How to sharpen a chain with an angle grinder. With the file

How to sharpen a chainsaw chain with an angle grinder

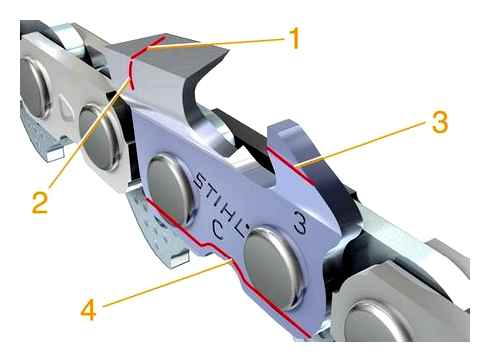

First of all, it must be remembered that the chain must be sharpened in accordance with the shape of its tooth. Thus, in modern tools, the teeth are arranged in two ways: on the side or on top.

Here it is important to consider the angle of sharpening, because the cutting elements are at a certain degree, which is almost the main criterion when processing the cutting edge. This parameter is usually indicated on the package

The denser the material to be sawn, the duller the sharpening angle should be. Generally, craftsmen who saw often and in large quantities have several chains with different tooth angles.

For example, for a longitudinal sawing of wood, its value is in the region of 10. 12 degrees.

The main signs of the need to perform the procedure are as follows:

- During work, the tool moves chaotically from side to side, regardless of the angle of inclination;

- the speed and efficiency will drop;

- The chips from wood sawing differ from the standard ones in appearance and texture;

- the cutting blade is not sufficiently tensioned.

It is a safety rule to work only with non-defective tools, in order to avoid not only damage to the equipment, but also dangerous injuries.

How to sharpen a chain with a file

You must first find a file that fits your needs, and they differ in diameter. Basic types: 40mm, 48mm, 52mm, and 55mm.

Sharpening a saw chain with a file is also possible in the field, but this is the longest way. If you have a special file clip, use it.

- Clamp the chain in a vise or hold it against a tree.

- Mark the tooth you will be sharpening.

- File over the cutting tooth at a 30 degree angle by yourself or use a clamp.

- Move the file away from you, toward you. Don’t put too much pressure on the tooth to avoid breaking/removing too much metal. Only sharpen the tooth blade. In the case of a new file, six such strokes on one side of the tooth is enough. If a file is used/sharpened, make up to 12 strokes.

- Move on to the next tooth.

- When you are finished sharpening one side of the cutter, turn the chain over.

- Repeat the process with the other side of the teeth.

Specially designed file holders are equipped with sharpening marks. We recommend that you practice sharpening the chain with it and then change to working without the carrier.

The dangers of working with a blunt tool are as follows?

A dull chainsaw chain should not be used

Working with a faulty tool is itself fraught with many unpleasant consequences, and here are some of them:

- Lower efficiency, i.e. less work will be done in the same amount of time.

- The mechanism begins to wear down and individual parts are at risk of breaking.

- Excessive fuel consumption.

Possible ways and methods of sharpening the chain

Working with a file

The best solution is simple “gadgets” for sharpening work. This kit includes round and flat files, special holders, jig-Caliber, hook for chip removal, etc. Structurally, the “gadgets” may differ, but the functionality has a common logic.

Angle Grinder Chain Saw Adapter

The diameter of the circular file is directly related to the size of the chain:

- – Chains with ø 1,3. require a file of ø 4 mm (used much more often);

- – Chains with ø 1.6 require a ø 5.2 mm file;

- – A flat file is used for sharpening the depth stop.

Grinding process

- With the chain brake on, clamp the guide bar firmly in a vice (a firmly clamped saw is the key to a successful sharpening)

- Position the template so that the arrow is pointing toward the nose of the bar. Be sure to mark (maybe with chalk) the tooth where you started the sharpening, otherwise you may go a second round;

- Grind in the direction indicated by the arrows. Remember, each tooth has a factory-designed notch in its tip. It indicates the maximum sharpening angle.

- In addition to the cutting tooth, there are limiters on each link. They are sharpened as needed. This is necessary if the height of the tooth is reduced as a result of sharpening, and problems arise in the performance of the chainsaw. It is usually necessary to sharpen the file stop after 2 to 3 sharpening intervals;

“If you are not skilled in sharpening, it is best to start with inexpensive chains.”.

