How To Sharpen A Saw Chain Correctly

Do-it-yourself chainsaw sharpening

Sharpening the chainsaw chain with your own hands The chain tooth planes the wood like a plane, and the thickness of the shavings is adjusted by the height of the limiter. Intense sawing results in rapid dullness

Chain teeth parameters

To achieve optimal cutting properties, the tooth blades are angled. The back of the tooth falling back at an angle forms the posterior angle of the upper blade. This angle is needed to cut the upper blade into the wood.

The backward tapering blade of the tooth forms the back angle of the end blade. This angle is needed for side cutting of the chips.

The edge of the end blade forms a rake angle with the sliding surface of the cutting link. The rake angles for different types of chains range from 60 ° to 85 °.

The back angle of the top blade refers to the backward tilt of the top blade.

This angle is measured relative to the sliding plane of the cutting link and, depending on the type of saw chain, ranges from 50 ° to 60 °. The top blade is the main blade and the back corner of the top blade. This is the most important corner. The clearance angle of the upper blade is difficult to measure, and the correct value is obtained by observing other prescribed values.

The grinding or entering angle is obtained by measuring from the top cutting edge at right angles to the guide bar.

The sharpening angle can be changed, depending on the application. As a rule of thumb, the larger the sharpening angle, the higher the cutting performance when cutting non-frozen softwood. Reducing the sharpening angle when cutting frozen and / or hard wood contributes to a smoother saw blade and less vibration. However, sharpening angles greater than 35 ° and less than 25 ° should be avoided (except for rip chains, where this angle is 10 °).

The rake angle, sharpening angle and upper blade angle change during sharpening. These angles have a decisive influence on the cutting performance of the chain. Be sure to observe the prescribed values.

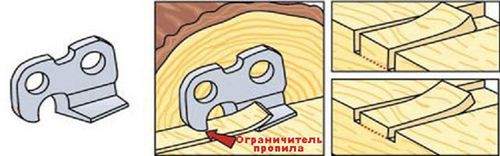

A depth gauge is located on each cutting link in front of the tooth blade. The difference in height between the top edge of the depth gauge and the front edge of the back of the tooth is defined as the distance of the depth gauge.

The depth of penetration of the upper blade into the wood (chip thickness) and thus productivity depends on the distance of the depth gauge. The distance of the depth gauge is set depending on the chain pitch and type of execution. Normally, it should be 0.5-0.8 mm, more often 0.6 mm. High values will result in an increased tendency of the chainsaw to kickback, too much grip and chain vibration. Low values lead to a drop in performance. Since the distance of the depth gauge decreases with each sharpening of the saw due to a decrease in the upper edge of the tooth, the depth gauge also needs to be filed periodically. After 5-10 chain sharpenings.

General rules for sharpening chainsaw chains

Do-it-yourself chainsaw sharpening

The chain tooth planes the wood like a plane, and the chip thickness is adjusted by the height of the stop.

Intense sawing will quickly dull the chain. Several sharpenings may be required within one day. The problem is aggravated by the fact that the tooth quickly dulls when it meets the ground. It is enough to hook the soil with the tire once or twice, and the work can be stopped. The shavings become fine and the saw stops going deep into the wood.

The sooner dull teeth are sharpened, the less material needs to be removed during sharpening, as a result. The service life of the saw chain is longer. Determining the moment when sharpening is already required is quite simple. An important feature is the feed force. A properly sharpened chain is pulled into the cut with just a little pressure. If, on the contrary, the chainsaw is forced to cut by increased feed force, then the teeth are dull. A dull chain can also be recognized if only small chips fly out of the cut instead of coarse, thick chips.

In this situation, the chainsaw must be sharpened urgently. Do not cut with a dull or defective saw chain. The consequence is high stress in the body, high cyclic load, poor cutting results. In addition, this means reduced productivity, high fuel consumption and increased wear on all parts of the chainsaw.

Device and shape of the teeth

First of all, you need to understand the structure of the chain tooth, which must be sharpened. The tooth cuts wood like a plane. It has a complex configuration and an unusual cutting surface. Two edges: one of them is lateral, and the other is upper, slightly beveled. The adjustable tooth stop adjusts the chip thickness. Of course, sharpening such teeth is much more difficult than, for example, a kitchen knife.

Chainsaw teeth have a more complex shape than other sharp objects to be sharpened

In this case, the correct angle of sharpening of the chainsaw should be set. It is clear that it is difficult to operate with one file, therefore there are various accessories that help to adhere to the exact parameters of sharpening. These kits are sold complete with chainsaws, as well as separately.

The diagram shows the angles of inclination that must be observed during sharpening

When sharpening, the location of the tool should be chosen correctly. The round file was not chosen in vain. Because of the rounded shape of the inner contour of the tooth. The edge of the file should be 20% higher than the cutting surface of its diameter, and the choice of diameter is influenced by the length of the chain pitch (usually 4 mm to 5.5 mm). The procedure should be followed: first, the cutting teeth are processed, then the stop tooth.

