How to Set Ignition on a Partner 350 Chainsaw

The device and principle of operation of the ignition system of a chainsaw

The standard carburetor engine ignition system consists of:

- Magneto;

- Spark plug;

- An electric cable connecting them to each other;

- Engine shutdown keys.

Ural chainsaw ignition scheme

Magneto is a type of alternator that supplies spark plugs with electricity. It consists of a fixed winding of an inductor and a permanent magnet mounted on a flywheel that rotates with the crankshaft of a gasoline engine. A moving magnetic field creates an electromotive force in the low-voltage winding, which is transformed by the transformer into voltage with a potential sufficient to produce a spark.

At contact magneto the first output of the high-voltage winding is connected to the spark plug, and the second through the mechanical switch to the ground. At a certain moment, a special structural element makes contacts, which leads to a sharp increase in the voltage in the network and the passage of sparks in the interelectrode space of the candle.

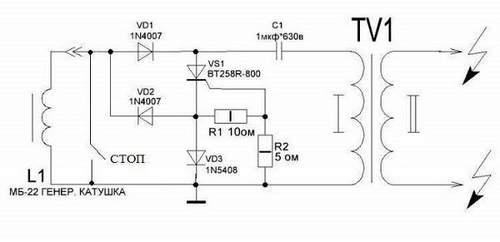

To prevent overheating and oxidation of the breaker contacts, a capacitor is connected to the electrical circuit.

Chainsaw ignition circuit with contactless magneto based on the operation of the control coil, which plays the role of a voltage regulator. The electronic unit also includes a diode, capacitor and thyristor, which transmits current with a voltage of a certain value. When it opens, the capacitor is intensively discharged, forming a current in the turns of the primary winding, which is inducted into a high voltage voltage, which gives a breakdown on the spark plug installed in the cylinder. The electric network operates in a pulsed mode to the beat with the rotation of the crankshaft and the translational movement of the cylinders.

Ignition timing

The mechanical device and the factory setting of magneto ensure that the spark discharge time coincides with the optimal position of the moving piston. For four-stroke gasoline engines, spark penetration should occur even before the piston arrives at top dead center. This is because the process of complete ignition of the air-fuel mixture takes a certain time. The speed of movement of engine parts is comparable to the speed of ignition of the fuel, so the piston manages to go some way from the moment the spark passes through to the moment the burning gases create extremely high pressure.

For every engine there is ignition timing. It is equal to the crank rotation expressed in degrees from the moment of breakdown in the interelectrode space of the spark plug to the moment when the piston is at top dead center. This indicator depends on many parameters, including the design features of the engine and the properties of the fuel mixture.

In practice, in the mass production of the engine at the factory, the individual ignition of each product is not adjusted, and the corresponding marks are set on rotating parts, which must be combined during installation.

When is the ignition setting required? There are basic symptoms of failure in system operation:

- Engine does not start;

- The motor works, but with noticeable interruptions;

- There is a decrease in tool power.

In these cases, do not rush to contact the service center. Try adjusting the ignition yourself first.

The procedure for checking and tuning the correct operation of the engine

The most vulnerable element of the carburetor engine is the spark plug. It also allows you to judge the probable causes of malfunction of individual units of the gasoline engine. The following procedure is recommended.

-

Dismantle the candle and inspect it. A dry candle with a light brown tint of the electrodes can be considered good.

Soot on a spark plug

Chainsaw ignition coil

During installation of a new electrical module on the engine, the magneto clearance should be adjusted.. The optimum distance between the flywheel and the ignition coil for most chainsaws is 0.2-0.4 mm.

The gap between the magneto and the flywheel

For fidelity, it is recommended to carefully study the documentation for the purchased model and follow the manufacturer’s requirements.

With such a small gap, it will not be possible to use an available measuring tool for direct measurement. In practice, Husqvarna saws are used pad template, cut from thin and flexible sheet material of the required thickness. It is clamped in the space between the flywheel and the coil when it is installed, and then pulled out.

To avoid having to resort to adjusting the ignition, operate the tool carefully, avoiding impacts. In particular, this applies to chainsaws with electronic chips in the ignition system, as they are very sensitive to mechanical damage.