Recommendations:

- The file should not extend beyond the top of the cutting edge by more than 1/5 of the file’s cutting edge. The pressure is applied with equal force;

- The sharpening tool should be moved to one side, “away from you,” with an equal number of strokes for each tooth;

- To sharpen the vertical plane, the file position must be at a right angle;

- To sharpen the horizontal plane, file position, at an angle of 20-30°

- If there are teeth of different height, the reference point is the smallest.

Advantages: Possibility to “charge the saw” in the field conditions. But it is cheap.

Drawback: Takes time and effort. It quickly “kills” a file. Speaking of files: it is better to pay a little more and get a quality product. than to buy for 40-50 and throw it away after the first sharpening (tested in practice). Also, if the chain has “plowed” the ground so well that its cutting edge has changed its original shape, it is difficult and not fast at all to sharpen it with a file.

Grinding with an angle grinder

Professionals consider this work, primitive. There is a risk of damaging the tire.

The process (easy on the face of it, but tricky in reality)

- The chain also stays on the bar;

- We mount the metal cutting disk with thickness of 1,5-2 mm on the angle grinder. It is desirable to take not new, that is, with filed edge;

- Put an obstacle in front of the chain and tire (a chip will do);

- Let’s sharpen it at the right angle;

- The chain should be tightened properly after finishing work.

With a professional and steady hand, more than 7 sharpening cycles are possible in this case.

“For the beginner, it’s best not to “experiment” with the saw, chain and. with their own body parts!”

Advantages of the method: Fast, cheap and does not take any effort;

Disadvantages: You need special skills, a steady hand and the ability to observe the safety.

Electric sharpening machines

They are equipped with special setting functions which help you to position the chain at a certain angle. But it is possible to guide the blade with precision and accuracy to the teeth of the chain. There are machines equipped with automatic vise. They are activated by bringing the disk to the edge to be sharpened. Convenience and functionality, of course high. You can find models at “reasonable” prices.

Machines with “manual drive”

This machine is similar in design to a compound bow saw. Only in the place where the saw blade is located, there is a round file. This machine can be used for sharpening and straightening teeth by adjusting the consistency of the top edges to the smallest (reference) size. The mechanism allows you to precisely set the parameters. After setting the “reference” tooth, the sharpening is done in two or three strokes. And then the transition is to the next tooth.

When it is necessary to grind the stop, change the round file for a flat file.

Advantages of the method: Allows high-quality, convenient and without great physical costs sharpening teeth, including those that have lost their original shape.

Drawbacks: Price of the tool and distance to the possible site of the saw.

“After finishing “sharpening procedures”, blow the chain with compressed air (from a compressor or pump) and put it in clean motor oil for a while. Of course, almost no one does such measures, but for the chain, it will only benefit.”

What to choose for sharpening, you decide. This depends on how often you use your chain saw. On the neatness of handling it. On the quality of the chain purchased. And, of course, from the possibility of spending an enriched sum of money. It is impossible to compare methods, for as the German proverb says. “apples should be compared with apples”.

How to start a chain saw without a starter motor

Regardless of the type of chainsaw and its manufacturer, all starters are arranged in almost the same scheme. To quickly start the tool, you need to pull the starter handle sharply, creating a spark for the clutch. Many people wonder how to start a chainsaw without a starter motor. Theoretically, this is not possible, as there are no alternatives and other ways to start. But “folk craftsmen” were able to get out of the situation with a broken starter.

Starting a chainsaw without a starter motor

To start the saw, it is necessary to sharply pull the handle, and then the cable is pulled out, which turns the drum. That is, you have to turn this drum to start it. An ordinary cordless drill or an electric screwdriver takes care of the problem. So:

- The chainsaw is placed on a level working surface

- The top cover is removed from the starter motor so that there is clearance to the drum

- there is a bolt in the middle of the drum

- to use the drill with a head of an appropriate size and to turn the drum artificially

In this way it is possible to start a chainsaw of any manufacturer in a fraction of a second. The main thing is to follow the safety rules, so that when starting the chainsaw does not fall, do not slip and do not hurt anyone.

How to sharpen the chain on a chainsaw manually with a file without additional devices: a step-by-step instruction

First you need to prepare the tool for this procedure. To do this, it is important to place the chainsaw (or electric saw) on a flat surface and block the movement of the chain with the brake lever. It is not necessary (but possible) to remove the chain from the tool, as this will only reduce the convenience of performing the procedure. If you prefer to perform sharpening not on the tool, then the vise is sure to help. In a vice the chain must not be clamped completely, but only the tail part.

