and be sure to wait until the screwdriver motor stops completely.

To block operation (e.g., when replacing parts), the switch must be set to the middle position. In this mode, for safety, the device will not be able to turn on at all.

Screwing screws correctly: 6 tips that will simplify this activity

Receive one of the most read articles in your inbox once a day. Join us on and

Self-tapping screw is a type of fasteners, the main feature of which is the ability to be wrapped into the material without prior drilling. Despite the overall simplicity and unsophisticated design, there are many important subtleties to consider when handling them. Let’s break down the most important and most frequently practiced.

How to choose the right nozzle of an electric screwdriver

There are two kinds of Phillips bits: PH. standard with 4 slots and PZ. modified with 8 slots. The latter are good in that they do not actually allow the nozzle to come off the metal part during operation. When choosing a nozzle, you should also take into account the size, which is indicated directly on the product. Bits come in 1, 2 and 3 sizes. The right bit ensures a secure grip.

How to screw a long self-tapping screw into hard material

In such a case, it is recommended to make a pre-drilling, as well as to lubricate the screw with paraffin or at least simple soap. Otherwise, there is a high risk of breaking the hardware or ripping off its slot.

How to correctly screw a self-tapping screw into a thin bar

The only way to avoid cracking the thin bar when screwing a self-drilling is to make pre-drilling. It is worth considering that most often a crack appears when trying to “sink” a self-drilling screw, which means that you should countersink with a wider drill.

How to work with small screws

When working with small metalware it is recommended to use a magnetized bit. If you do not have such at hand or to make such a bit with their own hands is not possible, for fixing screws you can use ordinary masking tape, advise consultants Novate.ru.

How to unscrew a self-tapping screw

There are several ways to do this. First, you can use a special extractor tool. Second, you can put some soft material, such as rubber, between the screw and the bit. Thirdly, you can solder the bit with a soldering iron and tin, if there is no other way to unscrew it.

How to unscrew a screw with a broken off head

In order to remove a self-tapping screw with a damaged or completely broken off head, you need to use a tubular drill bit for ceramics.

Want even more handy hints? Then read about 6 tricks and tricks that will ease the life of any driver on the road.