How to sharpen a chainsaw chain with an electric screwdriver. Grinding with an angle grinder

How to sharpen a chainsaw chain with your own hands

HDSG shows how to correctly sharpen a chainsaw chain at home with a file, angle grinder, and power tool. Detailed video of the process of sharpening with their own hands. Let’s show how to work properly with tools and devices.

It is very convenient to work with a chainsaw. Despite the fact that the unit weighs 5-7 kilograms or even more, sawing the tree trunk into billets, you’re just surprised how quickly it happens, and there is almost no fatigue. But here comes the moment when the tool blade enters the wood heavier and heavier. The diagnosis is that the chain saw is blunt and needs to be resharpened.

Who encounters this for the first time, a little upset, because it is not clear: to do it yourself or to give the tool to specialists in the workshop. And what is the right sharpening method?? But in fact, there is nothing terrible here, and with knowledge you can easily sharpen chainsaw chains with your own hands. The right solution strategy in this case directly depends on the workload of the machine.

If a chainsaw is used occasionally, a few times a year, it might not make sense to buy a special sharpening machine or device, it is easier to solve the problem by using the services of a service center. But if a chainsaw. a means of making money or there is a desire to master the process of sharpening itself, then you should definitely buy a sharpener or machine and manually carry out this simple manipulation of the chain. See below what proper chainsaw chain sharpening is based on.

When to sharpen?

If a chainsaw is used a lot, it is sharpened quite often, often several times in one day. Particular attention should be paid to the fact that the encounter between the chain and the ground greatly accelerates the process. That’s why chainsaws should be used in such a way that there is no chance of the chain and ground coming into contact. After a few touches, the chips will be very fine and the chain will go slightly deeper into the material.When considering such a question, it can be noted: the more often you have to sharpen a chainsaw chain, the smaller the layer of metal is removed. Also, if often sharpened, the service life of the cutting element of the chainsaw will be significantly increased. The main condition is that the work must be done properly, if it is done by hand. Correctly perform the procedure is possible only if there is a special machine.A sign that the cutting element of a hand chainsaw has become dull is that the cutting force is too great. Properly sharpened chainsaws determine a significant reduction in the feed force index, that is, chainsaws enter easily with a slight push. Another sign of the need to sharpen chains is that they receive very fine chips.The chain saw sharpening in case of the occurrence of the signs under consideration is obligatory. Chains are sharpened to reduce body stress, cyclic load index, fuel consumption. Also if the chain teeth are not sharpened in time there is a possibility that the wear of all components will increase, resulting in a shortened life of the chain saw.

In order to correctly sharpen with your own hands, even if you use a machine, you should know the geometry of the tooth. Its constituent elements include:

16 USEFUL LIFE HACKS FOR YOUR TOOLS

The blade of the tooth consists of the following elements:

To grind properly with your own hands one must take into account that the end blade and the upper blade must be positioned correctly in relation to each other to ensure the best cutting performance. The back of the tooth forms a specific angle of the upper blade. A similar angle is formed to plunge the blades into the material. To sharpen with their own hands should also take into account the fact that the back of the blade has a narrowing. this design feature forms the angle of the end blade. It is created to provide lateral cutting of chips.

The sliding surface and the end part of the blade form the front angle. In this case, the angle has a fixed value, it varies from 60 to 85 degrees.If you sharpen the tines with your own hands, it is worth bearing in mind that it is the upper blade that is the main one, and the angle formed by it is the most important angle.To summarize, when considering the features of geometry, we note that the sharpening angle can vary depending on the conditions of use. The basic rule that should be observed if you sharpen the tooth with your own hands, can include the following: the higher the angle, the greater the performance of the chainsaw, but reducing the index provides greater smoothness of the blades, reduced vibration and increased service life. It is worth sharpening, taking into account that the index should be between 25 and 35 degrees. The version of the blade, which is designed for longitudinal sawing, can be called an exception. many manufacturers of cutting element of a chainsaw withstand 10 degrees.

What’s the risk of working with a blunt instrument??

You should not use a dull chainsaw chain

Working with a faulty tool itself is fraught with many unpleasant consequences, and here are some of them:

- Reduced efficiency, i.e. less work will be done in the same amount of time.

- The mechanism begins to wear and tear, and individual parts are at risk of breaking.

- Excessive fuel consumption.

Files and jigs

The saw’s main tool for sharpening the working tooth is the circular file. Flat is used for setting the tooth height. depth of cut limiters.

A round file

The round ones vary in diameter. The main diameters are:

Depending on tooth size, the optimum diameter must be selected. Special file holders or support rollers with an indication of the tooth sharpening angle can be used to make the process easier.