Hand tools

A set of tools required for sharpening saw teeth:

- Flat file, which is taught to use in labor lessons at school. With it, the depth gauge is grinded.

- A round file of a certain diameter, required for cutting a cutting tooth. An additional device is attached to it. A holder with fishing lines, which suggest how to properly hold the tool in relation to the chain. The holder is placed on the saw tooth, taking into account the guiding lines, the position of the file is under the cutting surface.

- A template that serves for editing and observing parameters.

- The hook is needed to remove sawdust from the chain.

Metal sharpening templates help you calculate the sharpening depth

Sharpening of cutting teeth

The question arises: how to sharpen the chain so that all the teeth are evenly even and sharp? The work is facilitated by the use of a metal template, which is applied to the chain. It is installed in a strict position. Along the arrows, the ends of which are directed along the movement of the chain. The main pressure is applied to the leading edge, respecting the angle of inclination, which corresponds to the length of the chain pitch.

You need to try to have an equal number of movements for each tooth. The teeth are sharpened one at a time: one on the left side, the next on the right, and so on. For the convenience of performing the actions, the tire is clamped in a vice, and then processed through the prong on one side, then the same on the other.

During sharpening, the fixture must be held at a certain angle

Necessary tools and devices

It is best to have your saw chain sharpened by a specialist. This is quite justified if there is no automatic chain sharpener at hand, and there are no special skills to work with it. You can tweak the chain at home using a cylindrical file of the appropriate diameter. To do this, you need to prepare a flat file and a special combination template suitable for a particular saw. A vice can significantly facilitate the work, which will free your hands to work with the tool.

Each link of the saw chain acts as a small planer, and the degree of sawing efficiency depends on the difference in the height of the guard tooth and the cutting tooth. It is this difference that determines the depth of the cut into the wood. The ideal difference is 0.5-0.8 mm.

Chainsaw sharpening instructions

Grinding the restraining tooth

The key component of the saw headset is the chainsaw bar. Its length determines the depth of cut. The shorter it is, the smaller the barrel diameter the chainsaw can handle. At the same time, it must be remembered that the length of the bus must correspond to the power of the device.

Insufficient engine power will lead to the fact that the operator will need to make considerable efforts when cutting, which will soon lead to wear of the headset, an increase in the consumption of the fuel mixture, and possibly the failure of the chainsaw. Grinding the stop tooth is done as follows: a template is applied to it and the stop tooth is ground down to the template level using a flat file.

The template has two main positions: “S”. Soft, designed for soft wood, and “H”. Hard. For hard.

Here you need to understand that sharpening the stop tooth without using a template threatens with a too low cut. This increases the risk of kickback, increases vibration, decreases sawing accuracy and increases waste.

Sharpening angle grinder

Professionals consider this work to be primitive. There is a risk of tire damage, and more.

Process (seemingly easy, but really difficult)

- The chain also stays on the bus;

- We attach a metal cutting disc with a thickness of 1.5-2 mm to an angle grinder. It is advisable to take not a new one, that is, with a worn edge;

- We put an obstacle in front of the chain and the tire (the chip will come off);

- We sharpen at the right angle;

- Upon completion of work, the chain must be properly tightened.

With a professional approach and a “full hand”, the number of sharpenings in this case can be more than 7.

“For a beginner, it’s better not to“ experiment ”with a saw, chain, etc. With your body parts! “

Advantages of the method: Fast, cheap and does not take away energy;

Disadvantages: You need special skills, a steady hand and the ability to comply with safety techniques.

Chainsaw teeth

Chainsaw teeth have a specific geometry. You need to understand and know what part of them should be sharpened. In general, the “logic” of cutting wood resembles a plane.

The cutting surface has two edges. One side, the other slightly beveled. The cutting depth limiter adjusts the thickness of the chips. Let’s take a closer look. The elements of the cutting-working link are arranged as follows:

- Base with axle holes;

- Tooth scapula;

- Cutting depth limiter;

- End face of the blade (placement. Vertical);

- Upper edge of the blade (placement. Horizontal);

Sharpened edge Dull After touching the ground

Do not over-grind or change the location of the links. The normal operation of the instrument depends on the identity of their location. Otherwise, increased stress on the chassis, tire and engine is likely. The cut can be crooked. There is also a small chance of breaking the circuit.

We sharpen the chainsaw chain with our own hands. All possible and available ways

“A lumberjack working with a blunt ax was advised:. Sharpen the ax.

He replied:. No time. The forest must be cut down. “

Greetings to all readers!

Today I decided to tell you about the tool, without which, it seems to me, today it is simply impossible. A good tool should work well, and this largely depends on its owner.

Cleaning the autumn garden, preparing firewood for winter, building a bathhouse, repairing a wooden fence will require not only time and desire, but also the readiness of the “cutting” tool. If it is a chainsaw, then it must be properly sharpened.

Of course, there are paid specialists, and you, for example, have extra money. But we know that such a procedure is performed periodically, and therefore a natural question arises: how to sharpen a chainsaw chain at home? I’ll tell you about that. Go!

In this article, you will learn: