How To Sharpen A Saw Chain At Home

Do-it-yourself chainsaw sharpening

Sharpening the chainsaw chain with your own hands The chain tooth planes the wood like a plane, and the thickness of the shavings is adjusted by the height of the limiter. Intense sawing results in rapid dullness

Chain sharpeners

The round file holder has a mowing line that can be correctly positioned in relation to the chain. The holder fits onto the sharpened tooth in accordance with the line orientation. In this case, the insert itself rests on the upper edge of the tooth and the depth gauge, and the file is located under the cutting edge.

The use of a holder ensures that the file will fit to the tooth at the correct height. There are different holders for different pitches of the saw chain. The correct choice of holder, combined with the correct file diameter, ensures that the file protrudes over the back of the tooth by 1/5 of its diameter. Use only special saw chain files.

Before sharpening the chainsaw chain, it is advisable to secure the bar. When sharpening, it is necessary, keeping the position of the holder and pressing the file to the sharpened edge, to make several (2-3) turning movements away from you. Do not try to press too hard on the file, the movements should be smooth and measured. Rotate the file regularly to avoid one-sided wear. All other teeth are sharpened in the same way. It is more convenient to first sharpen the teeth in one direction, then change the position and do the same with the teeth in the other direction.

When sharpening all teeth, file the same number of strokes at the same pressure. This will result in the same tooth length. All cutting teeth must be of the same length. Different tooth lengths cause uneven chain running and cracking. If the length of the teeth is not the same, all cutting teeth must be filed to the length of the shortest tooth.

After several sharpening of the cutting teeth, the depth gauge is ground. To do this, a template is superimposed on it so that the limiter falls into the slot, and the tip protruding from the slot is grinded with a flat file.

The principle of using another set for sharpening chainsaws is no different from the first, although its design is different.

A round file is also used for sharpening the cutting tooth, and for sharpening the depth gauge. Flat. A special template provides parameters for sharpening both cutting teeth and stops. In the first case, it is superimposed on the chain in such a way that it falls into its slots. The file, placed on the template and brought under the cutting edge, rests on the guide rollers. The direction of movement of the file must be parallel to the lateral edges of the template.

When sewing the stopper, the template is applied so that the stopper falls into the slot, near which it says SOFT (for soft wood) or HARD (for hard wood). As in the case of the first device, the file is seamed with smooth, even movements of the flat file away from you.

Do-it-yourself chainsaw sharpening

The chain tooth planes the wood like a plane, and the chip thickness is adjusted by the height of the stop.

Intense sawing will quickly dull the chain. Several sharpenings may be required within one day. The problem is aggravated by the fact that the tooth quickly dulls when it meets the ground. It is enough to hook the soil with the tire once or twice, and the work can be stopped. The shavings become fine and the saw stops going deep into the wood.

The sooner dull teeth are sharpened, the less material needs to be removed during sharpening, as a result. The service life of the saw chain is longer. Determining the moment when sharpening is already required is quite simple. An important feature is the feed force. A properly sharpened chain is pulled into the cut with just a little pressure. If, on the contrary, the chainsaw is forced to cut by increased feed force, then the teeth are dull. A dull chain can also be recognized if only small chips fly out of the cut instead of coarse, thick chips.

In this situation, the chainsaw must be sharpened urgently. Do not cut with a dull or defective saw chain. The consequence is high stress in the body, high cyclic load, poor cutting results. In addition, this means reduced productivity, high fuel consumption and increased wear on all parts of the chainsaw.

Chain teeth parameters

To achieve optimal cutting properties, the tooth blades are angled. The back of the tooth falling back at an angle forms the posterior angle of the upper blade. This angle is needed to cut the upper blade into the wood.

The backward tapering blade of the tooth forms the back angle of the end blade. This angle is needed for side cutting of the chips.

The edge of the end blade forms a rake angle with the sliding surface of the cutting link. The rake angles for different types of chains range from 60 ° to 85 °.

The back angle of the top blade refers to the backward tilt of the top blade.

This angle is measured relative to the sliding plane of the cutting link and, depending on the type of saw chain, ranges from 50 ° to 60 °. The top blade is the main blade and the back corner of the top blade. This is the most important corner. The clearance angle of the upper blade is difficult to measure, and the correct value is obtained by observing other prescribed values.

The grinding or entering angle is obtained by measuring from the top cutting edge at right angles to the guide bar.

The sharpening angle can be changed, depending on the application. As a rule of thumb, the larger the sharpening angle, the higher the cutting performance when cutting non-frozen softwood. Reducing the sharpening angle when cutting frozen and / or hard wood contributes to a smoother saw blade and less vibration. However, sharpening angles greater than 35 ° and less than 25 ° should be avoided (except for rip chains, where this angle is 10 °).

The rake angle, sharpening angle and upper blade angle change during sharpening. These angles have a decisive influence on the cutting performance of the chain. Be sure to observe the prescribed values.