Flat file

The flat file needs to be no more than 1 cm wide. It is convenient to sharpen a limiting tooth with the help of a special bar (file gauge), which is set on the chain and shows to what maximum depth it is necessary to grind a tooth to achieve optimum performance of a chainsaw.

File holder for file

circular saw blade is inserted into the holder and fixed with special clamps. On the plane of the holder, there are several marks indicating a particular sharpening angle. When dressing a chain with a file holder, the markings on the fixture are parallel to the guide bar of the chain saw, so the required angle can be maintained quite accurately.

It is rather inconvenient to use the holder all the time. You can use this tool from time to time to check the correct tooth angle.

File gauges

These fixtures are used to control the tooth sharpening angle and the distance to the depth stop in conjunction with a flat file.

Sharpening chain with a chain sharpening machine

Dressing the chain with the sharpening machine is one of the most convenient, fastest and qualitative at home. You will have to buy the machine tool, which costs about 2000-3000, but you will forget about problems with chains.

The sharpening machines have a chain retainer (1) with a locking device that can secure the chain. It also allows you to set the horizontal angle of the chain from 0° to 40°. Place the chain on it and set the desired angle. then set the angle of the sharpening block with the lever (2), i.e. what angle it will go under the tooth. before sawing lower the disk onto the chain and set the limiter (4) in right position, so as not to cut the chain during sawing. sharpen every right tooth, then turn the chain and chain holder 180° and sharpen every left tooth.

The advantage of this method is that even the inexperienced operator can sharpen. The machine is also equipped with a blade guard (3) that prevents injuries at work. But, as we said before, you have to spend a little money for the machine. If you need a good model, but don’t want to overpay for big-name brands, get Champion C2001, which is by far the best among the budget ones.

How to sharpen the chain on a chainsaw manually with a file without additional tools: step-by-step instructions

First, you need to prepare the tool for this procedure. To do this it is important to place the chainsaw (or electric saw) on a flat surface and to block the movement of the chain with the brake lever. It is not necessary (but possible) to remove the chain from the tool, as this will only make the procedure more difficult. If you do not want to sharpen the tool, a vice should always be used to assist. Do not clamp the whole chain in a vice. only the tail end.

Before carrying out the direct file procedure, you should resort to observing the following recommendations:

- The file should be moved from inside out. In other words, the removal of the metal layer should occur when the sharpening tool moves from the base to the edge, that is, from the back to the front.

- This is done one tooth at a time. First you need to go through the chain, and sharpen the teeth, which are directed to one side. left, and then to the other. right.

- Before you start, mark where you want the sharpening to begin. Use chalk or a marker.

- The tooth where you begin the sharpening operation should be centered on the guide bar.

- The angle or degree of sharpening is chosen according to the chain. It is usually marked by a notch in the top of the bar by the manufacturer.

- Initially, sharpening should be carried out with a round file, and only afterwards with a flat file.

Wearing gloves is recommended, otherwise there is a risk of cutting yourself on the sharp edges of the chain links as you move the chain around the bar to sharpen the next teeth. Once you are prepared to perform the procedure, you can begin:

- To exclude the possibility of the chainsaw moving in relation to the surface on which it is placed (in other words, so that it does not slip), you can fix its tire in a vise, if available (in the field, of course, they will not be used).

- The sharpening angle is specified, which affects at what degree relative to the vertical and horizontal you need to hold a round file. Usually this angle varies between 30-35 degrees.

- The file should be about 1/5 higher than the tip of the tooth. The photo below shows.

- The next step is a simple movement. When moving the file forward you need to press it against the edge of the tooth, removing a layer of metal. The return motion is carried out without pressure.

- The file must be held with both hands at both ends.

- Repeat the file passages the appropriate number of times, until the edge of the first tooth becomes sharp. The number of movements of the file needs to be counted, and further reference this value for subsequent links.

- The effort for each tooth should be the same.

- The following photos show the sharpening angles depending on how the wood is sawn. It should be 30 degrees for a standard crosscut, and 10 degrees for a longitudinal cut.

- After the chain cutting edge has been sharpened, it is necessary to check and correct the cutting depth limiter value.

- The depth gauge indicates how much wood the blade grips when sawing. it follows that the smaller the limiter is relative to the top edge of the tooth, the better the wood grip, and therefore the faster and more productive the tool. However, it is important to keep in mind that if the limiter is too worn out, the tool motor will be more loaded. Its value in relation to the top edge should be 0.63 mm less. It is ground using a flat file.