Before carrying out the actual file procedure, the following guidelines should be observed:

- File movements should be carried out from the inside out. In other words, the removal of the metal layer should occur as the sharpening tool moves from the base to the edge, that is, from the back to the front.

- Use one tooth at a time. First you must go through the chain, and sharpen the teeth that point one way. left, and then the other way. right.

- Before beginning work, make a notation of the tooth at which the sharpening is to begin. Use chalk or a marker.

- The tooth with which the process begins must be in the middle of the bar.

- The angle or degree of sharpening depends on the chain. This is usually marked by a notch on the top of the chain by the manufacturer.

- Initially, sharpening involves working with a round file, and only finally with a flat file.

Work must be performed with gloves on, as otherwise there is a risk of cutting yourself on the sharp edges of the chain links as the chain is moved along the bar to sharpen the next set of teeth. After preparing to perform the procedure, you can begin:

- To eliminate the possibility of the chainsaw moving relative to the surface on which it is placed (in other words, to keep it from sliding), you can fix its bar in a vise if you have them (in the field, of course, you won’t use them).

- Check the sharpening angle, which affects how many degrees you have to hold the file horizontally and vertically. This angle usually varies between 30 and 35 degrees.

- The file should be about 1/5 of the way up over the tooth tip. The photo below shows.

- Then we make simple movements. As you move the file forward, you must press it against the edge of the tooth, removing a layer of metal. The reverse movement is carried out without pressure.

- A file should be held with both hands at both ends.

- Repeat the file process the appropriate number of times until the edge of the first tooth is sharp. The number of movements of the file should be counted, and later be guided by this value for subsequent links.

- The sharpening forces for each tooth must be identical.

- The following pictures show the sharpening angles depending on how the wood will be sawn. It should be 30 degrees for a standard crosscut and 10 degrees for a longitudinal cut.

- After the chain has been sharpened, it is necessary to check and correct the depth limiter values for the chain teeth.

- The depth gauge indicates how much wood the tooth grips when sawing. It follows from this that the smaller the limiter is relative to the top edge of the tooth, the better the wood grip is, and consequently the higher the speed and performance of the tool. However, it is important to take into account the fact that a too worn limiter will lead to an increased load on the engine of the tool. Its value in relation to the upper edge should be less by 0,63 mm. It is ground using a flat file.

- It is absolutely necessary to control the depth of cut, because the size of the cutting edge decreases during the sharpening process. This results in a shorter distance between the cutting depth and the saw tooth, and therefore less wood is grabbed by the chain. The result is a drop in efficiency and not a very satisfactory result. Higher fuel consumption and sharpening speed increase.

- If necessary the top edge of the saw tooth is also ground with a flat file if it has scoring or chipping.

At this point the process of sharpening the chain of a chainsaw or electric saw can be considered complete. The above procedure, which involves the use of a minimum number of auxiliary tools. You can also use special templates, holders and other devices to increase not only accuracy, but also quality. Whether you need these tools, however, is up to you to decide. The instructions above are particularly well-suited for the field.

That’s interesting! Manual chain sharpening procedure takes approx. 10-15 minutes. Once the process is completed successfully, the efficiency and productivity increases. That’s why you can increase your felling speed by taking just 15 minutes.

Many sawyers often do not know when the chain needs to be changed. You can determine this with the help of the resource marker on the cutter bar. Once this mark is reached, the chain can no longer be sharpened and should be replaced.

The advantage of the manual chain sharpening method is obvious. it is easy and can be done in the field. There are also disadvantages:

- Low speed;

- Physical effort required;

- The importance and rigor of controlling the sharpening of each tooth;

- The need for periodic file changes.

However, in any case, manual sharpening is not only the most correct but also the most effective option, although not in all cases fair to implement.

How to tell if a chain is blunt?

There are several indications that a chain is not currently serviceable:

- It takes more physical effort for the same action.

- Stretching of the chain.

- The feeling of vibration when working with the tool.

- Unevenness of the filings, which in addition become more like dust.

The chain can also become blunt for several reasons:

- Improper handling.

- Contact with too hard objects, such as rocks.

- Overly voluminous and time-consuming work.

How to sharpen a chainsaw chain with your own hands

And now let’s actually review all the ways by which it is possible to make a quality, and most importantly, the correct sharpening of the chain located on the chainsaw. So.

How to properly sharpen a saw chain with a file

The main advantage of this method is economy, because a file is in fact rather inexpensive. over, it is likely that this kind of tool is in the arsenal of any owner. But it is worth noting that not every file can be suitable for sharpening, because it first of all, or rather its diameter should correspond to the width of the chain itself. To help you orient yourself, here are the figures:

Also a flat file is used, so you can use it to remove the so-called limiters that hold cutting teeth.