A depth gauge is located on each cutting link in front of the tooth blade. The difference in height between the top edge of the depth gauge and the front edge of the back of the tooth is defined as the distance of the depth gauge.

The depth of penetration of the upper blade into the wood (chip thickness) and thus productivity depends on the distance of the depth gauge. The distance of the depth gauge is set depending on the chain pitch and type of execution. Normally, it should be 0.5-0.8 mm, more often 0.6 mm. High values will result in an increased tendency of the chainsaw to kickback, too much grip and chain vibration. Low values lead to a drop in performance. Since the distance of the depth gauge decreases with each sharpening of the saw due to a decrease in the upper edge of the tooth, the depth gauge also needs to be filed periodically. After 5-10 chain sharpenings.

Chainsaw chain sharpening rules

Since the inner contour of the tooth is quite close to circle, and the chain is made of sufficiently soft metal, sharpening is done with a round file with a small diameter. To sharpen the chainsaw correctly, you need to accurately position the file relative to the tooth. The upper edge of the file should protrude about 1/5 of its diameter relative to the upper edge of the tooth. Before sharpening, find out the parameters of your chain, since the file diameter is selected depending on the chain pitch. Usually it is 4–5.5 mm.

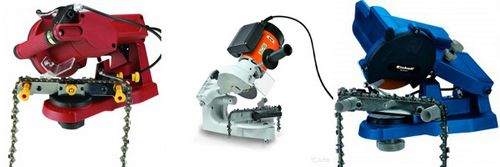

Chain sharpening machines

If the chain has plowed the gravel or sandy soil quite hard, then it will hardly be possible to sharpen it with a file with a high quality. Also, file sharpening will not help. With heavy chain wear, because she lost her shape. In such cases, it makes sense to use special machines. Such machines are divided into electrical and manual.

An electric machine is the best way to sharpen chains. It is versatile and comes with many settings and benefits such as:

- Setting the chain at the right angle;

- Drive the disc exactly to the sharpened edge;

- Automatic clamping of the vice when the disc is lowered onto the chain.

However, its only drawback is the high price. Its purchase is advisable only for workshops and enterprises engaged in the extraction of wood.

Manual machines also give a good sharpening result, and the price of some of them can be commensurate with the devices described above. We will describe the principle of their operation using the example of two models of hand-held machine tools manufactured by Stihl.

The design of these devices resembles a bow saw, which has a file instead of a blade. The model called “FG 1” mounts directly to the tire of the chainsaw, while the “FG 2” is stationary. These machines are good because you can not only sharpen the chain, but also fit them to the size of the smallest tooth. Although the tuning mechanism is quite heavy, it allows you to sharpen the chain with any tooth parameters and save this setting for subsequent teeth and chains. This allows the teeth to be perfectly identical to each other.

How to sharpen a chainsaw chain at home

At first glance, sharpening chainsaw chains with your own hands is a rather difficult and long task, but with special sharpening devices, this process will not be more difficult than sharpening other cutting tools. In this article we will tell you about how to sharpen a chainsaw chain.

Hand-operated machines

The design of such a machine is similar to a bow saw. Only where the saw blade is located is the round file. With such a machine, you can sharpen and straighten teeth, adjusting the proportionality of the upper edges to the smallest (control) size. The mechanism allows you to accurately set the parameters. After adjusting the “control” tooth, sharpening is carried out in two or three movements. And then the transition. To the next tooth.

When it is necessary to grind off the stopper, we change the round file to a flat one.

Advantages of the method: Allows you to sharpen teeth, including those that have lost their original shape, with high quality, convenient and without great physical costs.

Disadvantages: The price of the tool and the distance from the possible site of the saw operation.

What to choose for sharpening is up to you. This is due to how often you use your chainsaw. From the accuracy of handling it. From the quality of the purchased chain. And, of course, from the opportunity to spend a certain amount. It is impossible to compare the methods, because as the German proverb says. “apples should be compared with apples.”

Electric sharpening machines

They are equipped with special adjustment functions to help you position the chain at a certain angle. At the same time, it is possible to accurately and accurately bring the disc to the chain teeth. There are machines equipped with automatic vices. They are switched on when the disc approaches the sharpened edge. Convenience and functionality are certainly high. You can find models at “lifting” prices.

Chainsaw teeth

Chainsaw teeth have a specific geometry. You need to understand and know what part of them should be sharpened. In general, the “logic” of cutting wood resembles a plane.

The cutting surface has two edges. One side, the other slightly beveled. The cutting depth limiter adjusts the thickness of the chips. Let’s take a closer look. The elements of the cutting-working link are arranged as follows:

- Base with axle holes;

- Tooth scapula;

- Cutting depth limiter;

- End face of the blade (placement. Vertical);

- Upper edge of the blade (placement. Horizontal);

Sharpened edge Dull After touching the ground

Do not over-grind or change the location of the links. The normal operation of the instrument depends on the identity of their location. Otherwise, increased stress on the chassis, tire and engine is likely. The cut can be crooked. There is also a small chance of breaking the circuit.