- It is absolutely necessary to check the depth of cut, because the size of the cutting edge decreases during the sharpening process. This results in a smaller gap between the cutting depth and the saw tooth, which means that the chain grabs less wood. The result is a loss in efficiency and the results are not very good. Higher fuel consumption and sharpening speed increase.

- If necessary, the top edge of the saw tooth is also ground with a flat file if it has scoring or chipping.

Stihl Chainsaw Chain Grinder Sharpener & Grinding Wheels

That’s the end of the chain sharpening process for your chain saw or electric saw. Considered above is a procedure, which involves the use of a minimum number of auxiliary tools. You can also resort to the use of special jigs, holders and other devices, which will increase not only the accuracy, but also the quality. But whether you need these tools is up to you to decide. The above instruction is especially well-suited for use in the field.

This is interesting! A manual chain sharpening procedure takes about 10-15 minutes. Once the process has been completed successfully, it increases efficiency and productivity. That is why it is possible to increase felling speed by only 15 minutes.

Often many sawyers do not know when to perform a chain change. This can be determined by the resource marking on the cutter stop. Once this mark is reached, the chain can no longer be sharpened and must be replaced.

The advantage of the manual chain sharpening method is obvious. it is easy and can be done in the field. There are also disadvantages:

- Low speed;

- The physical effort involved;

- The importance and rigor of controlling the sharpening of each tooth;

- the need for periodic file changes.

However, in any case, manual sharpening is not only the most correct, but also the most effective option, although not in all cases fair to implement.

How to know if a chain is blunt?

There are several indications that a chain is not working at the moment:

- Requires more physical effort for the same operation.

- Stretching of the chain.

- Feeling of vibration when working with the tool.

- Unevenness of the sawdust, which in addition becomes more like dust.

There are also a number of reasons why a chain can become blunt:

- Improper handling.

- Contact with objects that are too hard, such as rocks.

- Working too hard and for too long.

How to sharpen a chain saw chain with a drill: Clear instructions

Receive one of our most-read articles in your inbox once a day. Join us on and

Like any other cutting object, the chain saw’s cutting edge will dull and wear out over time. Working with a blunt chain saw is not possible. For sharpening, it is possible to have the chain chain sharpened by an expert in a service center. However, for sure, many owners will want to try their forces in this matter, for the benefit of there is a very simple and accessible method using a drill.

Preparatory stage

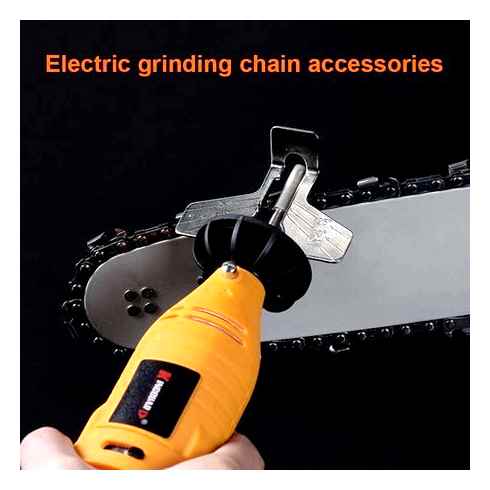

To sharpen your chainsaw you will need some tools. First of all you should get a non-conical round file whose diameter should correspond to the diameter of the rounding of your chain’s cutting tooth (a file with a diameter of 4mm is the most suitable).8 mm). Also for the method of sharpening you will need a drill or electric screwdriver with adjustable speed. Any small bearing is also needed.

When everything is prepared, you need to take a file and remove its tail (the part that goes into the handle). This is best done with an angle grinder. After that, we insert the file into the chuck of an electric screwdriver. Now you need to make a sleeve out of wood or plastic, which will be put on the opposite side of the file. On the outer part of the sleeve you should put the inner ring of the bearing. The sharpening tool must be designed so that it can be held with both hands: the first grip on the handle of the drill, the second on the outer ring of the bearing.

Work process

To begin with you need to put the saw on a horizontal sawing surface. It is recommended to clamp the tool in a vise for better safety and security. Using a marker, mark the tooth where the sharpening begins. place the file in the rounded edge of the cutting edge of the tooth, and set it at the desired angle. 30 degrees to the chain bar.

Most often on the outside of the chain, there are special marks that show the correct angle. The file should be parallel to the tooth flank. Use the file to file the tooth for 1-2 seconds. It is important to remember that the sharpening tool must be held with both hands.

topics. some expert advice:

“Newspaper ad: Trading a chainsaw for a denture”.

I hope the information was moderately helpful. If so, subscribe to the blog for updates and share the article with your friends All the best to you. Good luck!

Quote of wisdom: It is not the word, but the tone in which the word is pronounced (Belinsky).