It is worth noting that the process of sharpening should be carried out at a certain angle on the cutting tooth. The important thing is that each tooth of the chain has a factory-made notch, which actually indicates at what angle it is necessary to perform this manipulation.

Except the cutting tooth itself each chain link has a kind of limiter which defines acceptable depth of penetration into wooden material. It is worth noting that the sharpening of these limiters should be performed very rarely, moreover, only when necessary.

An important role in the sharpening is played by the so called clamping base. Which is a kind of mechanism designed precisely to secure and direct attachment of the saw bar. Basically, it is clamped either on the extreme corner of the table or on the workbench. Because perfectly established saw is a guarantor of quality sharpening.

It is also important that the guide bar has specific rollers for saw movement, and it is clamped exactly on the guide bar. You can choose the angle of the direct sharpening yourself, and then make its fixation by means of a molding.

The process itself consists in your chaotic movement by means of a file directly in the groove of this kind of device. It is worth noting that such a “tool” will reduce to a minimum the very possibility of making a wrong sharpening.

With an ordinary angle grinder

Most owners avoid this method of direct sharpening the chain, because they believe that such a tool can quite severely damage the cutting teeth. Especially this method is the most difficult of all existing today. Such concerns are not taken, as they say, out of thin air, as in fact the chainsaw can be damaged, especially if you are a novice in this business.

It is for this reason that if you are going to carry out this kind of manipulation for the first time, the best thing you can do is to use the method presented above. Nevertheless, we will still familiarize you with the direct features of the chainsaw with this method.

And so, during the sharpening process, the chain should not be removed from its place, as it is manipulated exactly on the chainsaw. It is also important to use a special disc that can be used to work with metal material and the diameter of which should be at least 2.5 mm. But remember that under no circumstances should the disk be new, but on the contrary, it should be used and have rounded edges.

It is also important that you can determine the angle at which the sharpening is made. Remember that between the chain and the lower part of the bar it is necessary to install a wedge, namely a wooden one. This process requires a direct skill. This is a very effective way and through this method of sharpening the chain you can use from 4 to 7 this kind of manipulations.

Proper sharpening with a manual machine

Every chain saw owner who has used a chainsaw for a long time knows that not all chains can be sharpened with a file. For example, if the chain cutting edge, through frequent use of the tool, simply lost its original form, then in this case, you are unlikely to return it “to life”, at least, this process will take you not only a lot of time but also forces.

That’s why the best way is to use the machine directly. They are available both electric and manual, equipped with either grinding wheels or sharpening stone. Although this method is not a novelty, it is nevertheless quite effective and accurate.

And now let’s get acquainted directly with the process of such sharpening. The first thing you have to do is directly loosen the adjusting screw of the chain clamp. Then you need to install the chain itself in such a position so that the links that are on it are turned directly to the sharpening stone.

Then decide on the angle at which the sharpening is going to be performed. It is noteworthy that this kind of “sharpening” can be done in two ways. Specifically:

The first method is a sequential sharpening, which consists in acting on each tooth individually, while periodically changing the direct polarity;

How to Sharpen a Chainsaw by hand with a file

The second method is sharpening, but only every second cog. For example, you sharpen the right tooth first and then the left tooth. It is worth noting that this method does not have a direct change of polarity.

Useful tips

It is possible to increase the service life by alternating manual sharpening with a special sharpening machine. The latter enables the sharpening angles to be aligned as accurately as possible on the sharpening machine. The depth of sharpening should not be too deep.

It is necessary to comply with safety measures, which allow you to cut wood of any size with maximum efficiency and with a minimum level of danger to humans:

- Before assembling the chain tool and setting up the headset, it is advisable to familiarize yourself with the rules of use. It is connected with the fact that each tool has its own peculiarities.

- Work using the saw should be performed with gloves and safety glasses.

- When working with chain saws choose close-fitting clothing made of thick natural materials and shoes that are as sturdy as possible.

- It is necessary to cut wood with a chainsaw in a stable and safe position, and to position the material as steadily as possible. A toothed end stop on the log will help ensure stability.

- Hold the chainsaw steady with both hands, always check that the cut is being made.

Modern chainsaws are used in domestic and industrial settings. It is important to keep the performance and efficiency of the tool high and dependent on the condition of the sharpened chain headset.